Patents

Literature

51 results about "Zinc dibutyldithiocarbamate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Zinc dibutyldithiocarbamate is a Standardized Chemical Allergen. The physiologic effect of zinc dibutyldithiocarbamate is by means of Increased Histamine Release, and Cell-mediated Immunity. The chemical classification of zinc dibutyldithiocarbamate is Allergens.

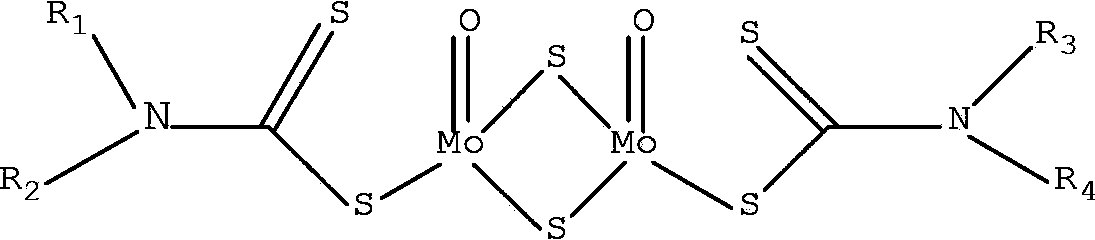

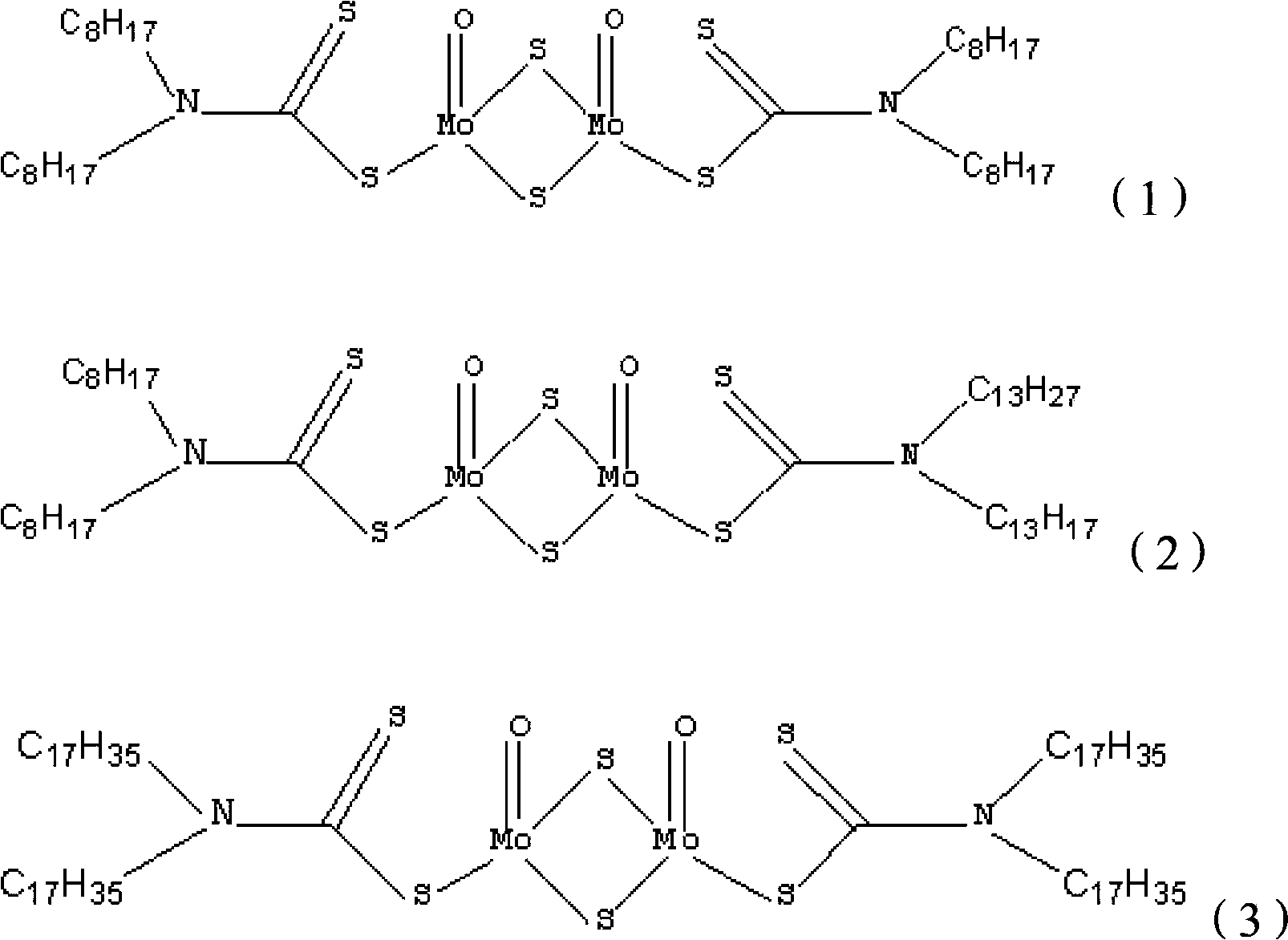

Petroleum-engine oil composition and application thereof

InactiveCN103666661AImprove the lubrication effectExcellent detergency and dispersibilityLubricant compositionWear resistantButylated hydroxytoluene

The invention relates to a petroleum-engine oil composition and application thereof, and mainly aims to solve the problem of poor wear resistance of petroleum and engine oil existing in the prior art. The problem is well solved by adopting the technical scheme that the petroleum-engine oil composition comprises the following components in parts by weight: (a) 1-20 pars of a detergent, a dispersant or a mixture thereof, (b) 0.5-15 parts of an anti-oxygen wear-resistant agent, (c) 1-20 parts of a viscosity index modifier, (d) 0.01-5 parts of a pour point depressant, (e) 0.001-3 parts of an anti-foaming agent, and (f) 60-95 parts of base oil, wherein the anti-oxygen wear-resistant agent is selected from at least one of 2,6-di-tert-butyl-4-methylphenol, 2,6-di-tert-butyl mixed phenol, alkylated arylamine, zinc butyl octyl dithiophosphate, base zinc salt of dioctyl thiophosphate, di(octadecyl)-3,3-thiodipropionate, zinc(II)dibutyl dithiocarbamate, thiadiazole, molybdenum dithiocarbamate or molybdenum dialkyldithiophosphat. The petroleum-engine oil composition can be applied to industrial production of the petroleum-engine oil composition.

Owner:CHINA PETROLEUM & CHEM CORP

Formula of environment protection type flame-retardant rubber pipe

InactiveCN101463166ALow costGood physical and mechanical propertiesFlexible pipesMorpholineAluminium hydroxide

The invention relates to a formula of an environment-friendly flame retardant hose, which comprises the following compositions and weight portions: 100 portions of ethylene propylene diene rubber, 20 portions to 40 portions of fast extruded carbon black, 40 portions to 60 portions of calcined clay, 120 portions to 160 portions of aluminium hydroxide, 5 portions to 10 portions of zinc borate, 10 portions to 20 portions of antimony trioxide, 0.5 portion to 0.8 portion of thiuram tetrasulfide, 1.5 portions to 2.0 portions of zinc dibutyl dithiocarbamate, 0.5 portion to 0.8 portion of tetramethyl thiuram disulfide, 3 portions to 5 portions of zinc oxide, 1 portion to 3 portions of stearic acid, 1 portion to 3 portions of polyethylene glycol, 1.5 portions to 2.0 portions of morpholine disulfide, 0.3 portion to 0.6 portion of sulfur and 20 portions to 40 portions of paraffin oil. Compared with the traditional product, the invention has the tensile strength of physical and mechanical property of 14MPa, which is higher than the traditional formula by 1.5 times. The invention can obtain FV-0 grade of vertical burn of national standard of flame resistance, namely the requirements of nonflammable material, can achieve the same flame resistant effect with the traditional method and meet the requirements of environment protection and safety of the hose of the modern automobile.

