Patents

Literature

33results about How to "Keep it thin" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

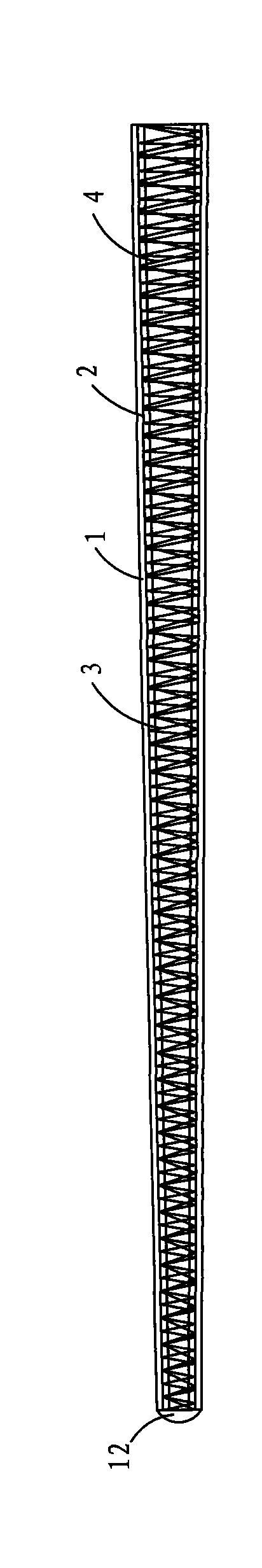

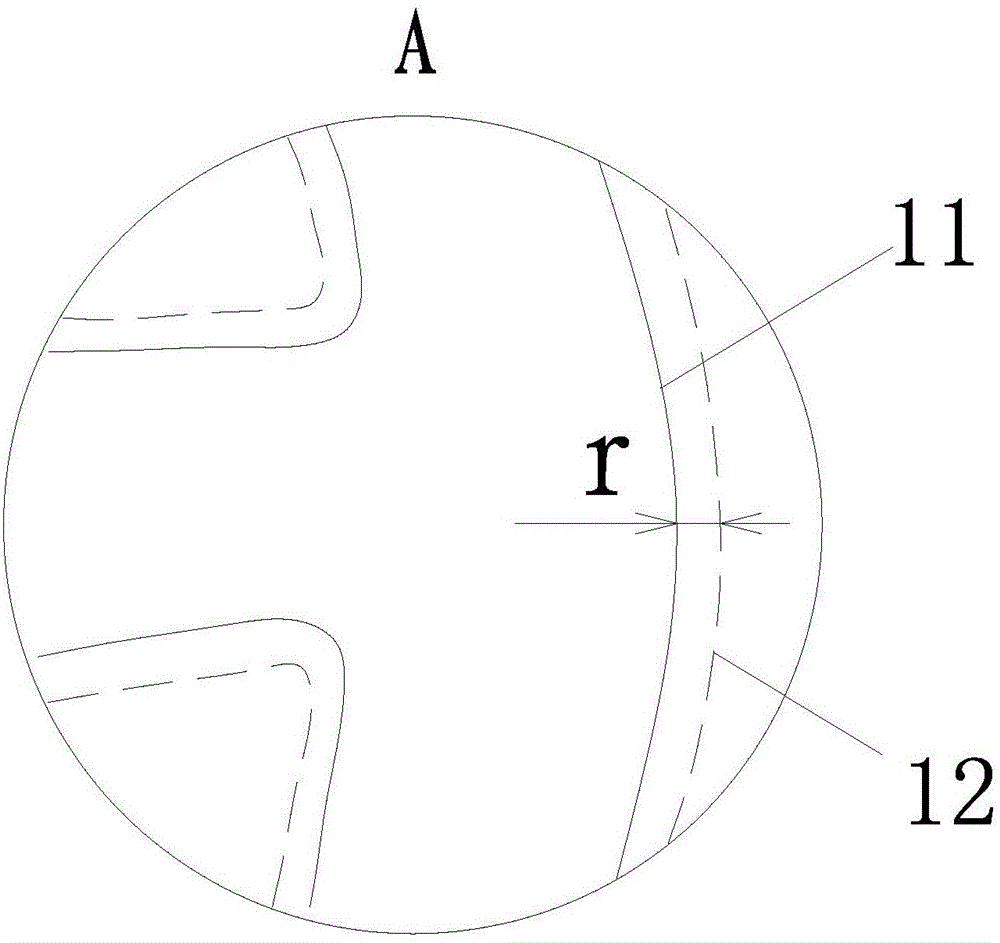

Annular prestressed concrete electric pole and production process thereof

InactiveCN101654963AHigh strengthUniform stressShaping reinforcementsTowersPre stressArchitectural engineering

The invention relates to an overhead line apparatus for power communication transmission, in particular to a concrete electric pole used for erecting a transmission line and a production process thereof. The electric pole comprises a concrete pole body and a steel reinforcement cage buried in the pole body. The concrete pole body is of a cone shape of which the conical degree of the concrete polebody is 1:75. The head of the concrete pole body is provided with an end cover. The steel reinforcement cage is formed by binding a plurality of main reinforcements, internally spiral reinforcements and externally spiral reinforcements which are equal in length. The main reinforcements are uniformly distributed in the annular side wall of the concrete pole body with the central line of the concrete pole body as an axis. The internally spiral reinforcements and externally spiral reinforcements are uniformly wound and distributed on the inner and outer sides of the main reinforcements with the central line of the concrete pole body as an axis as well. A concrete protective layer of the steel reinforcement cage in the concrete pole body is no less than 10mm.

Owner:陈子成

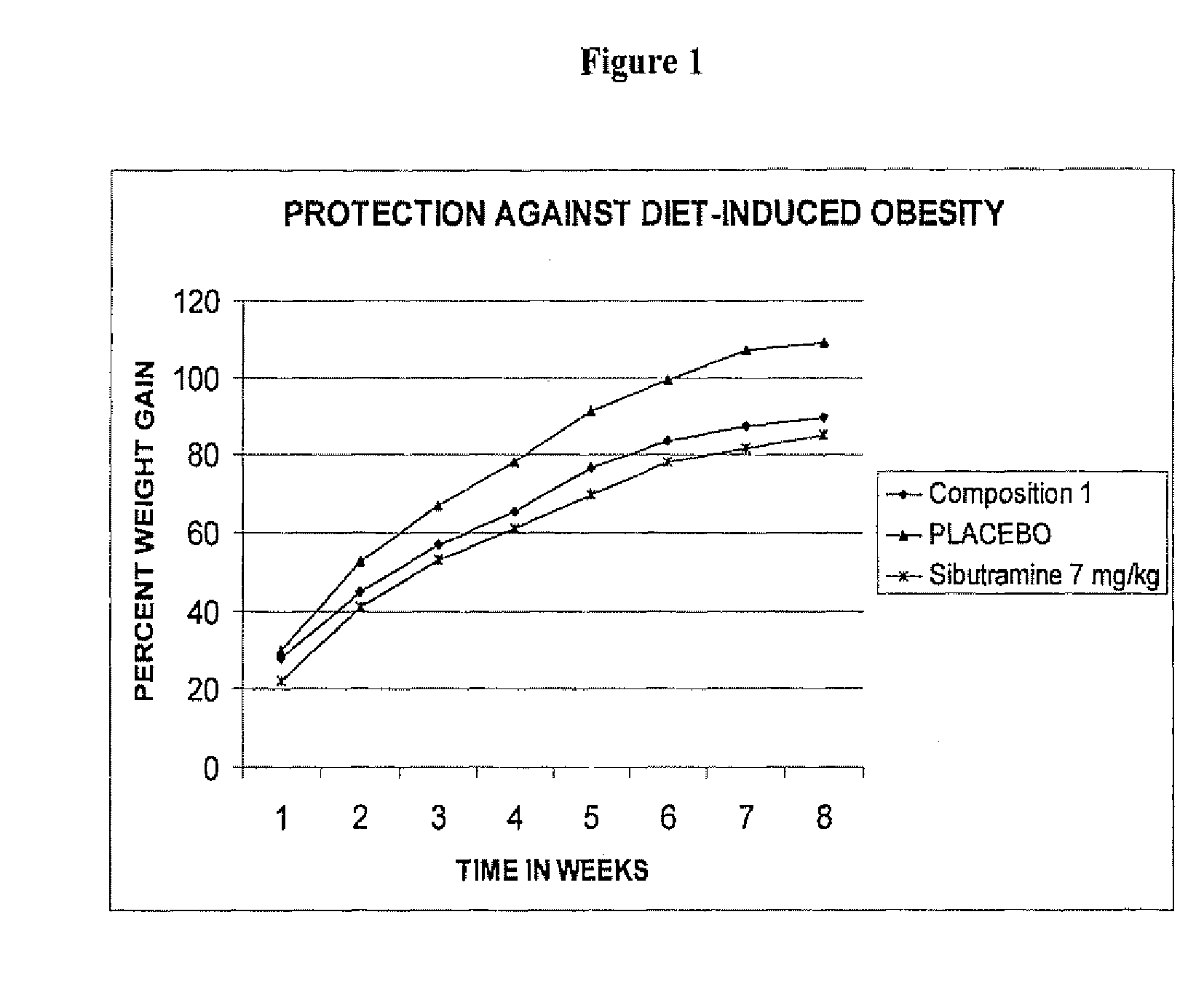

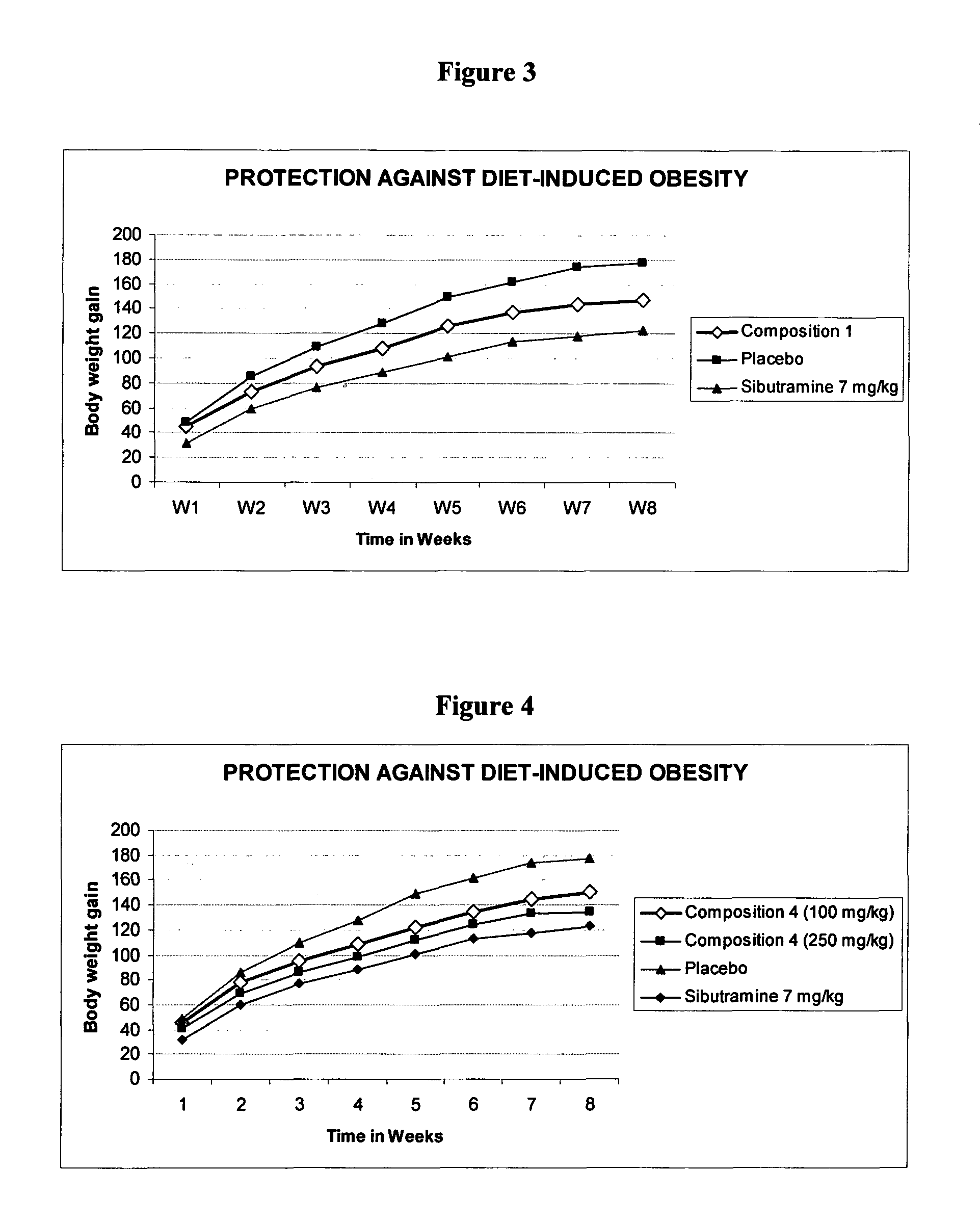

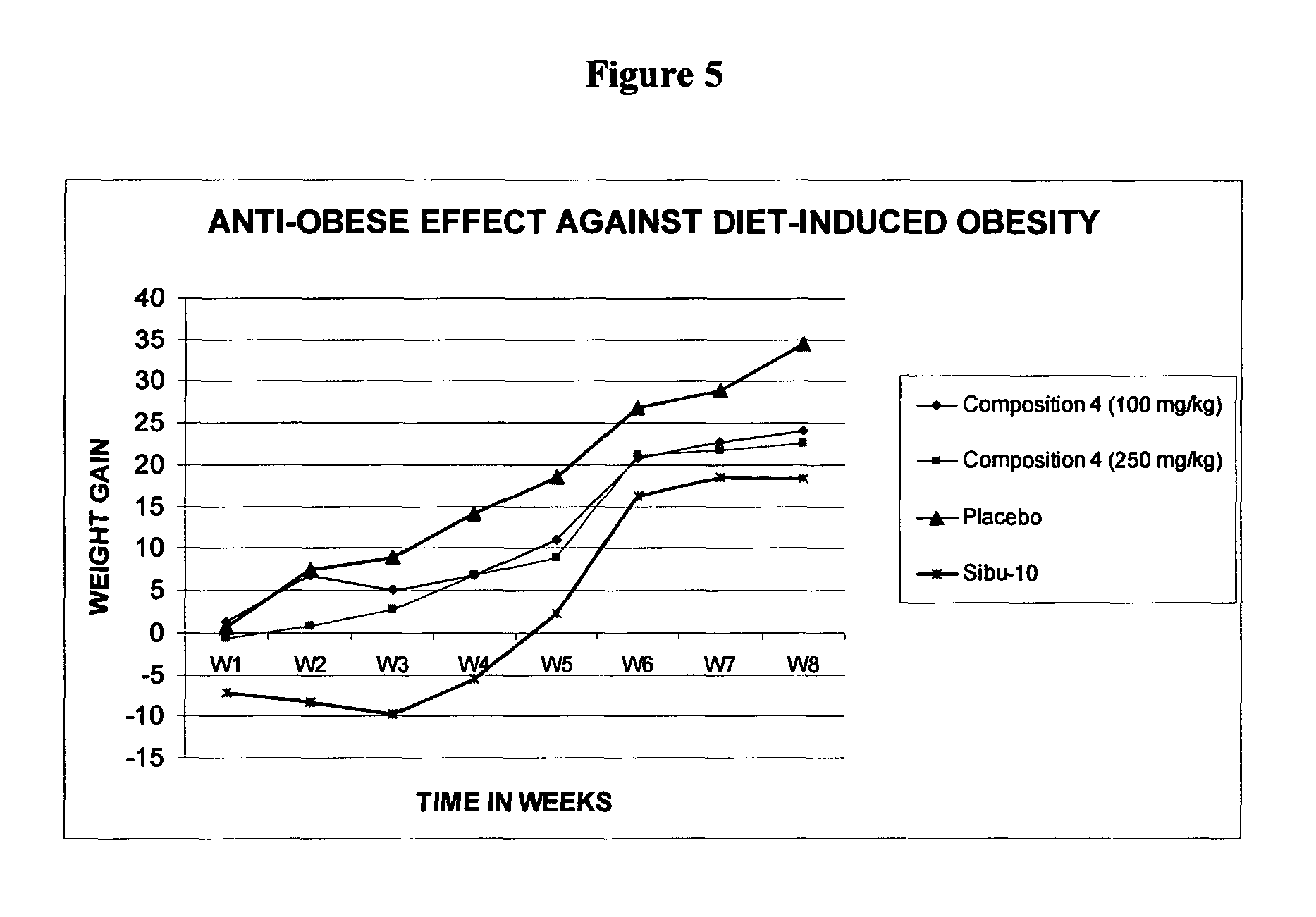

Synergistic phytochemical composition for the treatment of obesity

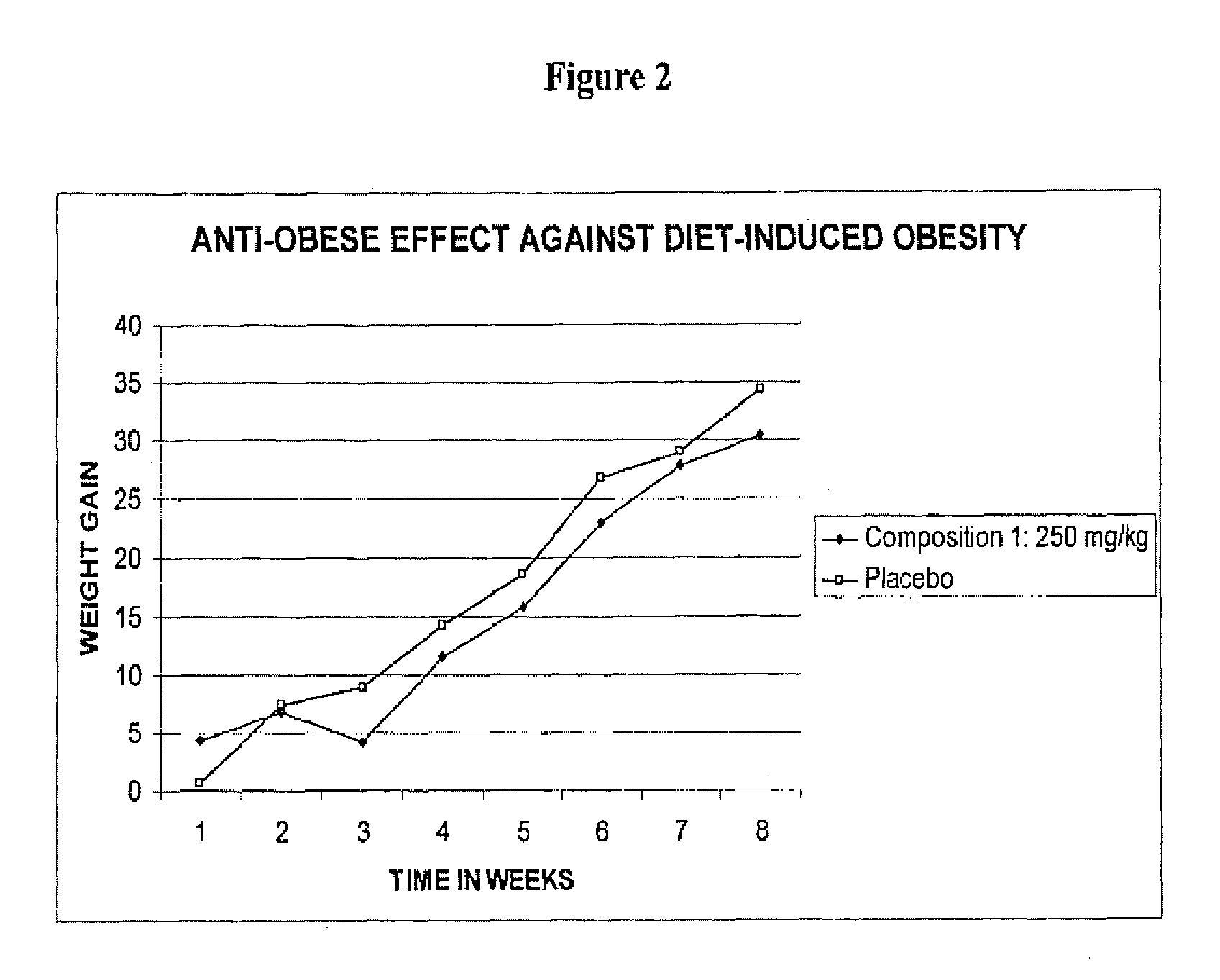

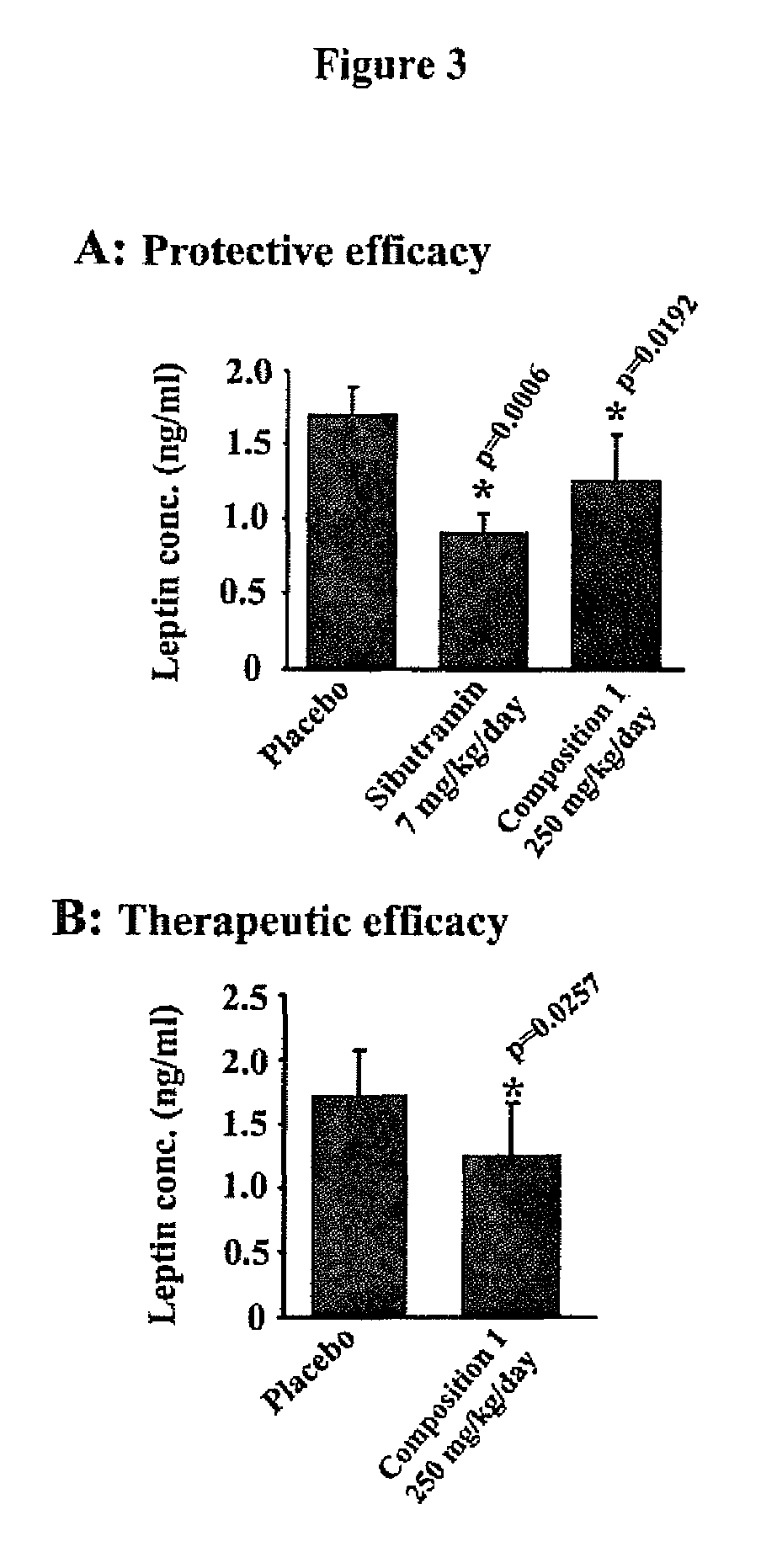

ActiveUS8541383B2Keep it thinPreventing and reducing adipose tissue massBiocideCosmetic preparationsDiseaseMoringa

Owner:LAILA NUTRACEUTICALS

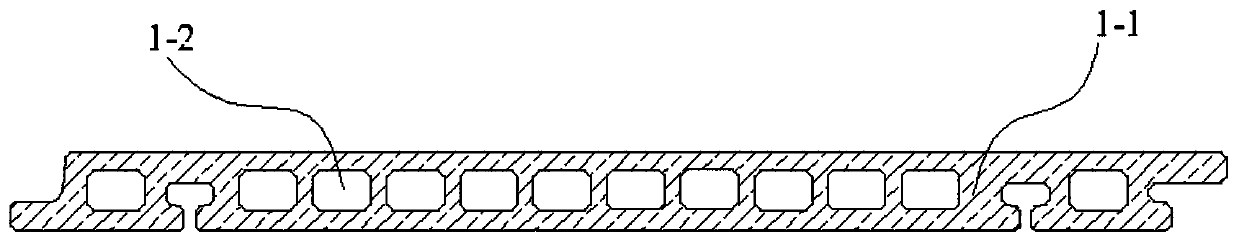

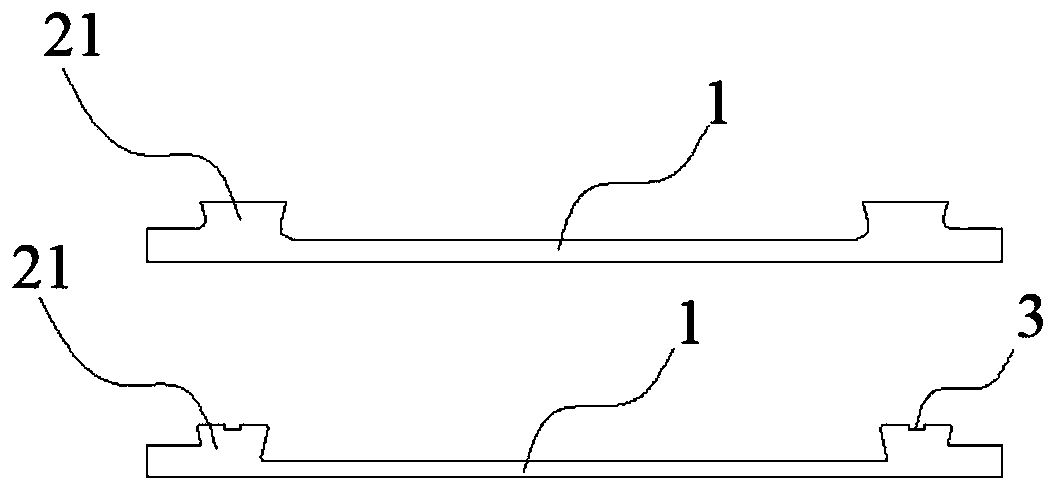

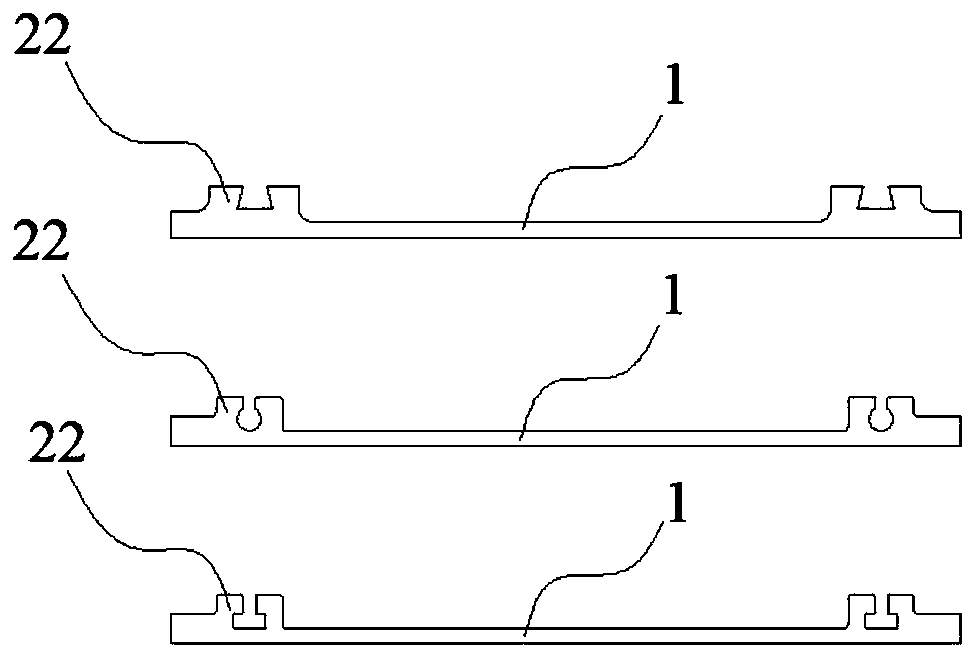

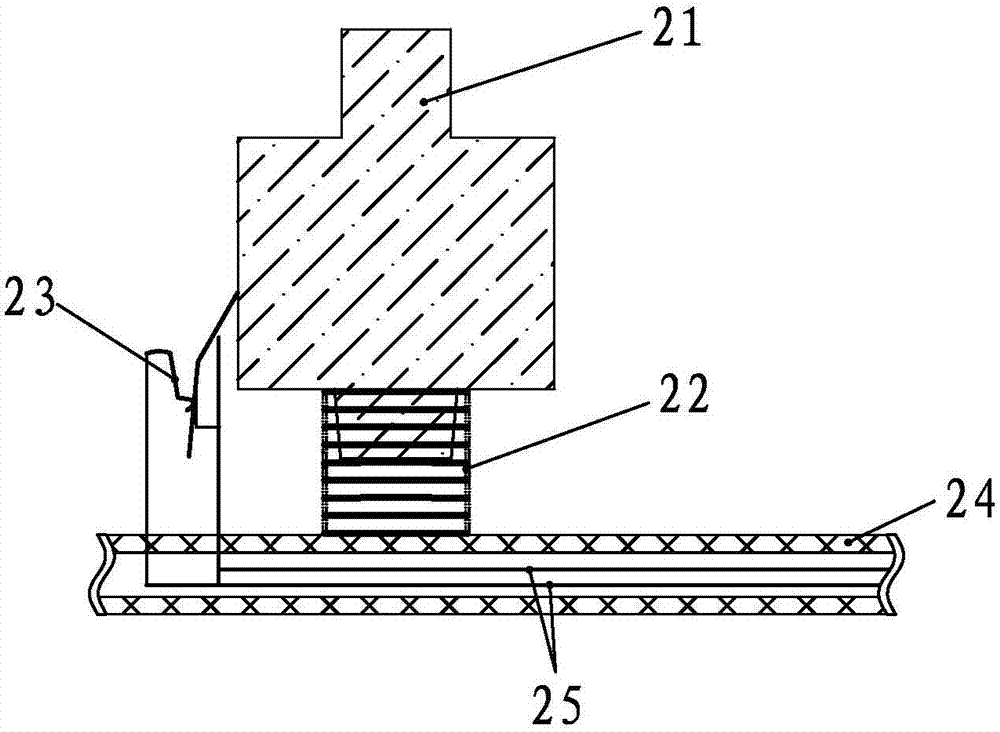

Convex and concave curtain wall plate

The invention provides a convex and concave curtain wall plate which comprises a plate body and a convex clamping block arranged on the surface of the plate body. The plate body and the clamping blockare formed into a whole through the same material. According to the convex and concave curtain wall plate, the convex clamping block structure which is formed on the surface of the plate body and formed integrally serves as a connection part between the plate and a hanging part connection part. The connection part does not occupy the internal space of the plate body and has a thickening functionon the plate body, and therefore the formed connection part has higher mechanical strength. In addition, the clamping block on the surface of the convex and concave curtain wall plate is in surface contact with the hanging part connection part, the contact area is large, thus, the hanging part connection part can provide enough bearing capacity for the plate, and the plate can be hung firmly and reliably.

