Preparation method of ternary zinc sulfide manganese nanowire

A technology of nanowires and zinc sulfide, applied in the field of preparation of new ternary zinc manganese sulfide nanowires, can solve the problems of uneven size of ZnS nanowires, narrow doping amount modulation range, low manganese doping amount, etc. Conducive to mass production and industrialization, excellent product quality and uniform composition

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0030] Preparation of ternary ZnMnS nanowires

[0031] (1) In a flask with a vacuum stopper, add 15 mL of dodecanethiol, 15 mL of dodecylamine, 0.705 g of zinc dibutyldithiocarbamate (Zn(ddtc) 2 ) precursor, 0.690 g of manganese dibutyldithiocarbamate (Mn(ddtc) 2 ) precursor, and 20 mg silver sulfide nanoparticle catalyst;

[0032] (2) Stir evenly, vacuumize, and the vacuum condition is 0.003 MPa; and quickly raise the temperature to 120 °C, and react for 10 min; the product is washed 5 times with methanol and cyclohexane, and dried to obtain ternary zinc-manganese sulfide nanowires.

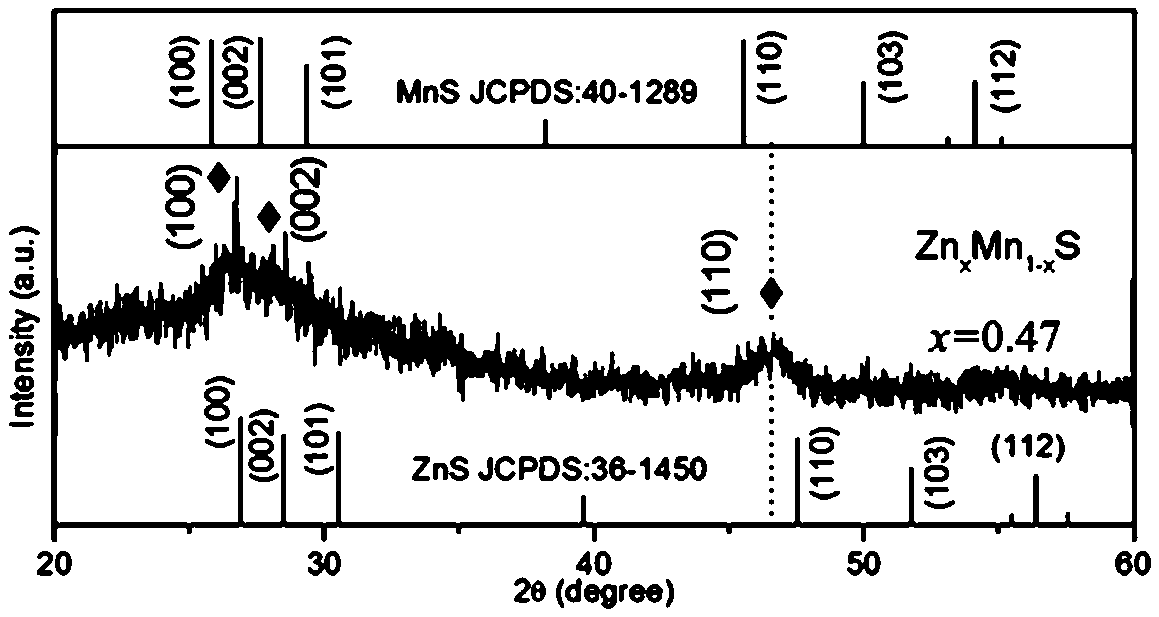

[0033] Depend on figure 1 It can be seen that the composition of the product is uniform, and no other phases appear in the XRD spectrum of the product. The XRD characteristic diffraction peak of the product is between the standard ZnS and MnS phase characteristic diffraction peaks, which is Zn x mn 1-x For the S phase, x=0.47 can be calculated by Vegard's theorem.