Owner:TIANJIN PENGYI GRP CO LTD

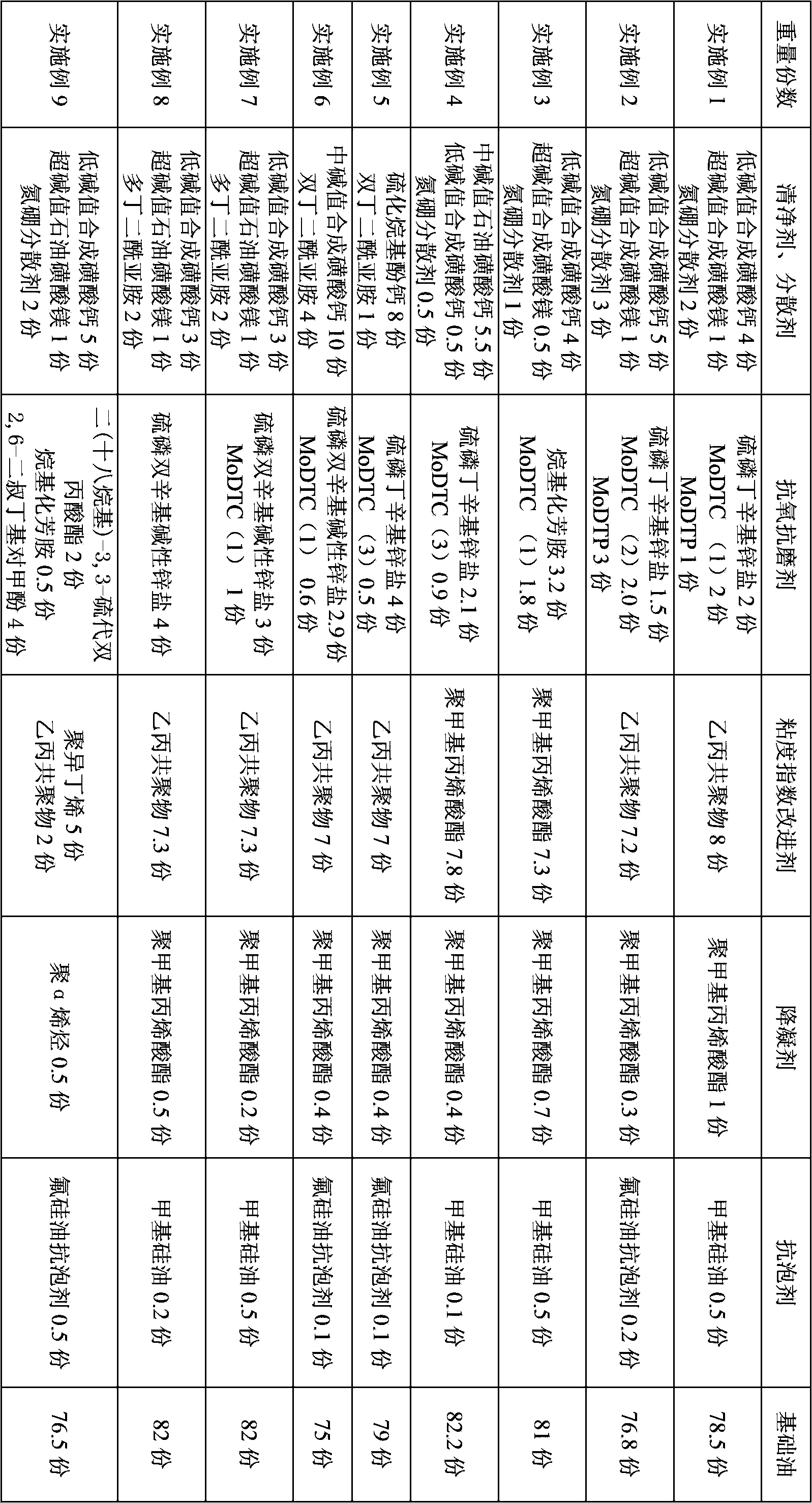

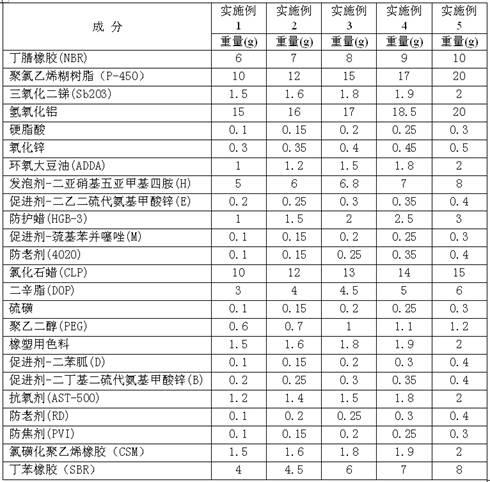

Color rubber and plastic heat-insulating material and preparation method thereof

The invention relates to a color rubber and plastic heat-insulating material and a preparation method thereof. The rubber and plastic heat-insulating material is prepared from polrvinyl chloride paste resin, dinitrosopentamethylene tetraamine, an antiager, styrene rubber, protective wax, an antioxidant, chlorosulfonated polyethylene rubber, diphenyl guanidine, mercaptobenzothiazole, zinc dibutyl dithiocarbamate, zinc diethydithiocarbamate and the like. The performance and the color difference of the product are stabilized by adding a coloring material to perform banburying on the finished rubber again and combining a new vulcanizing foaming technology and a super-long water-cooling system; the prepared color rubber and plastic heat-insulating material does not have fibers and dust, prevents dew formation, has a smooth surface and high cleanliness, has the same bright color as equipment, is environmentally-friendly and non-toxic, reduces secondary construction, saves cost, greatly improves the using performance of the product, prolongs the service life and takes full advantage of the product performance.

Owner:WINCELL INSULATION CO LTD

Electrochemical corrosion resistant inner ply compound formula

InactiveCN101423638AGood physical and mechanical propertiesExtended service lifeFlexible pipesPolyethylene glycolStearic acid

The invention relates to an inner hose formula for an electrochemical corrosion resistant hose, which comprises the following compositions in portion by weight: 30 to 70 portions of low-mooney ethylene propylene diene rubber, 70 to 30 portions of high-mooney ethylene propylene diene rubber, 60 to 80 portions of semi-reinforcing carbon black, 60 to 90 portions of silica fume, 1.2 to 1.8 portions of bi-thiuram tetrasulfide, 1.7 to 2.3 portions of zinc dibutyl dithiocarbamate, 0.5 to 0.8 portion of tetramethyl thiuram disulfide, 3 to 5 portions of zinc oxide, 1 to 3 portions of polyethylene glycol, 1.5 to 2.0 portions of morphine disulfide, 0.3 to 0.6 portion of sulfur, 50 to 60 portions of paraffin oil, 1 to 3 portions of stearic acid and 2 to 4 portions of 2, 2, 4-trimethyl-1, 2-biquionlyl dihydride polymers. Compared with the prior product, the inner hose formula for the electrochemical corrosion resistant hose has obvious differences; the tensile strength is 12.0 MPa; the volume resistivity is 1X10<12> omega.cm and 1X10<5> omega.cm higher than that of the prior product; the service life of the electrochemical corrosion resistant hose is greatly improved; and the inner hose formula for the electrochemical corrosion resistant hose can well meet the demands of heat resistance and electrochemical corrosion resistance of a radiator hose of a motor vehicle.

