Preparation method of silver sulfide-zinc sulfide semiconductor nanometer heterojunction

A silver sulfide and zinc sulfide technology, which is applied in chemical instruments and methods, physical/chemical process catalysts, chemical/physical processes, etc., can solve problems such as high vacuum requirements, cumbersome preparation process, and expensive equipment

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

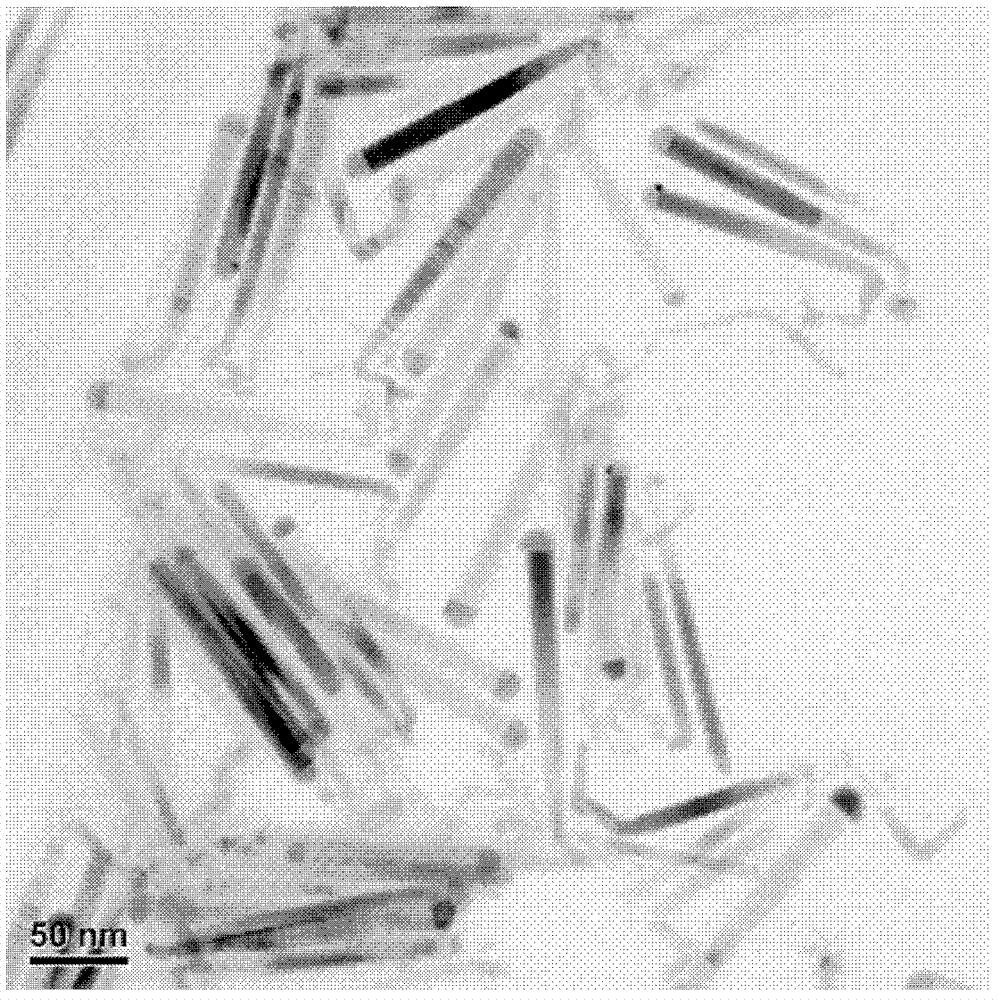

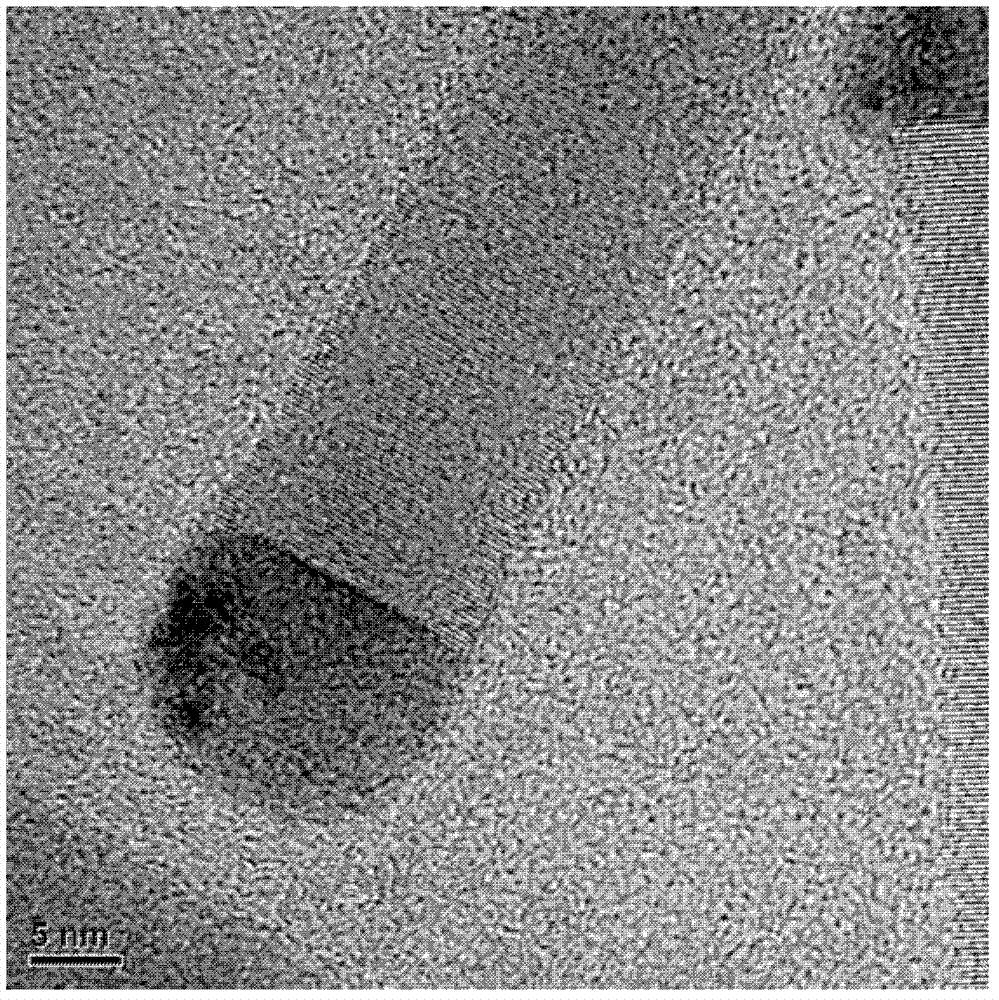

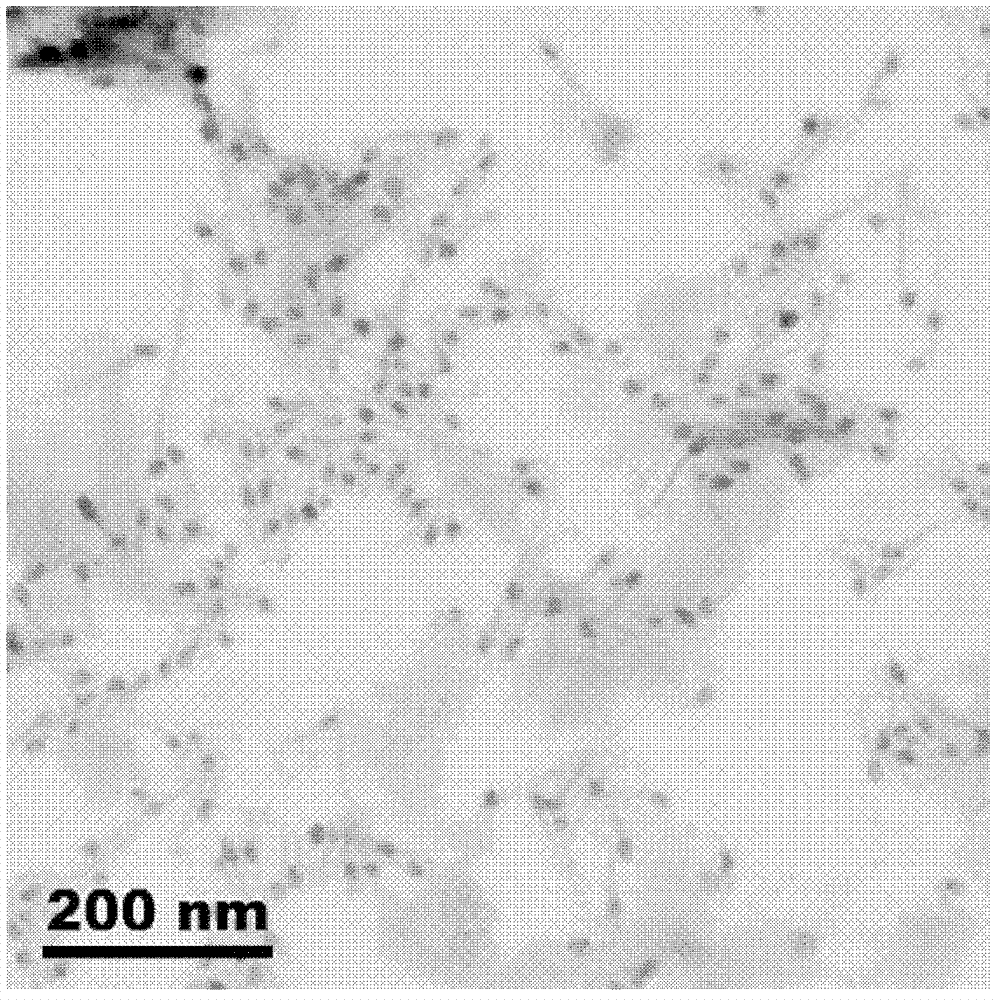

[0018] Add 10 mg of the reaction precursor silver dibutyldithiocarbamate to a 50 mL round bottom flask, add 6 mmol of octadecylamine, 2 mmol of n-trioctylphosphine oxide, and 8 mmol of n-octadecylmercaptan in sequence, and put the flask into oil at a constant temperature of 180 ° C. In the bath, magnetically stir and react for 5 minutes. After the reaction is completed and cooled, take out the solution with a dropper to a test tube, dilute with n-hexane, and ultrasonically oscillate for 10 minutes, then centrifuge at a speed of 12000 rpm for 10 minutes. The product sinks to the bottom of the container and discards the supernatant. solution to obtain