Environment-friendly low-smoke flame-retardant rubber composition and preparation method thereof

A rubber composition and a low-smoke flame-retardant technology are applied in the field of environmentally friendly low-smoke flame-retardant rubber compositions and their preparation, and can solve the problems of lack of flame-retardant effect, black smoke from rubber, single rubber function, and the like, Achieve the effect of saving preparation time and increasing flame retardant properties

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further explained below in conjunction with specific embodiments.

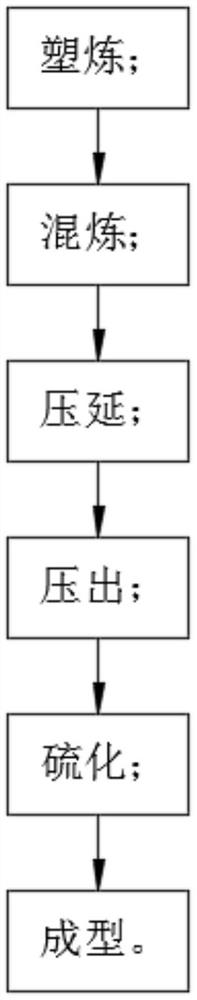

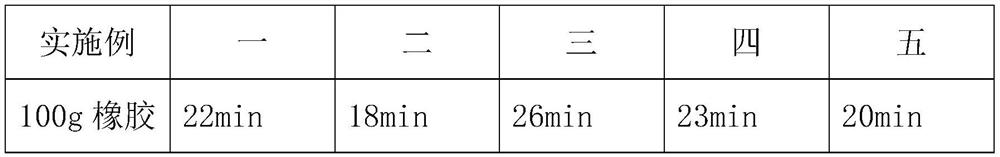

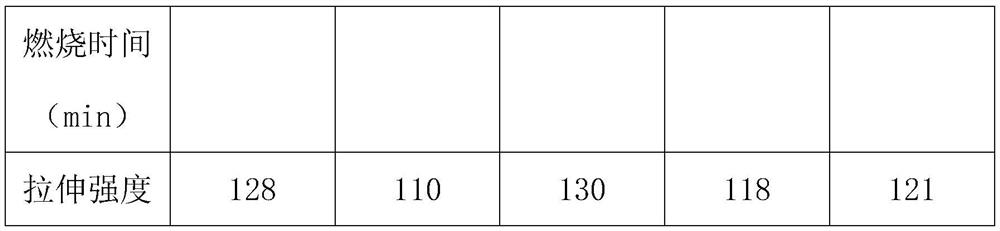

[0025] refer to figure 1 , embodiment one

[0026] In this example, a formulation of an environmentally friendly low-smoke flame-retardant rubber composition is proposed, including the following raw materials: 35 parts of natural rubber, 42 parts of styrene-butadiene rubber, 4 parts of flame retardant, 6 parts of vulcanizing agent, accelerator 4 parts of antioxidant, 3 parts of anti-aging agent, 5 parts of stabilizer, 5 parts of toughening agent, and the ratio of flame retardant is 4:5:3. It is prepared by mixing magnesium hydroxide, tributyl phosphate and tricresyl phosphate. The ratio of the vulcanizing agent is 6:4:7 of sulfur powder, dicumyl peroxide and dicumin peroxide, and the ratio of the accelerator is 5:5:4 of tetramethyl disulfide Qiulan It is prepared by mixing thiuram monosulfide, tetramethylthiuram monosulfide and zinc dibutyldithiocarbamate, and the anti-ag...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com