Owner:TIANJIN PENGYI GRP CO LTD

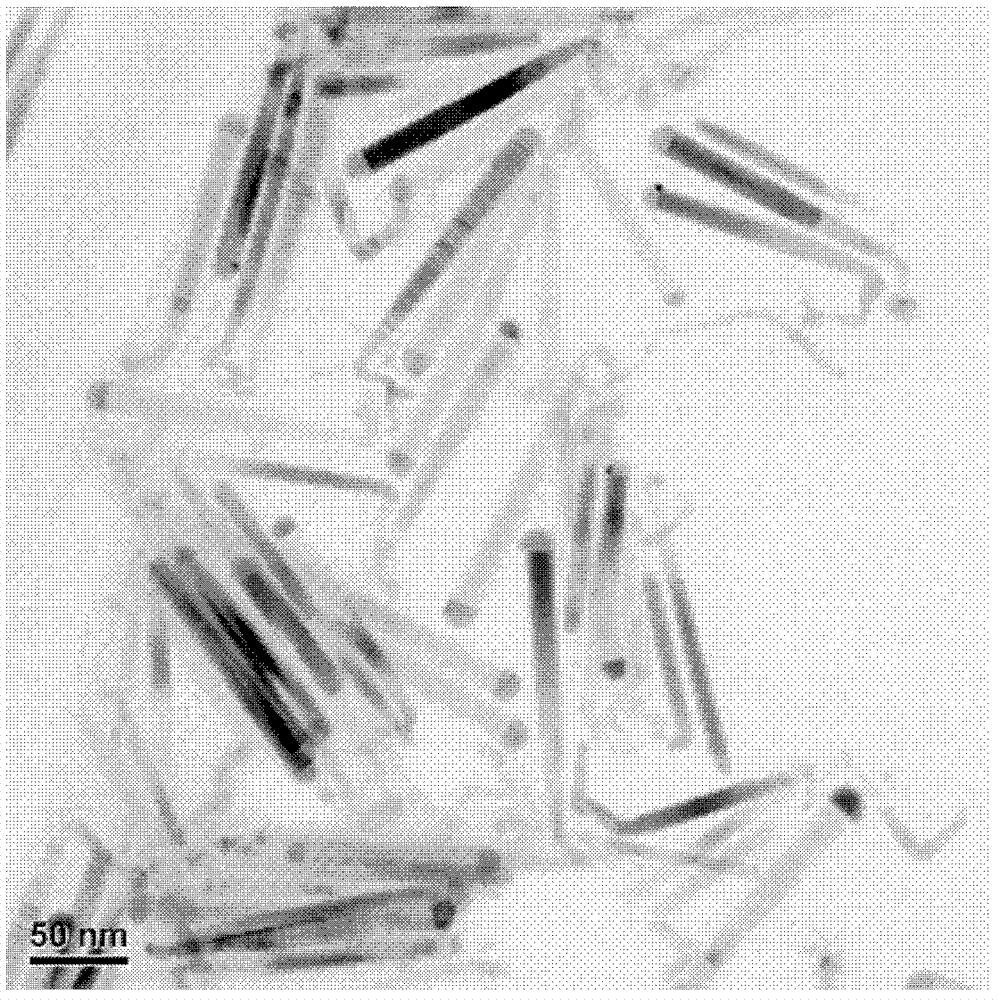

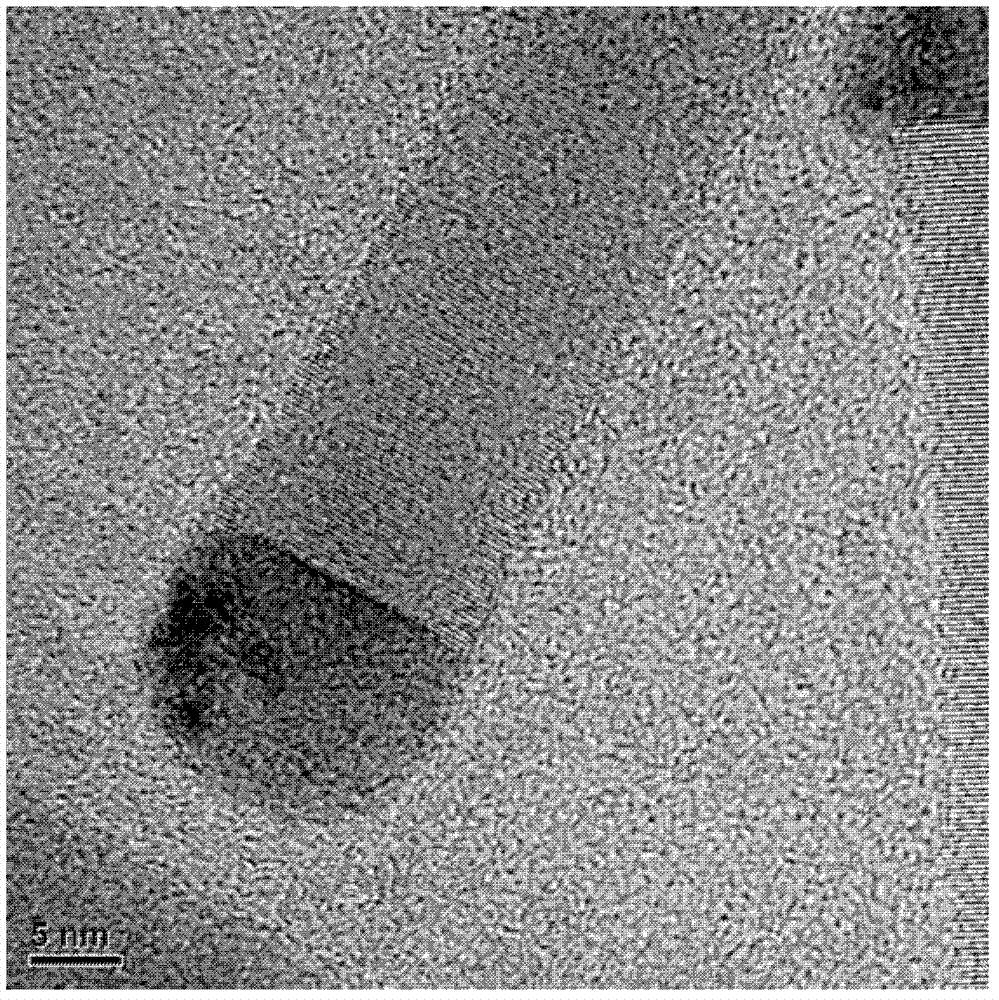

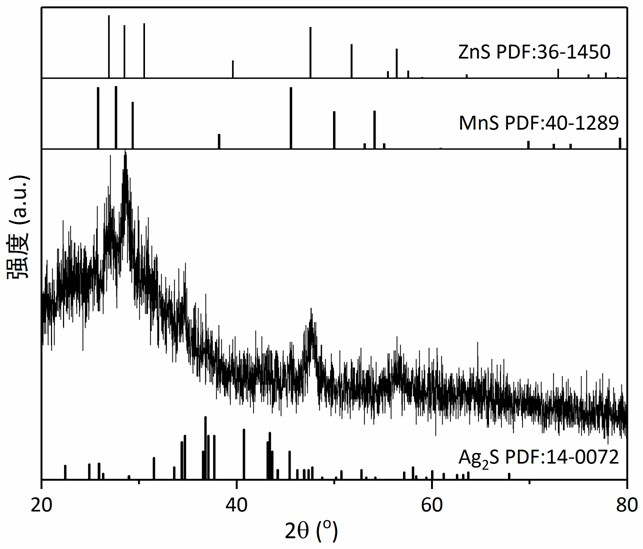

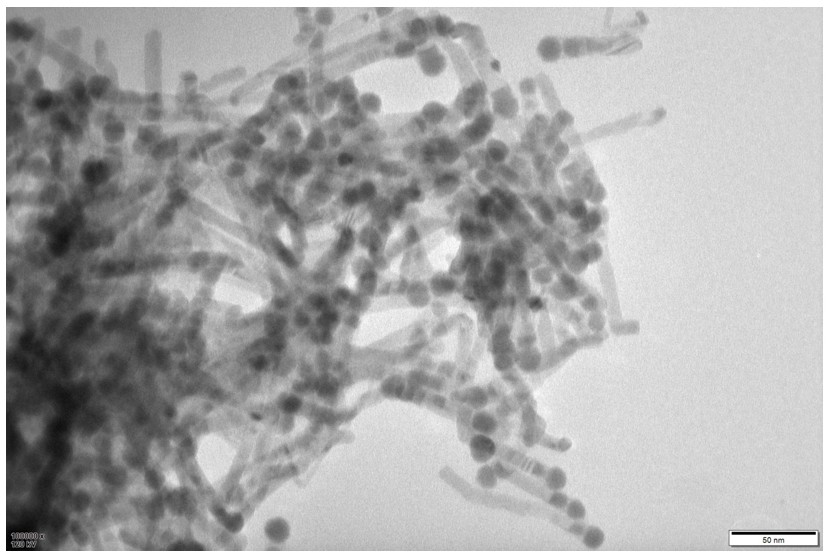

Preparation method of silver sulfide-zinc sulfide semiconductor nanometer heterojunction

InactiveCN102814185AOvercoming complexityOvercome the shortcomings of cumbersome controlPhysical/chemical process catalystsWater/sewage treatment by irradiationHeterojunctionTrioctylphosphine

The invention provides a preparation method of a silver sulfide-zinc sulfide semiconductor nanometer heterojunction. The preparation method comprises a step (A) of enabling reaction precursor silver dibutyl dithiocarbamate to undergo pyrolysis in a mixed solvent to obtain silver sulfide particles; and a step (B) of enabling the silver sulfide obtained in the step (A) to serve as a catalyst, enabling an intermediate product formed by pyrolysis of zinc dibutyl dithiocarbamate to be dissolved in the mixed solvent containing the silver sulfide particles, separating out zinc sulfide nanorods from the silver sulfide particles under the effect of trioctylphosphine and n-octadecyl mercaptan, and forming the silver sulfide-zinc sulfide semiconductor nanometer heterojunction. The preparation method of the silver sulfide-zinc sulfide semiconductor nanometer heterojunction is simple and convenient, high in rate of production and suitable for industrial production. The shape and the structure of the silver sulfide-zinc sulfide semiconductor nanometer heterojunction can be controlled under normal pressure, and the rate of production can be over 80%.

Owner:WENZHOU UNIVERSITY

Wear-resistant and aging-resistant cable sheath material

InactiveCN105623112AHigh mechanical strengthImprove wear resistanceRubber insulatorsPolymer scienceWear resistant

The invention discloses a wear-resistant and aging-resistant cable sheath material. The material is prepared from, by weight, 40-60 parts of ethylene propylene diene monomer rubber, 15-30 parts of polyamide 66, 10-20 parts of modified white mica powder, 2-5 parts of a wear-resisting auxiliary agent, 10-20 parts of semi-reinforced carbon black, 1-4 parts of a flame-retardant auxiliary agent, 1-2 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 2-4 parts of N, N'-m-phenylene dimaleimide, 3-8 parts of stearic acid, 0.5-1 part of zinc dibutyl dithiocarbamate, 0.5-1 part of an anti-aging agent DPPD, 2-5 parts of white oil and 2-3 parts of fortifier DH-3. The wear-resistant and aging-resistant cable sheath material is good in mechanical strength, wear resistance, aging resistance, weatherability, impact elasticity, chemical corrosion resistance and excellent in electrical insulation property, and meanwhile the modified white mica powder is adopted, so that the processing property of the ethylene propylene diene monomer rubber is improved, and the obtained cable sheath material can be used in environments with various climatic conditions.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

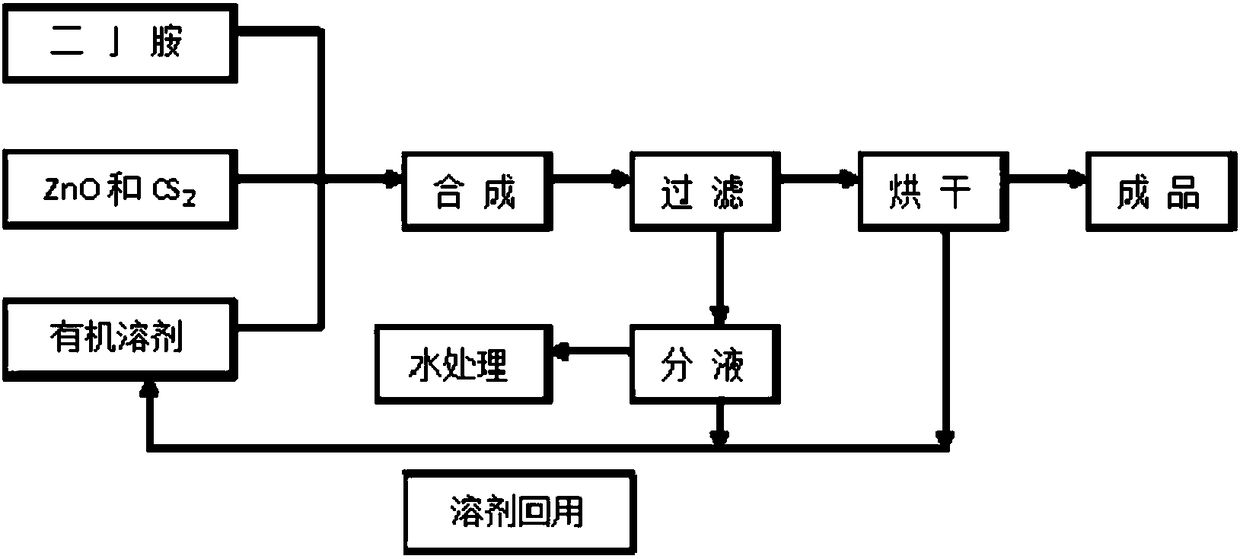

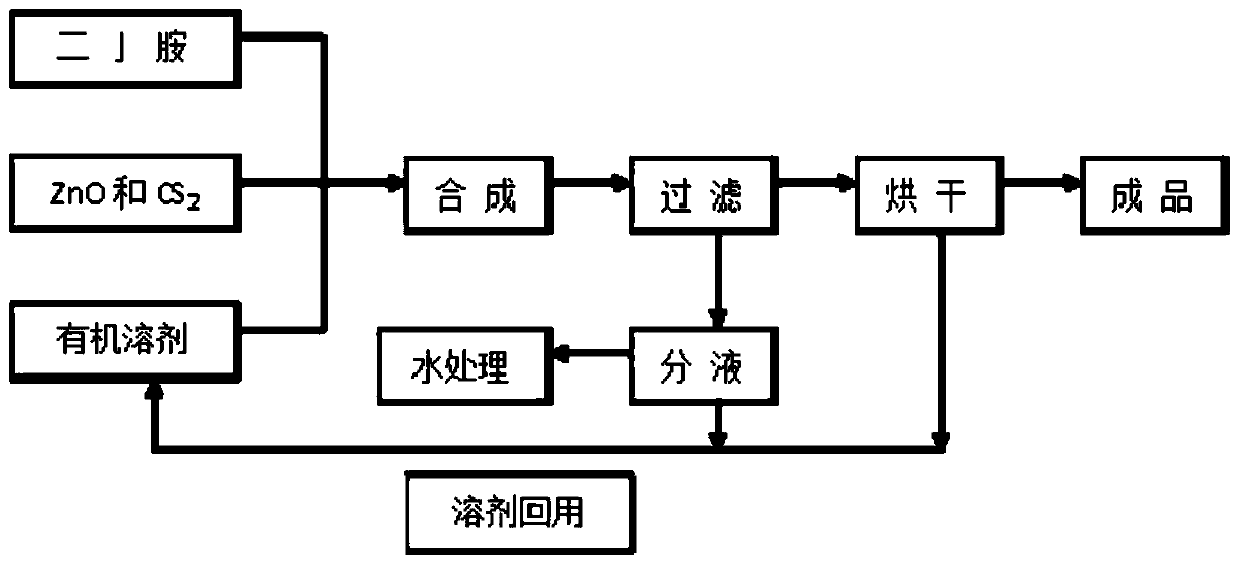

Production process of dithiocarbamate zinc salt rubber accelerator

InactiveCN108558722AAvoid it happening againSimple production processOrganic chemistryReaction temperatureZinc dibenzyldithiocarbamate

The invention provides an environment-friendly harmless new production process of a dithiocarbamate zinc salt rubber accelerator. The process comprises the following steps of S1. putting water and zinc oxide in a clean reactor and stirring; S2. putting organic amine, stirring for half hour and then adding CS2 dropwise, and controlling reaction temperature at 40DEG C or below; S3. stopping stirringwhen PH value is detected neutral; and S4. treating the paste to obtain znic dimethyldithiocarbamate (PZ), zinc diethyl dithiocarbamaate (ZDC), zinc dibutyl dithiocarbamate (BZ), 1,5-zinc sulfinyl dithiocarbamate (ZPD) and / or zinc dibenzyl dithiocarbamate (DBZ). The process optimizes the steps, and changes an original two-step method into a one-step method, thereby improving the efficiency and simplifying the production process. The processing process does not generate sodium chloride wastewater, thereby being environmentally friendly; and the product has higher performance, and zinc oxide does not contain chloride.