Owner:罗忆

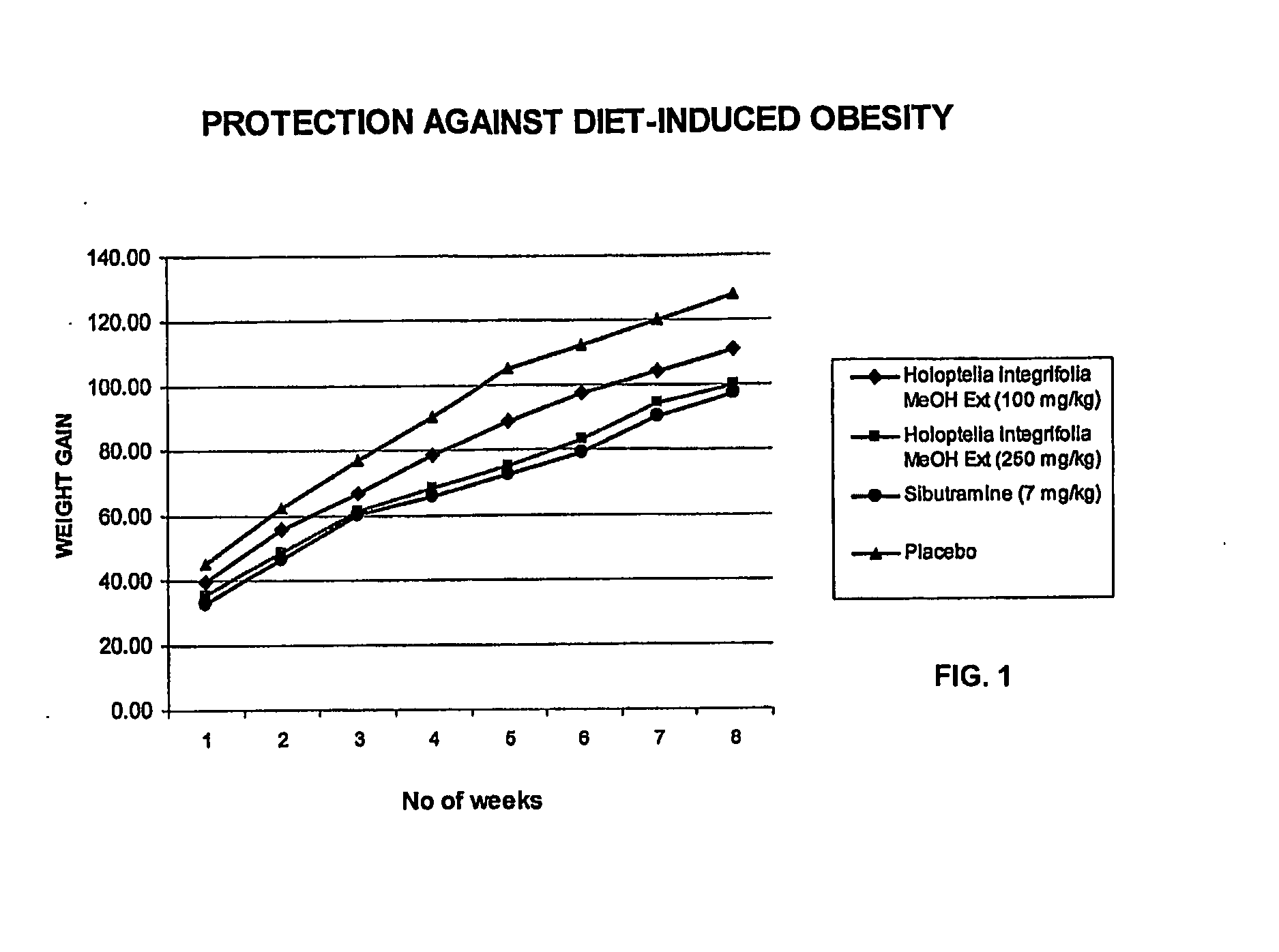

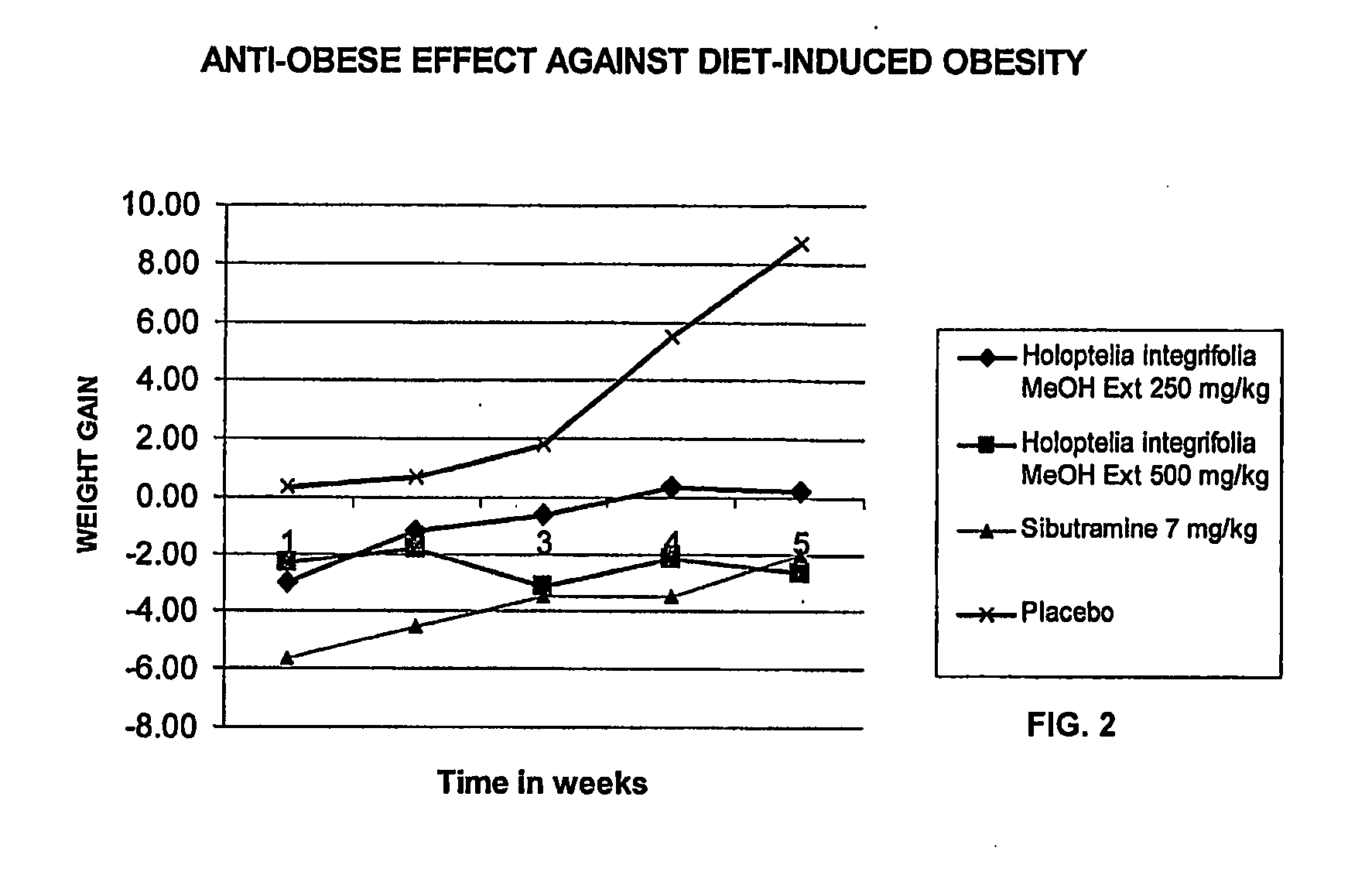

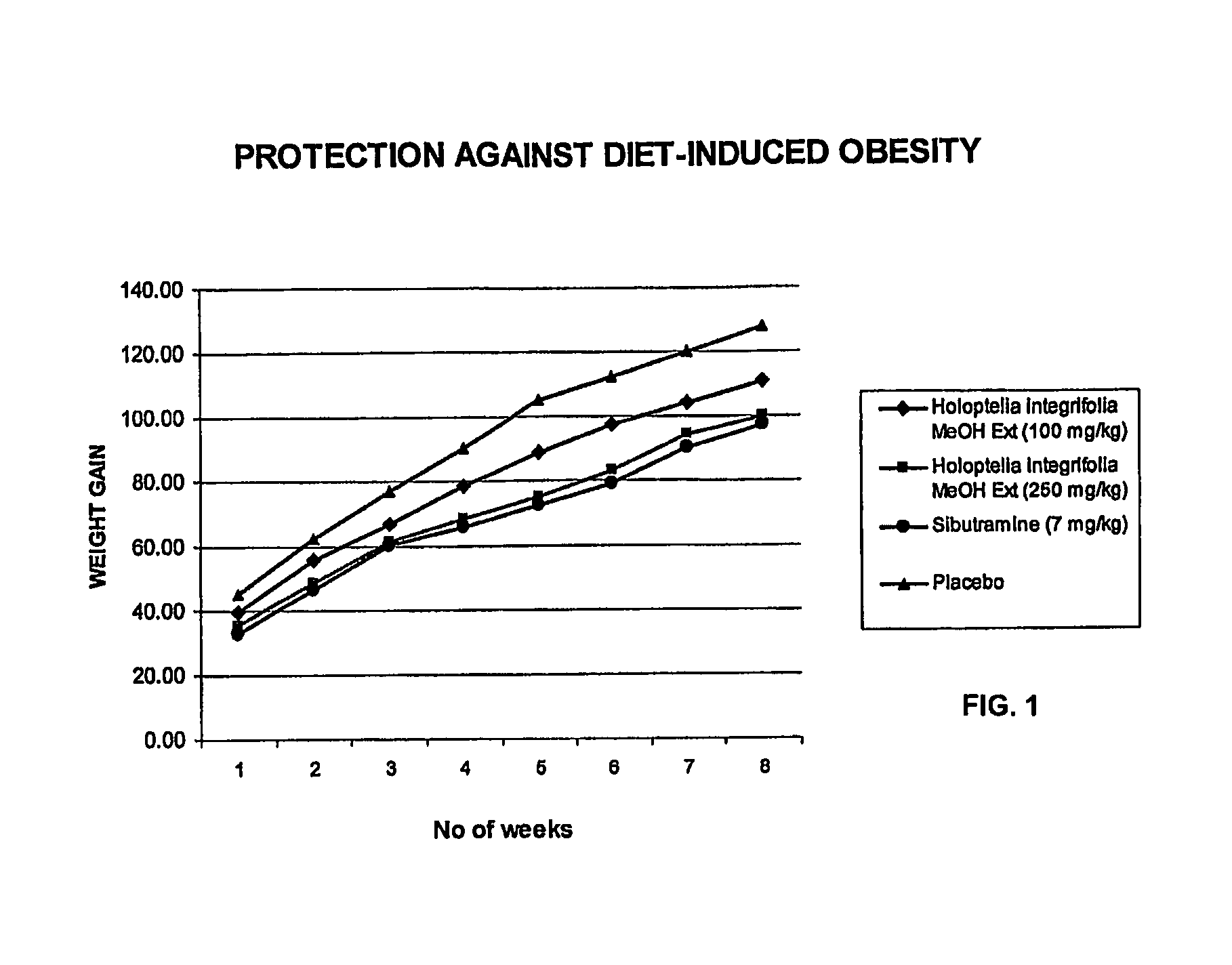

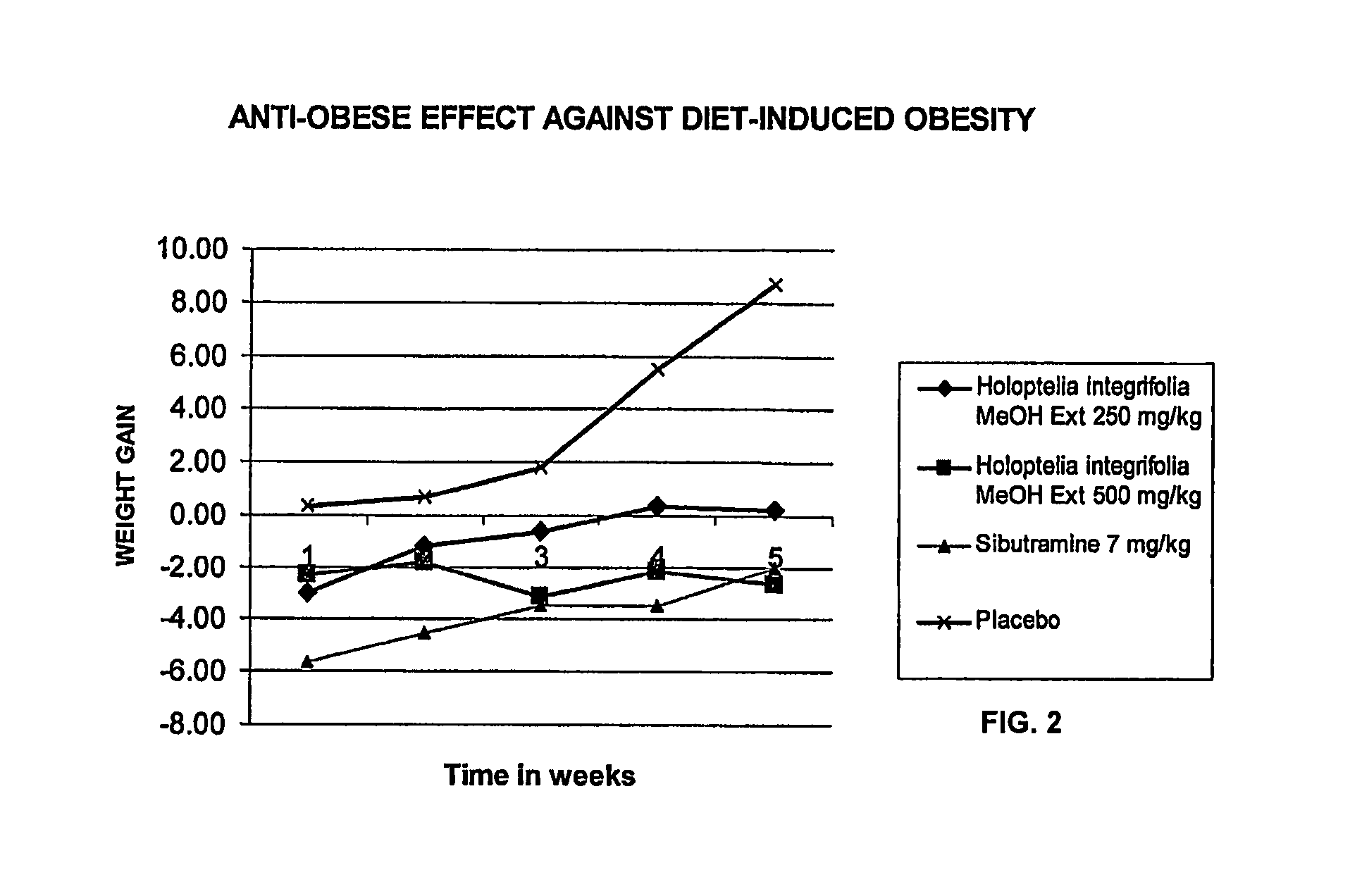

Anti-obese compositions containing holoptelea integrifolia extracts

ActiveUS20100203078A1Lower Level RequirementsReduce weightOrganic active ingredientsBiocideDiseaseIncreased Lipolysis

The present invention discloses the extracts of Holoptelea integrifolia or the purified fractions isolated there from and the dietary, nutraceutical and pharmaceutical compositions comprising the same or optionally in combination with one or more known anti-obesic agents useful for the purpose of inhibition, amelioration or prevention of adipogenesis and lipolysis involved diseases. The invention further discloses a method for treating or preventing obesity and adipogenesis and lipolysis involved diseases using the compositions containing the extracts of purified fractions of Holoptelea integrifolia.

Owner:LAILA NUTRACEUTICALS

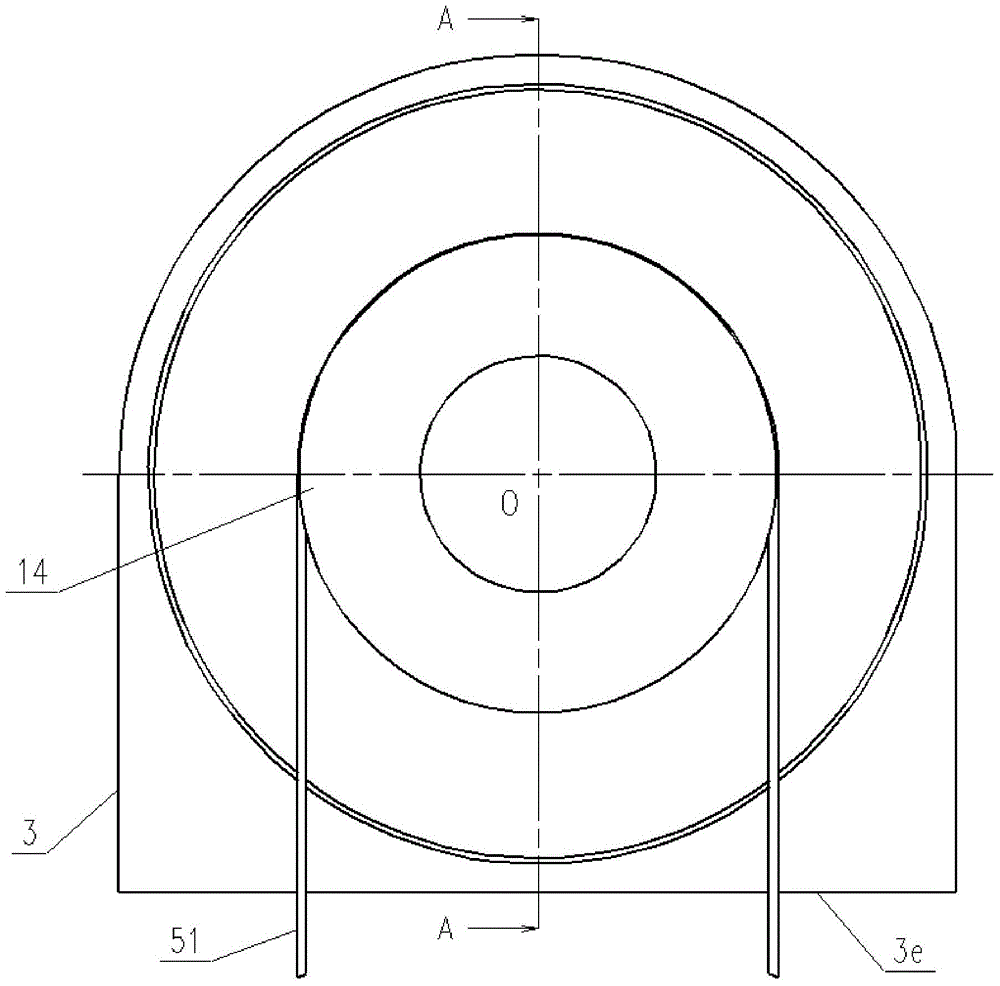

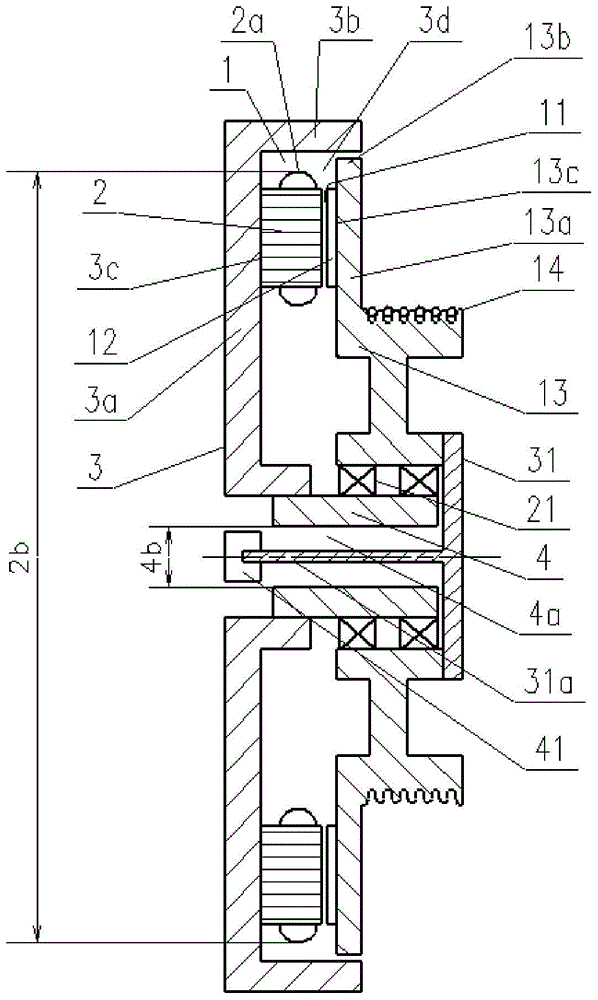

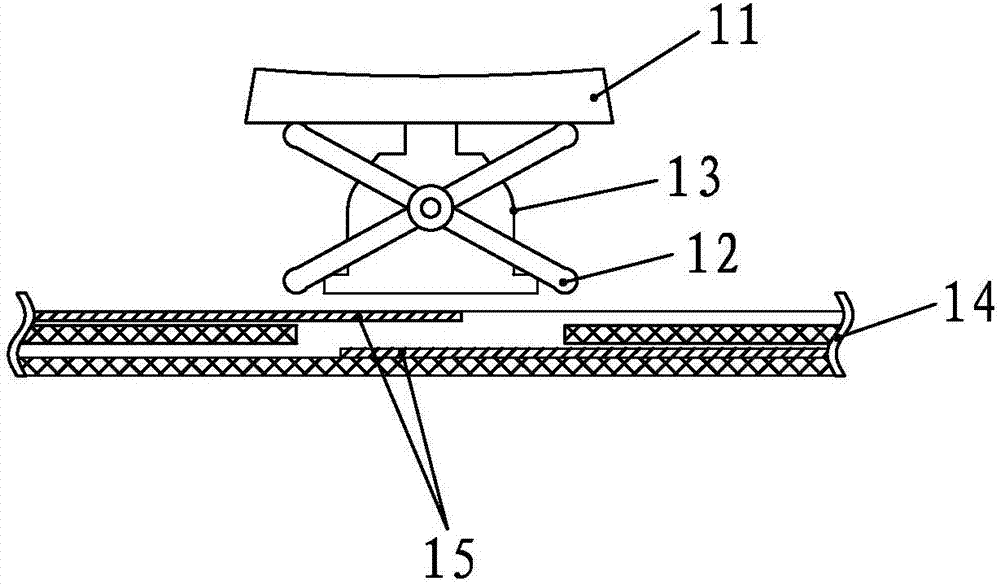

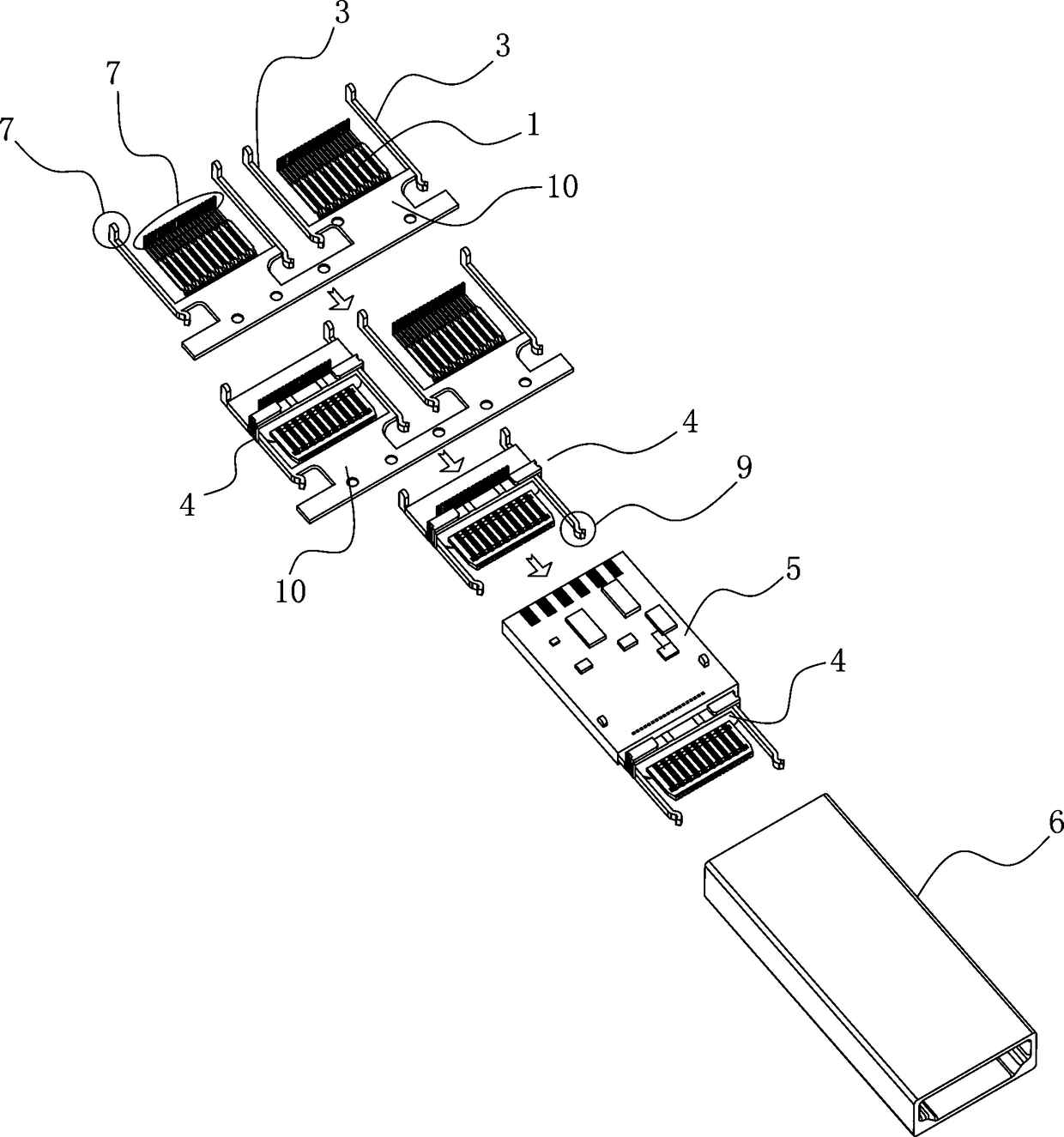

Tractor for elevator

InactiveCN105270969AKeep it thinStrengthen the mechanical connectionBuilding liftsEngineeringTractor

The present invention discloses a tractor for an elevator. The tractor comprises a motor, a fixed machine base, a fixed main shaft, a rotor case, a rope wheel for driving ropes of the elevator, a bearing, a rotating body and an encoder, wherein a stator installation part is disposed at a hollow disc-type extension part of the fixed machine base, a rotor installation part is disposed at a hollow disc-type extension part of the rotor case and is opposed to the stator installation part, the diameter of a hollow part of the fixed main shaft is larger than that of a rotating shaft part of the rotating body, the rotating body rotates along with the rotor case, and the encoder is disposed at the rotating shaft part of the rotating body. A novel structure is provided for the elevator tractor using a disc-type electric motor, the tractor is fully utilized to fix space of the hollow part of a main shaft, arrangement and operation of the encoder become convenient, overall thinness of the tractor is maintained, and the tractor is suitable for elevators, with small machine rooms or without machine rooms, requiring thinness of the tractor.