silver sulfide nanoparticles for later use. Disperse 0.5 mg of silver sulfide nanoparticles in n-hexane, drop them into a 50 mL round bottom flask, add 4 mmol of octadecylamine, heat in an oil bath at a constant temperature of 210°C for 10 min to remove n-hexane, and then add dibutyl disulfide Substituted zinc carbamate 0.05mmol, n...

Embodiment 2

[0020] Add 12 mg of silver dibutyldithiocarbamate, the reaction precursor, into a 50 mL round bottom flask, add 6 mmol of octadecylamine, 4 mmol of n-trioctylphosphine oxide, and 8 mmol of n-octadecylmercaptan in sequence, and put the flask into oil at a constant temperature of 180 ° C. In the bath, magnetically stir and react for 5 minutes. After the reaction is completed and cooled, take out the solution with a dropper to a test tube, dilute with n-hexane, and ultrasonically oscillate for 10 minutes, then centrifuge at a speed of 12000 rpm for 10 minutes. The product sinks to the bottom of the container and discards the supernatant. solution to obtain silver sulfide nanoparticles for later use. Disperse 1.0mg of silver sulfide nanoparticles in n-hexane, drop them into a 50mL round bottom flask, add 8mmol of octadecylamine, put them in an oil bath with a constant temperature of 210°C and heat for 10min to remove n-hexane, then add dibutyl disulfide Substituted zinc carbamate ...

Embodiment 3

[0022] Add 15 mg of silver dibutyldithiocarbamate, the reaction precursor, into a 50 mL round bottom flask, add 8 mmol of octadecylamine, 4 mmol of n-trioctylphosphine oxide, and 16 mmol of n-octadecanethiol in sequence, and put the flask into oil at a constant temperature of 180°C. In the bath, magnetically stir and react for 5 minutes. After the reaction is completed and cooled, take out the solution with a dropper to a test tube, dilute with n-hexane, and ultrasonically oscillate for 10 minutes, then centrifuge at a speed of 12000 rpm for 10 minutes. The product sinks to the bottom of the container and discards the supernatant. solution to obtain silver sulfide nanoparticles for later use. Disperse 2.0mg of silver sulfide nanoparticles in n-hexane, drop them into a 50mL round bottom flask, add 16mmol of octadecylamine, put them in an oil bath at a constant temperature of 210°C and heat for 10min to remove n-hexane, then add dibutyl disulfide Substituted zinc carbamate 0.1mm...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com