Owner:宜兴市鸿远精细化工有限公司

Ethylene-propylene-diene monomer mould pressing abnormal shape sponge sheath rubber composition

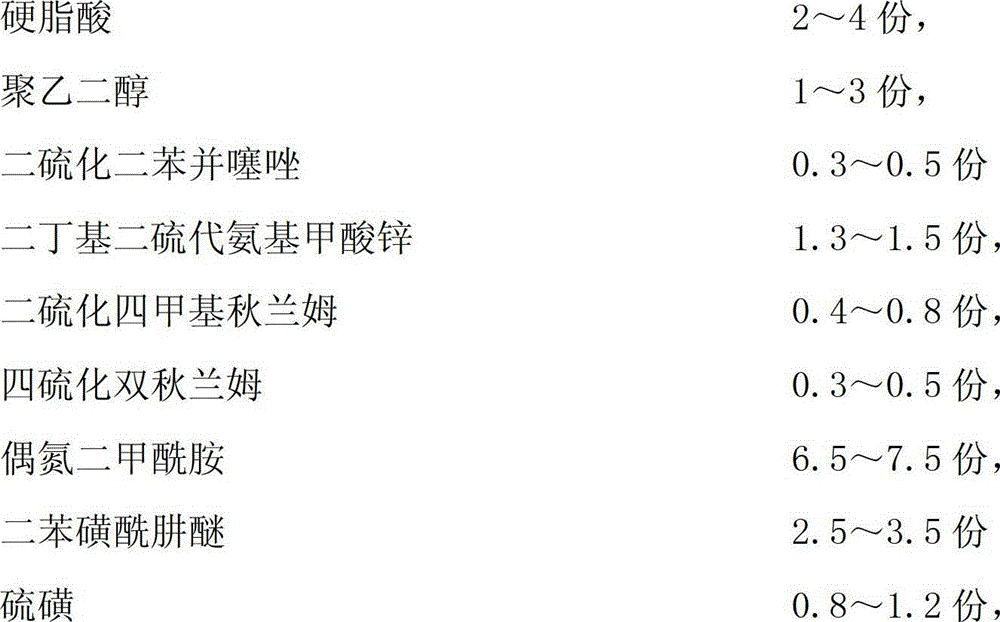

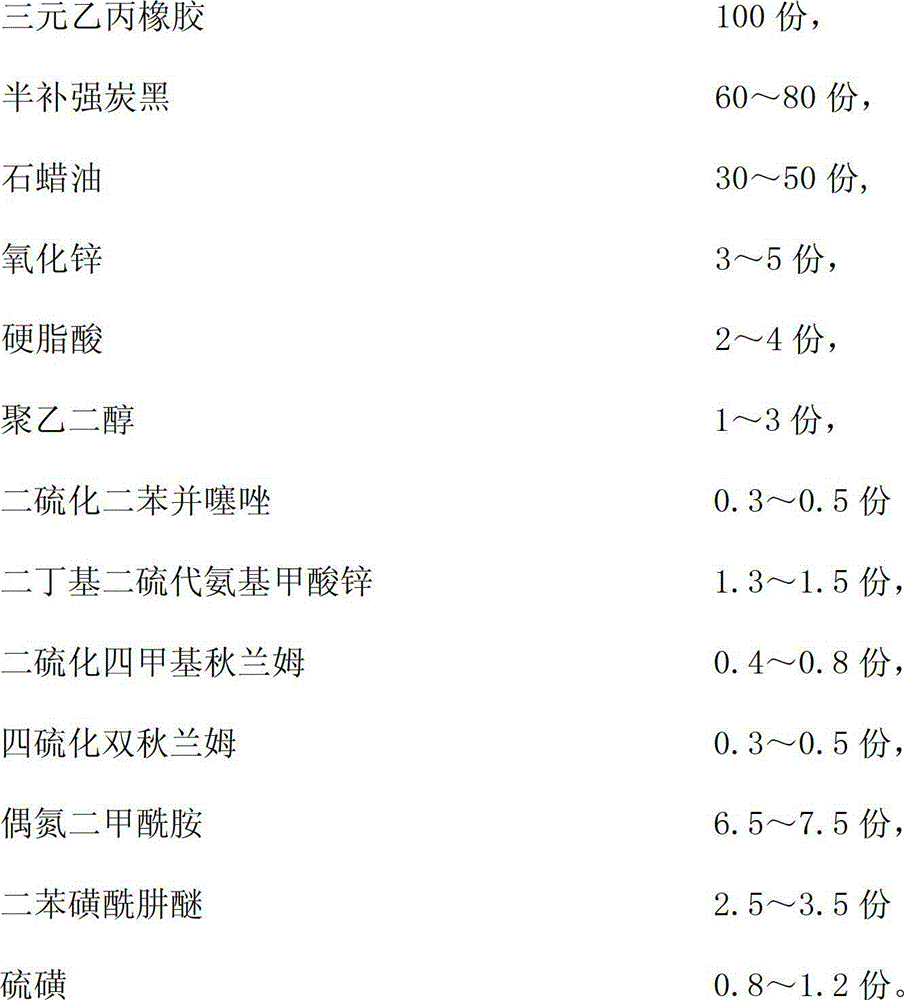

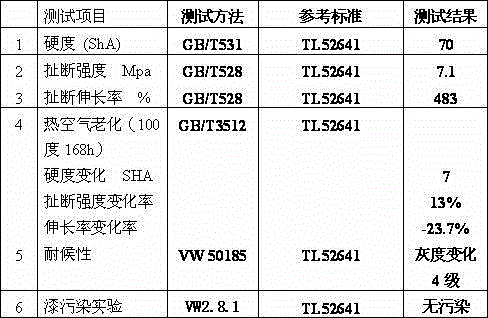

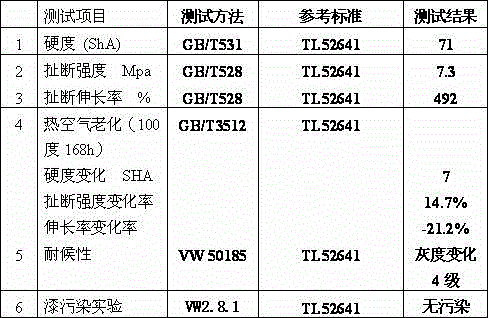

The invention relates to an ethylene-propylene-diene monomer (EPDM) mould pressing abnormal shape sponge sheath rubber composition. The composition includes the components by weight: 100 parts of EPDM rubber, 60-80 parts of semi-reinforcing carbon black, 30-50 parts of paraffin oil, 3-5 parts of zinc oxide, 2-4 parts of stearic acid, 1-3 parts of polyethylene glycol, 0.3-0.5 parts of dibenzothiazole disulfide, 1.3-1.5 parts of zinc dibutyldithiocarbamate, 0.5-0.8 parts of tetramethylthiuram disulfide, 0.3-0.5 parts of dithiuram tetrasulfide, 6.5-7.5 parts of azodicarbonamide, 2.5-3.5 parts of 4,4'-oxybis(benzenesulfonyl hydrazide), and 0.8-1.2 parts of sulfur. The EPDM rubber is used in the invention. By adjusting the ratio of various components in the recipe and process conditions, the abnormal shape sponge sheath with excellent heat aging resistance, small density, stable dimension and smooth and exquisite surface can be prepared.

Owner:TIANJIN PENGYI GRP CO LTD

Colorized ethylene propylene terpolymer rubber sealing strip and preparation method thereof

The invention relates to a colorized ethylene propylene terpolymer rubber sealing strip which is prepared from the following raw materials in parts by weight: 90-100 parts of ethylene propylene terpolymer rubber, 160-180 parts of complex mineral filler, 60-80 parts of colorless paroline, 0.8-1.2 part of toner, 0.3-0.6 part of sulfur, 1-2 parts of zinc dibutyldithiocarbamate, 0.8-1.5 part of 2-mercaptobenzothiazole, 0.3-0.8 part of tetramethyl thiuram disulfide, 0.2-0.6 part of Zinc dimethyldithiocarbamate, 0.8-2 parts of 4,4'-dithiodimorpholine, 4-6 parts of zinc oxide and 0.8-1.2 part of stearic acid. The colorized ethylene propylene terpolymer rubber sealing strip provided by the invention is easy for extruding production, and has the advantages that the color assortment effect is good, no aromatic hydrocarbon is separated out so that the attractive appearance is ensured, and the ageing resistance and the weather fastness are better.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Strong repairing agent for automobile

The invention provides a strong repairing agent for automobile, which can repair the abraded engine cylinder surface quickly and recover the air-tightness and comprises the following components by weight percentage: 60-70% of base oil, 3-5% of thickening agent, 15-25% of antioxidant and corrosion inhibitor, 2-3% of cleaning agent, 1-3% of dispersant, 1-3% of SAP surfactant, 1-3% of zinc dibutyl dithiocaarbamate and 1% of gear oil complexing agent. The strong repairing agent has the beneficial effects of quickly repairing the abraded engine cylinder surface, recovering the air-tightness of the cylinder, obviously improving the power of the engine and quickly eliminating the failures such as blue smoke of the combustion of engine oil, and the like; and simultaneously, the strong repairing agent also has the advantages of obvious oil-saving effect, inhibiting the generation of carbon distribution and oil sludge, protecting the parts from being corroded, reducing friction resistance, reinforcing lubrication performance, reducing noise and prolonging the service life of engine.

Owner:SHENZHEN PINGCHI IND

Preparation method of butyl rubber modified SIS hot-melt pressure-sensitive adhesive

InactiveCN104650781ANo pollution in the processImprove cohesive strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesViscous liquidPolymer science

The invention discloses a preparation method of a butyl rubber modified SIS hot-melt pressure-sensitive adhesive. The method comprises the following steps: 1, adding a styrene-isoprene-styrene block copolymer SIS and butyl rubber in a weight ratio of 1:1 in a reactor, adding naphthenic oil 30 wt.% of the mixture, soaking for 6-8 h, adding 50% the petroleum resin, 50% terpene resin and 3% of zinc dibutyl dithiocarbamate; and 2, introducing nitrogen, heating to 120 DEG C, stirring until complete melting of the resin, heating to 160 DEG C, continuing stirring until the system becomes a transparent uniform viscous liquid, stopping the stirring, and discharging the material while hot to obtain a butyl rubber modified SIS hot-melt pressure-sensitive adhesive. The hot-melt pressure-sensitive adhesive provided by the invention does not contain organic solvent, is non-toxic, harmless and pollution-free, and has the advantages of higher cohesive strength than a solvent-type pressure sensitive adhesive, fast curing, wide bonding plane, simpleness to manufacture, convenience to use, and a wide range of usage.

Owner:青岛欧美亚橡胶工业有限公司

Preparation method of zinc dibutyldithiocarbamate

The invention relates to the field of rubber vulcanizing promoter and particularly relates to a preparation method of zinc dibutyldithiocarbamate. The preparation method comprises the following stepsof: dropping carbon disulfide into reaction solution containing zinc oxide, dibutylamine, a dispersing agent and a first organic solvent to carry out reaction, and after reaction is ended, obtaining the zinc dibutyldithiocarbamate, wherein the first organic solvent is insoluble in water and the obtained zinc dibutyldithiocarbamate is insoluble or slightly soluble in the first organic solvent. Thepreparation method of the zinc dibutyldithiocarbamate has the beneficial effects that an anhydrous solvent method is adopted to prepare the zinc dibutyldithiocarbamate, so that the generation of salt-containing waste water is avoided; since the first organic solvent is insoluble in water, the first organic solvent and the water can be separated by liquid-separating operation; the first organic solvent after water removal can be repeatedly utilized, so that the solvent cost is reduced and simultaneously the yield of a product is increased; the operation is simple and convenient, the generationof the salt-containing waste water is avoided, and the method is a cleaning environment-friendly new method, and is easily applied in large-scale production practice.

