Colorized ethylene propylene terpolymer rubber sealing strip and preparation method thereof

A technology of EPDM rubber and sealing strip, applied in the field of rubber sealing strip, can solve the problem of the mismatch between paint and interior color around black EPDM rubber sealing strip, aging resistance and weather resistance of TPE/PVC color sealing strip Poor performance, pollution of curtain walls and car interiors, etc., to achieve the effect of good color matching effect, good aging resistance and weather resistance, and reduce the possibility of yellowing and discoloration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0073] A colored EPDM sealing strip, which is prepared from the raw materials with the following mass fractions:

[0074] EPDM rubber 90 parts

[0075] Composite mineral filler 160 parts

[0076] 60 parts of colorless paraffin oil

[0077] Toner 0.8 parts

[0078] Sulfur (S) 0.4 parts

[0079] Zinc di-n-butyldithiocarbamate (BZ) 1.2 parts

[0080] 2-Mercaptobenzothiazole (M) 1 part

[0081] Tetramethylthiuram disulfide (TMTD) 0.45 part

[0082] Zinc dimethyl dithiocarbamate (PZ) 0.6 part

[0083] 4,4'-dithiodimorpholine (DTDM) 2 parts

[0084] Zinc oxide 6 parts

[0085] Stearic acid 1.2 parts

[0086] Wherein the composite mineral filler is prepared from raw materials with the following mass fractions:

[0087] Aluminum silicate 90 parts

[0088] 45 parts diatomaceous earth

[0089] 19 parts of heavy calcium carbonate

[0090] White carbon black 4.5 parts

[0091] Zinc stearate 2.2 parts

[0092] 32 parts of titanium dioxide.

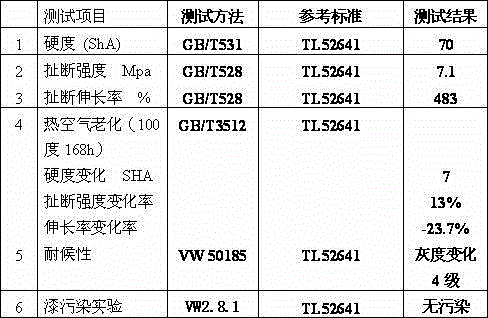

[0093] Physi...

Embodiment 2

[0098] A colored EPDM sealing strip, which is prepared from the raw materials with the following mass fractions:

[0099] EPDM rubber 92 parts

[0100] Composite mineral filler 165 parts

[0101] 64 parts of colorless paraffin oil

[0102] Toner 1 part

[0103] Sulfur (S) 0.3 parts

[0104] Zinc di-n-butyldithiocarbamate (BZ) 1 part

[0105] 2-Mercaptobenzothiazole (M) 0.8 parts

[0106] Tetramethylthiuram disulfide (TMTD) 0.3 parts

[0107] Zinc dimethyl dithiocarbamate (PZ) 0.4 parts

[0108] 0.9 parts of 4,4'-dithiodimorpholine (DTDM)

[0109] Zinc oxide 5 parts

[0110] 1 part stearic acid

[0111] Wherein the composite mineral filler is prepared from raw materials with the following mass fractions:

[0112] Aluminum silicate 92 parts

[0113] Diatomaceous earth 48 parts

[0114] 18 parts of heavy calcium carbonate

[0115] White carbon black 4 parts

[0116] Zinc stearate 2 parts

[0117] 30 parts of titanium dioxide.

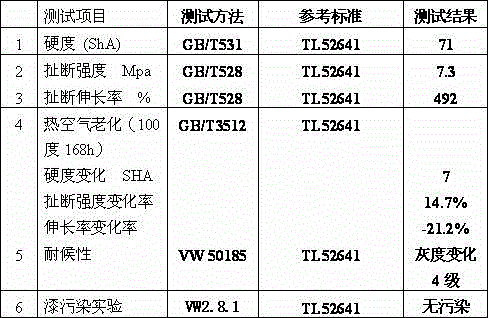

[0118] Physical ...

Embodiment 3

[0123] A colored EPDM sealing strip, which is prepared from the raw materials with the following mass fractions:

[0124] EPDM rubber 100 parts

[0125] Composite mineral filler 180 parts

[0126] 80 parts of colorless paraffin oil

[0127] Toner 1.2 parts

[0128] Sulfur (S) 0.6 parts

[0129] Zinc di-n-butyldithiocarbamate (BZ) 2 parts

[0130] 2-Mercaptobenzothiazole (M) 1.5 parts

[0131] Tetramethylthiuram disulfide (TMTD) 0.8 parts

[0132] Zinc dimethyl dithiocarbamate (PZ) 0.2 parts

[0133] 0.8 parts of 4,4'-dithiodimorpholine (DTDM)

[0134] Zinc oxide 4 parts

[0135] 0.8 parts of stearic acid

[0136] Wherein the composite mineral filler is prepared from raw materials with the following mass fractions:

[0137] Aluminum silicate 100 parts

[0138] Diatomaceous earth 55 parts

[0139] 22 parts of heavy calcium carbonate

[0140] White carbon black 6 parts

[0141] Zinc stearate 1.8 parts

[0142] 28 parts of titanium dioxide.

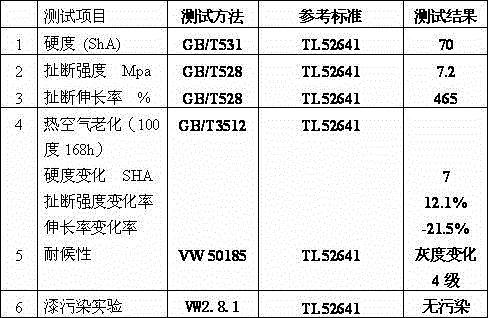

[0...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com