Owner:SHANGHAI MITSUBISHI ELEVATOR CO LTD

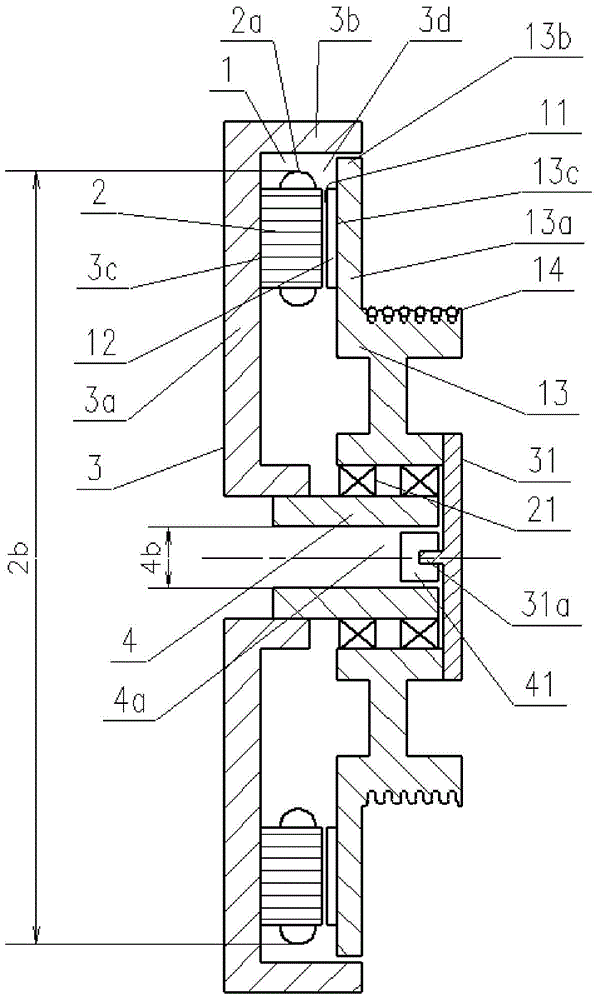

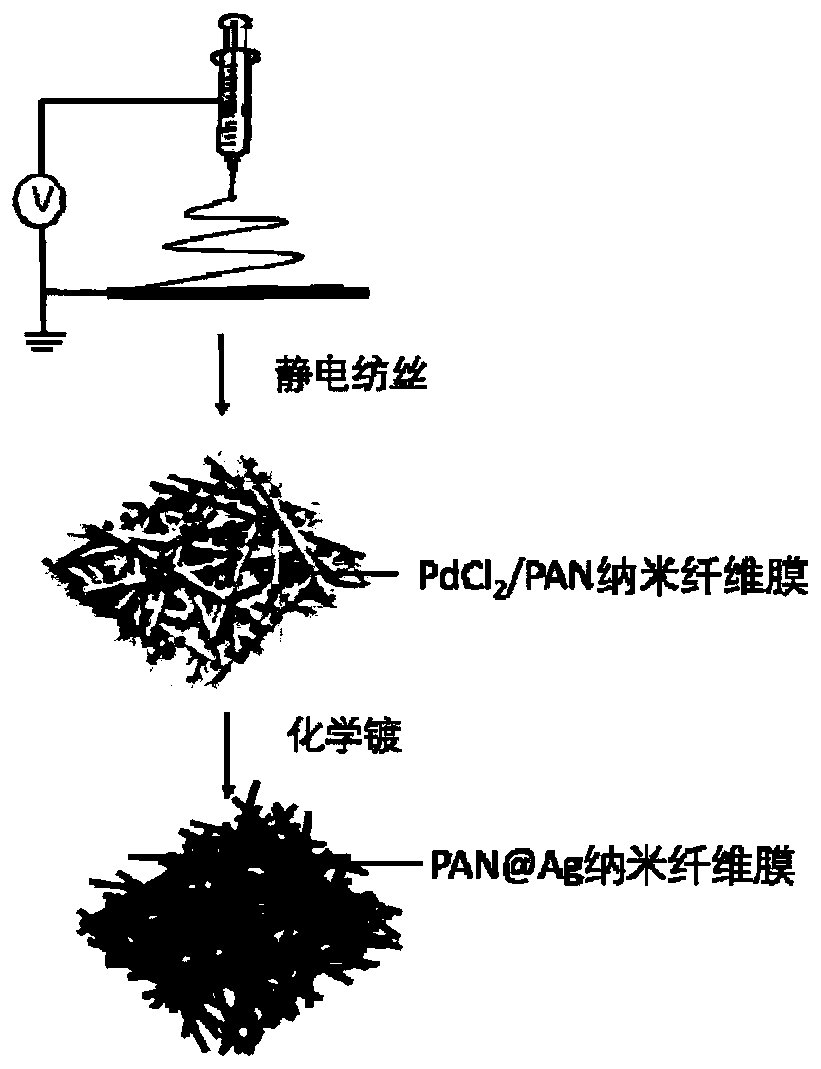

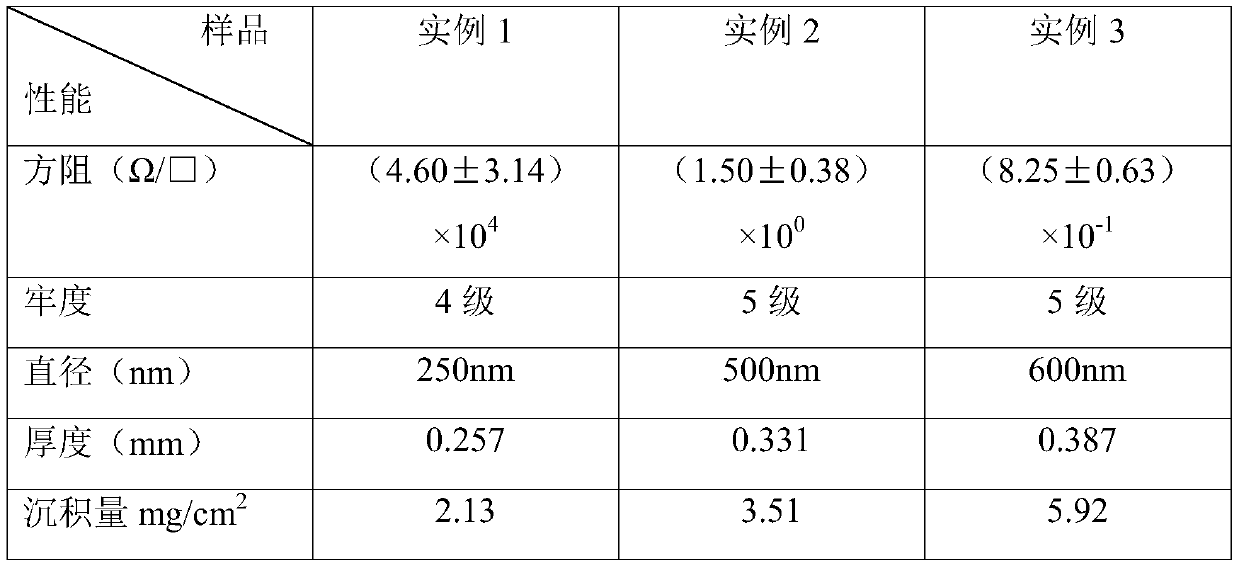

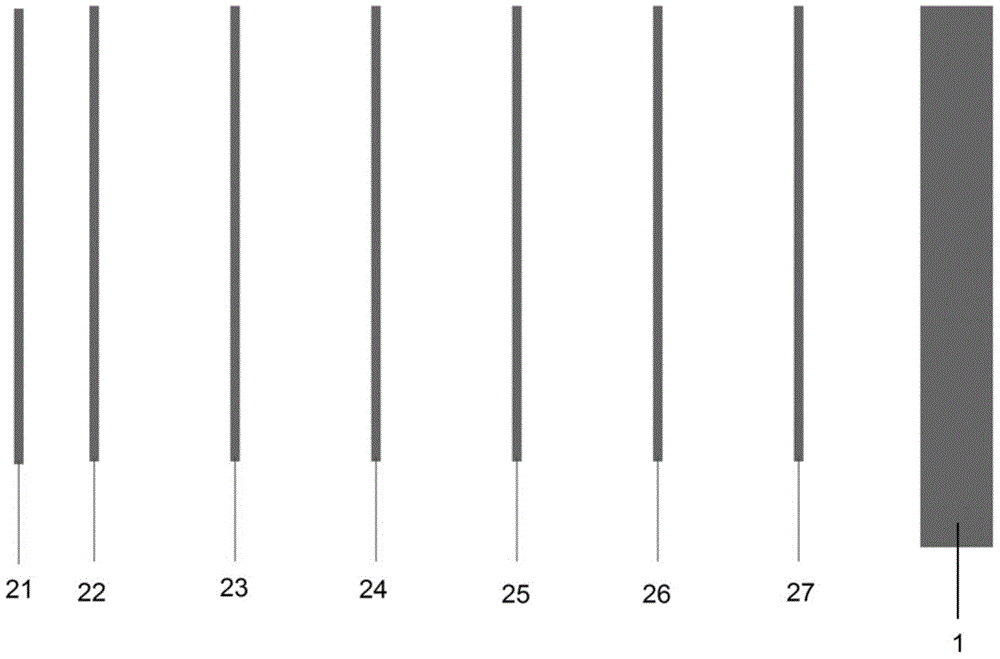

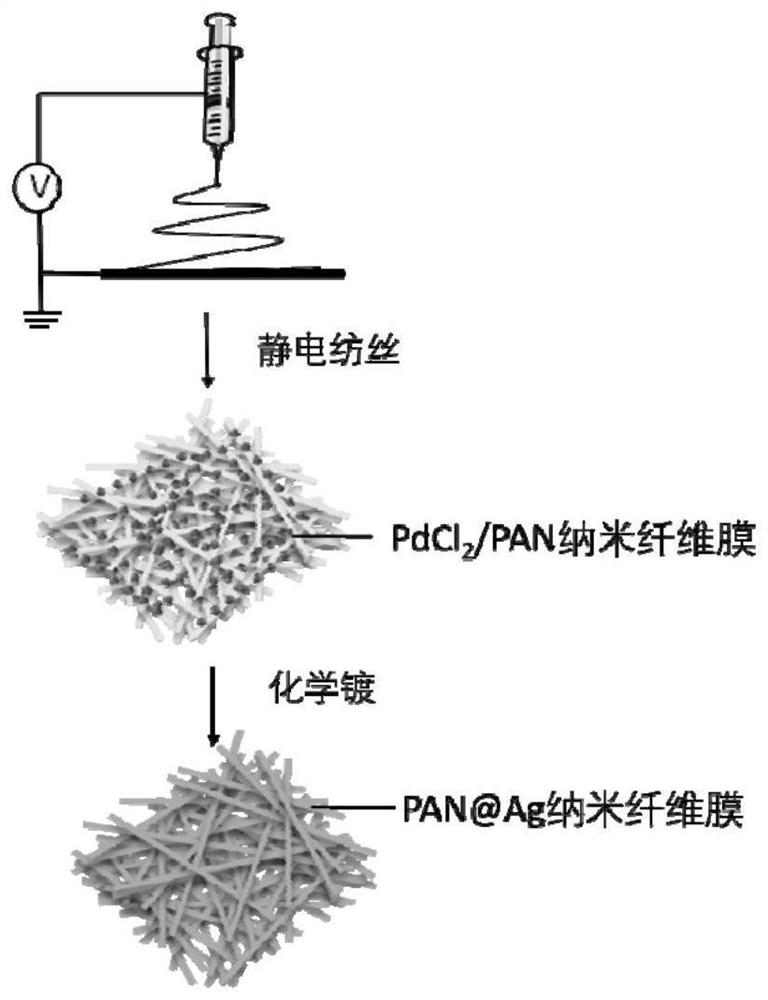

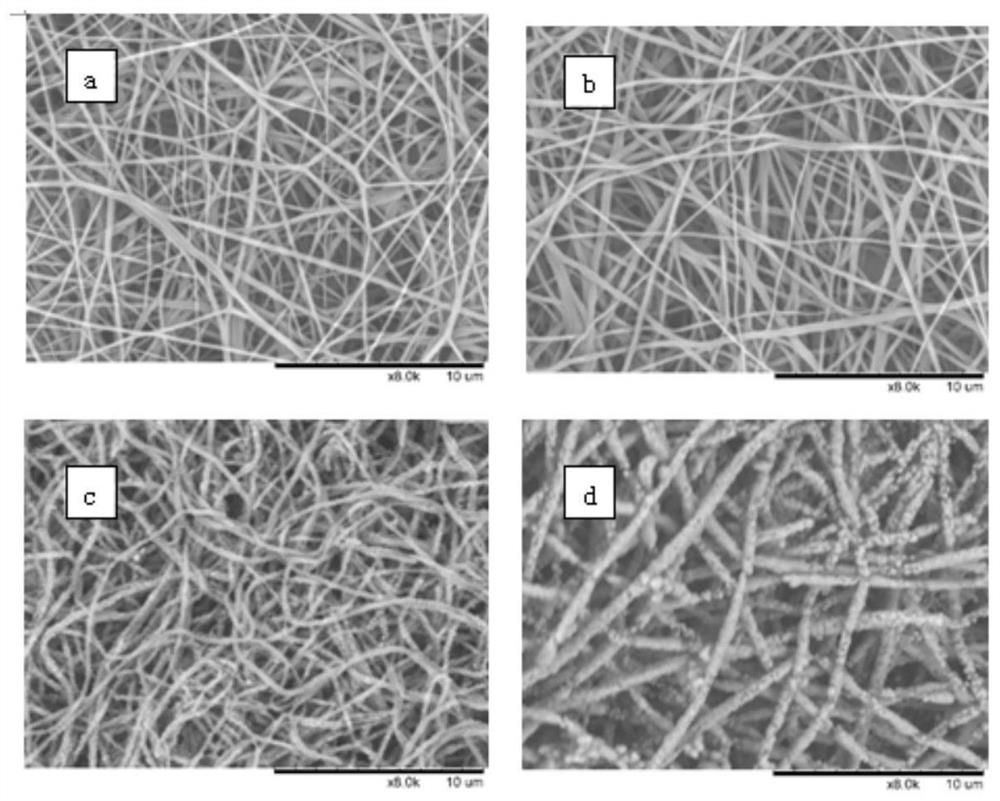

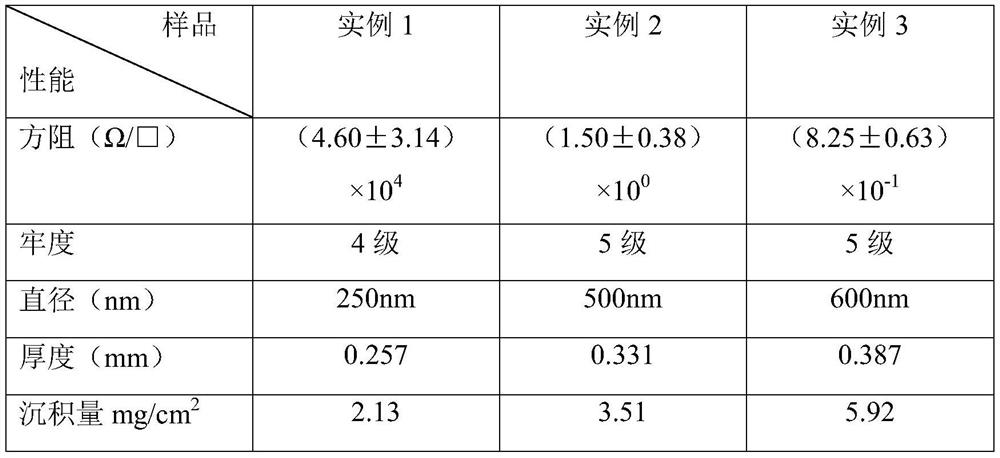

Conductive nanofiber membrane and preparation method thereof

ActiveCN110894677AKeep it thinRetain flexibilityFibre typesElectro-spinningPolymer scienceAcrylonitrile

The invention relates to a conductive nanofiber membrane and a preparation method thereof. The fiber membrane is obtained by performing chemical silver plating by taking a palladium-containing polyacrylonitrile PAN nanofiber membrane as a carrier. According to the preparation method, the conductivity of the nanofiber membrane and the morphology of the nanofiber membrane can be changed by adjustingprocess parameters. The preparation method is novel, simple in process, flexible in adjustment and high in repetition rate; and the membrane is convenient to process, high in flexibility and light and thin and is particularly suitable for application in the field of intelligent textiles.

Owner:DONGHUA UNIV

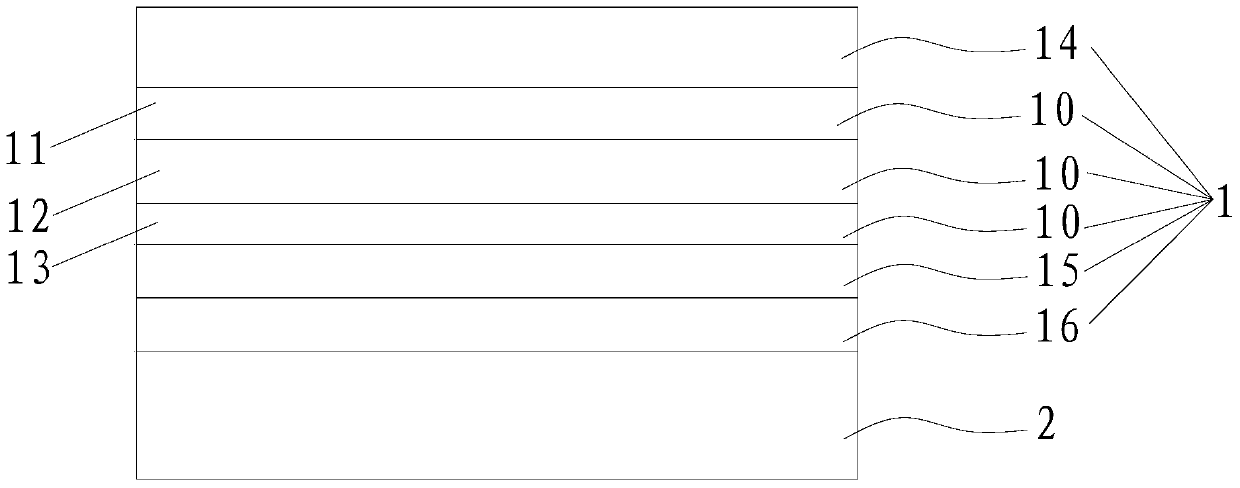

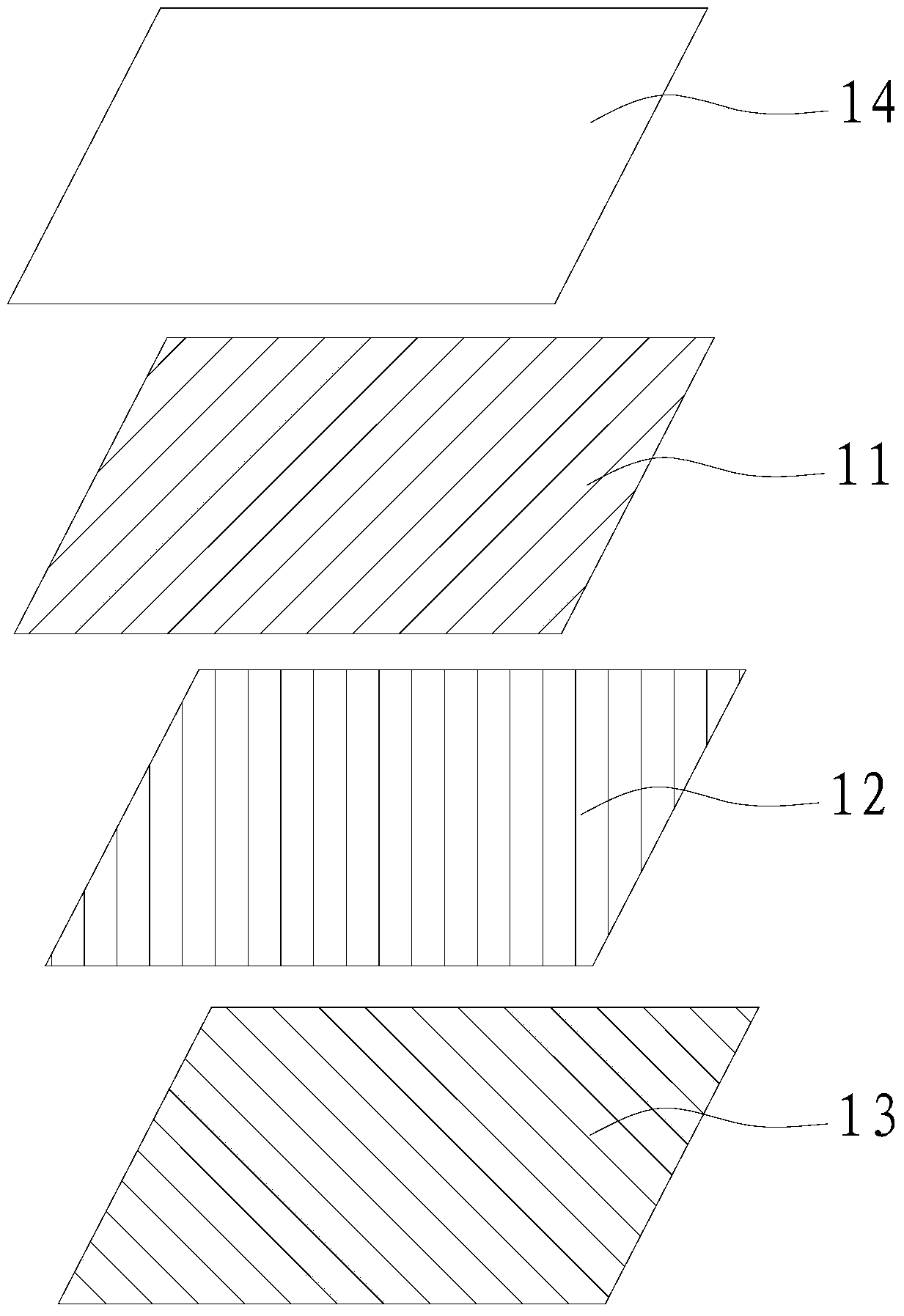

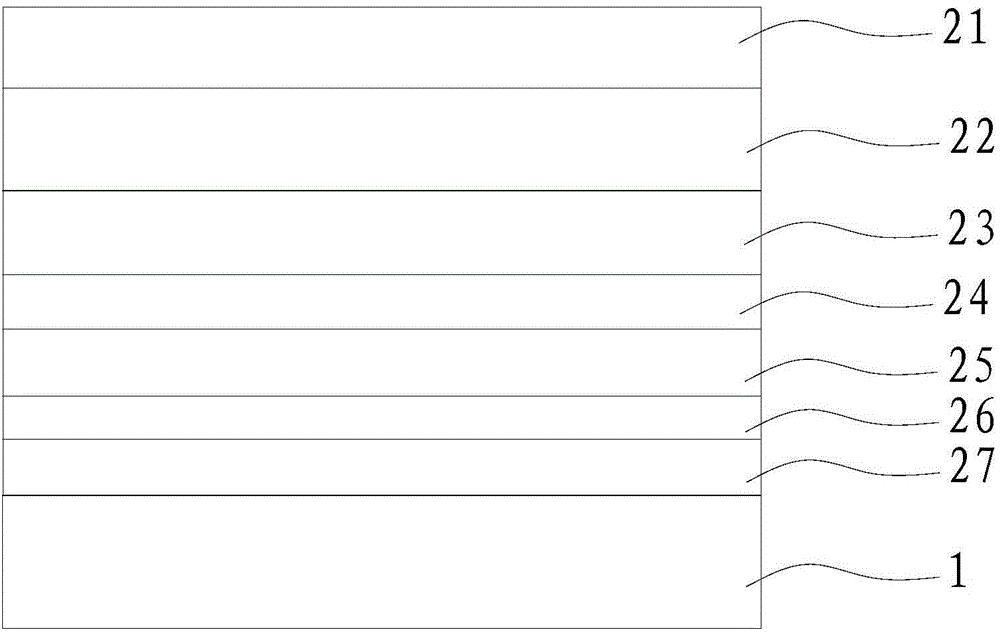

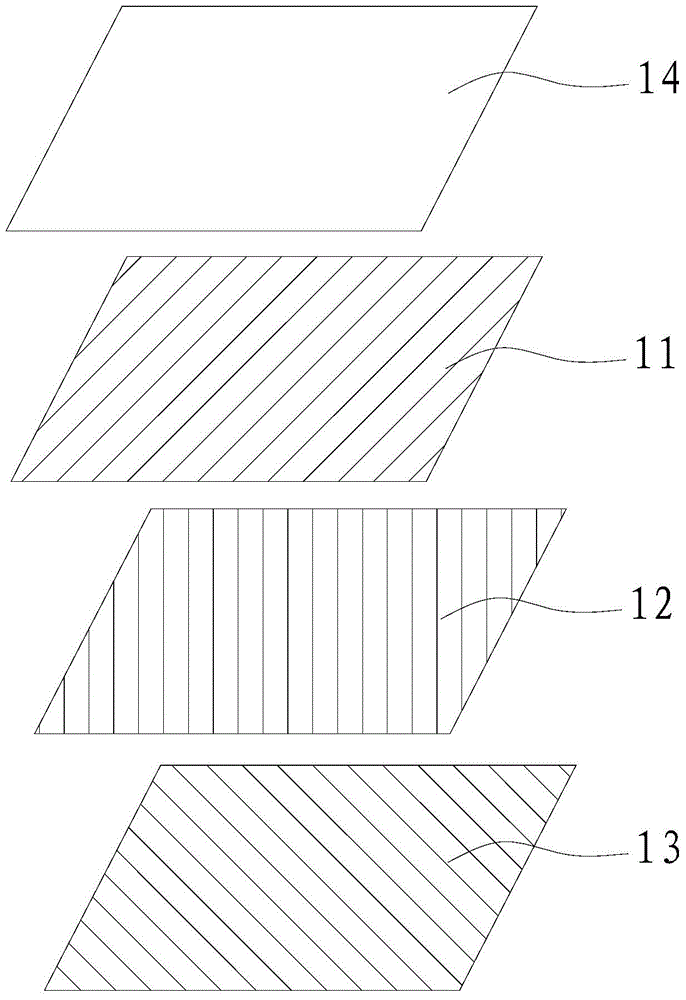

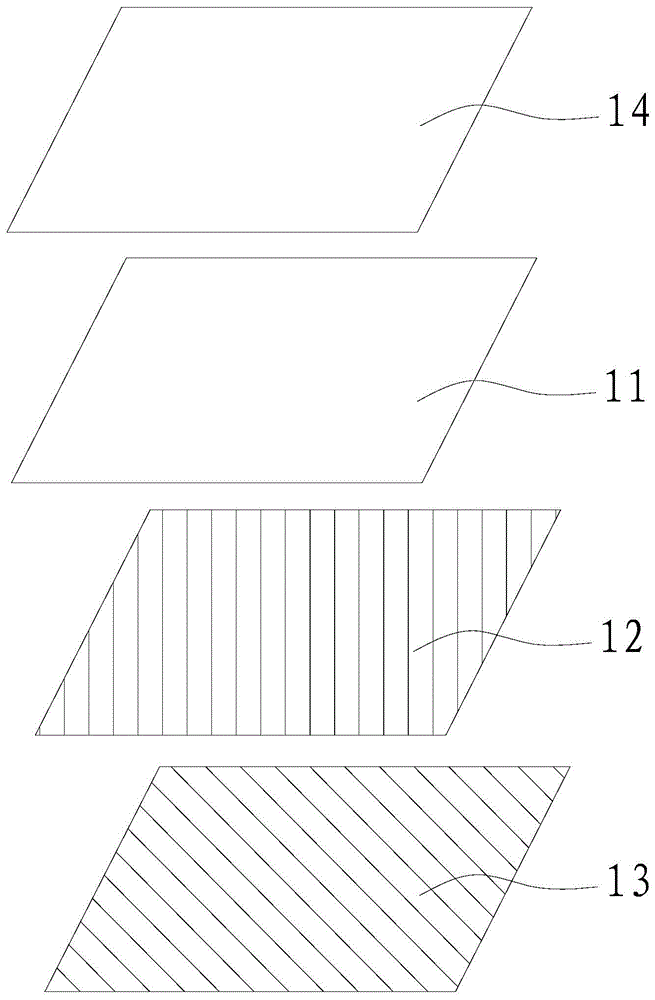

One glass solution (OGS) capacitive touch screen and manufacturing method thereof

InactiveCN103257774AKeep it thinDiversified inputInput/output processes for data processingProduction lineCapacitance

The invention discloses a one glass solution (OGS) capacitive touch screen which comprises a PET protective film, optical cement, an ITO functional piece and a soft circuit board, wherein the PET protective film, the optical cement and the ITO functional piece are arranged in an up-down overlapping mode, and the soft circuit board is attached to the upper surface or the lower surface of the ITO functional piece. The invention further discloses a manufacturing method of the OGS capacitive touch screen. The manufacturing method of the OGS capacitive touch screen includes the following steps: 1, preparing the PET protective film, and preparing the soft circuit board; 2, converting a functional pattern into a laser path; 3, leading the laser path into a laser device; 4, etching a large-piece ITO plate by using the laser device; 5, dividing the large-piece ITO plate and forming the single ITO functional piece in a splicing and combined mode; 6, connecting the soft circuit board to the ITO functional piece, and carrying out electrical logging on functions; 7, splicing the ITO functional piece and the PET protective film; 8, carrying out the electrical logging on finished products. The OGS capacitive touch screen and the manufacturing method of the OGS capacitive touch screen are rich in color, capable of preparing soft touch screens, simplified in production procedure, less in investment of production lines and environment-friendly in production, and products have higher competitiveness.