Owner:WILLING NEW MATERIALS TECH CO LTD

Preparation method of one-dimensional heterogeneous nano material of manganese sulfide and zinc sulfide

Owner:HEFEI UNIV OF TECH

Latex foaming thermal insulation material and application thereof in field of latex gloves

The invention discloses a latex foaming thermal insulation material, which comprises a basic component and a foaming component, wherein the basis component comprises low protein natural latex, sulphur, zinc dibutyl dithiocarbamate (BZ), and zinc oxide, and the foaming component comprises low protein natural latex, a foaming agent, sulphur, zinc dibutyl dithiocarbamate (BZ), and zinc oxide. The foaming component is subjected to a foaming process and then mixed with the basic component to obtain the thermal insulation material, thus ensuring that the foamed latex has a good thermal insulation effect and a better decompression effect. The thermal insulation material has a good decompression effect during thermal insulation, and can be suitable for using in environments in which thermal insulation is needed and hard objects needed to be contacted.

Owner:BEIJING REAGENT LATEX PRODS

Power cable for ethylene propylene rubber insulating ship

InactiveCN106188885AImprove flame retardant performanceGood anti-aging performanceRubber insulatorsPower cables with screens/conductive layersElectrical conductorEngineering

The invention discloses a power cable for an ethylene propylene rubber insulating ship. The power cable comprises a conductor, an insulating layer, an insulation shielding layer, a tape layer, an armoring layer and a sheath layer, and is characterized in that the insulating layer is arranged at the outside of the conductor, so that an insulating wire core is formed; the tape layer, the armoring layer and the sheath layer are sequentially arranged at the outside of the insulating wire core; the insulating layer is prepared from the following raw materials: ethylene propylene rubber, zinc dibutyl dithiocarbamate, polybutadiene, vinyl chloride-vinyl acetate copolymer, butyl chlorocarbonate, dimethylaminoethyl acrylate and the like. The power cable disclosed by the invention has the advantages that good flame resistance, high ageing resistance, high working stability and high reliability are achieved; the insulating layer has excellent flame resistance and excellent insulation property by means of improving the raw materials of the insulating layer, so that the whole service life is long.

Owner:ANHUI GUANGFU CABLE CO LTD

Environment-friendly oil-resistant rubber sealing piece and preparation process thereof

InactiveCN106146923ALow expansion rate after oil immersionGood oil resistancePolymer scienceP-tert-octylphenol

The invention discloses an environment-friendly oil-resistant rubber sealing piece and a preparation process thereof. The sealing piece is prepared from the following raw materials: natural rubber, nitrile rubber, silicon rubber, butylene succinate, p-t-octylphenol formaldehyde resin, calcium stearate, L-lysine diisocyanate, crylic acid-acrylonitrile copolymer, ethylene-octylene-alkadiene terpolymer, spraying carbon black, copper ammonia fibers, ethylene glycol salicylate, tea-seed oil acid, tetrachlorophthalic acid dioctyl phthalate, tri-n-butyl citrate, an aluminate coupling agent, dicumyl peroxide, 2,4-DCBP, zinc dibutyl dithiocarbamate, zinc oxide, N-octyl N-octadecyl sulfo-amino MoDDC and butyl acetate. The rubber sealing piece provided by the invention is high in oil resistance and comprehensive mechanical property, green and environment-friendly, and is very suitable for being used as the rubber sealing piece widely applied to various fields.

Owner:潘明华

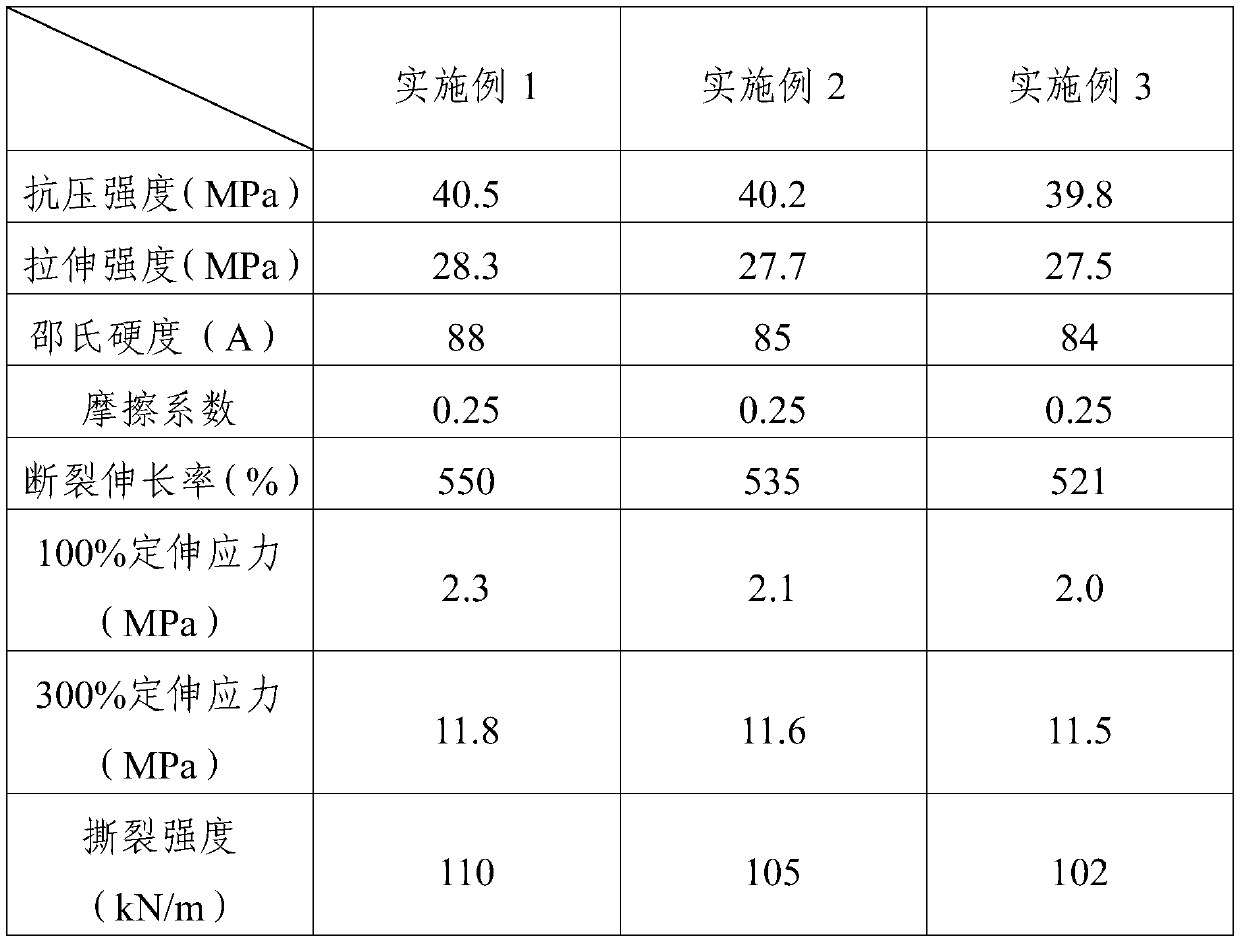

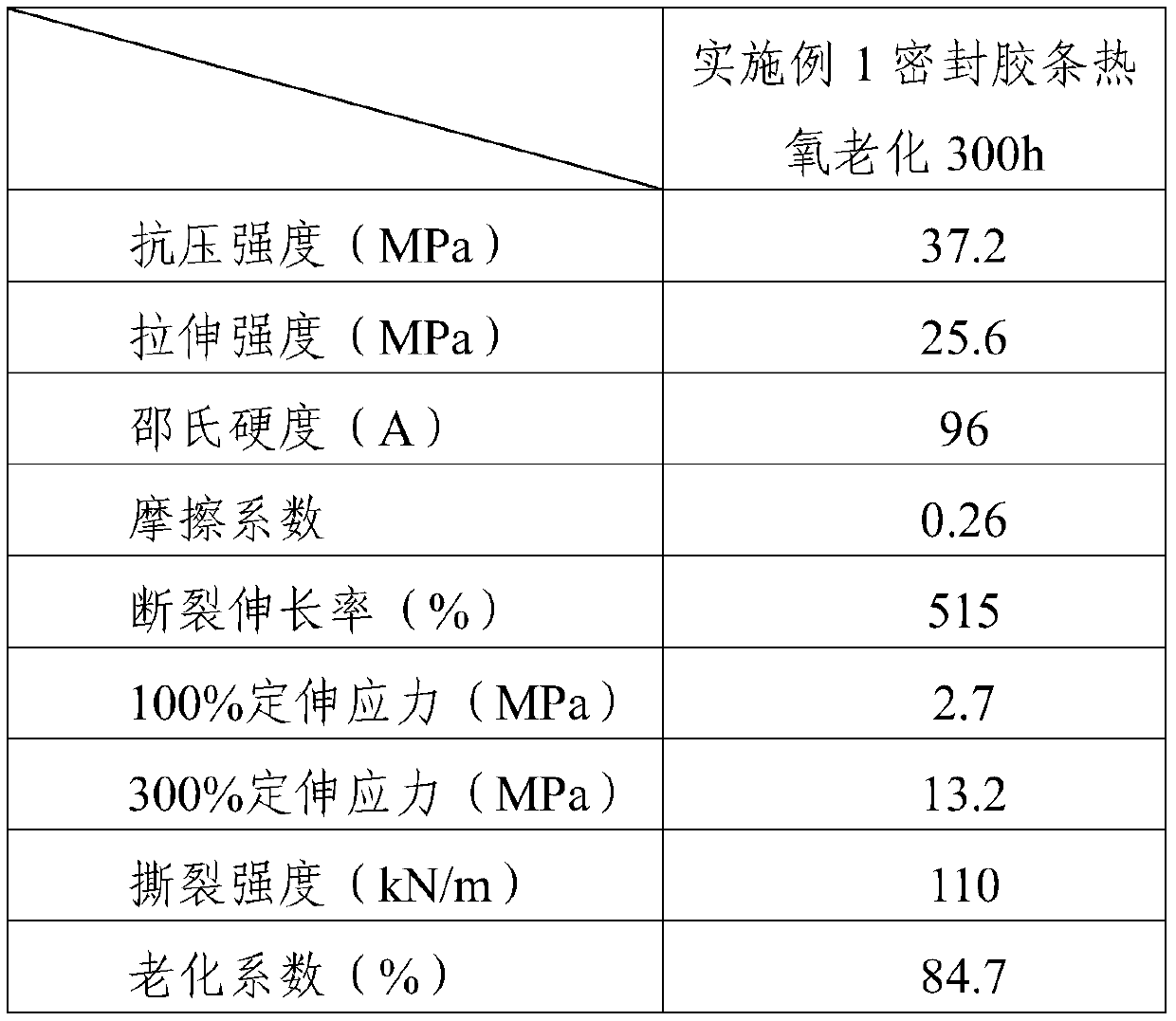

Anti-aging sealing rubber strip for building doors and windows and preparation method thereof

