Preparation method of one-dimensional heterogeneous nano material of manganese sulfide and zinc sulfide

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Benefits of technology

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0026] (1) In a flask with a vacuum stopper, add 9 dodecanethiol, 6 mL dodecylamine and 0.02 g zinc dibutyldithiocarbamate (Zn(ddtc) 2 ) precursor, and 2 mL of silver sulfide (Ag 2 S) Catalyst dispersion, stir evenly;

[0027] (2) Nitrogen protection was introduced, and the temperature was rapidly raised to 120°C, and reacted for 20 minutes to obtain zinc sulfide nanowires;

[0028] (3) Add 0.02 g manganese dibutyldithiocarbamate (Mn(ddtc) 2 ), stirred evenly, passed nitrogen protection, and rapidly raised the temperature to 120 °C, and reacted for 15 min; cooled to room temperature, and washed with cyclohexane for 6 times to obtain one-dimensional heterogeneous nanomaterials of manganese sulfide and zinc sulfide.

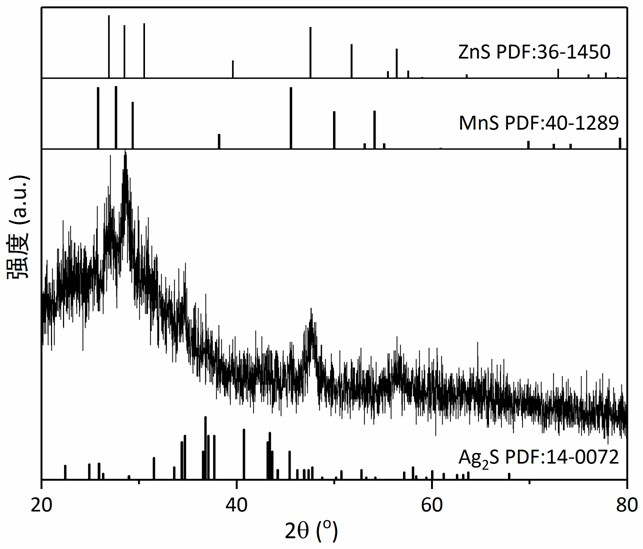

[0029] Depend on figure 1 Visible, the characteristic diffraction peak in the product XRD spectrogram of present embodiment 1 shows that product is made of Ag 2 S, ZnS and MnS three phase composition.

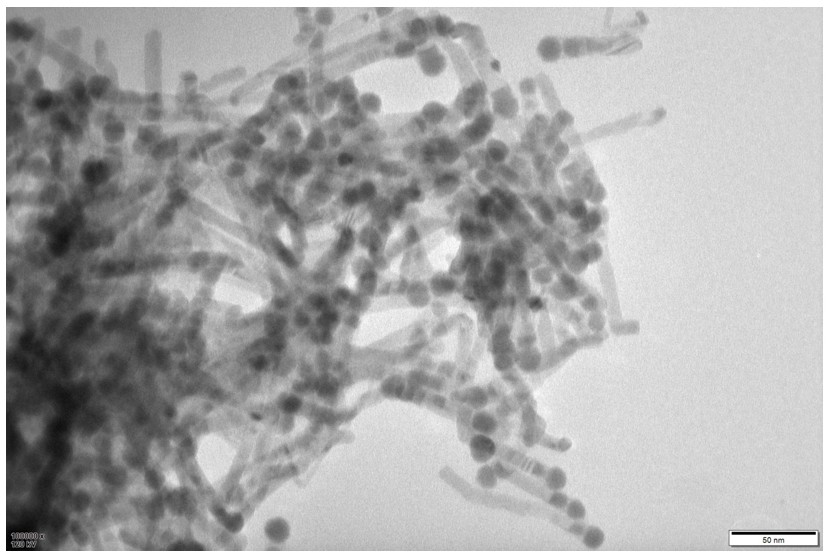

[0030] Depend on figure 2 It can be seen that the one-d...

Embodiment 2

[0034] (1) In a flask with a vacuum stopper, add 9 dodecanethiol, 6 mL dodecylamine and 0.02 g manganese dibutyldithiocarbamate (Mn(ddtc) 2 ) precursor, and 2 mL of silver sulfide (Ag 2 S) Catalyst dispersion, stir evenly;

[0035] (2) Introduce argon (Ar) protection, rapidly raise the temperature to 120°C, and react for 15 minutes to obtain manganese sulfide nanowires;

[0036] (3) Add 0.02 g zinc dibutyldithiocarbamate (Zn(ddtc) 2 ), stirred evenly, protected by argon (Ar), and rapidly heated to 120 ° C, reacted for 20 min; cooled to room temperature, washed with cyclohexane for 6 times to obtain one-dimensional heterogeneous nanoparticles of manganese sulfide and zinc sulfide Material.

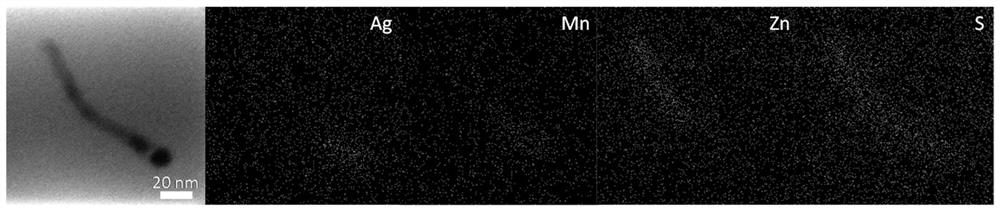

[0037] Depend on Figure 5 It can be seen that the one-dimensional heterogeneous nanomaterials of manganese sulfide and zinc sulfide in Example 2 are gray powder after drying, the shape of the powder particles is a cotton swab rod, the head is composed of silver and sulfur elements, and...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

| Diameter | aaaaa | aaaaa |

| Length | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com