Owner:LEAD COMM

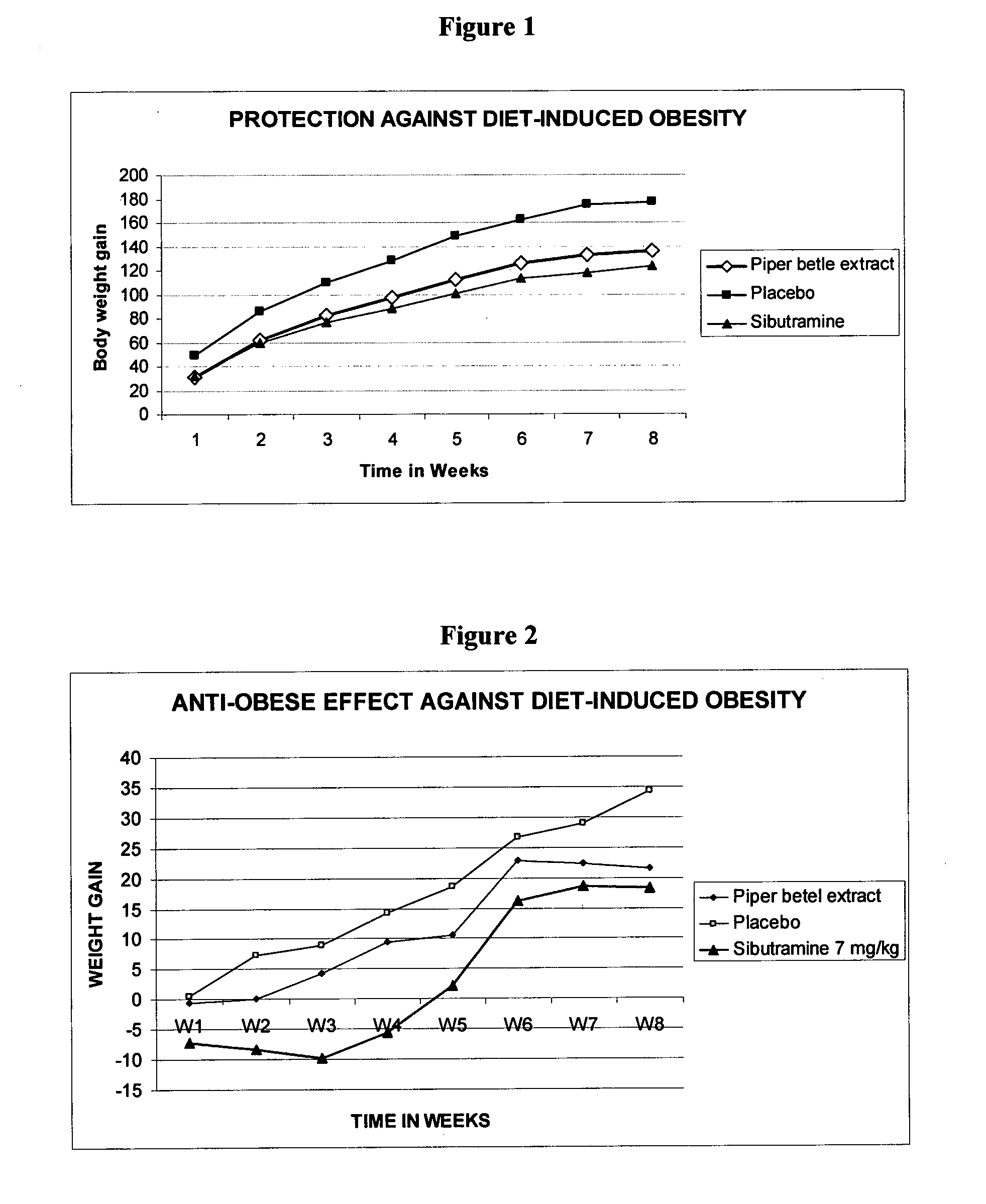

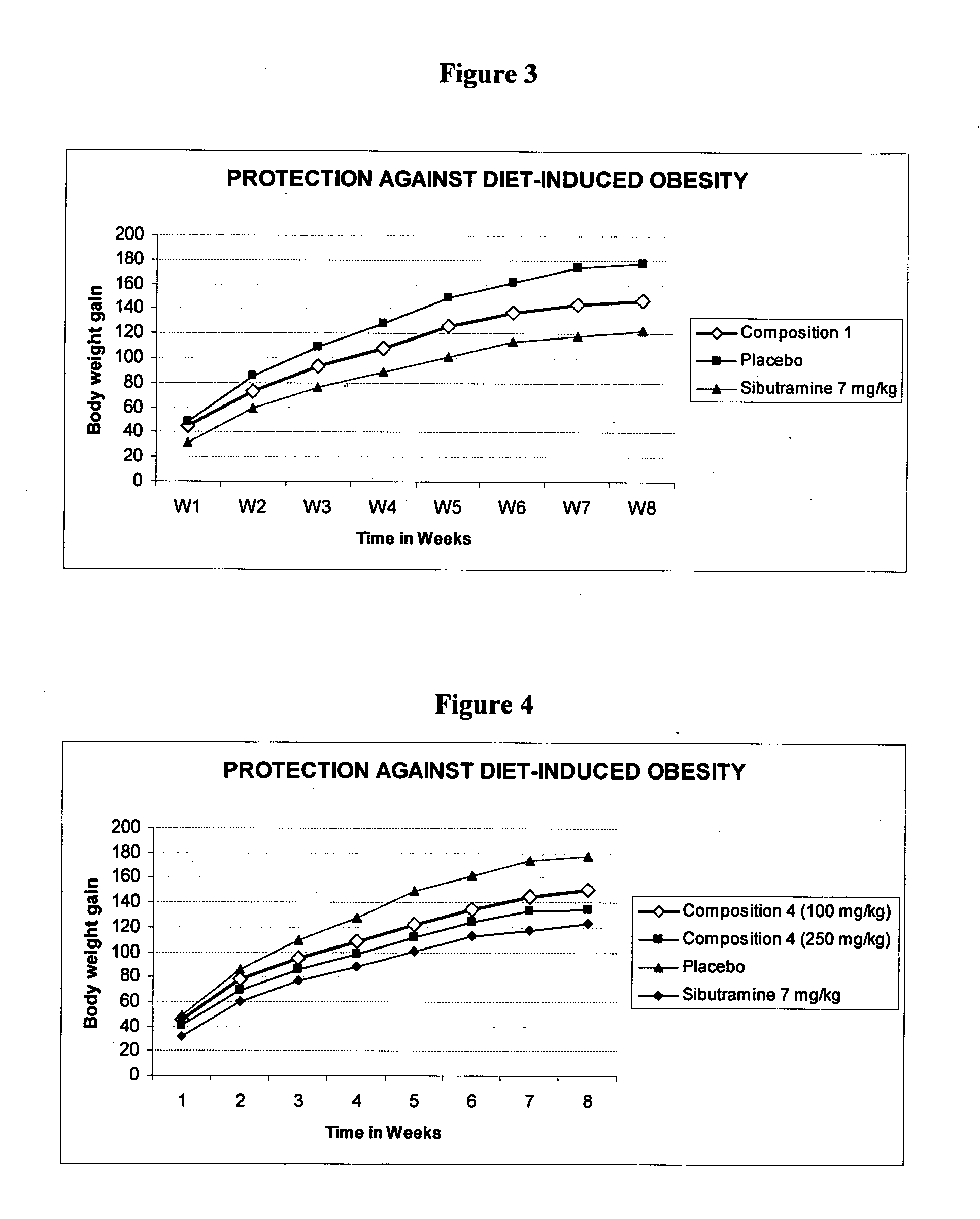

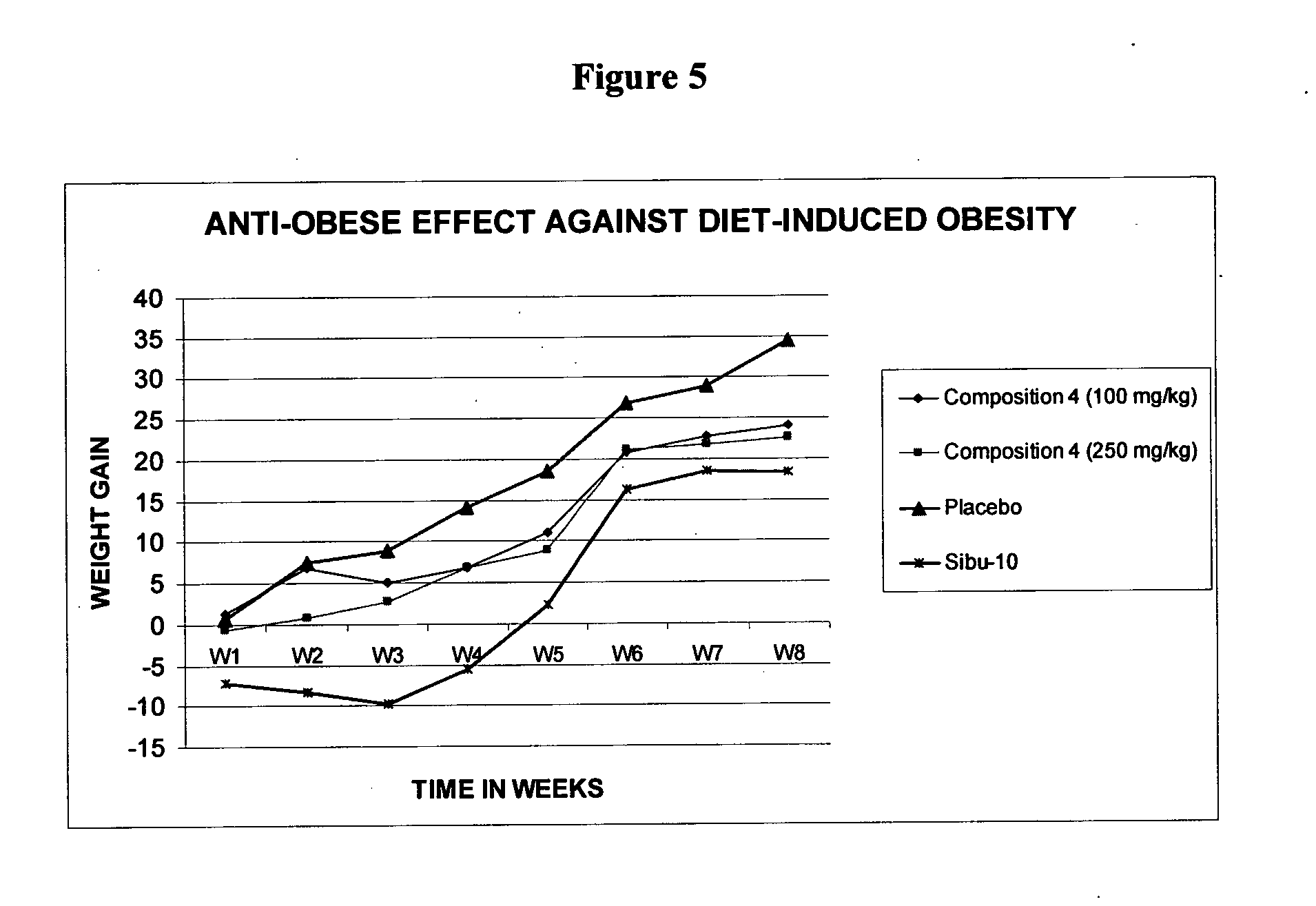

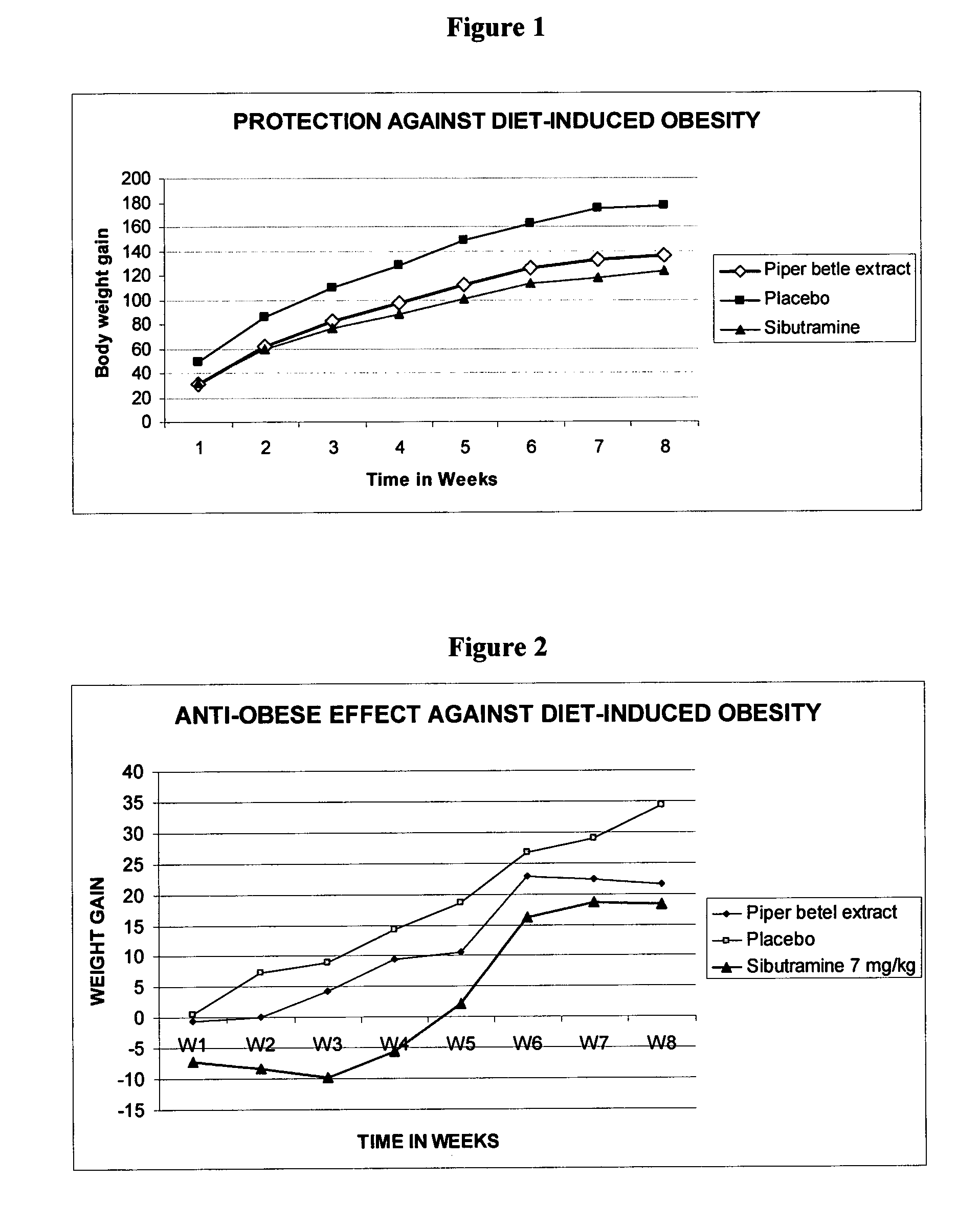

Anti-adipogenic compositions containing piper betle and dolichos biflorus

ActiveUS20100203117A1High activityImprove securityHeavy metal active ingredientsBiocideAdipogenesisLipid storage disease

Herbal compositions are useful for inhibition, amelioration or prevention of adipogenesis mediated diseases such as obesity, lipid storage disease and hyperlipemia. The herbal compositions comprise biologically effective amounts of extracts or fractions from Piper betle in combination with one or more of the extracts or fractions derived from Dolichos biflorus, Commiphora mukul, Boerhaavia diffusa, Tribulus terrestris and Zingiber officinale as active ingredients. The compositions optionally contain a bio-enhancing agent or a bio-protecting agent, along with biologically acceptable carriers or diluents. The herbal compositions may be used in a method for treating or preventing adipogenesis involved diseases in mammals.

Owner:LAILA NUTRACEUTICALS

Anti-adipogenic compositions containing Piper betle and Dolichos biflorus

ActiveUS9301987B2Improve securityPotent anti-adipogenic actionBiocideHeavy metal active ingredientsLipid storage diseaseAdipogenesis

Herbal compositions are useful for inhibition, amelioration or prevention of adipogenesis mediated diseases such as obesity, lipid storage disease and hyperlipemia. The herbal compositions comprise biologically effective amounts of extracts or fractions from Piper betle in combination with one or more of the extracts or fractions derived from Dolichos biflorus, Commiphora mukul, Boerhaavia diffusa, Tribulus terrestris and Zingiber officinale as active ingredients. The compositions optionally contain a bio-enhancing agent or a bio-protecting agent, along with biologically acceptable carriers or diluents. The herbal compositions may be used in a method for treating or preventing adipogenesis involved diseases in mammals.