InactiveCN110982269AImprove aging resistanceDisruption of regularityCarbon fibersEthylene propylene rubber

The invention provides an anti-aging sealing rubber strip for building doors and windows and a preparation method thereof, and relates to the field of sealing materials. The anti-aging sealing rubberstrip comprises the following raw materials in parts by weight: 40-60 parts of p-phenylene silicone rubber, 30-40 parts of tin coupling type solution polymerized styrene-butadiene rubber, 30-40 partsof natural rubber, 1-3 parts of zinc methacrylate, 4-8 parts of liquid polyisoprene rubber, 1-1.8 parts of dioctyl sebacate, 10-20 parts of 774 carbon black, 10-20 parts of 550 carbon black, 2- 5 parts of nanometer magnesium hydroxide, 10-15 parts of asphalt-based chopped carbon fibers, 5-10 parts of polyvinylidene chloride, 1-3 parts of microcrystalline wax, 1-3 parts of stearic acid, 0.1-1.2 parts of maleic anhydride grafted ethylene propylene diene monomer, 1-1.5 parts of sulfur, 0.2-0.6 part of dicumyl peroxide, 0.5-1.5 parts of zinc dibutyl dithiocarbamate, 1-2 parts of accelerant, 1-5 parts of reinforcing component and 1.5-2.2 parts of anti-aging agent. The sealing rubber strip has excellent mechanical properties, and the related properties of the sealing rubber strip are slightly changed through a 100 DEG C and 300 h thermo-oxidative aging test and the sealing rubber strip has excellent thermal oxidation resistance and long service life.

Owner:安徽领珂数据科技有限公司

Ethylene propylene diene monomer rubber sealing strip compatible with silicone adhesive

ActiveCN102181097AWon't turn yellowWide variety of sourcesWallsSealing arrangementsPolymer scienceEthylene-propylene-diene-monomer

The invention relates to an ethylene propylene diene monomer rubber sealing strip compatible with a silicone adhesive. The sealing strip is prepared by compounding the following raw materials: 100 mass parts of ethylene propylene diene monomer rubber, 45 to 55 mass parts of paroline with the arene content of less than 0.5 percent, 100 to 120 mass parts of carbon black, 0.3 to 0.5 part of sulphur, 1.5 to 2 parts of zinc dibutyldithiocarbamate, 1.2 to 1.5 parts of benzothiazolethiol, 0.3 to 0.5 part of tetramethyl thiuram disulfide, 0.5 to 0.6 part of zinc dimethyldithiocarbamate, and 1.5 to 2 parts of dithiodimorpholine. The ethylene propylene diene monomer rubber sealing strip compatible with the silicone adhesive is compatible with the silicone adhesive, has low cost, high intensity and tearing property, and long service life and can be produced on a large scale.

Owner:JIANGYIN HAIDA RUBBER & PLASTIC GROUP

Butyl rubber modified SIS hot-melt pressure-sensitive adhesive

InactiveCN104650782ANo pollution in the processImprove cohesive strengthMineral oil hydrocarbon copolymer adhesivesNon-macromolecular adhesive additivesPolymer scienceSolvent

The invention discloses a butyl rubber modified SIS hot-melt pressure-sensitive adhesive, including the following raw materials by weight: 50 portions of styrene-isoprene-styrene block copolymer SIS, 50 portions of butyl rubber, 50 portions of C5 petroleum resin, 50 portions of terpene resin, 30 portions of naphthenic oil and 3 portions ofzinc dibutyl dithiocarbamate. The butyl rubber modified SIS hot-melt pressure-sensitive adhesive provided by the invention does not contain organic solvent, is non-toxic, harmless and pollution-free, and has the advantages of higher cohesive strength than a solvent-type pressure sensitive adhesive, fast curing, wide bonding plane, simpleness to manufacture, convenience to use, and a wide range of usage.

Owner:青岛欧美亚橡胶工业有限公司

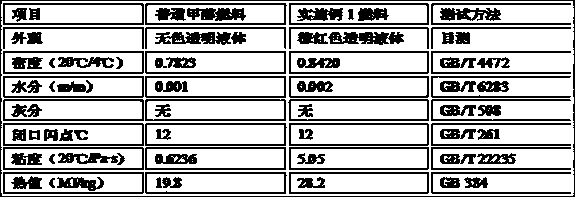

High-cleanness alcohol-based liquid fuel

PendingCN110923022AImprove the lubrication effectHigh viscosityLiquid carbonaceous fuelsLiquid fuelBenzioc acid

The invention provides a high-cleanness alcohol-based liquid fuel, and belongs to the technical field of alcohol-based liquid fuels. The high-cleanness alcohol-based liquid fuel is prepared from methanol, ethanol gasoline and an additive; and the additive is prepared from polyisooctyl methacrylate, 2,4-dimethyl-6-tert-butyl phenol, N,N'-disalicylidene-1,2-propanediamine, dodecyl methacrylate, diethylene glycol monomethyl ether, methyl palmitate, diethylaminoethyl methacrylate, zinc dibutyl dithiocarbamate, 2-n-octyl-4-isothiazolin-3-one, dioctyl phthalate, N-phenyl-N'-sec-butylphenylenediamineand isopropyl benzoate. The alcohol-based liquid fuel has the advantages of small corrosivity to metal parts, good lubricity, high viscosity and high heat value, has reddish brown color, achieves a blue-green combustion fire, does not generate residual liquid, smoke dust, carbon deposition, sulfur dioxide or other harmful gases in the combustion process, and meets environmental protection requirements.

Owner:中油新能源有限公司

The preparation method of zinc dibutyl dithiocarbamate

Owner:WILLING NEW MATERIALS TECH CO LTD

Heat-resistant high-strength cable sheath material and preparation method thereof

InactiveCN105623016AGood physical and mechanical propertiesReduce dosageRubber insulatorsAcrylonitrileStearic acid

The invention discloses a heat-resistant high-strength cable sheath material. The material is prepared from, by weight, 50-70 parts of SBR-1712 emulsion polymerized butadiene styrene rubber, 30-50 parts of NBR-3604 butadiene-acrylonitrile rubber, 1-2 parts of N-tertiary butyl-2-benzothiazole sulfenamide, 2-4 parts of N, N'-m-phenylene dimaleimide, 1-2 parts of stearic acid, 0.5-1 part of zinc dibutyl dithiocarbamate, 2-6 parts of paraffin, 0.5-1.5 parts of an anti-aging agent, 3-8 parts of hydroxyapatite powder, 2-5 parts of white oil, 15-25 parts of semi-reinforced carbon black and 10-20 parts of light calcium carbonate. Meanwhile, the invention discloses a preparation method of the heat-resistant high-strength cable sheath material. The heat-resistant high-strength cable sheath material is excellent in processability, heat resistance and mechanical strength, simple in processing technology, great in practicability and easy to popularize.

