Discharge-induced explosion loading driving device

A technology of driving device and electric explosion, which is applied in the direction of measuring device, impact test, machine/structural component test, etc., can solve the problems such as difficulty in cutting flying pieces of plexiglass barrel, ablation of metal projectiles, etc., to overcome flying pieces The effect of difficult cutting, complete structure and small time drift

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0012] The present invention will be further described below in conjunction with the accompanying drawings and embodiments.

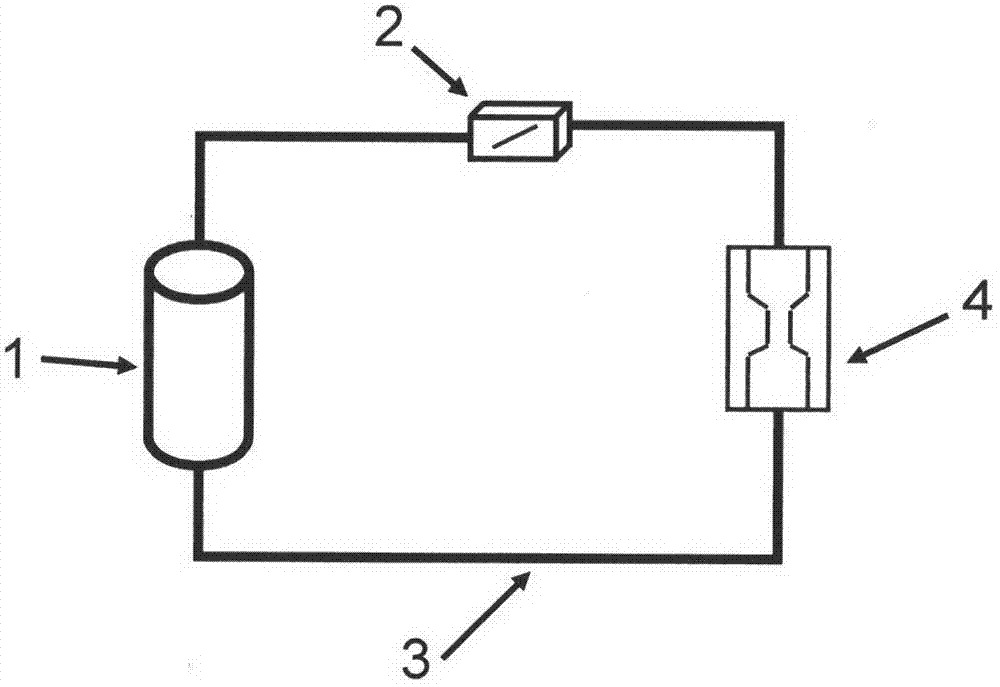

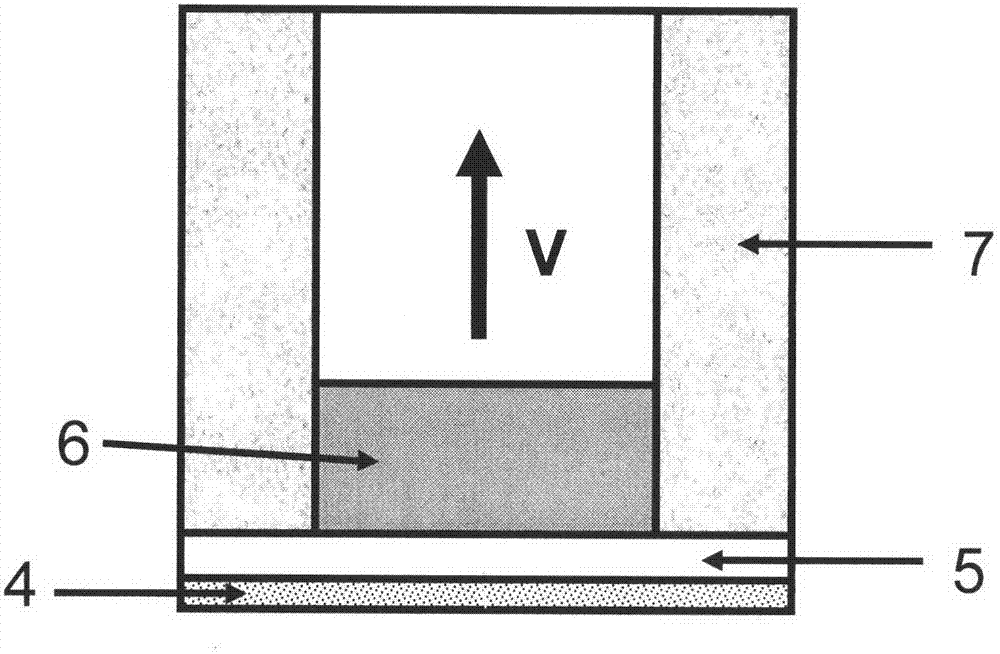

[0013] like figure 1 and figure 2 , an electric explosion loading driving device, comprising a barrel 7, an insulating sheet 5 