Owner:LAILA NUTRACEUTICALS

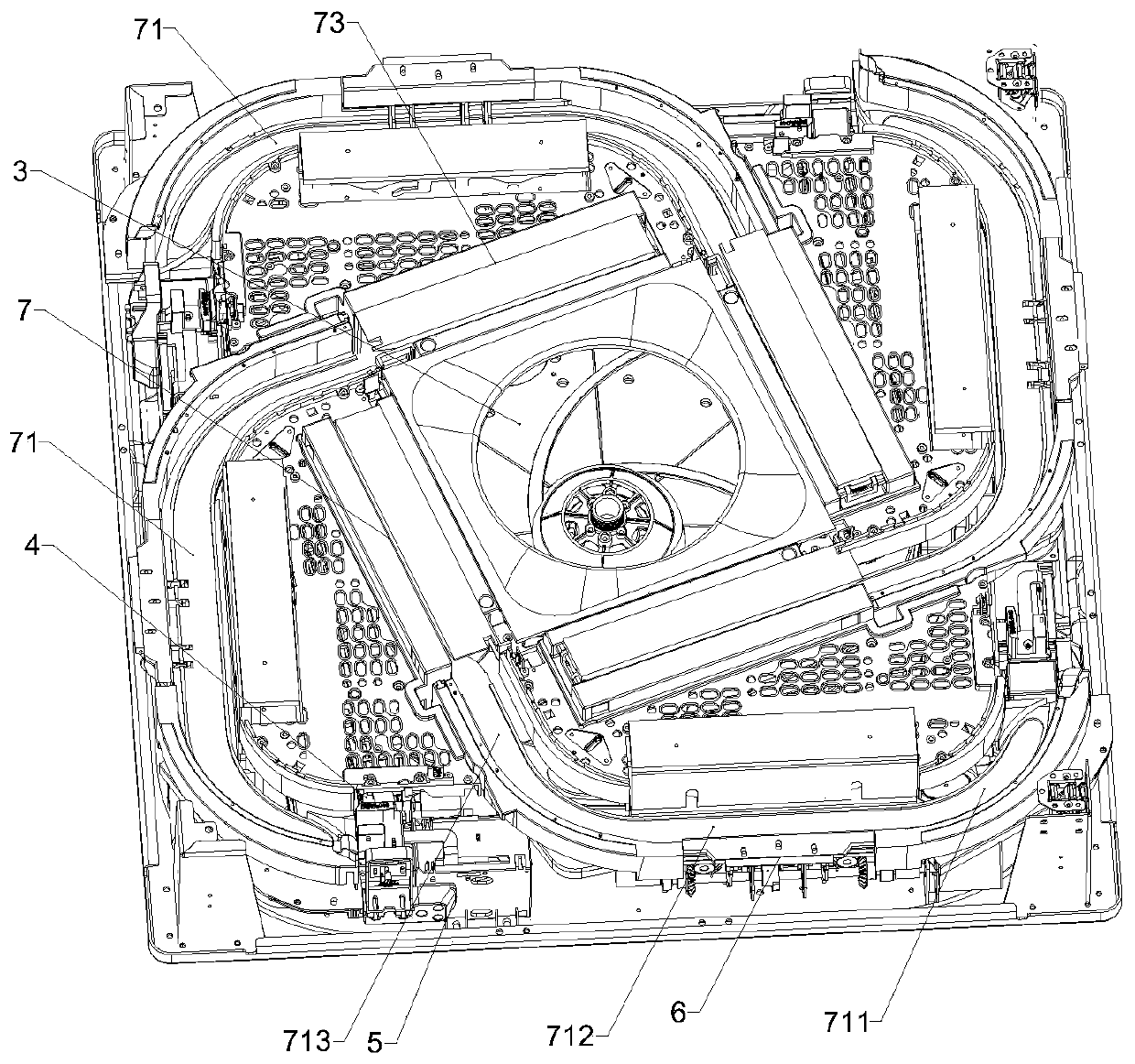

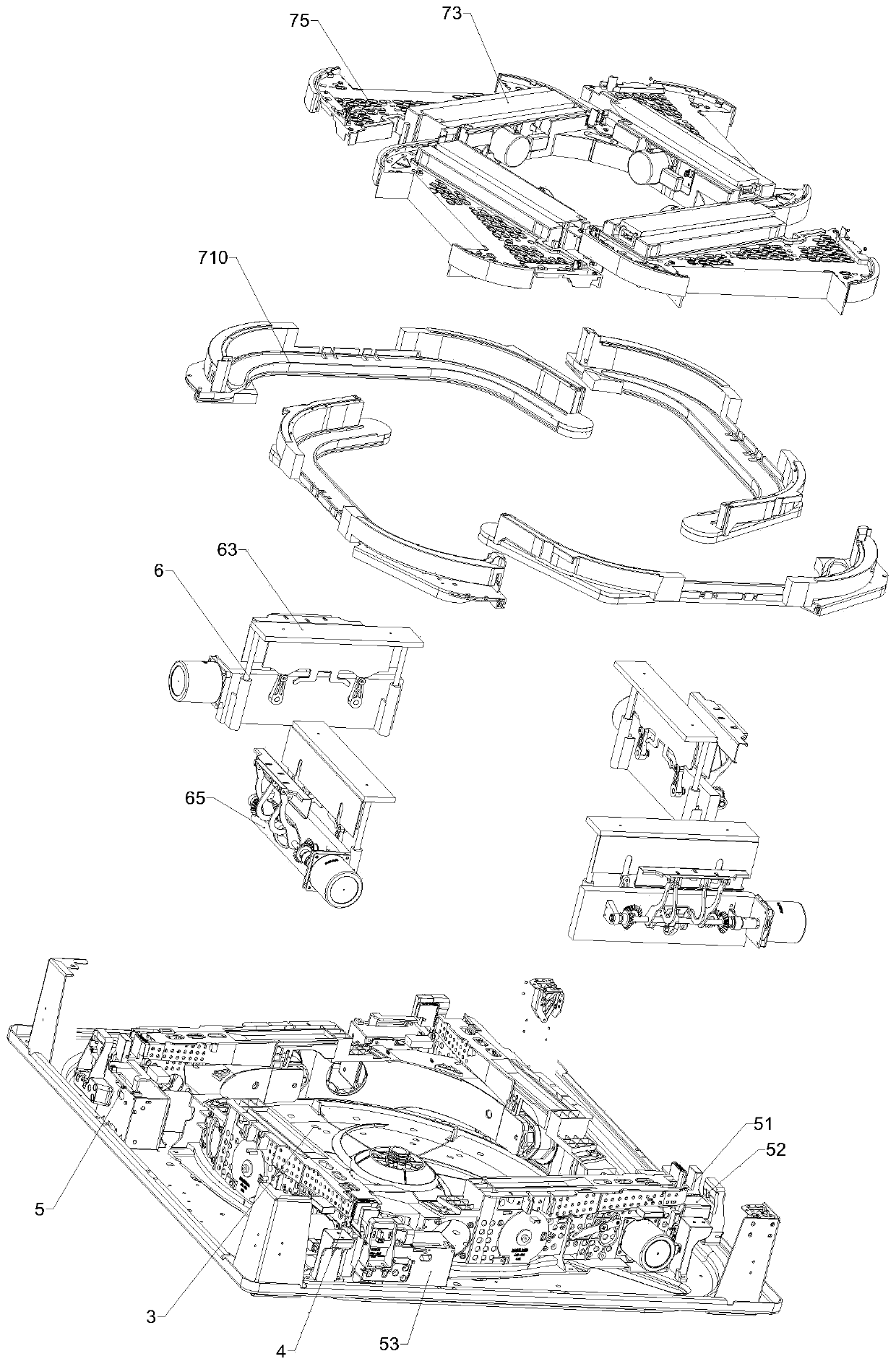

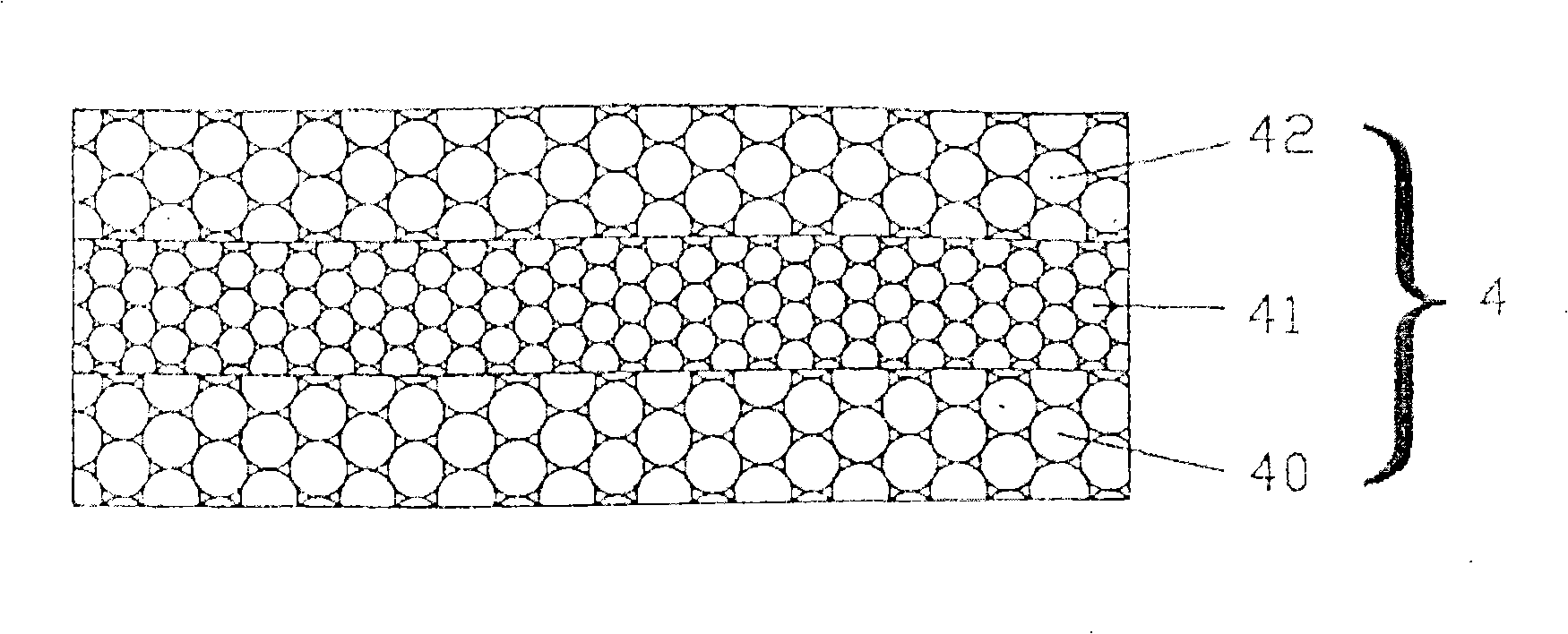

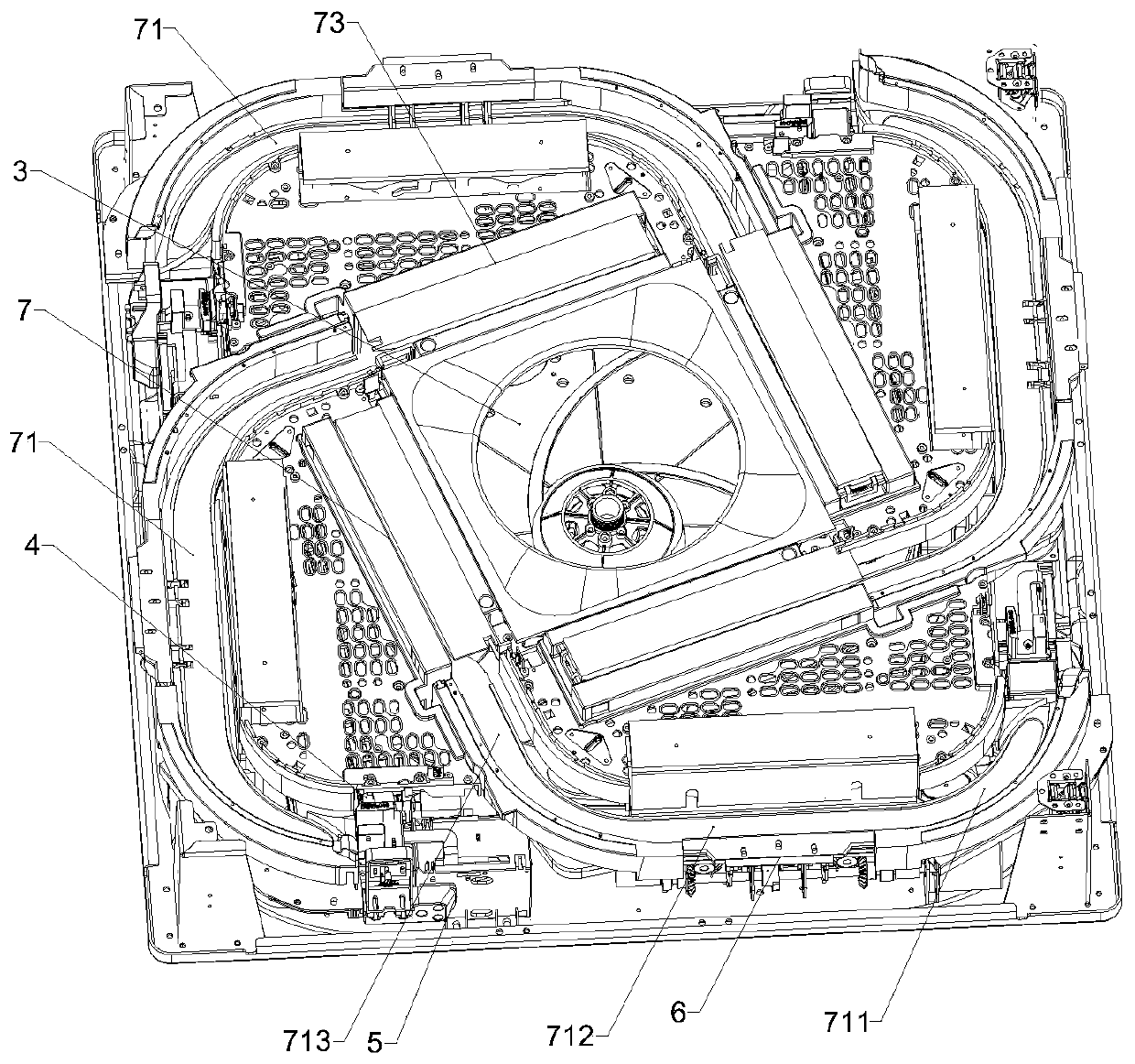

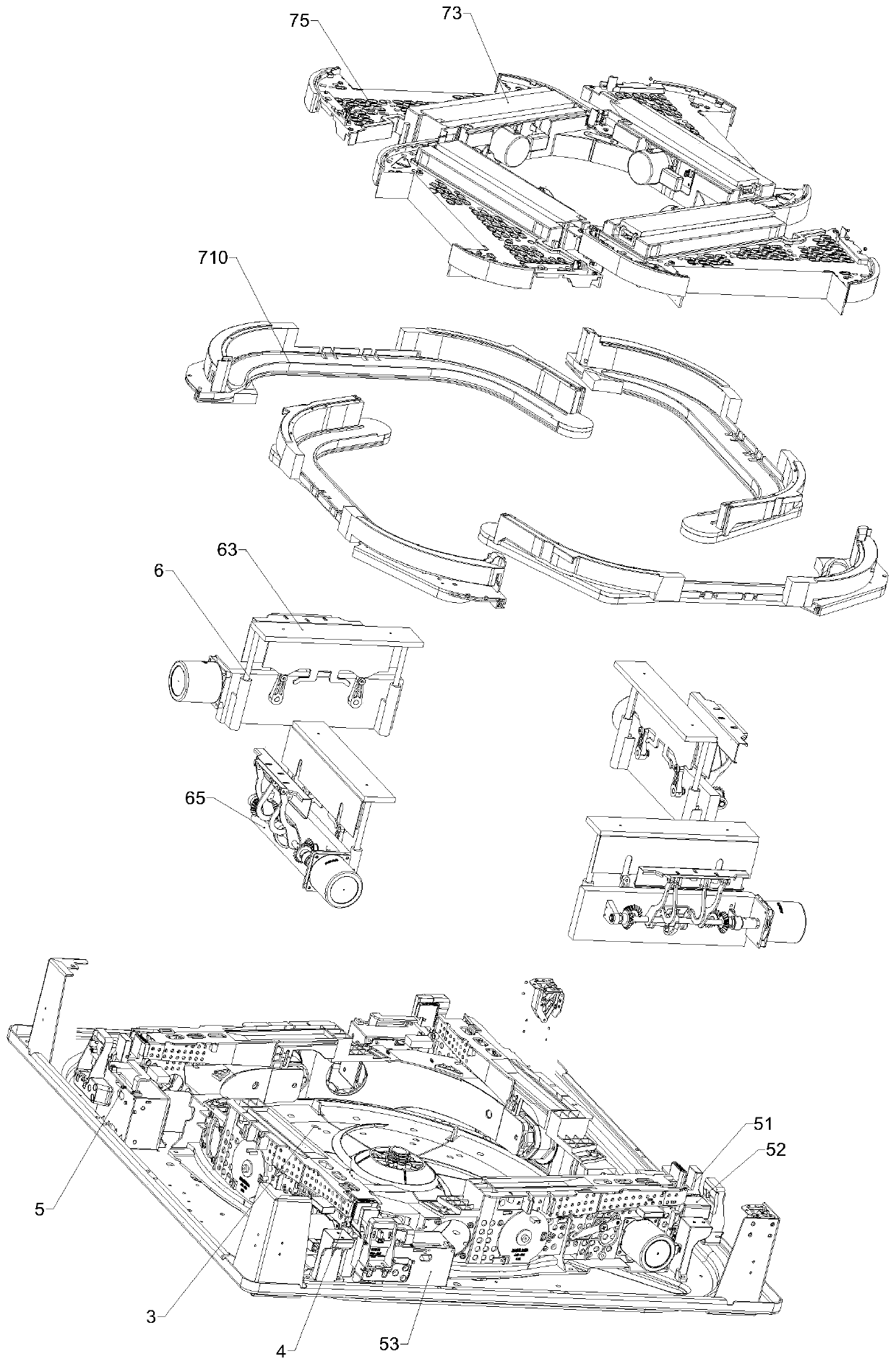

Mahjong machine and mahjong tile arranging method thereof

PendingCN111228786ANot easy cardRealize functionIndoor gamesStructural engineeringMechanical engineering

The invention relates to a mahjong machine and a mahjong tile arranging method thereof. The mahjong machine comprises a mahjong machine tabletop, a rack, a central control panel assembly, a shufflinglarge panel and four mahjong picking and carrying systems. The tile picking and carrying system comprises a tile conveying device, a horizontally-pushing tile feeding device, a stacking and pushing device, a tile lifting assembly, a tile storage groove, a tile feeding push head and a slope tile feeding driving mechanism of the tile feeding push head. Four inner mahjong outlets and four outer mahjong outlets are formed in the mahjong machine tabletop; in the same card picking and carrying system, cards can be picked up and carried; the tile feeding device and the horizontal pushing tile feedingdevice are located on the same side of the mahjong machine and are adjacent inside and outside. The stacking and pushing device and the tile lifting assembly are arranged at the two ends of the tilestorage groove. The horizontal pushing tile feeding device is arranged in the middle of the tile storage groove, the tile storage groove at least comprises a straight line section, the bottom wall ofthe straight line section is formed by a tile bearing plate in the horizontal pushing tile feeding device, the outer side wall of the straight line section is formed by a tile pushing plate in the horizontal pushing tile feeding device, and the tile lifting assembly and the horizontal pushing tile feeding device are located on the adjacent sides of the mahjong machine respectively. The device is simple and reasonable in structure, low in manufacturing cost, stable and reliable in operation and few in fault.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

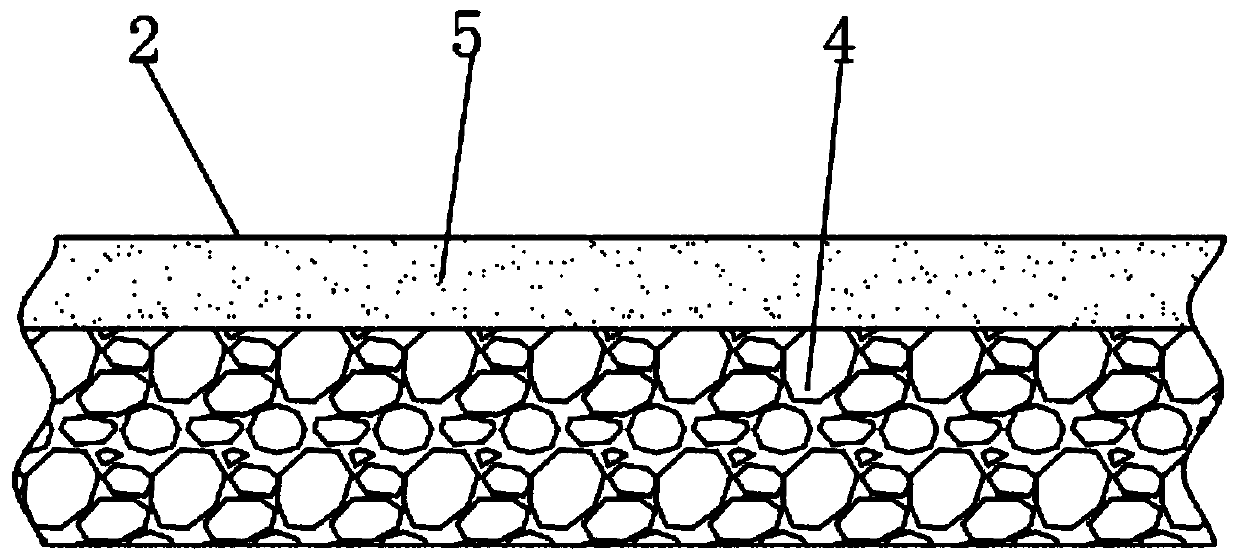

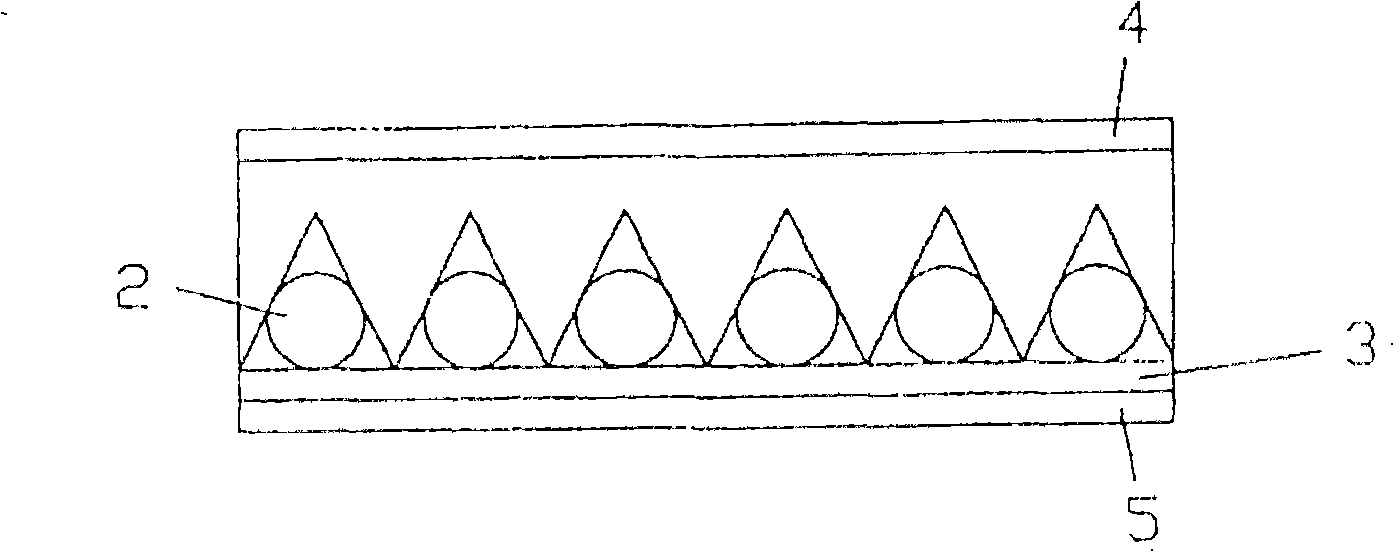

Elastic embossing warp knitted blanket and preparation method thereof

The invention discloses an elastic embossing warp knitted blanket and a preparation method thereof. The blanket is prepared from 12 to 22 parts of PET polyester, 5 to 18 parts of chinlon, 35 to 65 parts of wool, 2 to 11 parts of corn fiber, 1 to 7 parts of coconut fiber, and 20 to 35 parts of dacron, wherein the fineness of the wool is 16 to 19 micrometers. According to the elastic embossing warpknitted blanket and the preparation method thereof provided by the invention, the stretched fine wool is adopted as a main component of a woolen blanket, so that the blanket has the advantages of capability of reserving light wool fabrics, fineness, softness, suitability for personal use, convenience in caring, and applicability for four seasons; the blanket overcomes the defects of poor toughnessand small elasticity of a wool blanket made of finedrawn wools.

Owner:SUQIAN SHENLONG HOME TEXTILE

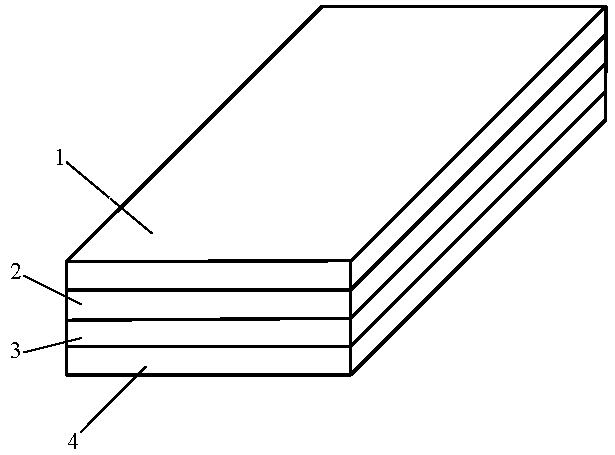

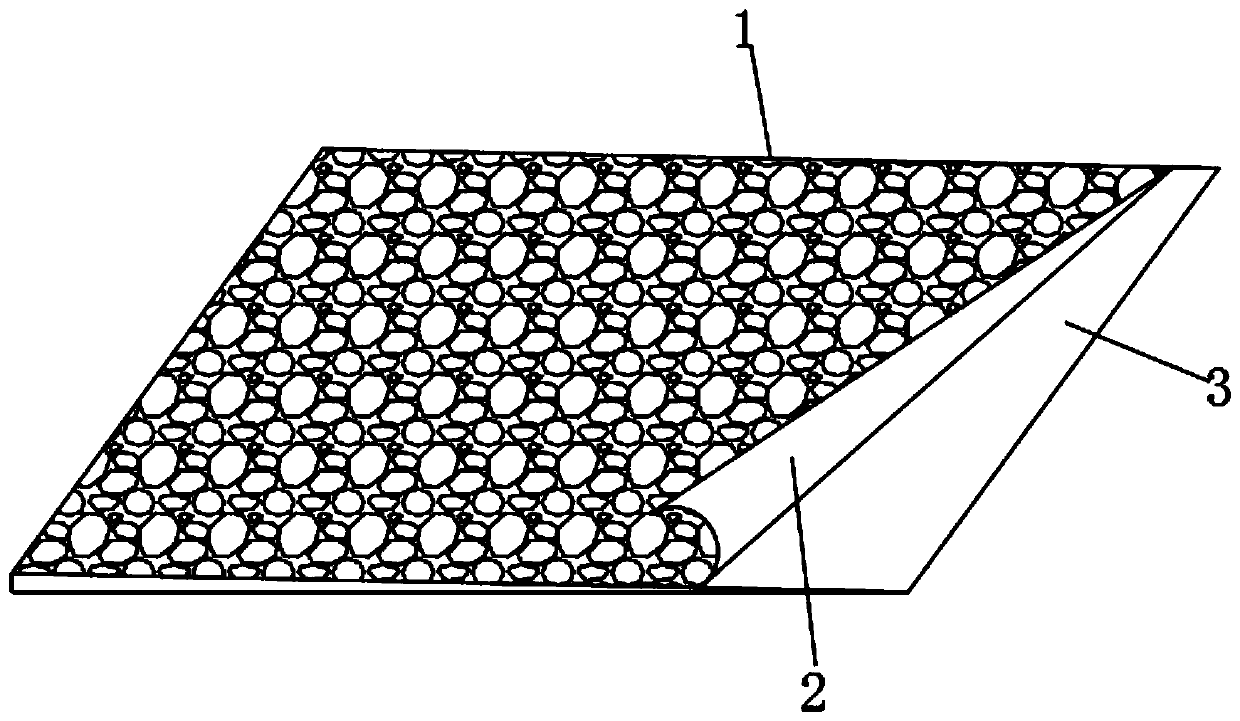

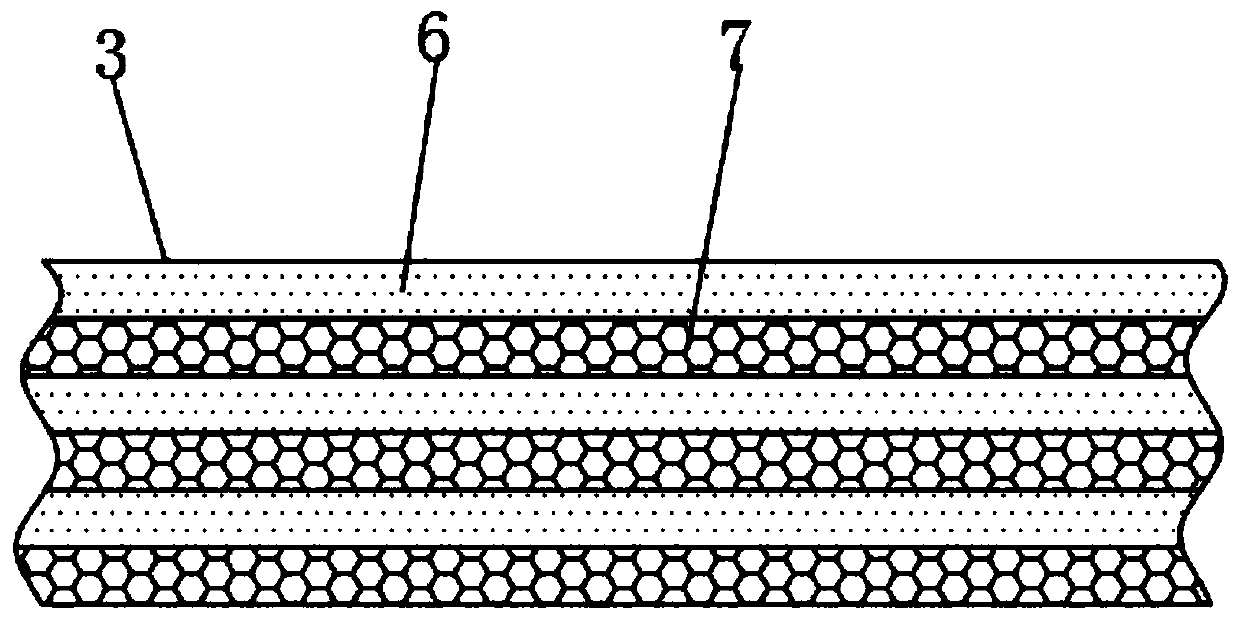

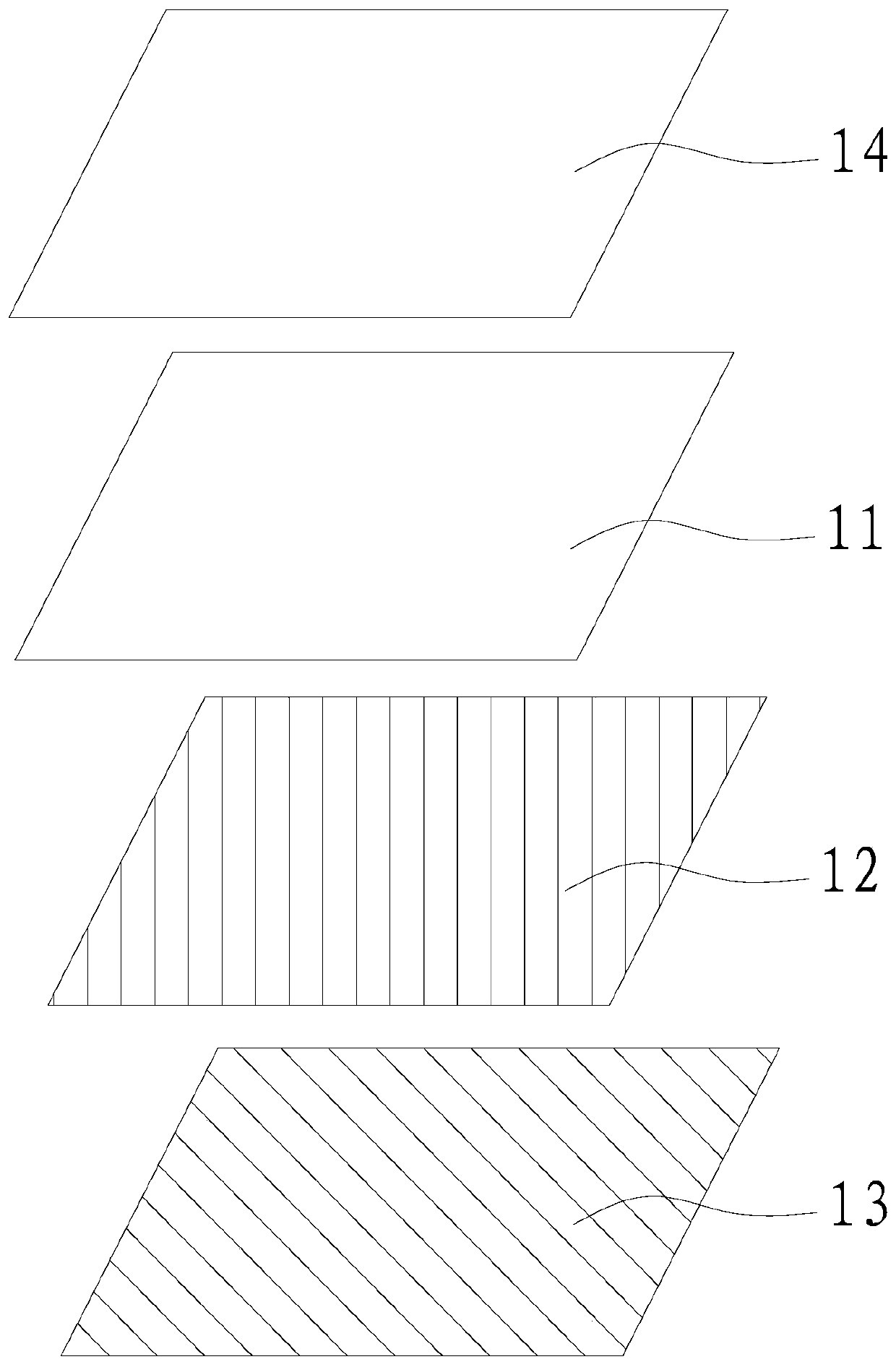

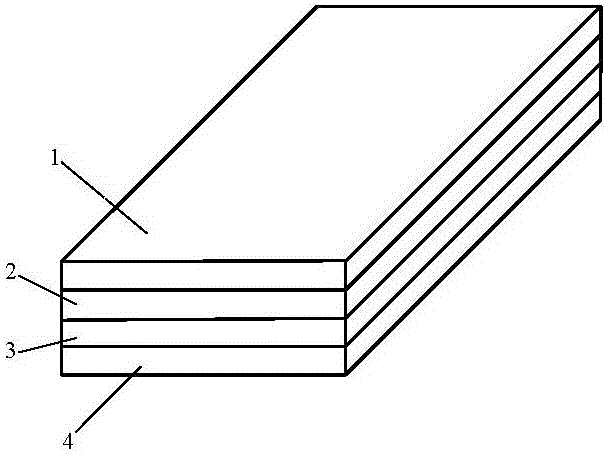

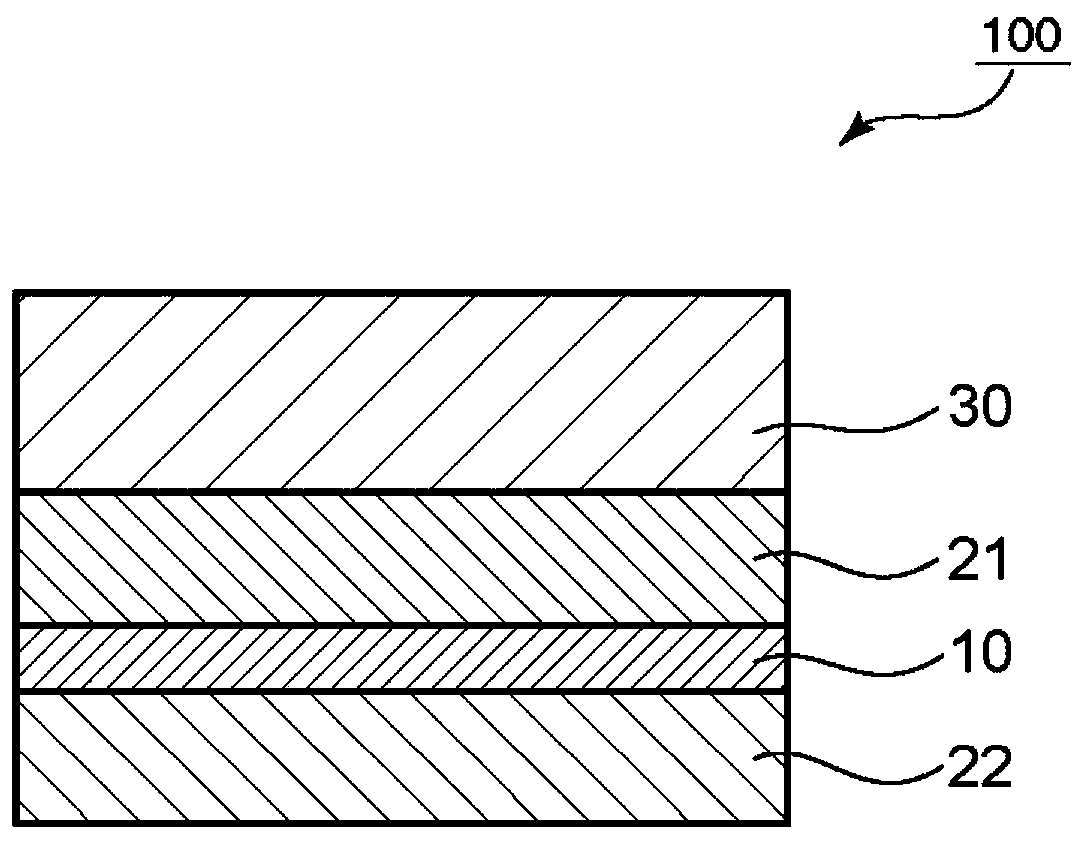

Environmentally-friendly breathable microfiber synthetic leather structure and production process

PendingCN110172834AGood flexibilityKeep it thinMedical preparationsCoatingsEnvironmental resistanceSurface layer

The invention discloses an environmentally-friendly breathable microfiber synthetic leather structure and a production process. The environmentally-friendly breathable microfiber synthetic leather structure comprises a synthetic leather main body; the synthetic leather main body mainly comprises a leather face layer and a basal layer; the leather face layer mainly comprises polyurethane semi-finished leather and a photocatalyst coating; and the basal layer comprises a plurality of layers of polytetrafluoroethylene films and a nylon fabric. According to the environmentally-friendly breathable microfiber synthetic leather structure and the production process, a primary backing fabric of the synthetic leather is made of a microporous polytetrafluoroethylene film and nylon fabric layer laminating composite material, so that the breathability of the primary backing fabric of the basal layer is improved; a certain dosage of polyethylene powder is added in surface layer PU (polyurethane) glueof the synthetic leather, so that the breathability of a leather face is improved; and meanwhile, the compact photocatalyst coating is sprayed on the surface layer of the leather face, and by means of the capacity of decomposing harmful substances by a photocatalyst, the environmental protection property of the synthetic leather is improved, and the application range of the synthetic leather is extended.