Owner:SUZHOU KEMAO ELECTRONICS MATERIALS TECH

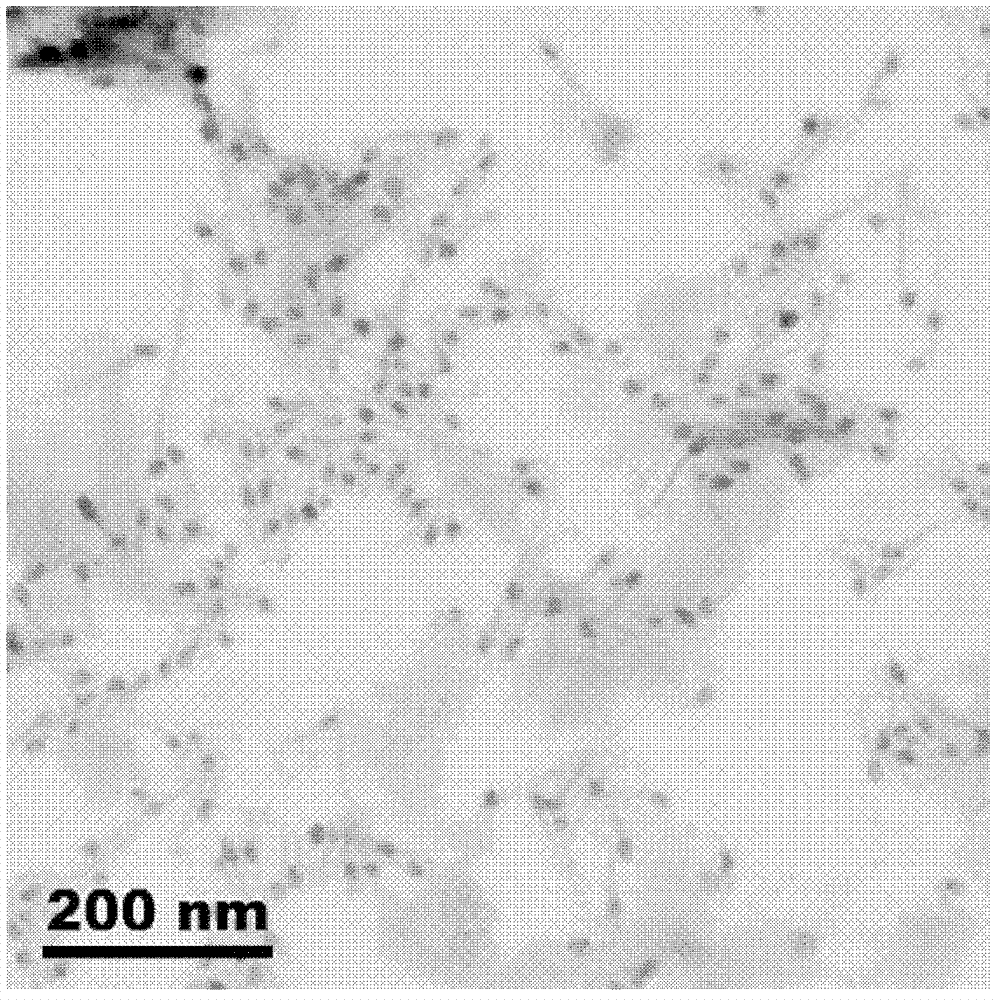

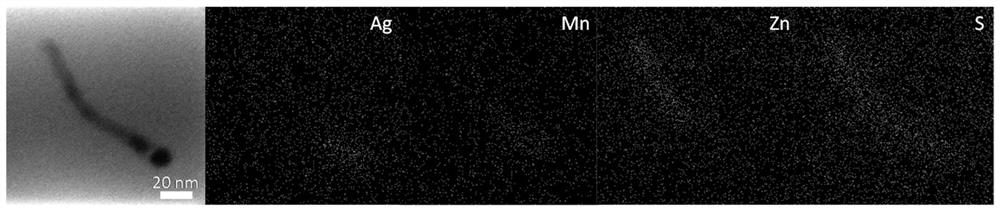

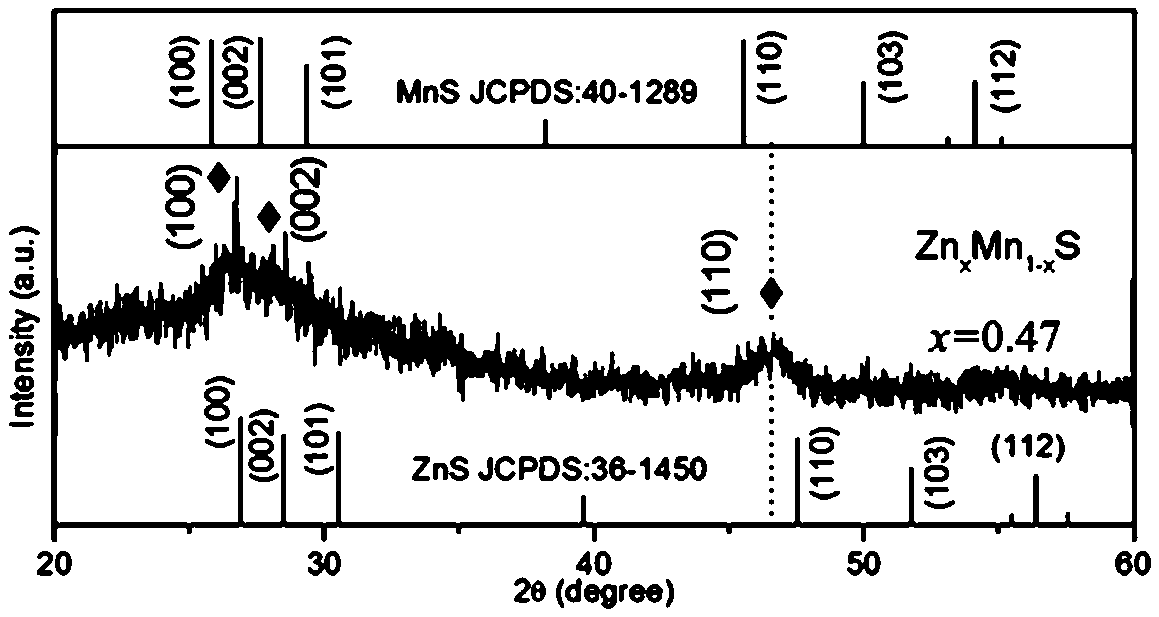

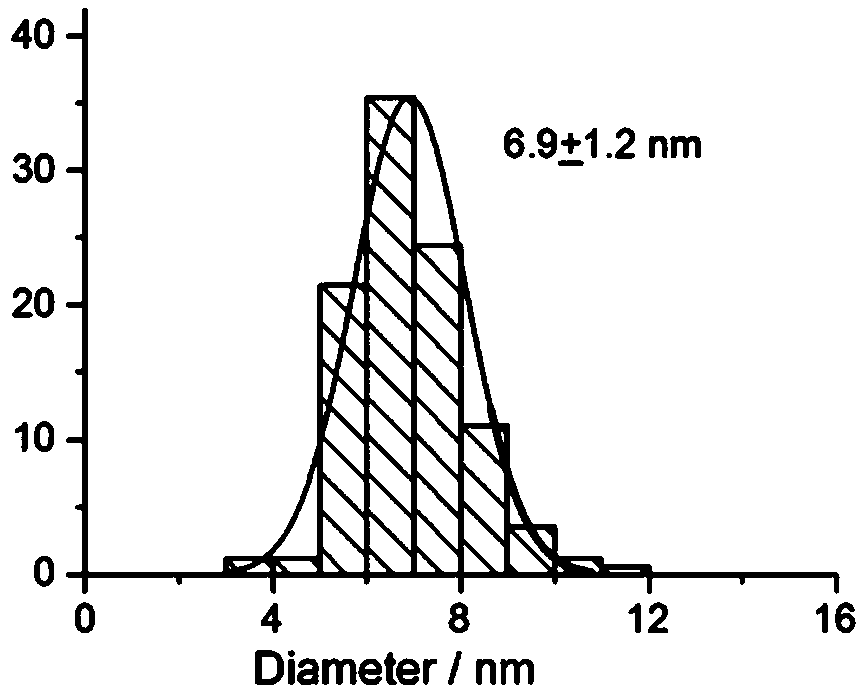

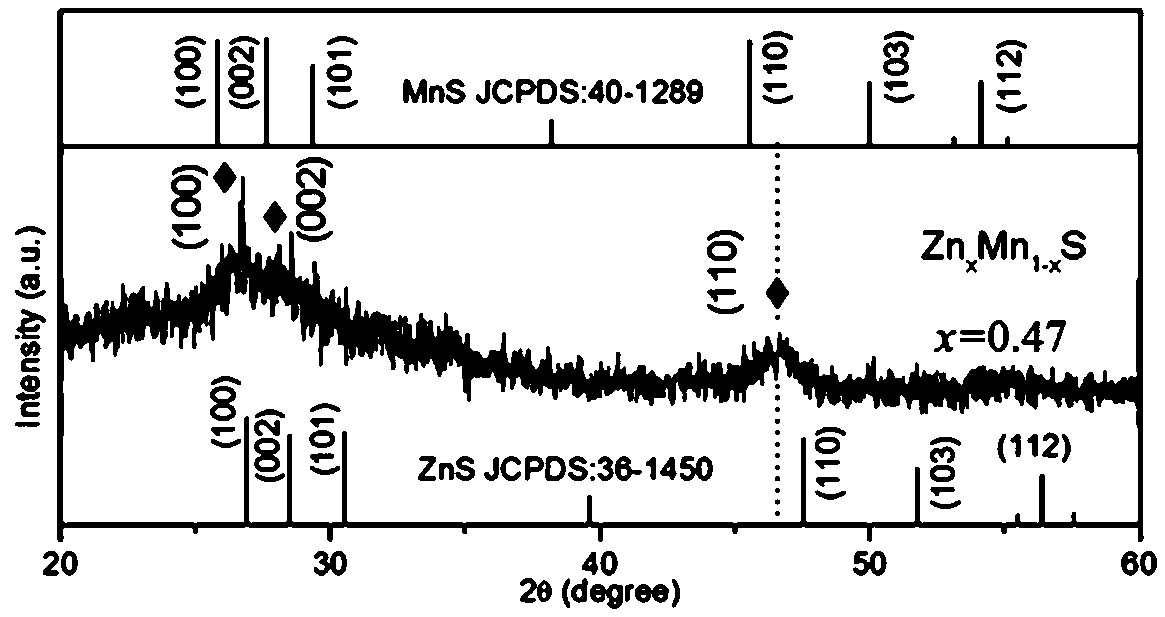

Preparation method of ternary zinc sulfide manganese nanowire

ActiveCN107720827AUniform sizeUniform compositionMaterial nanotechnologyManganese compoundsNanowireManganese

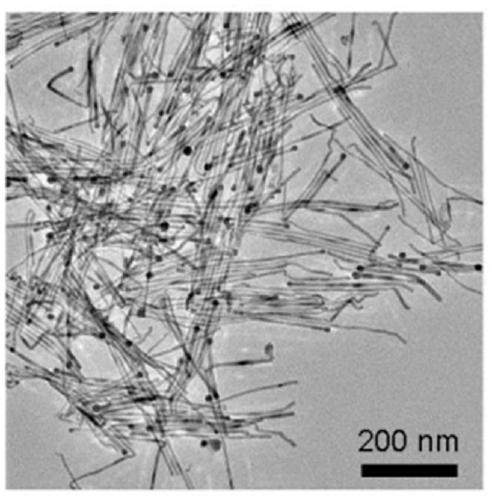

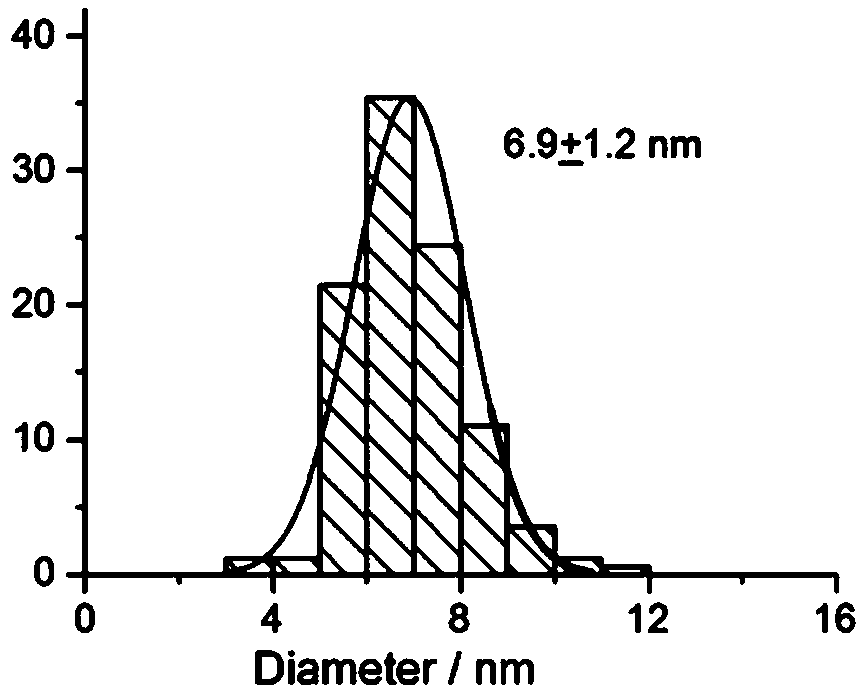

The invention relates to a preparation method of a ternary zinc sulfide manganese nanowire. The doping amount of manganese is 26 to 84 percent, the nanowire is uniform in size, the diameter is 6.9+ / -1.2 nm and the manganese is doped uniformly; the structural general formula of the ternary zinc sulfide manganese is ZnxMn1-xS, and the numerical range of the subscript x is 0.26 to 0.84; and the ternary zinc sulfide manganese nanowire serves as a magnetic material and is applied to magnetic devices, or serves as a light-emitting material and is applied to photoelectric devices. The preparation method particularly comprises the following steps: adding a silver sulfide (Ag2S) nanoparticle catalyst, zinc dibutyl dithiocarbamate (Zn(ddtc)2) and manganese dibutyl dithiocarbamate (Mn(ddtc)2) into amixed solvent; stirring uniformly, heating to 120 to 140 DEG C under the inert gas protection or vacuum conditions, and performing heat preservation for 5 to 15 minutes to obtain the ternary zinc sulfide manganese nanowire. The raw materials adopted by the process are common simple raw materials, the cost is low, the process controllability is high, the quality of products is high, and batched production and industrialization of the ternary zinc sulfide manganese nanowire are benefited.