that is close to the bottom of the barrel 7, a metal bridge foil 4 that is close to the lower surface of the insulating sheet 5, and the two ends of the metal bridge foil 4 are connected with electric transmission lines 3. It is characterized in that: the barrel 7 is equipped with a high-density projectile 6 , and the high-density projectile 6 is bonded to the upper surface of the insulating sheet 5 . in:

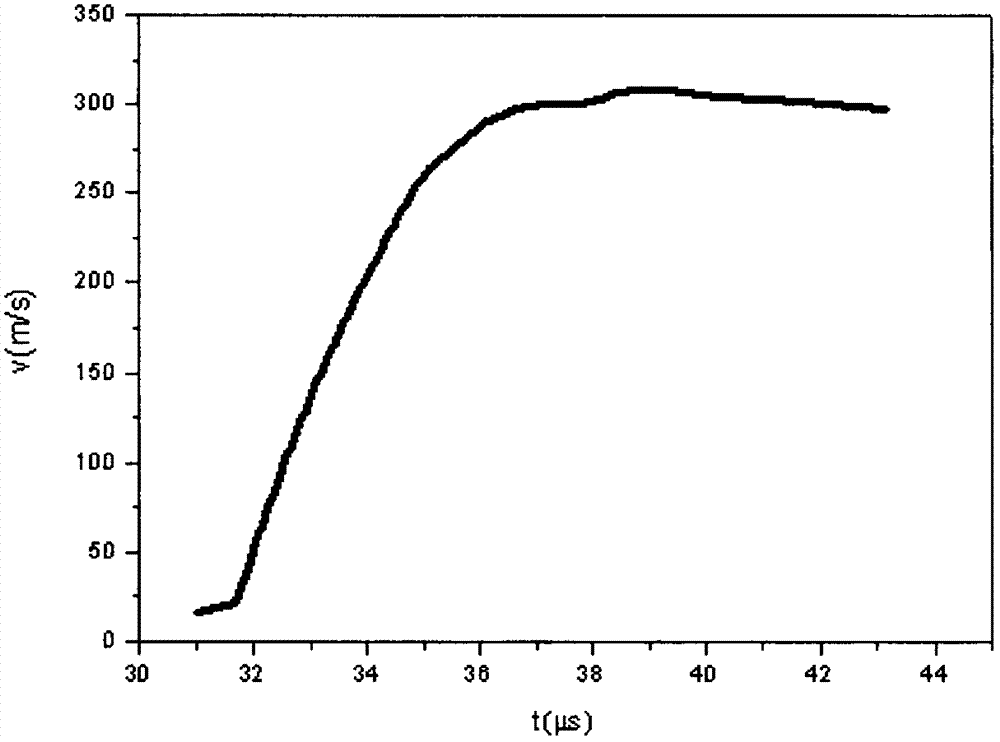

[0014] figure 1 It is the system layout diagram of the present invention. The present invention uses the energy stored in the capacitor 1, which is generally tens of kilojoules, to discharge through a series circuit, and to drive the metal projectile 6 through the electric explosion of the metal bridge foil 4, so as to co...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com