Owner:ZHEJIANG JINSHANG SYNTHETIC LEATHER

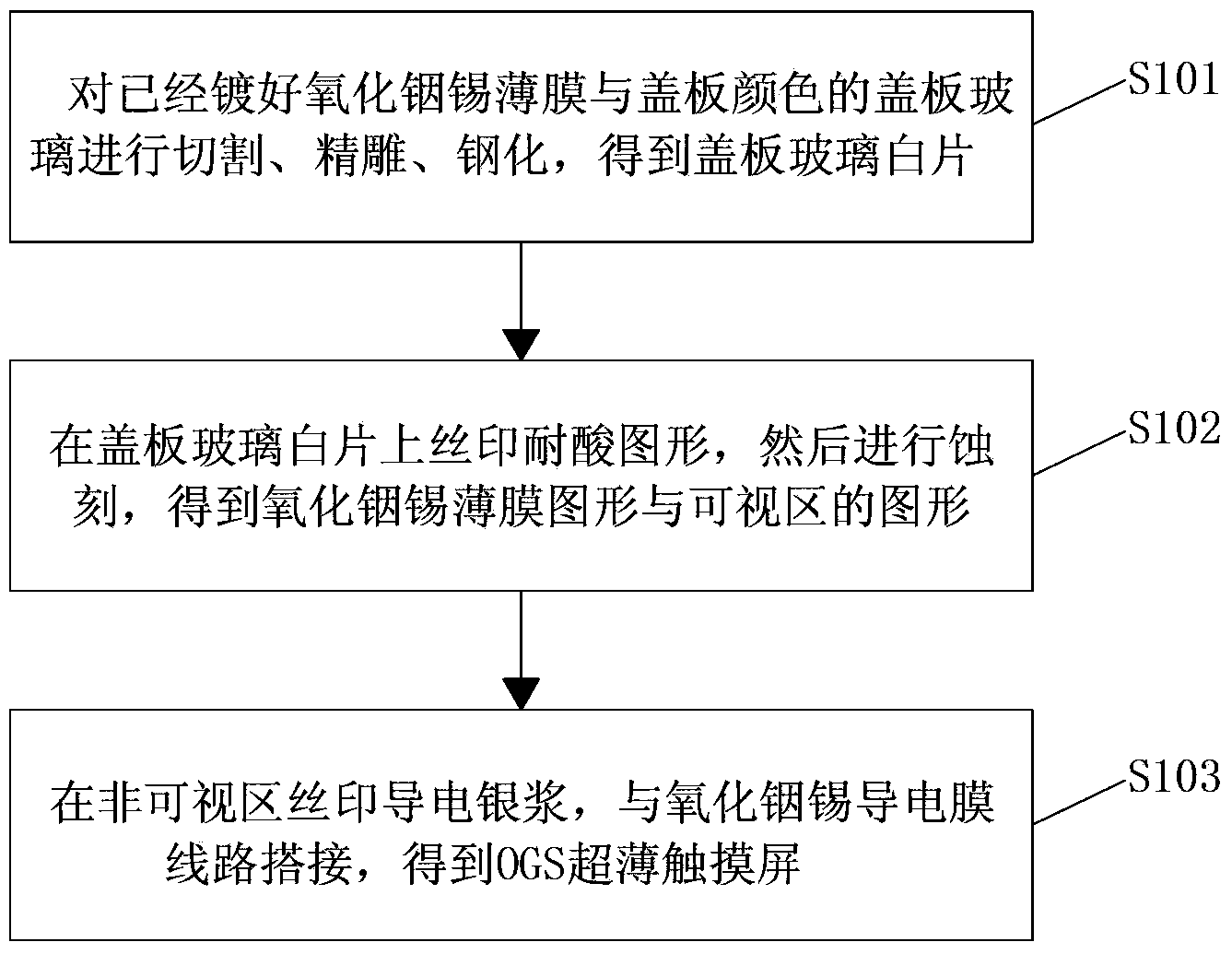

Improved manufacturing method of OGS (one glass solution) ultrathin touch screen

InactiveCN103472954AKeep it thinLow costInput/output processes for data processingSilver pasteScreen printing

The invention discloses an improved manufacturing method of an OGS (one glass solution) ultrathin touch screen. The method comprises the following steps that A, cover plate glass plated with an indium tin oxide thin film and a cover plate color is subjected to cutting, engraving and tempering, and a required cover plate glass white piece is obtained; B, acid resistance patterns are printed on the cover plate glass white piece in a silk-screen printing way, then, the etching is carried out, and the indium tin oxide thin film patterns and the visible region patterns are obtained; C, conductive silver paste is printed in a non-visible region in a silk-screen printing way, and is in lap joint with the indium tin oxide thin film through a circuit, and the OGS ultrathin touch screen is obtained. The improved manufacturing method has the advantages that the early stage equipment investment for manufacturing the OGS touch screen is reduced, the production efficiency is improved, in addition, the cost of the touch screen is reduced, and meanwhile, the characteristics of light weight and thin appearance of the OGS touch screen are also remained.

Owner:无锡宇宁智能科技有限公司

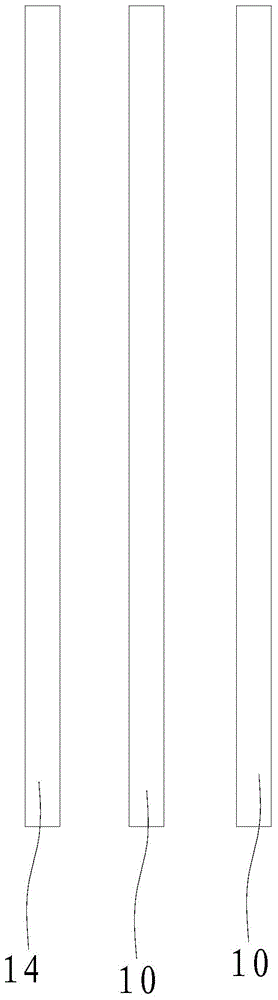

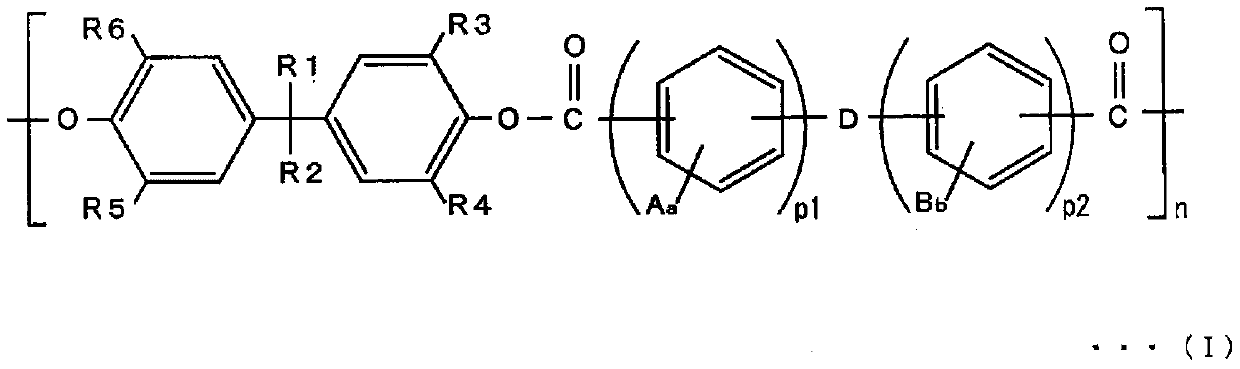

Membrane, product housing with the membrane and method for manufacturing the product housing

ActiveCN104486466BIncrease diversityEasy to useThermometers using physical/chemical changesTelephone set constructionsChange colorBiochemical engineering

The invention is applicable to the technical field of housings, and discloses a membrane, a product housing with the membrane and a manufacturing method for the product housing. The diaphragm includes at least two thermochromic layers, each thermochromic layer is stacked up and down, and at least two adjacent thermochromic layers have different thermochromic critical temperature values. The product housing has the above-mentioned diaphragm. The mobile terminal has the above-mentioned diaphragm. The manufacturing method of the product casing is used to prepare the above-mentioned product casing. The diaphragm provided by the present invention, the product casing with the diaphragm and the manufacturing method of the product casing, when the temperature is different, each thermochromic layer can change the color state accordingly, so as to increase the diversity of the appearance of the product casing , easy to use and low cost, and the thickness of the product shell and the external dimensions of the product are not affected, which is conducive to ensuring the development of the product in the direction of light weight.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Product shell, mobile terminal and manufacturing method of product shell

InactiveCN104411135AIncrease diversityEasy to useCasings/cabinets/drawers detailsUltravioletEngineering

The invention is applicable to the technical field of product shells and discloses a product shell, a mobile terminal and a manufacturing method of the product shell. The product shell comprises a body; the body is covered with at least one layer of photosensitive color changing diaphragm; the photosensitive color changing diaphragm is provided with at least one photosensitive color changing layer of which the color is changed under the irradiation of ultraviolet rays. The mobile terminal is provided with the product shell. The manufacturing method comprises the following steps: preparing the body and arranging the photosensitive color changing diaphragm with at least one photosensitive color changing layer on the body; or, preparing the photosensitive color changing diaphragm with at least one photosensitive color changing layer, placing the photosensitive color changing diaphragm in a die and forming the body connected to the photosensitive color changing diaphragm in the die. According to the product shell, the mobile terminal and the manufacturing method of the product shell, which are provided by the invention, the color of the photosensitive color changing layer is changed under the irradiation of ultraviolet rays, so that diversity of appearance of the product shell is increased; the product shell is convenient to use and is low in cost; moreover, lightness and thinness of the mobile terminal product can be kept.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

Screen lens and mobile terminal provided with same

InactiveCN104536872AIncrease diversityReduce diversityHardware monitoringTelephone set constructionsChange colorComputer terminal

The invention is applicable to the technical field of screen lenses and discloses a screen lens and a mobile terminal provided with the screen lens. The screen lens comprises a transparent lens and at least two thermo-chromic layers changing colors when thermo-chromic critical temperature values are reached, wherein the thermo-chromic layers are vertically stacked and connected to the inner side of the transparent lens, the thermo-chromic critical temperature values of at least two adjacent thermo-chromic layers are different. The mobile terminal is provided with the screen lens. When temperatures are different, the thermo-chromic layers of the screen lens can correspondingly change color states to increase diversity of product appearance, the screen lens is convenient to use and low in cost, the thickness and appearance size of the screen lens are not influenced, and development towards the lightweight direction of the screen lens is facilitated.

Owner:GUANGDONG OPPO MOBILE TELECOMM CORP LTD

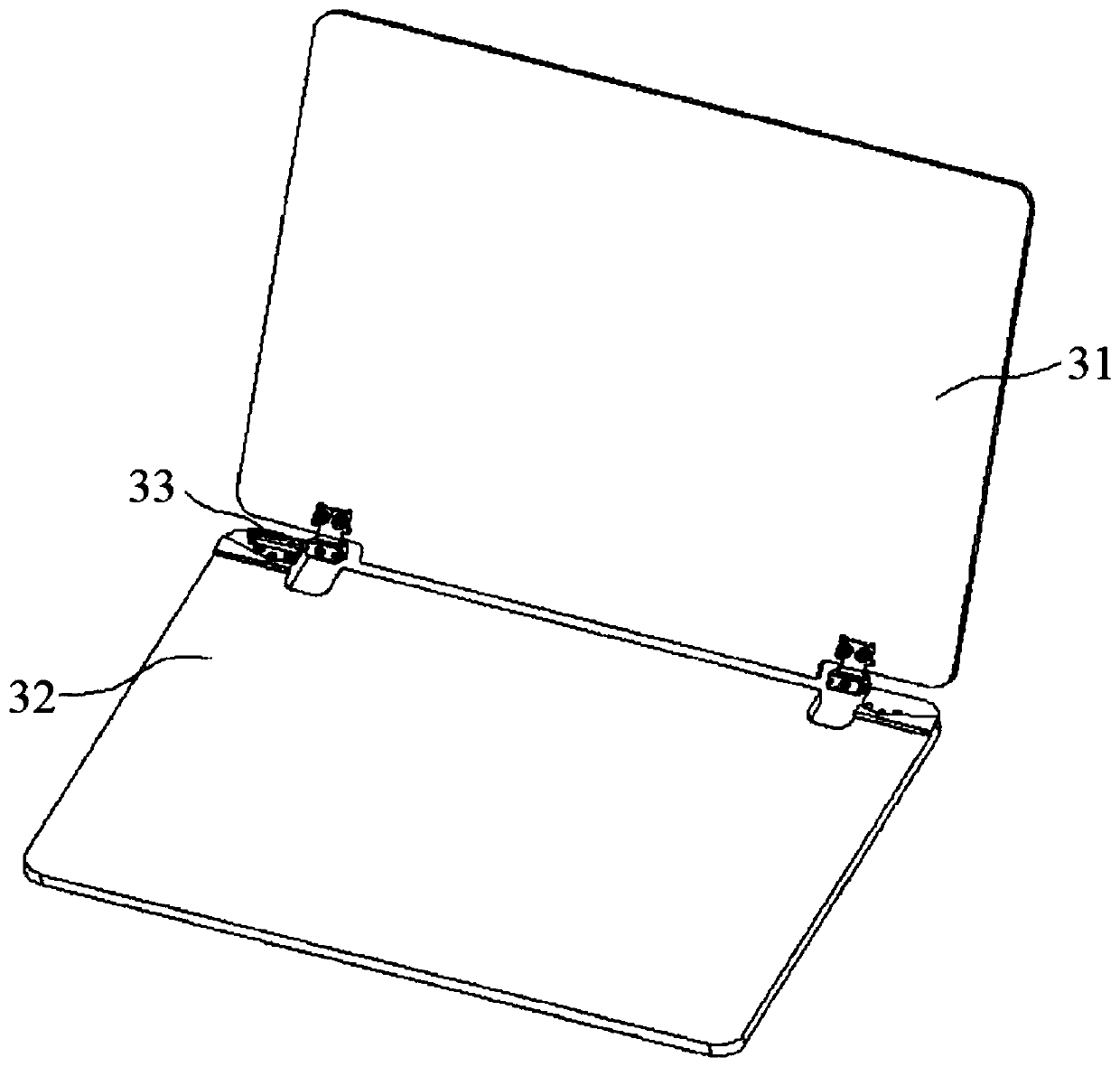

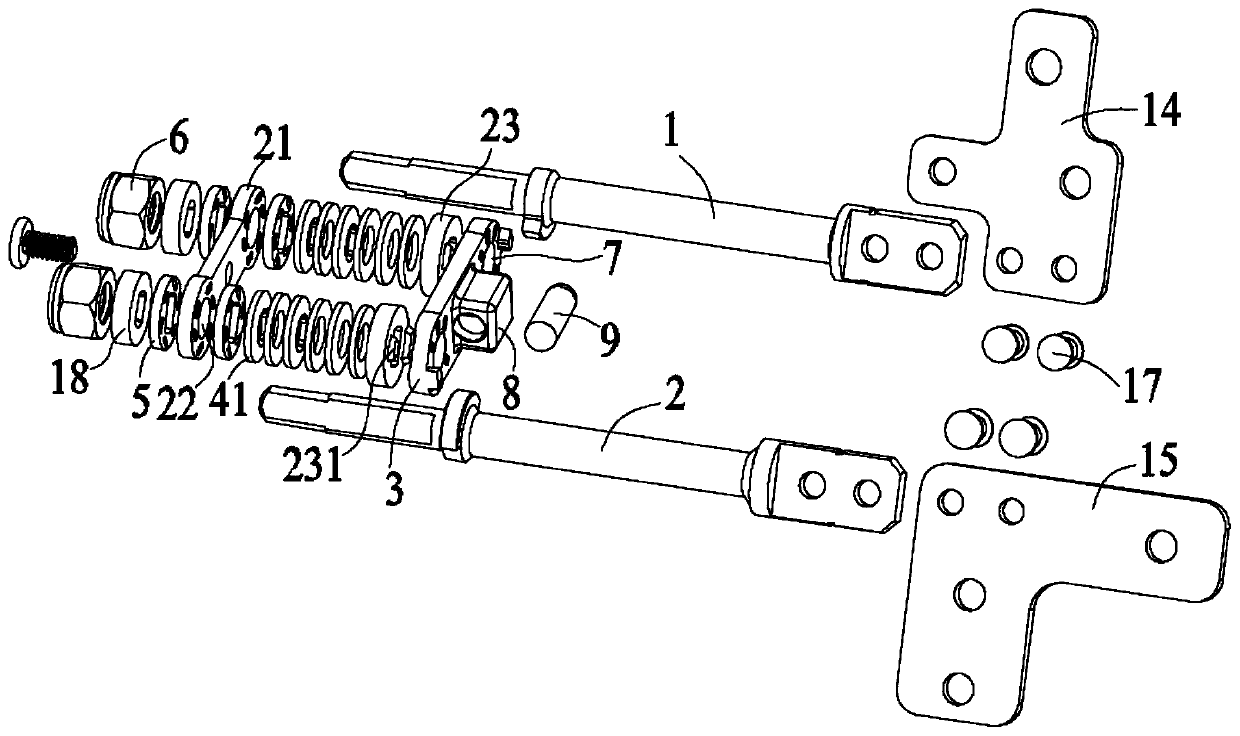

Ultra-thin notebook computer

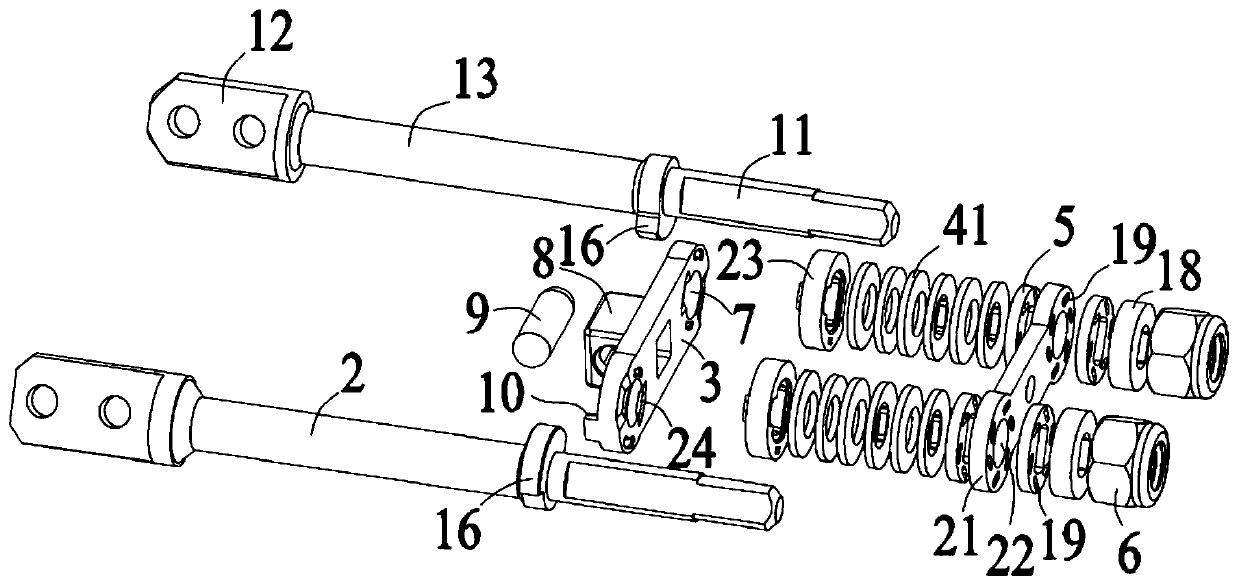

InactiveCN110630627AKeep it thinSimple structure installationDigital data processing detailsPivotal connectionsElastic component

The invention discloses an ultra-thin notebook computer. The ultra-thin notebook computer comprises a display surface, a base surface and a rotating shaft mechanism, wherein the rotating shaft mechanism is used for connecting the display surface and the base surface; the rotating shaft mechanism further comprises a first rotating shaft, a second rotating shaft, a supporting plate connecting the first rotating shaft and the second rotating shaft, an elastic component, a plurality of friction sheets and blocks, wherein the supporting plate, the elastic component and friction sheets sequentiallysleeve the first rotating shaft and the second rotating shaft and are pressed and fixed by the blocks; and a first connecting plate is connected to the connecting portion of the first rotating shaft,a second connecting plate is connected to the connecting portion of the second rotating shaft, the first connecting plate is connected with the display surface, and the second connecting plate is connected with the base surface. According to the ultra-thin notebook computer, 360-degree rotation positioning between the display surface and the base surface can be realized, and adjustment of the center distance between the rotating shafts is achieved by adjusting the length of a sliding top block, thus being suitable for notebook computers of different specifications and sizes, and meanwhile thelightness and thinness of the notebook computers can be kept.

