Ethylene-propylene-diene monomer mould pressing abnormal shape sponge sheath rubber composition

A technology of EPDM rubber and rubber composition is applied in the field of EPDM molded special-shaped sponge sheath, which can solve the problems of difficult control of dimensional stability, and achieve the effects of dimensional stability, good elasticity and good heat resistance.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

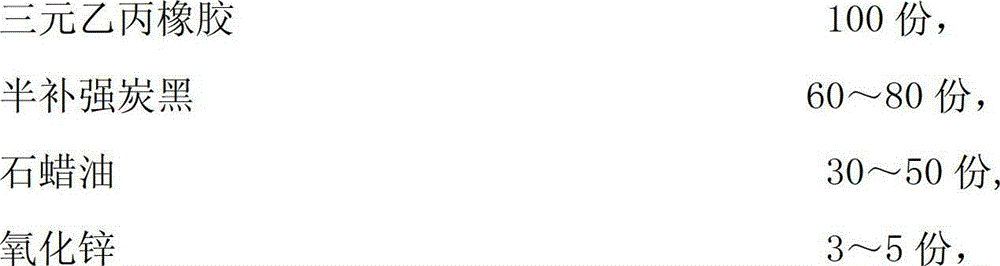

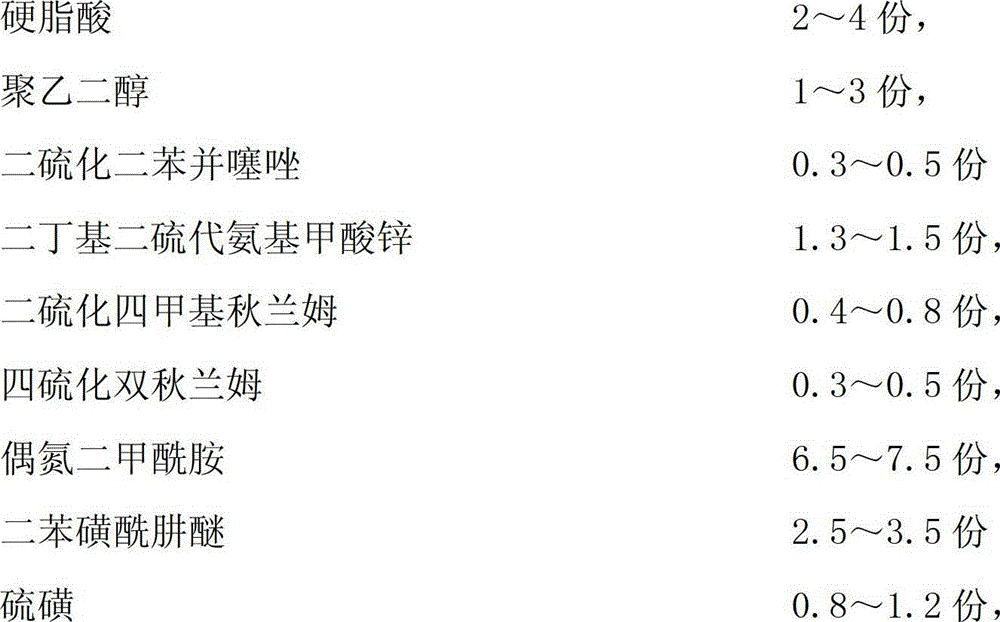

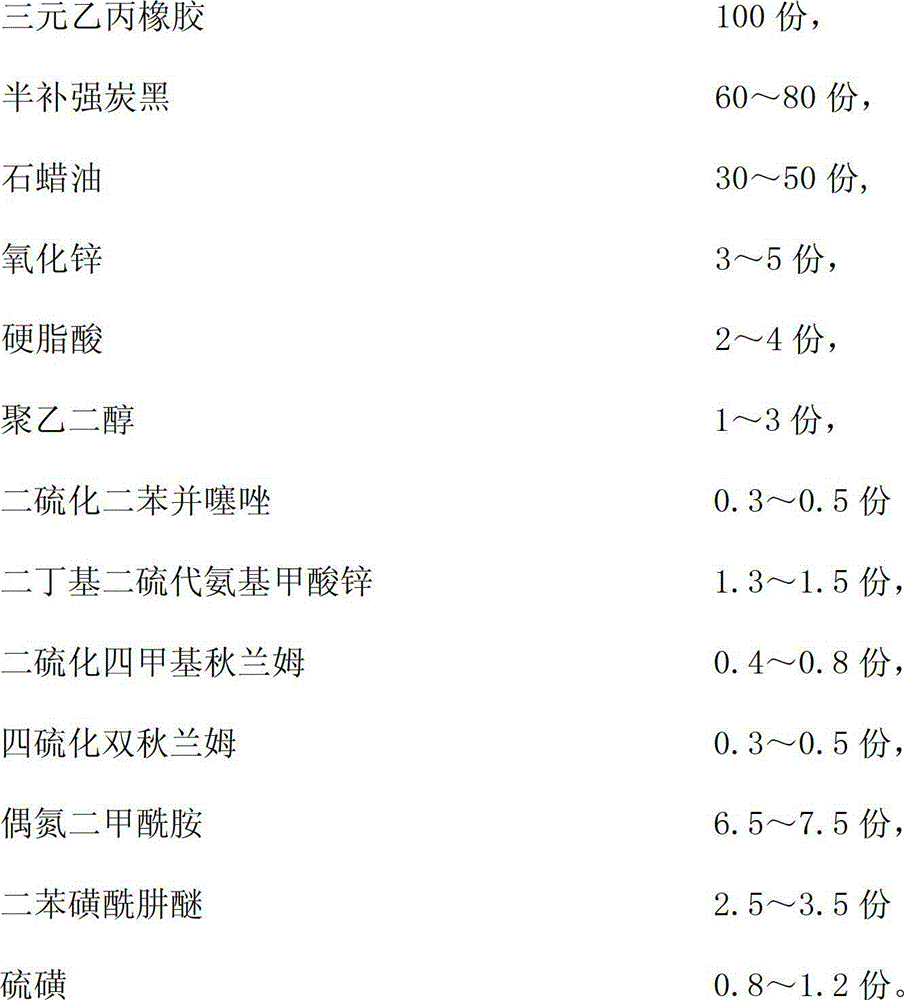

[0022] (blending unit: parts by weight)

[0023] components Example 1 Example 2 Example 3

[0024] dithiuram tetrasulfide 0.3 0.4 0.5

[0025] As can be seen from the foregoing examples, select EPDM rubber, dibenzothiazole disulfide, zinc dibutyl dithiocarbamate, tetramethylthiuram disulfide, dithiuram tetrasulfide, four kinds The combination of vulcanization accelerator, azodicarbonamide and diphenylsulfonylhydrazide ether two foaming agents and other related ingredients can prepare special-shaped sponges with excellent heat aging resistance, low density, stable size, and smooth and delicate surface. jacket.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com