High-cleanness alcohol-based liquid fuel

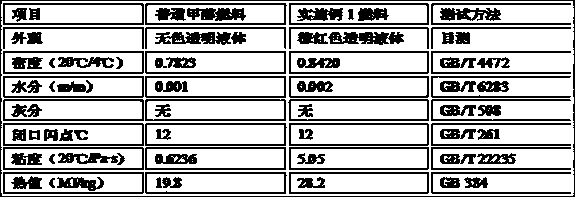

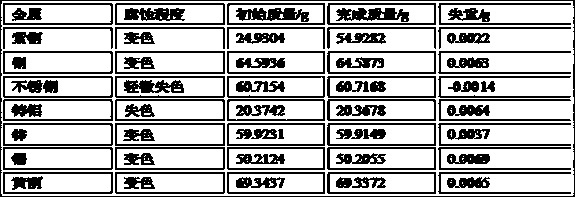

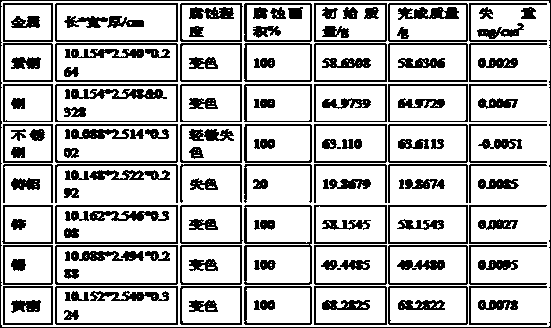

A liquid fuel, clean alcohol technology, applied in liquid carbon-containing fuel, fuel, petroleum industry and other directions, can solve the problems of corrosion of metal parts, poor lubricating performance of alcohol-based fuel, accidental drinking and eating, etc., and achieves low corrosion and lubrication. Good performance and high calorific value

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0042] The high-clean car alcohol-based liquid fuel of this embodiment is prepared from the following raw materials in parts by volume: 80 parts of methanol, 15 parts of ethanol gasoline, and 8 parts of additives.

[0043] The additive is prepared from the following raw materials in parts by volume:

[0044] 10 parts of polyisooctyl methacrylate;

[0045] 15 parts of 2,4-dimethyl-6-tert-butylphenol;

[0046] 4 parts of N,N'-disalicylidene-1,2-propanediamine;

[0047] 14 parts of lauryl methacrylate;

[0048] 10 parts of diethylene glycol monomethyl ether;

[0049] 28 parts of methyl palmitoleate;

[0050] 8 parts of diethylaminoethyl methacrylate;

[0051] 7 parts of zinc dibutyldithiocarbamate;

[0052] 7 parts of 2-n-octyl-4-isothiazolin-3-one;

[0053] 16 parts of dioctyl phthalate;

[0054] 12 parts of N-phenyl-N'-sec-butylphenylenediamine;

[0055] 4 parts of isopropyl benzoate.

[0056] The preparation method of the additive is as follows: at normal temperature...

Embodiment 2

[0066] The high-clean car alcohol-based liquid fuel of this embodiment is prepared from the following raw materials in parts by volume: 60 parts of methanol, 20 parts of ethanol gasoline, and 12 parts of additives.

[0067] The additive is prepared from the following raw materials in parts by volume:

[0068] 5 parts of polyisooctyl methacrylate;

[0069] 20 parts of 2,4-dimethyl-6-tert-butylphenol;

[0070] 2 parts of N,N'-disalicylidene-1,2-propanediamine;

[0071] 20 parts of lauryl methacrylate;

[0072] 5 parts of diethylene glycol monomethyl ether;

[0073] 35 parts of methyl palmitoleate;

[0074] 5 parts of diethylaminoethyl methacrylate;

[0075] 12 parts of zinc dibutyldithiocarbamate;

[0076] 5 parts of 2-n-octyl-4-isothiazolin-3-one;

[0077] 20 parts of dioctyl phthalate;

[0078] 8 parts of N-phenyl-N'-sec-butylphenylenediamine;

[0079] 6 parts of isopropyl benzoate.

[0080] The preparation method of additive is the same as embodiment 1.

[0081] Co...

Embodiment 3

[0087] The high-clean car alcohol-based liquid fuel of this embodiment is prepared from the following raw materials in parts by volume: 100 parts of methanol, 10 parts of ethanol gasoline, and 5 parts of additives.

[0088] The additive is prepared from the following raw materials in parts by volume:

[0089] 15 parts of polyisooctyl methacrylate;

[0090] 6 parts of 2,4-dimethyl-6-tert-butylphenol;

[0091] 6 parts of N,N'-disalicylidene-1,2-propanediamine;

[0092] 8 parts of lauryl methacrylate;

[0093] 15 parts of diethylene glycol monomethyl ether;

[0094] 15 parts of methyl palmitoleate;

[0095] 12 parts of diethylaminoethyl methacrylate;

[0096] 5 parts of zinc dibutyldithiocarbamate;

[0097] 10 parts of 2-n-octyl-4-isothiazolin-3-one;

[0098] 10 parts of dioctyl phthalate;

[0099] 16 parts of N-phenyl-N'-sec-butylphenylenediamine;

[0100] 2 parts of isopropyl benzoate.

[0101] The preparation method of additive is the same as embodiment 1.

[0102] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com