Owner:KUNSHAN KERSEN SCI & TECH

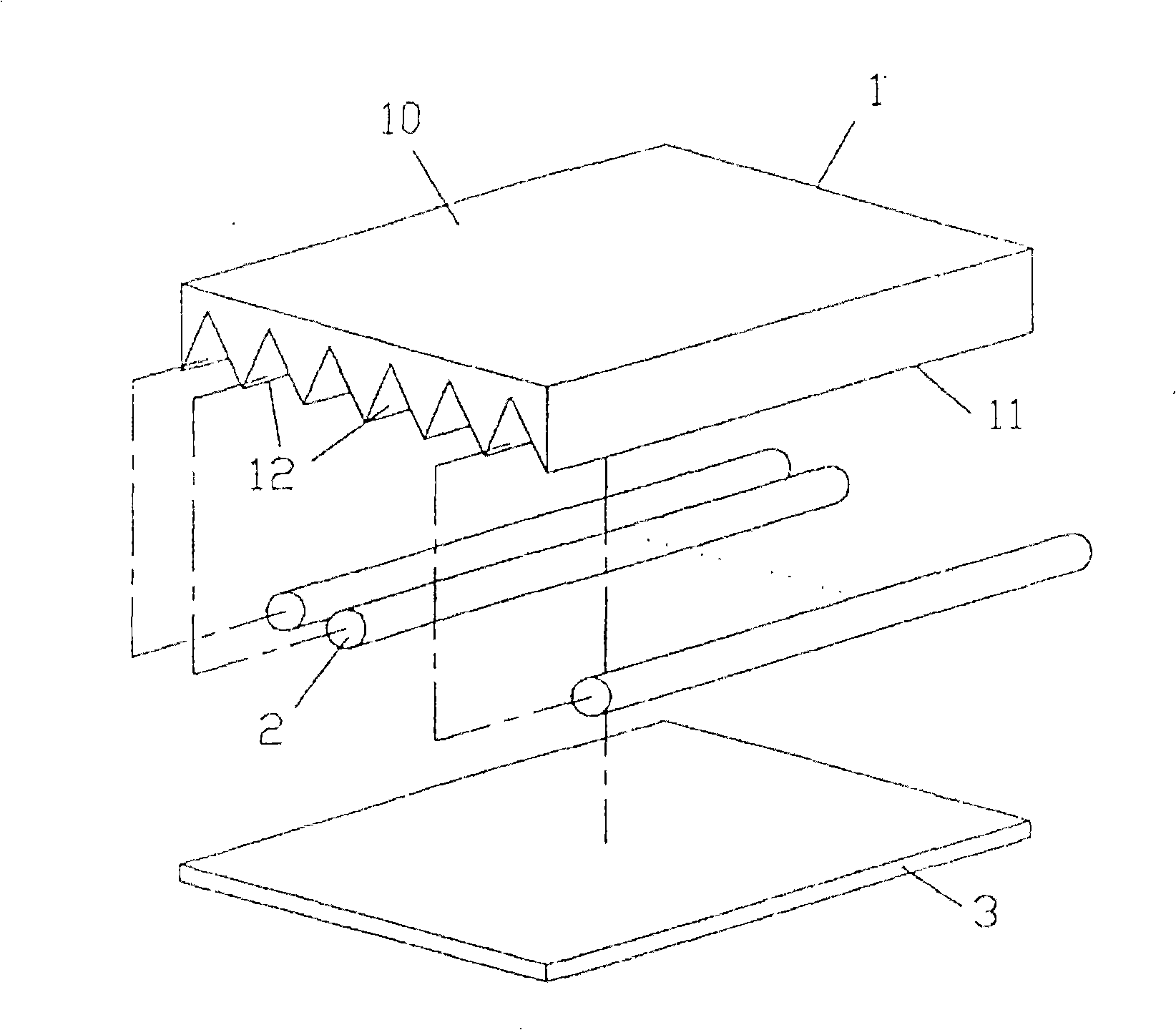

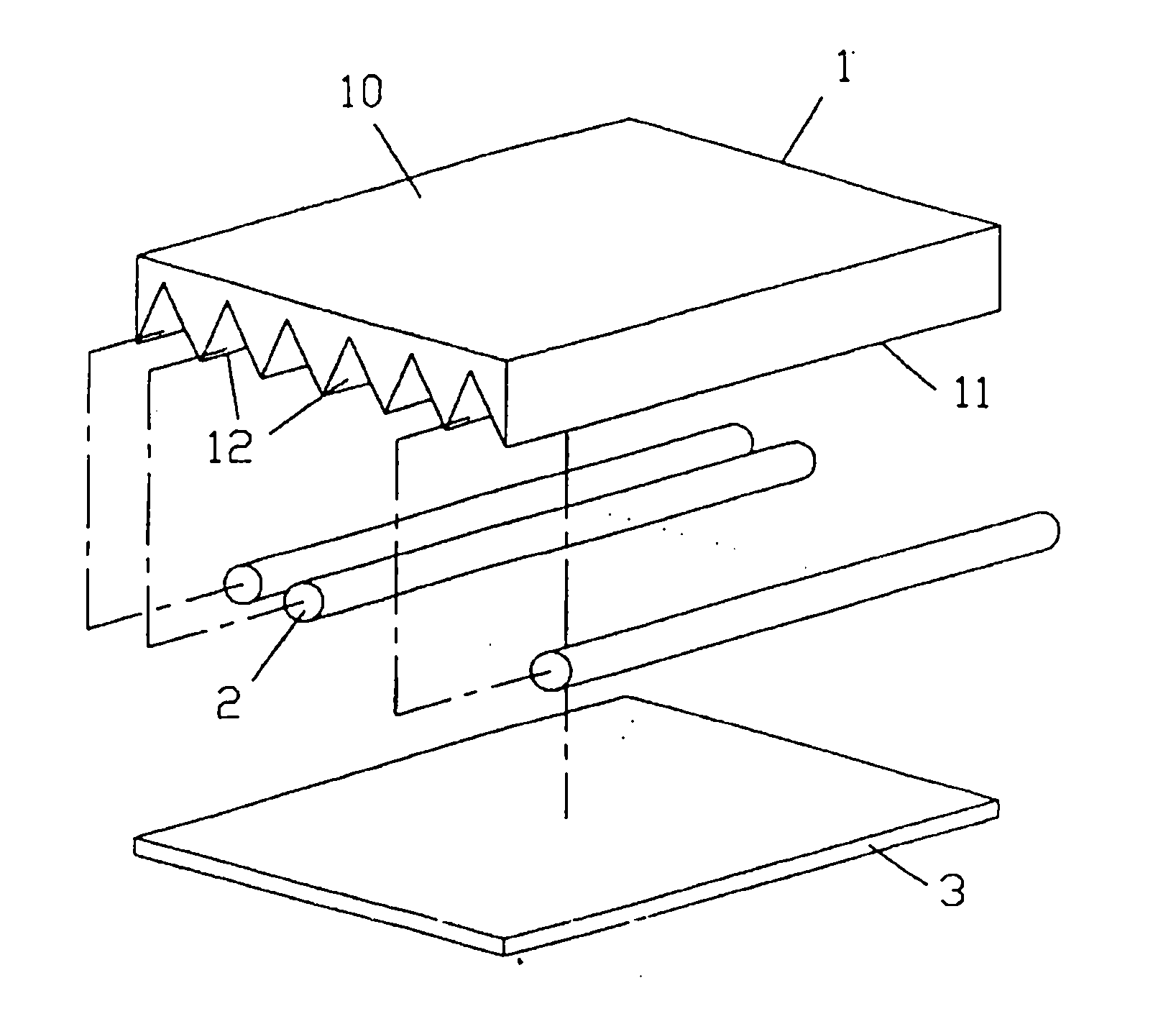

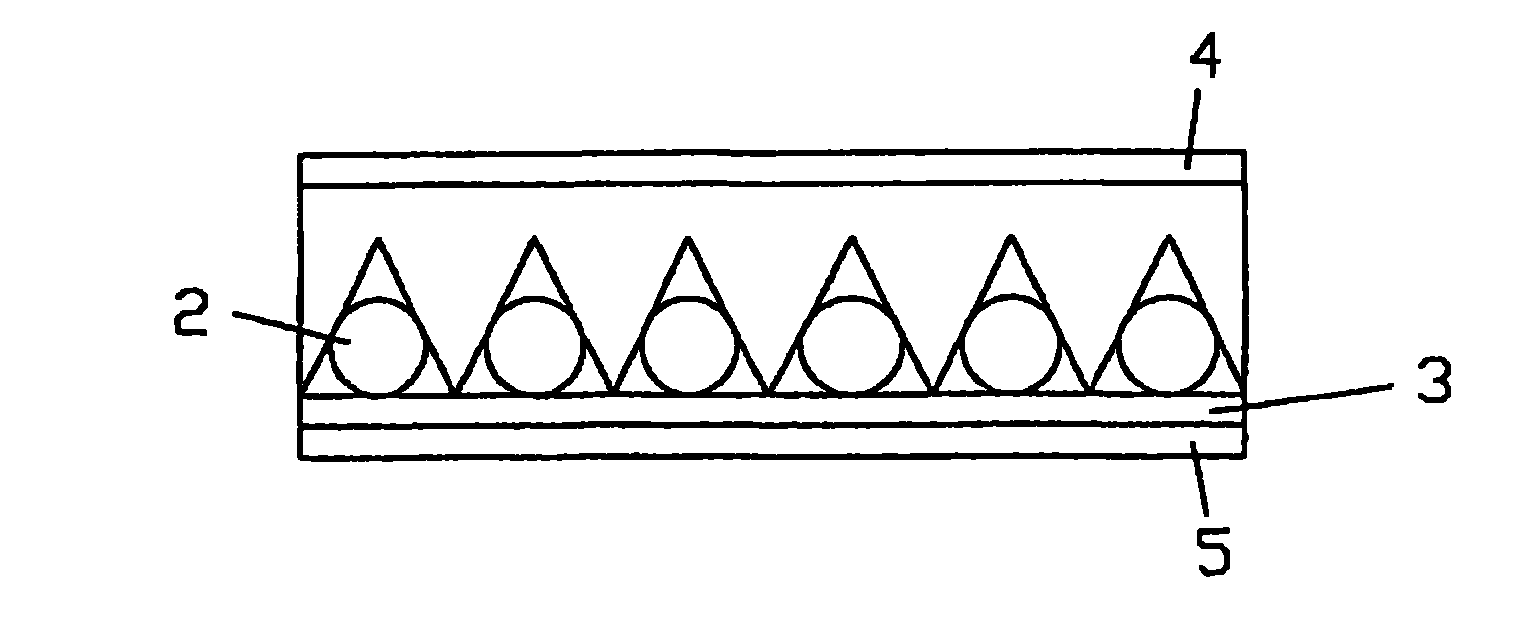

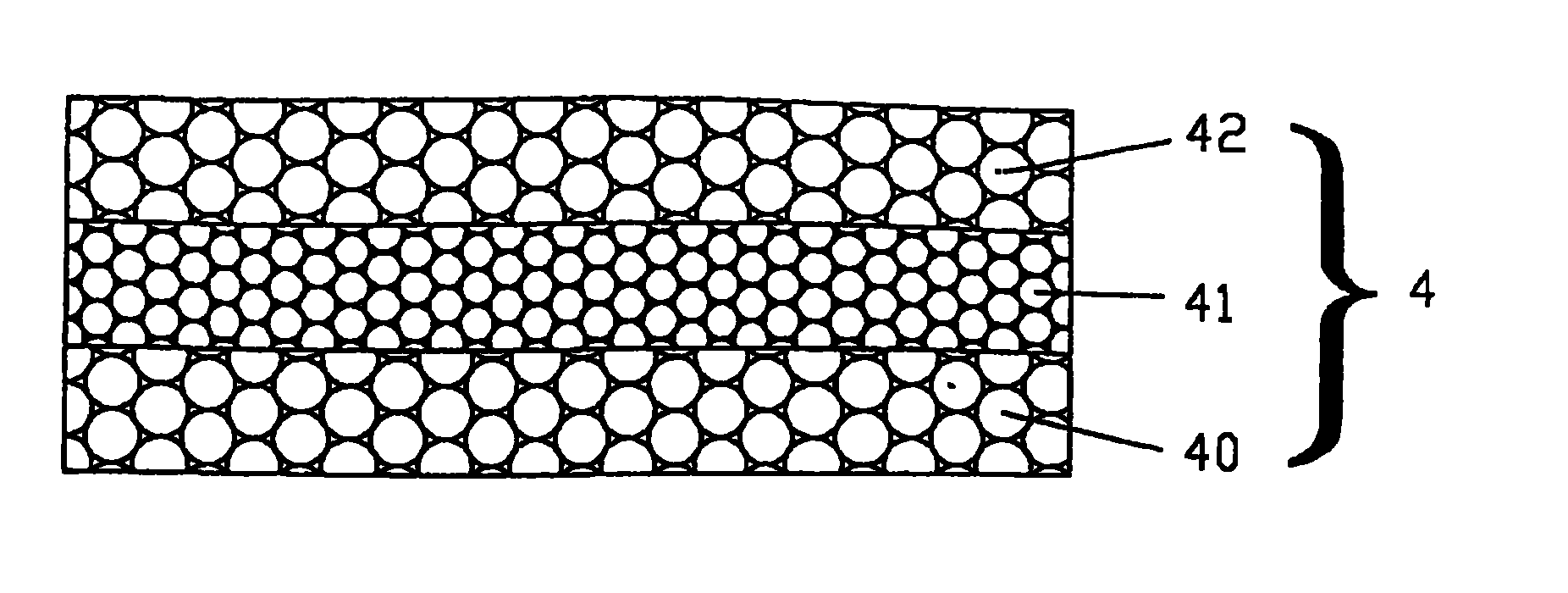

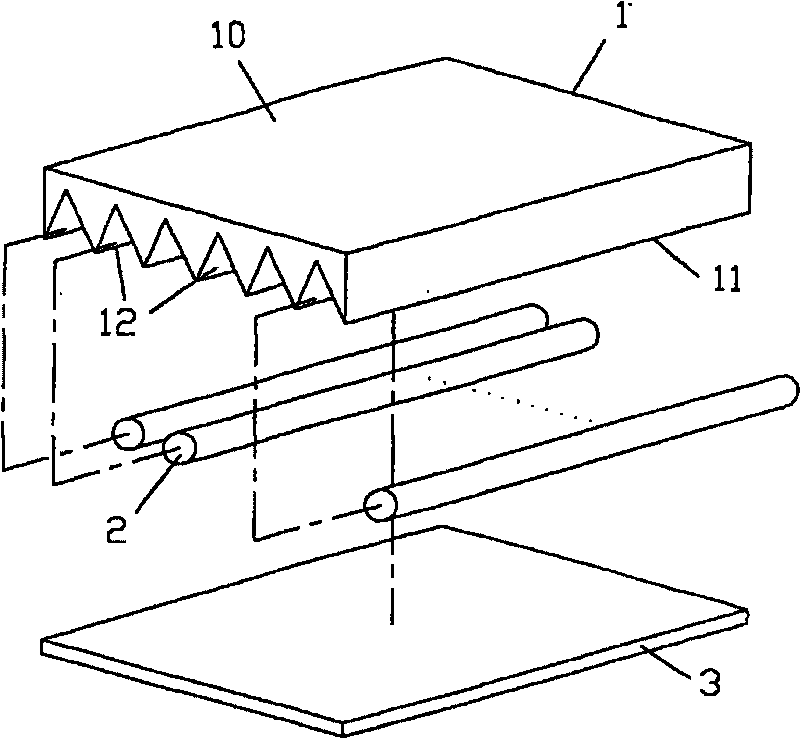

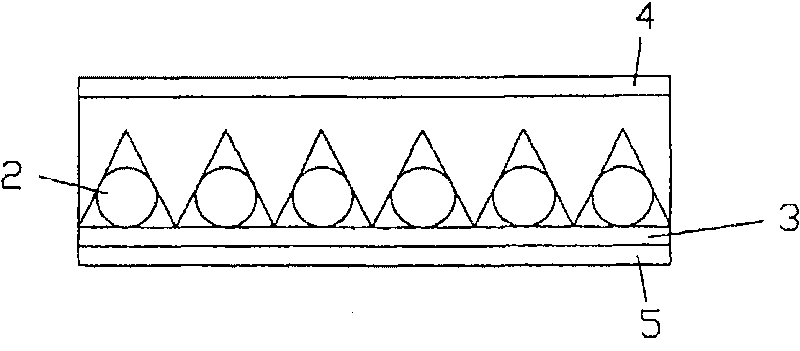

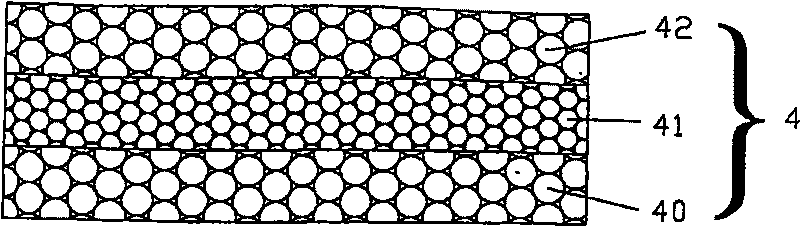

Back light source device

Owner:沈育浓

A kind of conductive nanofiber film and preparation method thereof

ActiveCN110894677BKeep it thinRetain flexibilityFibre typesElectro-spinningPolymer scienceAcrylonitrile

The invention relates to a conductive nanofiber membrane and a preparation method thereof. The fiber membrane is obtained by chemically silver-plating the palladium-containing polyacrylonitrile PAN nanofiber membrane as a carrier. The preparation method of the invention can change the conductivity of the nanofiber membrane and the morphology of the nanofiber membrane by adjusting process parameters. The preparation method is novel, the process is simple, the adjustment is flexible, the repetition rate is high, the processing is convenient, the flexibility is large and thin, and it is especially suitable for application in the field of intelligent textiles.

Owner:DONGHUA UNIV

Backlight device

Owner:沈育浓

Single-sided fabric

PendingCN113151951ABreathableImprove breathabilityWeft knittingSwivel-woven fabricsYarnConvex structure

The inventor provides the single-sided fabric. The surface of the single-sided fabric is of a concave-convex structure, wherein the convex parts and the concave parts are woven by adopting different yarns, and the water absorption speed of the yarns for weaving the concave parts is greater than or equal to that of the yarns for weaving the convex parts. The concave-convex structure of the fabric can reduce the contact area between the skin and clothes, a hollow air channel is formed, and ventilation and perspiration are facilitated. The speed of the concave part for absorbing sweat from the convex part is greater than or equal to the speed of the convex part for absorbing sweat from the skin, so that the sweat can be effectively transferred, and the situation that the sweat is accumulated on the lower end surface of the convex part and adhered to the skin to cause discomfort due to gravitational potential energy and surface energy is avoided. The fabric has the advantages of lightness, thinness, breathability, moisture absorption and sweat releasing.

Owner:FUJIAN HUAFENG NEW MATERIALS

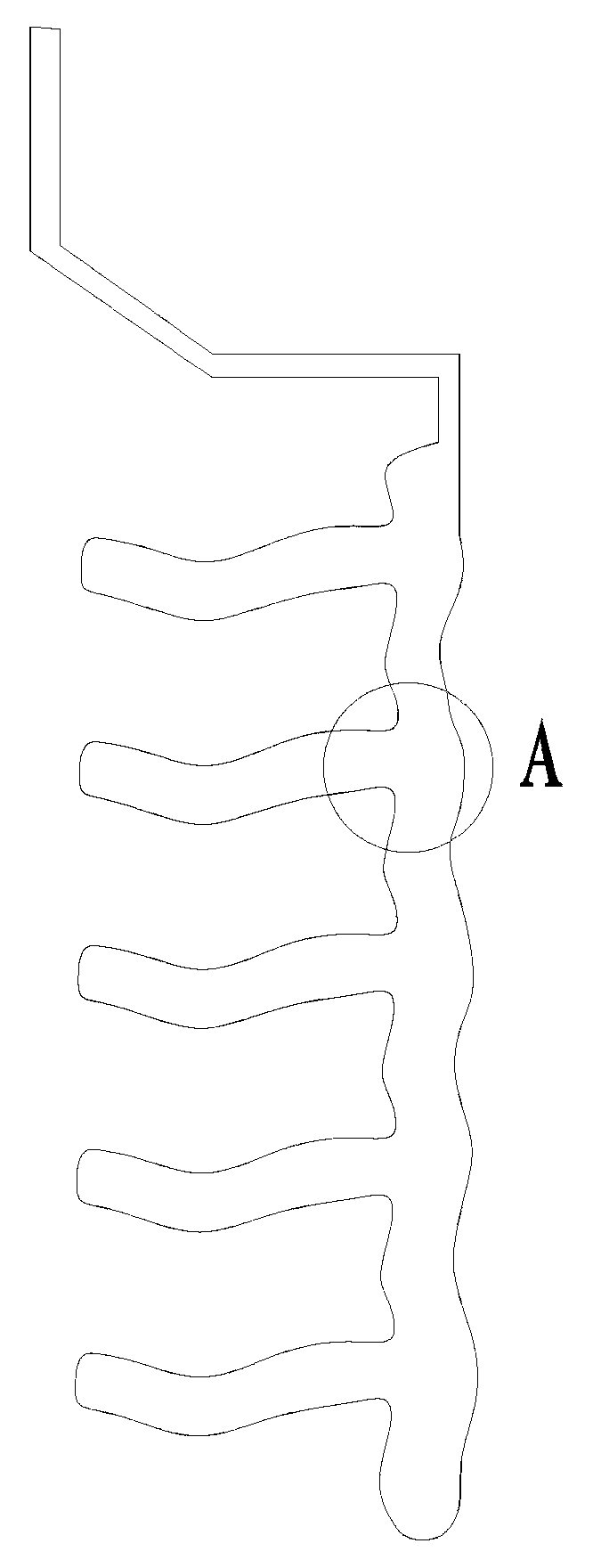

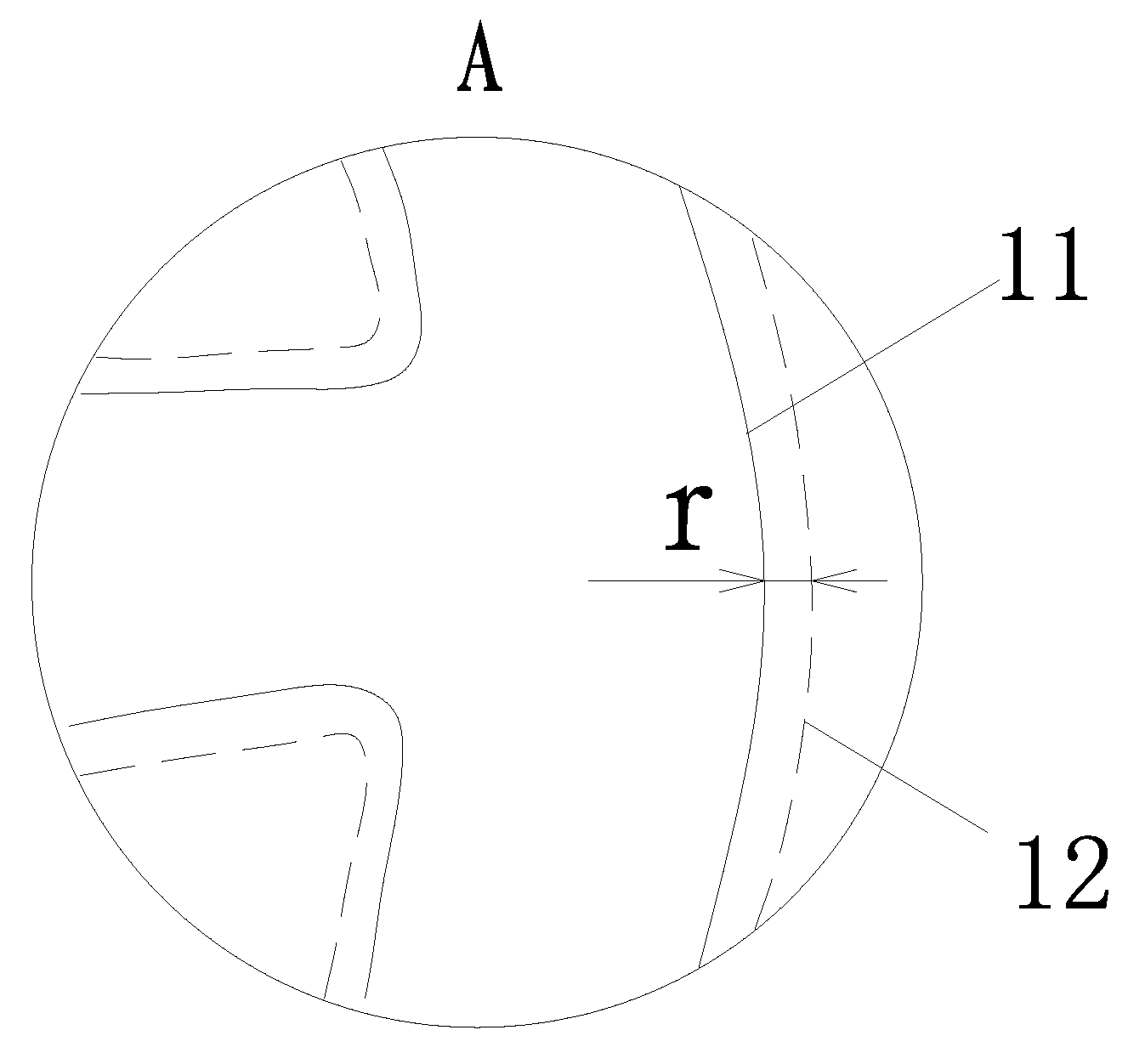

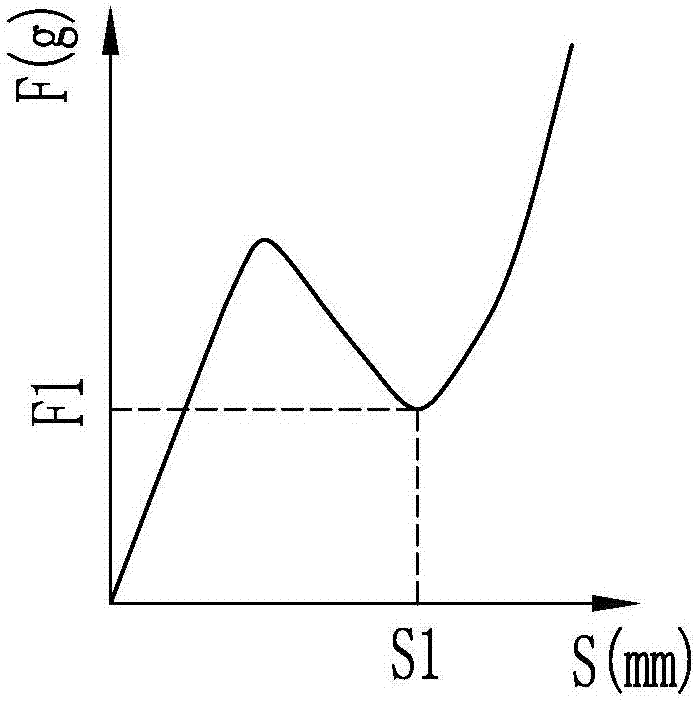

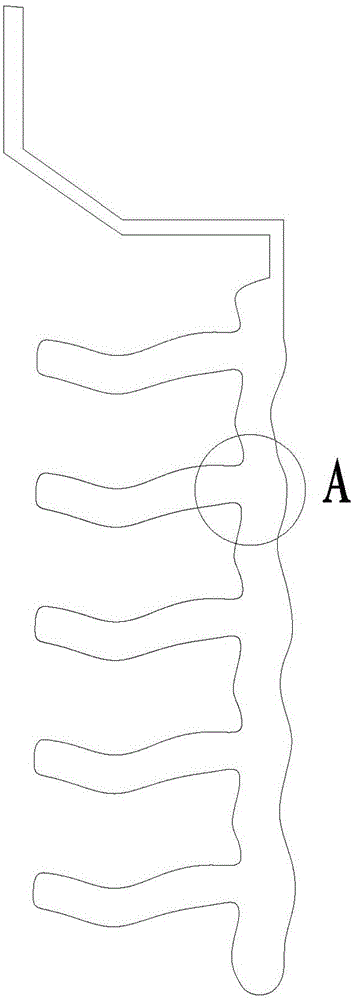

Mechanical thin film keyboard

ActiveCN107068462APlay an elastic reset roleKeep it thinElectric switchesEmergency springsKey pressingEngineering

The invention discloses a mechanical thin film keyboard including a thin film circuit layer, an X-shaped bracket and a key cap. A capped bowl-shaped silicone key corresponding to the thin film circuit layer is arranged on the inner side of the key cap. A bowl opening part of the silicone key is mounted on the inner side of the key cap and the top of the silicone key protrudes to correspond to the thin film circuit layer. A linear spring is arranged between the key cap and the thin film circuit layer. Through pushing the key cap and further compressing the linear spring and make vertical movement to the thin film circuit layer along the guiding direction of the X-shaped bracket, the silicone key on the inner side of the key cap is driven to move to the thin film circuit layer. The top protrusion of the silicone key achieves electrode contact point conduction of the thin film circuit layer and further achieves conduction of a conductive circuit in the thin film circuit layer. The keyboard is designed by combining the advantages of thin film keyboards and mechanical keyboards, thus keeps the light weight and low cost of thin film keyboards, and has the advantages of mechanical keyboards such as high sensitivity, good hand feeling and long service life.

Owner:INJECTION PRECISION RUBBER SUZHOU CO LTD

Anti-obese compositions containing holoptelea integrifolia extracts

ActiveUS9504722B2Lower Level RequirementsReduce weightBiocideOrganic active ingredientsMedicineAdipogenesis

The present invention discloses the extracts of Holoptelea integrifolia or the purified fractions isolated there from and the dietary, nutraceutical and pharmaceutical compositions comprising the same or optionally in combination with one or more known anti-obesic agents useful for the purpose of inhibition, amelioration or prevention of adipogenesis and lipolysis involved diseases. The invention further discloses a method for treating or preventing obesity and adipogenesis and lipolysis involved diseases using the compositions containing the extracts of purified fractions of Holoptelea integrifolia.