Owner:HEFEI UNIV OF TECH

Formula of environment protection type flame-retardant rubber pipe

InactiveCN101463166BLow costGood physical and mechanical propertiesFlexible pipesMorpholineAluminium hydroxide

The invention relates to a formula of an environment-friendly flame retardant hose, which comprises the following compositions and weight portions: 100 portions of ethylene propylene diene rubber, 20 portions to 40 portions of fast extruded carbon black, 40 portions to 60 portions of calcined clay, 120 portions to 160 portions of aluminium hydroxide, 5 portions to 10 portions of zinc borate, 10 portions to 20 portions of antimony trioxide, 0.5 portion to 0.8 portion of thiuram tetrasulfide, 1.5 portions to 2.0 portions of zinc dibutyl dithiocarbamate, 0.5 portion to 0.8 portion of tetramethylthiuram disulfide, 3 portions to 5 portions of zinc oxide, 1 portion to 3 portions of stearic acid, 1 portion to 3 portions of polyethylene glycol, 1.5 portions to 2.0 portions of morpholine disulfide, 0.3 portion to 0.6 portion of sulfur and 20 portions to 40 portions of paraffin oil. Compared with the traditional product, the invention has the tensile strength of physical and mechanical property of 14MPa, which is higher than the traditional formula by 1.5 times. The invention can obtain FV-0 grade of vertical burn of national standard of flame resistance, namely the requirements of nonflammable material, can achieve the same flame resistant effect with the traditional method and meet the requirements of environment protection and safety of the hose of the modern automobile.

Owner:TIANJIN PENGYI GRP CO LTD

Environment-friendly low-smoke flame-retardant rubber composition and preparation method thereof

The invention discloses an environment-friendly low-smoke flame-retardant rubber composition and a preparation method thereof, and the rubber composition comprises the following raw materials: 30-50 parts of natural rubber, 40-50 parts of butadiene styrene rubber, 1-6 parts of a flame retardant, 2-7 parts of a vulcanizing agent, 1-9 parts of an accelerant, 1-5 parts of an anti-aging agent, 2-7 parts of a stabilizer and 4-6 parts of a flexibilizer. The flame retardant is prepared by mixing magnesium hydroxide, tributyl phosphate and tricresyl phosphate according to a ratio of (1-7): (2-6): (1-5), and the vulcanizing agent is prepared by mixing sulfur powder, dicumyl peroxide and dicumyl peroxide according to a ratio of (4-8): (1-5): (6-12). The accelerant is prepared by mixing tetramethyl thiuram disulfide, tetramethyl thiuram monosulfide and zinc dibutyldithiocarbamate according to the ratio of (2-6): (1-8): (1-6), carbon black ash added in a traditional rubber composition is removed, and then the flexibilizer is used for reinforcement, so smoke generated in the combustion process of rubber can be greatly reduced, and the service life of the rubber composition is prolonged. Meanwhile, the flame retardant is added, so that the flame retardant property of the rubber composition can be greatly improved.

Owner:南京固瑞橡胶有限公司

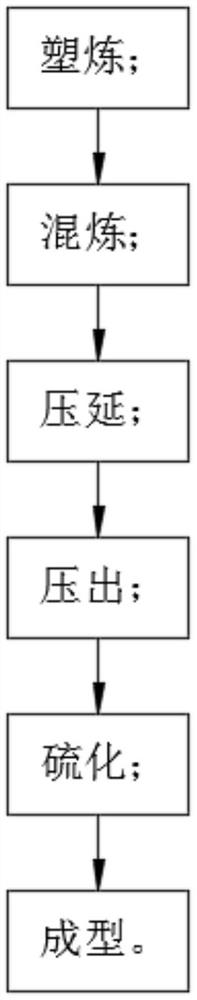

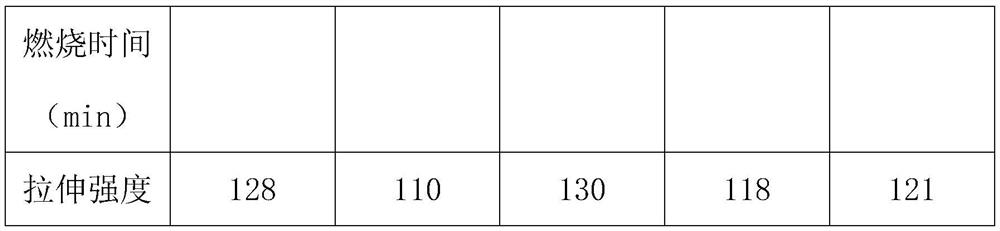

Modified nanometer LDHs low-smoke zero-halogen flame-retardation EPDM (ethylene propylene diene monomer) rubber and preparation method thereof

The invention discloses modified nanometer LDHs low-smoke zero-halogen flame-retardation EPDM (ethylene propylene diene monomer) rubber and a preparation method thereof. The preparation method comprises successively performing raw rubber mixing, addition and mixing, rubber compound forming, sulfuration and obtaining of a finished product. The modified nanometer LDHs low-smoke zero-halogen flame-retardation EPDM rubber is low in smoke, free of halogen, resistant to flame, and good in mechanical properties and electrical performances, and comprises the following compositions in parts by mass: 100 parts of EPDM rubber and a maleic-acid-grafted EPDM rubber copolymer elastomer, or EPDM rubber and an ethylene-octene copolymer elastomer, 40-70 parts of nanometer LDHs complexing agent, 30-60 parts of a coupling agent, 5-15 parts of microcapsule red phosphorus,30-50 parts of 50nm carbon black,3-6 parts of zinc oxide,30-50 parts of paraffin oil,2-5 parts of stearic acid,1-3 parts of sulphur,0.5-2 parts of 2-mercaptobenzothiazyl disulfide,0.5-2 parts of (dibutyldithiocarbamato)zinc(II), and 0.5-3 parts of tetramethylthiuram disulfide.

Owner:ANHUI PACIFIC CABLE CO LTD

Novel environmental-friendly glue

InactiveCN103589346AEliminate pollutionReduce investmentNon-macromolecular adhesive additivesOrganic non-macromolecular adhesiveEmulsionPolyethylene glycol

The invention discloses a novel environmental-friendly glue, relates to the technical field of fine chemical engineering, and particularly relates to a preparation method of the novel environmental-friendly glue. The glue is characterized by being prepared from following raw materials according to the following ratio: 33-50 g of vinyl acetate emulsion, 42-50 g of a vinylacetate copolymer resin, 5-8 g of propyltrimethoxysilane, 2-7 g of dioctyl pyrophosphate, 8-13 g of acrylic acid, 18-36 g of paraffin, 9-15 g of 2-methylaziridine, 7-17 g of furfuralcohol, 4-18 g of polyethylene glycol, 3-6 g of calcium carbonate, 8-10 g of zinc dimethyldithiocarbamate, 0.5-2.8 g of zinc dibutyldithiocarbamate, 2-5 g of octadecanol and 0.1-6 g of unsaturated resin paint. The glue is nontoxic and odorless, and has good viscosity, flexibility and light resistance. The glue can be manufactured simply. The production cost and the raw material cost can be reduced effectively.

Owner:SHENZHEN TAIQIANG CHEM

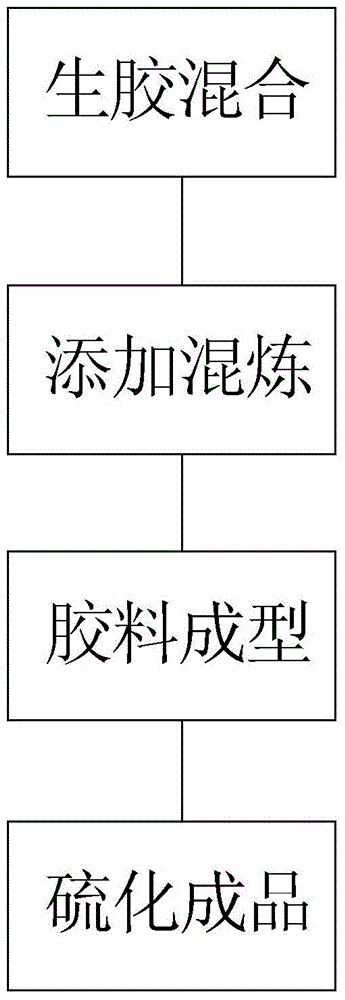

EPDM flame-retardant rubber

The invention relates to the technical field of rubber, in particular to EPDM flame-retardant rubber. The EPDM flame-retardant rubber is prepared from 35.1 parts by weight of ethylene-propylene-diene monomer rubber, 52.6 parts of an efficient composite flame retardant, 2 parts of carbon black, 4.8 parts of paraffin oil, 1.8 parts of zinc oxide, 0.55 part of stearic acid, 0.55 part of an internal release agent, 0.55 part of sulfur, 0.73 part of tetramethylthiuram disulfide, 0.18 part of zinc dibutyldithiocarbamate, and 1.14 part of a composite accelerant. According to the invention, a halogen-containing flame retardant does not need to be added.

Owner:DONGGUAN CENTURY CREATION INSULATION

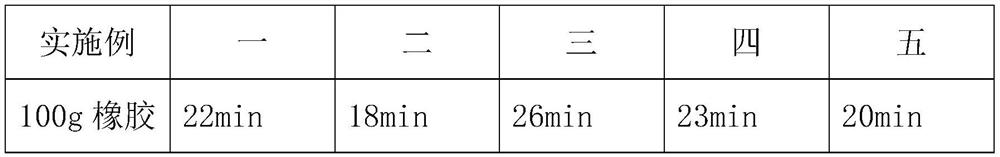

Graphene-ZDBC composite pre-dispersed rubber master batch and preparation method for same

The invention discloses a graphene-ZDBC composite pre-dispersed rubber master batch which includes, by weight, 40-48% of graphene, 25-35% of zinc dibutyldithiocarbamate, 3-7% of a coupling agent, 1-3% of saturated fatty acid, 1-3% of fatty acid alcohol ester, 1-3% of triethanolamine, 1-3% of zinc stearate, 6-14% of a rubber substrate, and 6-16% of paraffin oil, the sum of weight percentages of the components is 100%. The rubber master batch contains two active components, graphene and zinc dibutyldithiocarbamate (ZDBC), and has synergistic acceleration effect. When being used for producing vulcanized rubber in subsequent steps, the rubber master batch can promote vulcanization of rubber and improve tensile strength, tear strength, wear resistance and aging resistance of rubber. The graphene-ZDBC composite pre-dispersed rubber master batch has low Mooney viscosity and maintains the original activities of the graphene and ZDBC, so that the graphene and ZDBC are uniformly dispersed in the rubber master batch.

Owner:NINGBO ACTMIX POLYMER

A kind of preparation method of ternary zinc manganese sulfide nanowire

ActiveCN107720827BUniform sizeUniform compositionMaterial nanotechnologyManganese compoundsNanowireNanoparticle

Owner:HEFEI UNIV OF TECH

Popular searches

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com