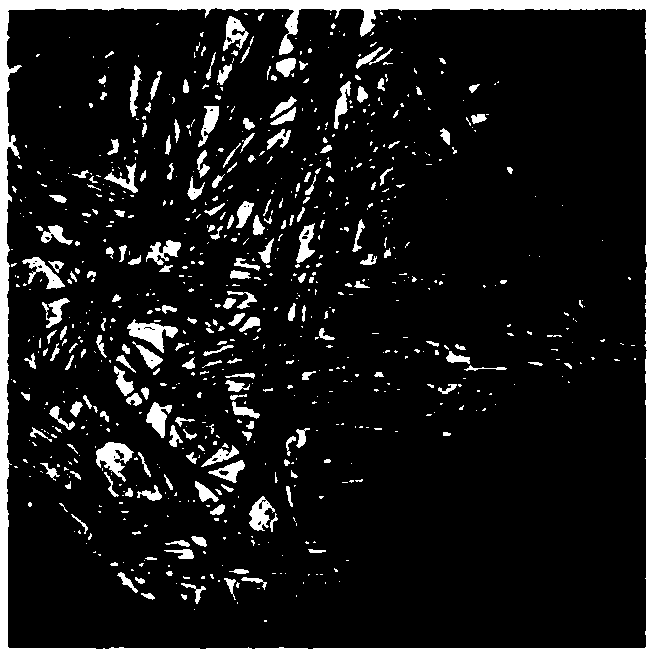

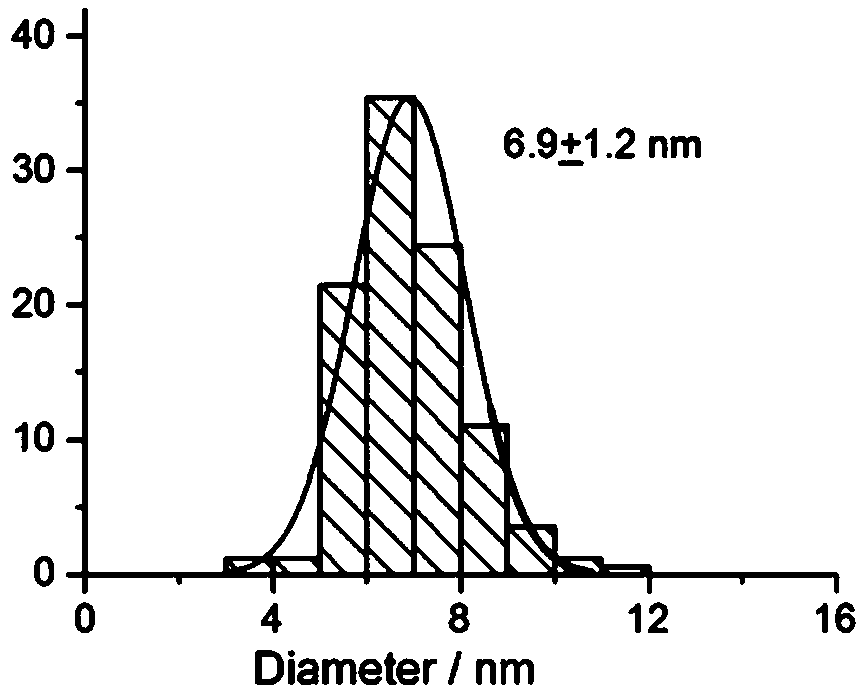

[0034] Depend on figu...

Embodiment 2

[0037] Preparation of ternary ZnMnS nanowires with other compositions

[0038] (1) In a flask with a vacuum stopper, add 15 mL of dodecanethiol, 15 mL of dodecylamine, 1.125 g of zinc dibutyldithiocarbamate (Zn(ddtc) 2 ) precursor, 0.135 g of manganese dibutyldithiocarbamate (Mn(ddtc) 2 ) precursor, and 20 mg silver sulfide (Ag 2 S) nanoparticle catalysts;

[0039] (2) Stir evenly, vacuumize, and then pass through argon (Ar) protection; quickly heat up to 120°C, react for 5 minutes; wash the product with methanol and cyclohexane for 5 times, and dry to obtain ternary zinc manganese sulfide Nanowires.

[0040] Depend on Figure 5 It can be seen that the product composition x=0.26, and the manganese doping amount is 26%.

Embodiment 3

[0042] Preparation of ternary ZnMnS nanowires with other compositions

[0043] (1) In a flask with a vacuum stopper, add 15 mL of dodecanethiol, 15 mL of dodecylamine, 0.570 g of zinc dibutyldithiocarbamate (Zn(ddtc) 2 ) precursor, 0.825 g of manganese dibutyldithiocarbamate (Mn(ddtc) 2 ) precursor, and 20 mg silver sulfide (Ag 2 S) nanoparticle catalysts;

[0044] (2) Stir evenly, vacuumize, and then pass Ar protection; quickly heat up to 120 °C, and react for 5 min; the product is washed with methanol and cyclohexane for 5 times, and dried to obtain ternary zinc-manganese sulfide nanowires.

[0045] Depend on Figure 5 It can be seen that the product composition x=0.69, and the manganese doping amount is 69%.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com