Anti-aging sealing rubber strip for building doors and windows and preparation method thereof

A technology of sealing strips and building doors and windows, which is applied in the field of sealing materials, can solve problems such as difficulty in meeting sealing requirements, loss of softness of sealing strips, corrosion of steel linings of plastic-steel doors and windows, etc., to achieve increased strength, excellent thermal oxidation resistance, and improved Effect of aging resistance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

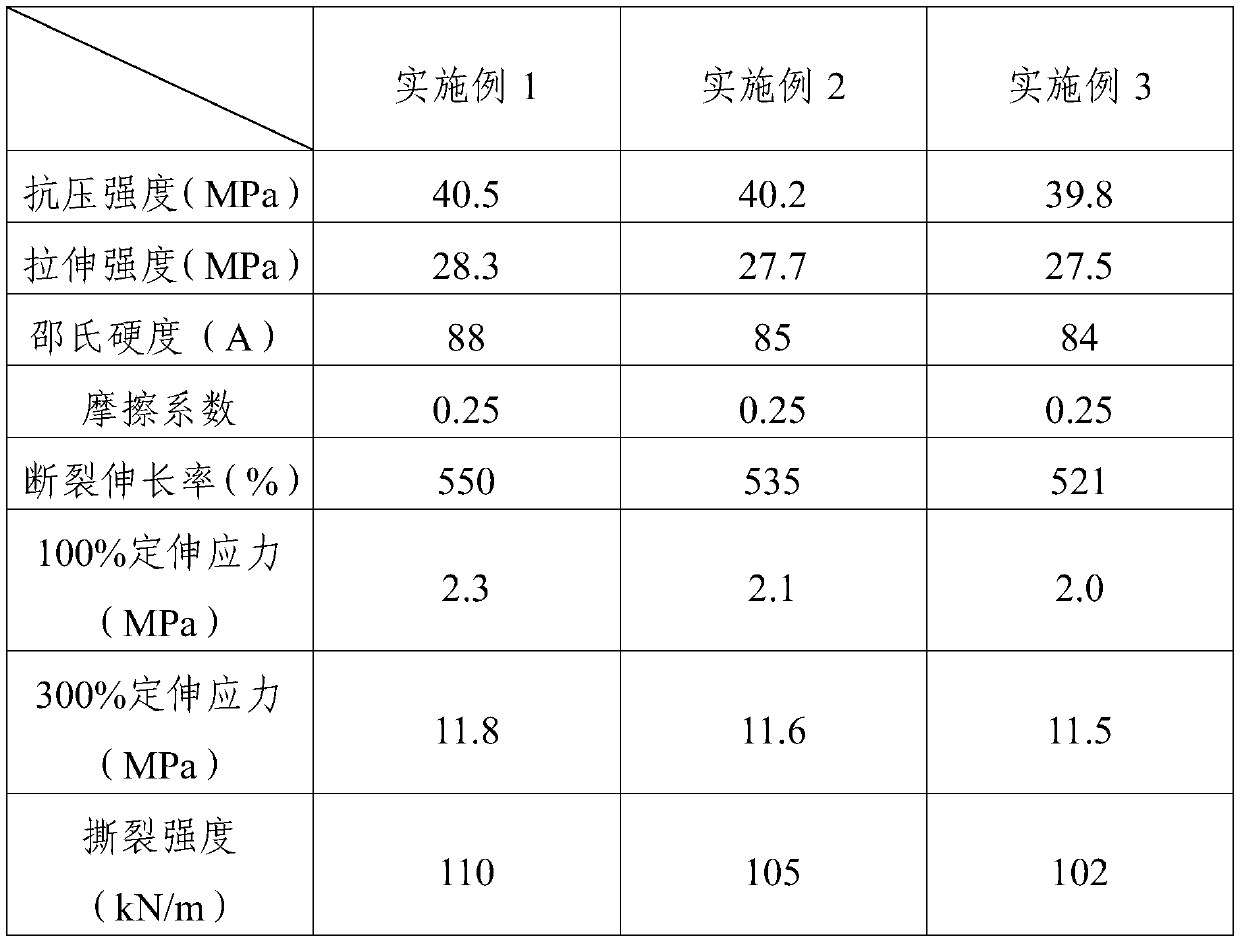

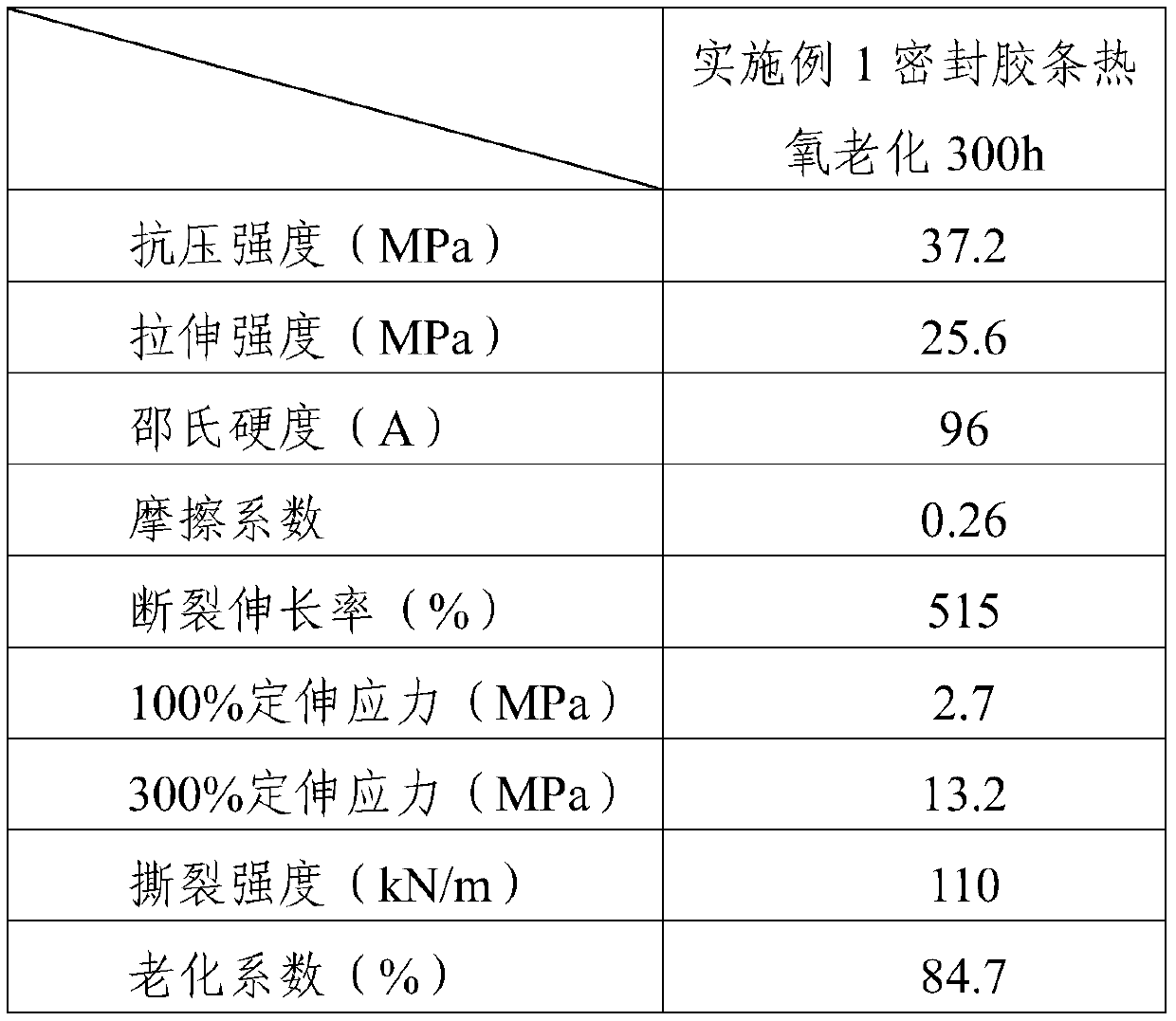

Embodiment 1

[0033] An aging-resistant sealing strip for building doors and windows, comprising the following raw materials in parts by weight:

[0034]48 parts of p-phenylene silicone rubber, 30 parts of tin-coupled solution polystyrene-butadiene rubber, 35 parts of natural rubber, 1.2 parts of zinc methacrylate, 5 parts of liquid polyisoprene rubber, 1.3 parts of dioctyl sebacate Parts, 12 parts of 774 carbon black, 15 parts of 550 carbon black, 3 parts of nano-magnesium hydroxide, 14 parts of pitch-based chopped carbon fiber, 10 parts of polyvinylidene chloride, 3 parts of microcrystalline paraffin, 2.5 parts of stearic acid, horse 1 part of toric anhydride grafted EPDM rubber, 1.2 parts of sulfur, 0.5 parts of dicumyl peroxide, 1.5 parts of zinc dibutyl dithiocarbamate, accelerator M, accelerator DM, accelerator TMTD by weight 2 parts of accelerator compounded at a ratio of 1:1:6, 4 parts of reinforcing ingredients compounded with nanocellulose and rod-shaped active silica at a weight ...

Embodiment 2

[0042] An aging-resistant sealing strip for building doors and windows, comprising the following raw materials in parts by weight:

[0043] 55 parts of p-phenylene silicone rubber, 40 parts of tin-coupled solution polystyrene-butadiene rubber, 32 parts of natural rubber, 1 part of zinc methacrylate, 6 parts of liquid polyisoprene rubber, 1.3 dioctyl sebacate Parts, 20 parts of 774 carbon black, 12 parts of 550 carbon black, 4 parts of nano-magnesium hydroxide, 14 parts of pitch-based chopped carbon fiber, 5.5 parts of polyvinylidene chloride, 3 parts of microcrystalline paraffin, 1 part of stearic acid, horse 0.4 parts of EPDM grafted with anhydride, 1 part of sulfur, 0.5 parts of dicumyl peroxide, 0.8 parts of zinc dibutyldithiocarbamate, accelerator M, accelerator DM, accelerator TMTD by weight Accelerator 1.5 parts compounded at a ratio of 1:1:5, nanocellulose, rod-shaped active silica compounded at a weight ratio of 1:1, reinforcing ingredients compounded at a weight ratio...

Embodiment 3

[0051] An aging-resistant sealing strip for building doors and windows, comprising the following raw materials in parts by weight:

[0052] 45 parts of p-phenylene silicone rubber, 40 parts of tin-coupled solution polystyrene-butadiene rubber, 32 parts of natural rubber, 1 part of zinc methacrylate, 5 parts of liquid polyisoprene rubber, 1 part of dioctyl sebacate Parts, 15 parts of 774 carbon black, 20 parts of 550 carbon black, 5 parts of nano-magnesium hydroxide, 12 parts of pitch-based chopped carbon fiber, 10 parts of polyvinylidene chloride, 3 parts of microcrystalline paraffin, 2 parts of stearic acid, horse To acid anhydride grafted EPDM rubber 0.5 part, sulfur 1 part, dicumyl peroxide 0.4 part, dibutyl zinc dithiocarbamate 0.8 part, accelerator M, accelerator DM, accelerator TMTD by weight 1 part of accelerator compounded at a ratio of 1:1:6, 2 parts of reinforcing ingredients compounded with nanocellulose and rod-shaped active silica at a weight ratio of 5:1, anti-ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com