Owner:LAILA NUTRACEUTICALS

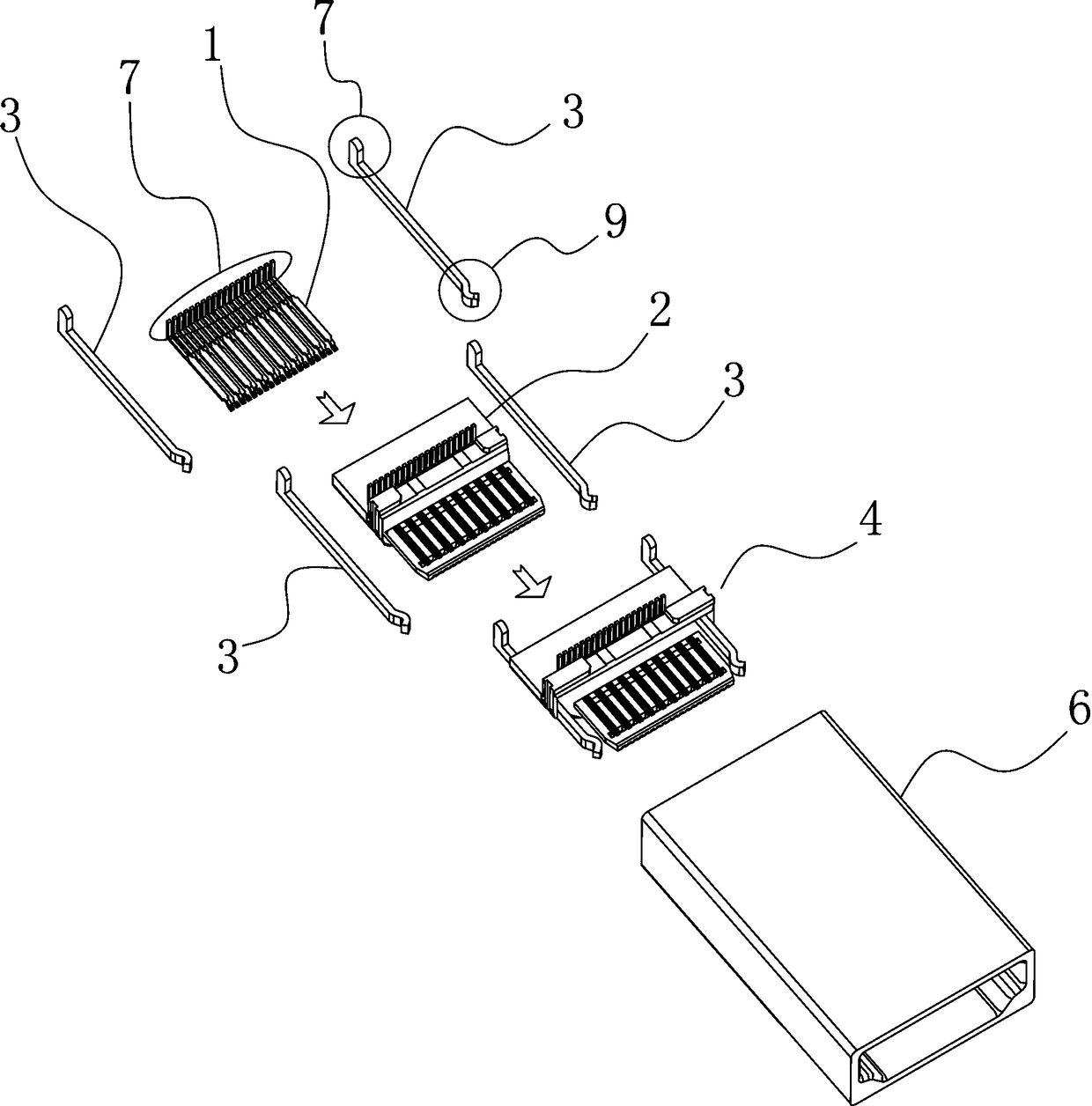

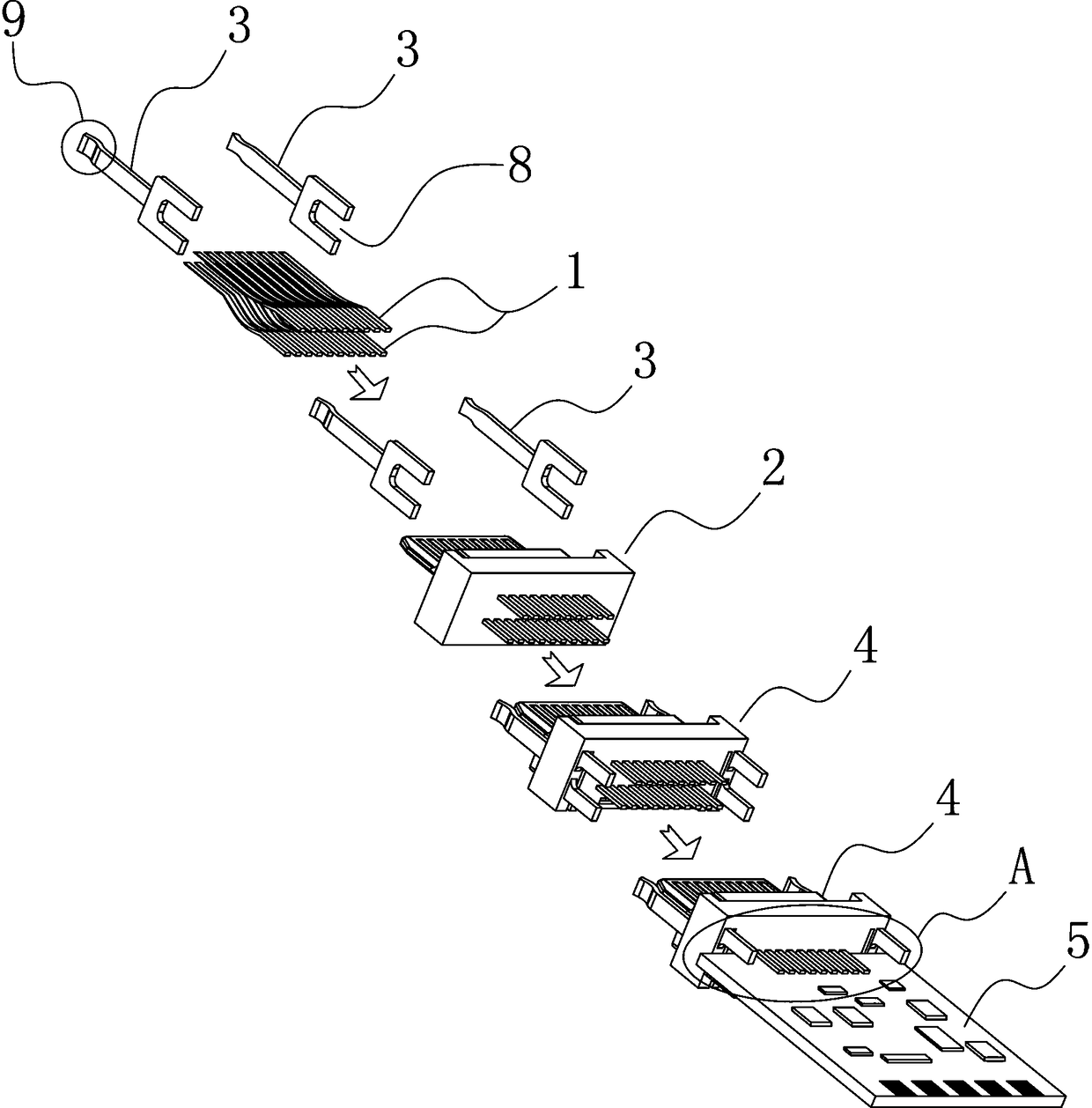

A HDMI connector and a preparation method thereof

InactiveCN109004422ASmall sizeKeep it thinContact member assembly/disassemblyCoupling protective earth/shielding arrangementsEngineeringTest requirements

The invention discloses an HDMI connector and a preparation method thereof. The structure of the HDMI connector mainly comprises a first module which performs injection molding of a PIN pin, and a grounding elastic piece with a snap joint function, and the grounding elastic piece and the first module form a second module. The PIN pin and the grounding elastic piece are in conductive connection with a PCB separately, and the second module and the PCB are sleeved by a plastic shell. The metal elastic piece is added around the plane of the PIN pin of an HDMI connector female seat, so as to strengthen the strength of male and female connectors when the connectors are inserted into each other, a grounding pin can be provided for the connectors, conditions are provided for an electronic productto meet the EMI test requirements, and the iron shells of the connectors are removed, thereby achieving the effect of reducing the sizes of the connectors.

Owner:陈晋益

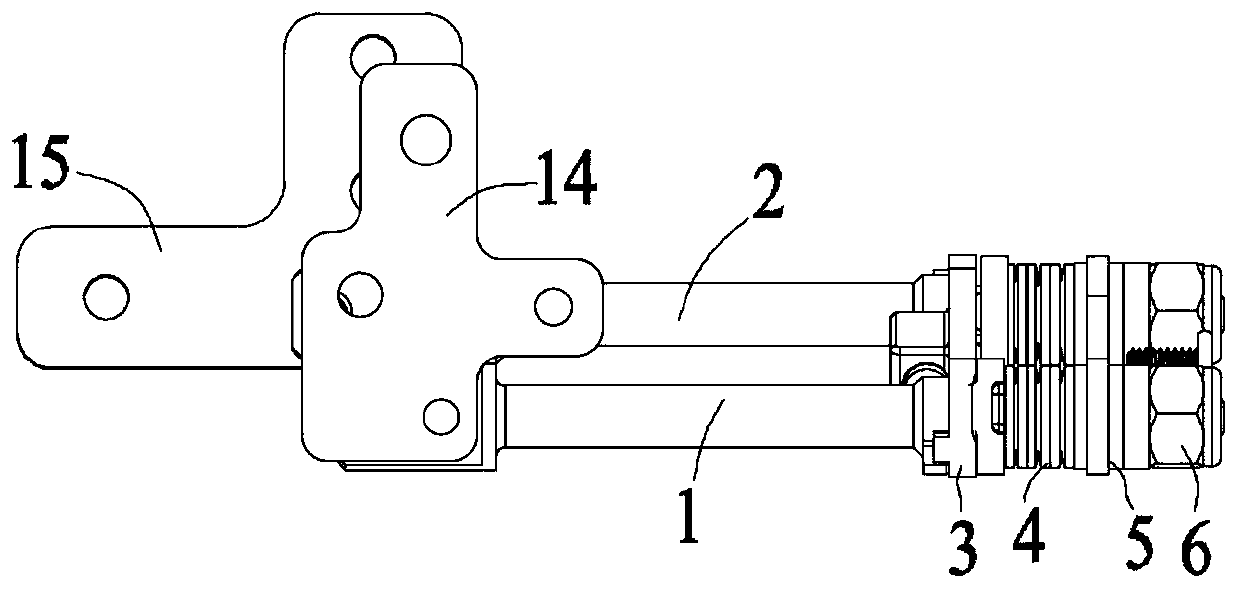

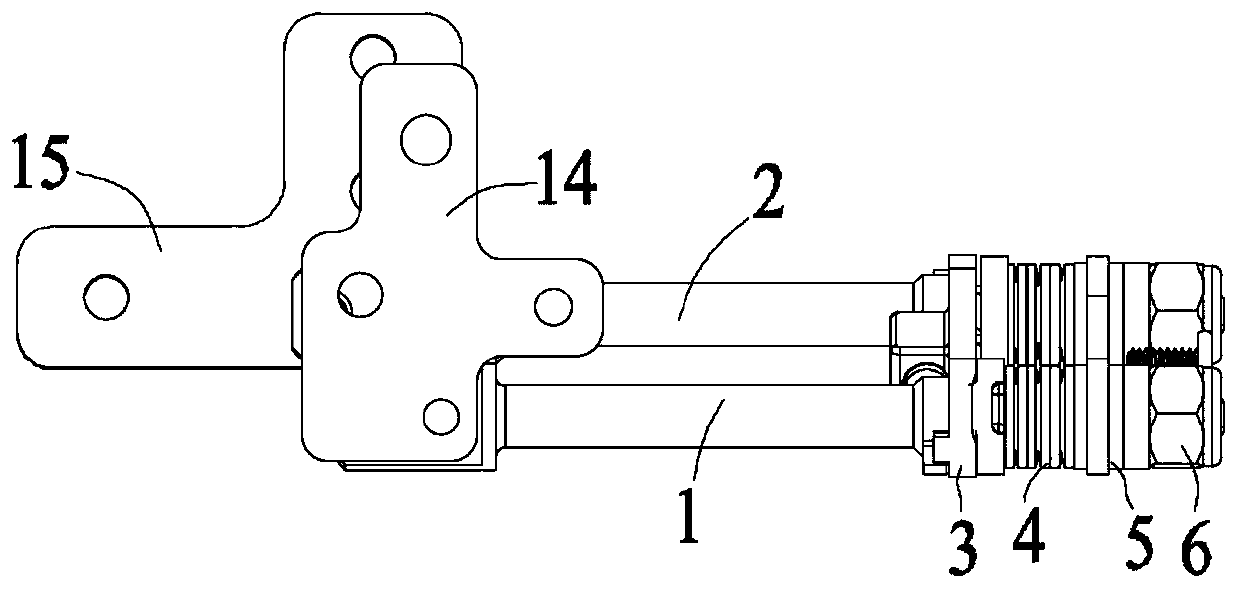

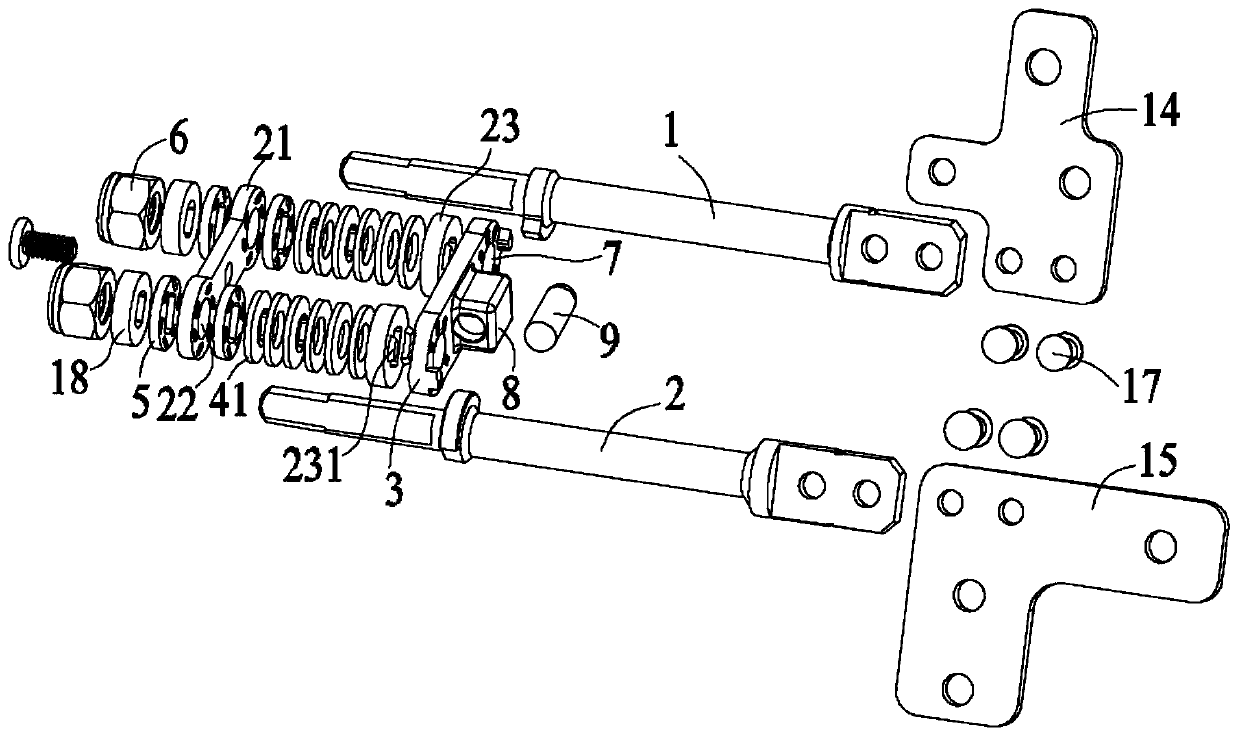

Rotating shaft mechanism for notebook computer

InactiveCN110792687AKeep it thinSimple structure installationDigital data processing detailsPivotal connectionsEngineeringMechanical engineering

The invention discloses a rotating shaft mechanism for a notebook computer. The rotating shaft mechanism comprises a first rotating shaft, a second rotating shaft, a supporting plate connecting the first rotating shaft with the second rotating shaft, an elastic assembly, a plurality of friction sheets and stop blocks, wherein the supporting plate, and the elastic assembly and the friction sheets sequentially sleeve the first rotating shaft, the second rotating shaft and are extruded and fixed through the stop blocks; a second supporting plate connecting the first rotating shaft with the secondrotating shaft is arranged between the stop blocks and the elastic assembly, wherein two second through holes allowing force storing portions of the first rotating shaft and the second rotating shaftto pass through are correspondingly formed in the second supporting plate, and the plurality of friction sheets are located on the two sides of the second supporting plate correspondingly; a cam is arranged between the supporting plate and the elastic assembly, and a groove matched with a convex block of the cam is formed in the surface, opposite to a sliding block base, of the supporting plate.According to the rotating shaft mechanism for the notebook computer, 360-degree rotation positioning can be realized, adjustment of center distances for the rotating shafts can be achieved only by adjusting the length of a sliding top block, and therefore the rotating shaft mechanism is suitable for notebook computers with different specifications and sizes.

Owner:KUNSHAN KERSEN SCI & TECH

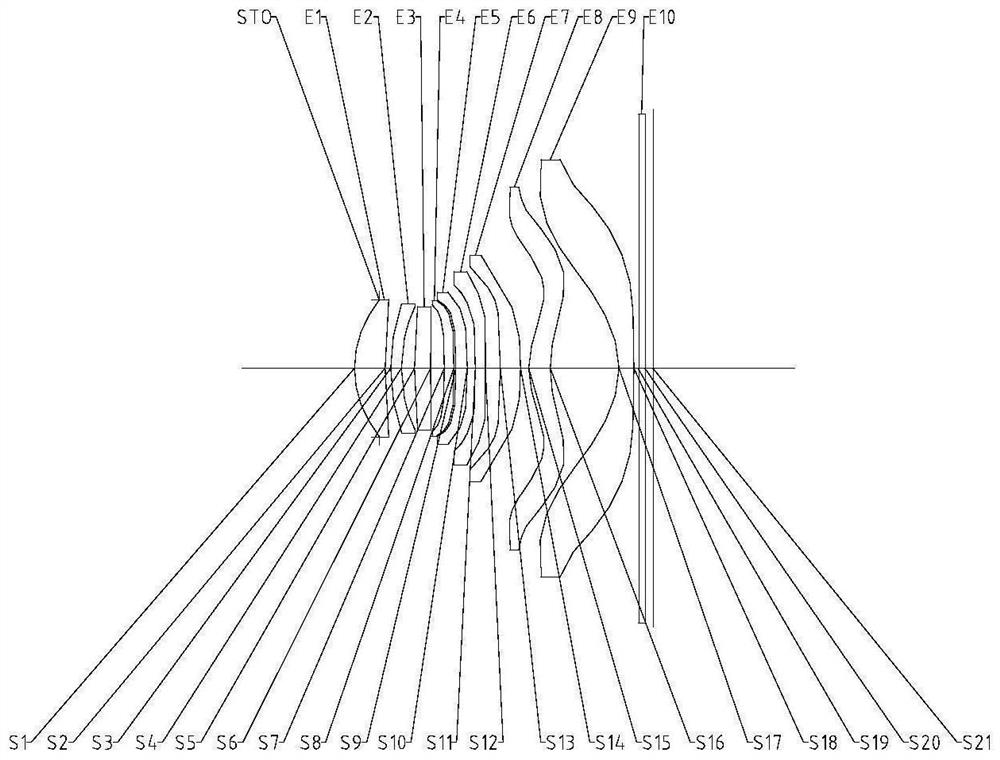

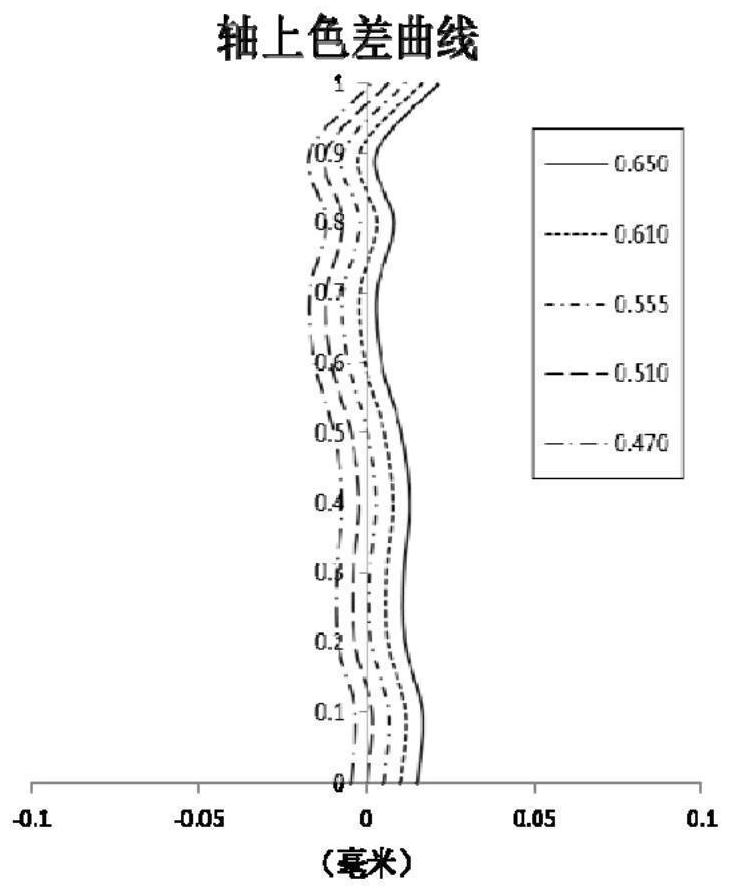

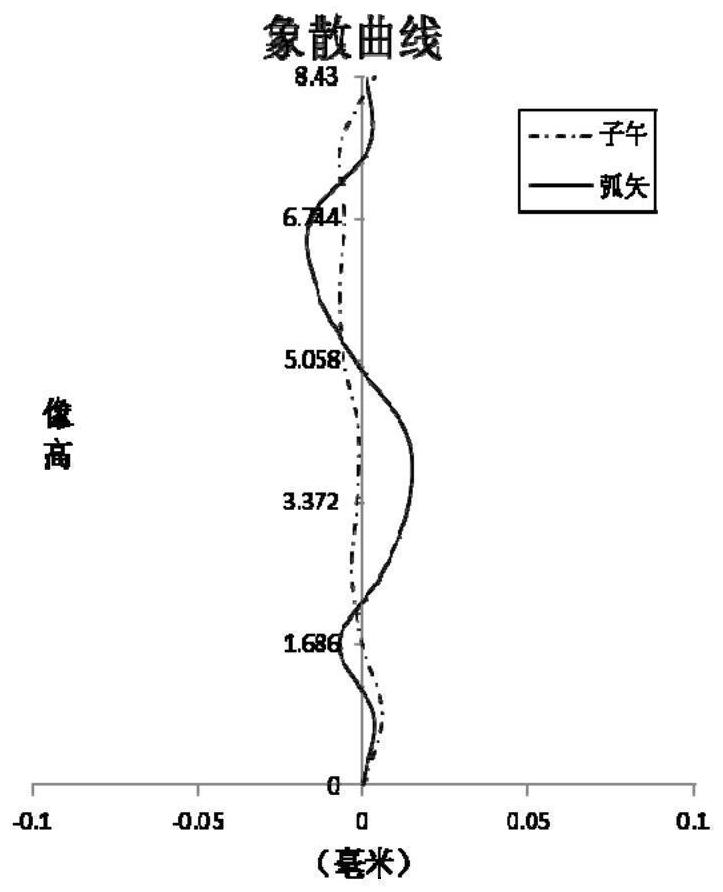

Imaging system

The invention provides an imaging system, which comprises a first lens, a second lens, a third lens, a fourth lens, a fifth lens and a sixth lens from the light incident side to the light emergent side of the imaging system, a second lens; the third lens has positive focal power; the fourth lens has focal power; the surface, facing the light incident side, of the fifth lens is a concave surface, and the surface, facing the light emergent side, of the fifth lens is a convex surface; the sixth lens has negative focal power; the surface, facing the light incident side, of the seventh lens is a concave surface, and the surface, facing the light emergent side, of the seventh lens is a convex surface; the eighth lens has focal power; the surface, facing the light emitting side, of the ninth lens is a convex surface; wherein the half ImgH of the diagonal length of an effective pixel area on the imaging surface of the imaging system and the on-axis distance TTL from the surface, facing the incident side, of the first lens to the imaging surface meet the condition that TTL / ImgH is smaller than 1.3. The problem that in the prior art, an imaging system is poor in performance is solved.

Owner:ZHEJIANG SUNNY OPTICAL CO LTD

Backlight device

Owner:沈育浓

Mahjong machine and tile picking and carrying system thereof

PendingCN111054057ANot easy cardRealize functionIndoor gamesStructural engineeringMechanical engineering

The invention relates to a mahjong machine and a tile picking and carrying system thereof. The tile picking and carrying system comprises a tile conveying device, a stacking and pushing device, a horizontal pushing tile feeding device and a slope tile feeding device. The slope tile feeding device comprises a tile feeding assembly and a tile lifting assembly, the tile feeding assembly comprises a tile storage groove, a tile feeding push head and a tile feeding driving mechanism, the tile lifting assembly comprises a tile lifting supporting plate and a tile lifting driving mechanism of the tilelifting supporting plate, and the horizontal pushing tile feeding device is installed outside the tile lifting assembly; the tile feeding device and the horizontal pushing tile feeding device are located on the same side of the mahjong machine and are adjacent inside and outside, the stacking and pushing device and the tile lifting assembly are arranged at two ends of the tile storage groove, thehorizontal pushing tile feeding device is arranged in the middle of the tile storage groove, the tile storage groove at least comprises a straight line section, a bottom wall of the straight line section is formed by a tile bearing plate in the horizontal pushing tile feeding device, an outer side wall of the straight line section is formed by a tile pushing plate in the horizontal pushing tile feeding device, and the tile lifting assembly and the horizontal pushing tile feeding device are located on adjacent sides of the mahjong machine respectively. The tile picking and carrying system is simple and reasonable in structure, low in manufacturing cost, stable and reliable in operation and few in fault.

Owner:ZHEJIANG CHAOSHENG ELECTROMECHANICAL TECH CO LTD

A kind of ogs capacitive touch screen and manufacturing method thereof

InactiveCN103257774BKeep it thinDiversified inputInput/output processes for data processingCapacitanceFlexible circuits

The invention discloses a one glass solution (OGS) capacitive touch screen which comprises a PET protective film, optical cement, an ITO functional piece and a soft circuit board, wherein the PET protective film, the optical cement and the ITO functional piece are arranged in an up-down overlapping mode, and the soft circuit board is attached to the upper surface or the lower surface of the ITO functional piece. The invention further discloses a manufacturing method of the OGS capacitive touch screen. The manufacturing method of the OGS capacitive touch screen includes the following steps: 1, preparing the PET protective film, and preparing the soft circuit board; 2, converting a functional pattern into a laser path; 3, leading the laser path into a laser device; 4, etching a large-piece ITO plate by using the laser device; 5, dividing the large-piece ITO plate and forming the single ITO functional piece in a splicing and combined mode; 6, connecting the soft circuit board to the ITO functional piece, and carrying out electrical logging on functions; 7, splicing the ITO functional piece and the PET protective film; 8, carrying out the electrical logging on finished products. The OGS capacitive touch screen and the manufacturing method of the OGS capacitive touch screen are rich in color, capable of preparing soft touch screens, simplified in production procedure, less in investment of production lines and environment-friendly in production, and products have higher competitiveness.

Owner:LEAD COMM

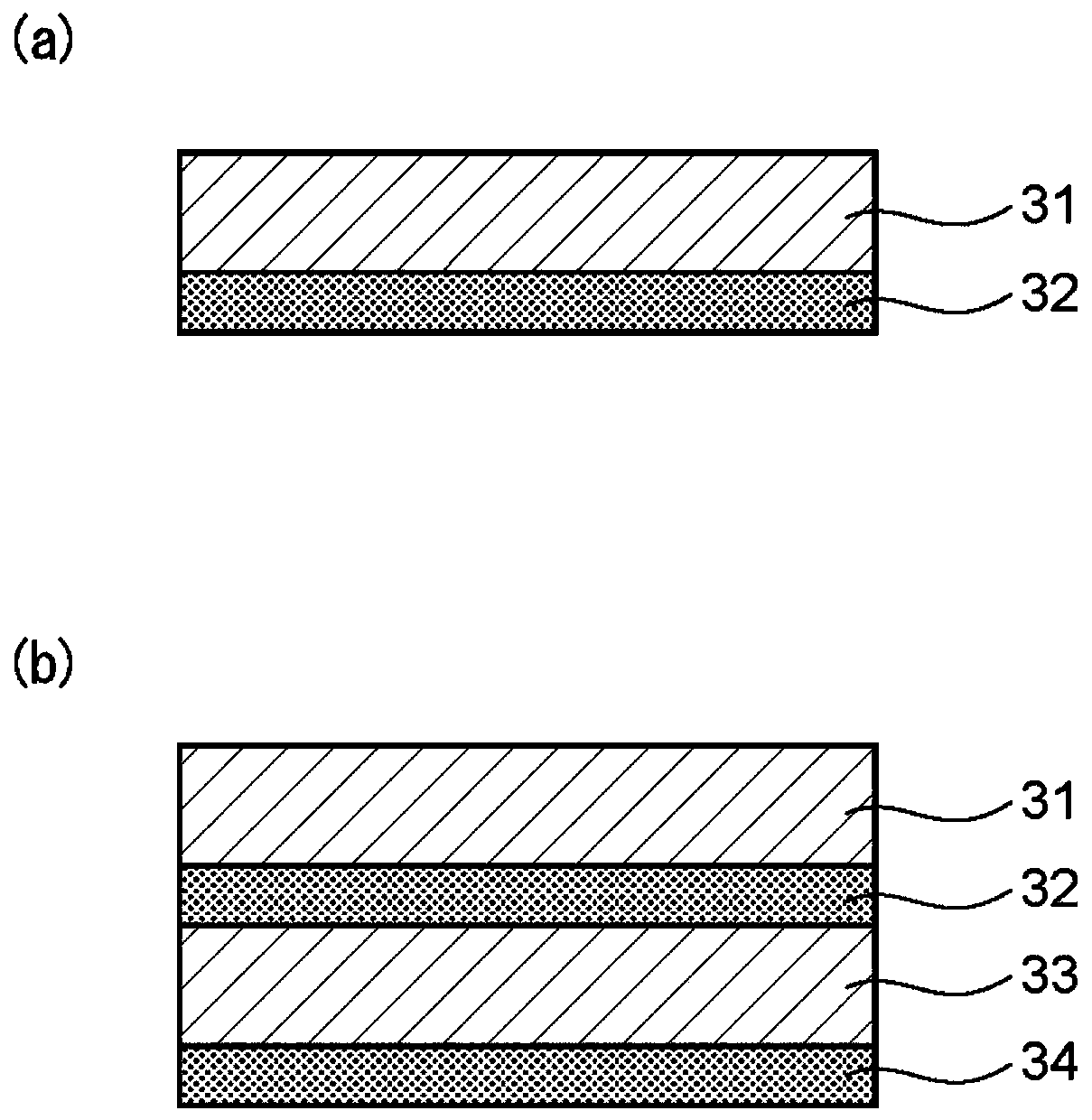

Polarizing plate with surface protective film

ActiveCN110531455ASuppress display unevennessKeep it thinPolarising elementsPhotoelasticityPolarizer

The present invention addresses the problem of providing a polarizing plate with a surface protective film, said polarizing plate being capable of suppressing display unevenness when bonded to a display unit. The polarizing plate with a surface protective film according to the present invention has: a polarizer; a first protective layer and a second protective layer arranged on the two sides of the polarizer, and a surface protective film that can be temporarily attached to the side, opposite to the polarizer, of the first protective layer in a strippable mode. The second protective layer hasan in-plane phase difference Re (550) of 250 nm to 350 nm, a thickness of 30 [mu] m or less, a photoelastic coefficient of 10 * 10<-12> m<2> / N or more, and a thickness of 80 [mu] m or more.

Owner:NITTO DENKO CORP

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com