A kind of conductive nanofiber film and preparation method thereof

A nanofiber membrane, conductive nanotechnology, applied in the direction of fiber processing, fiber type, fiber chemical characteristics, etc., can solve the problems of cumbersome silver plating process, large amount of palladium, uneven silver plating layer, etc., and achieves novel method, repeatability High, simple process effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

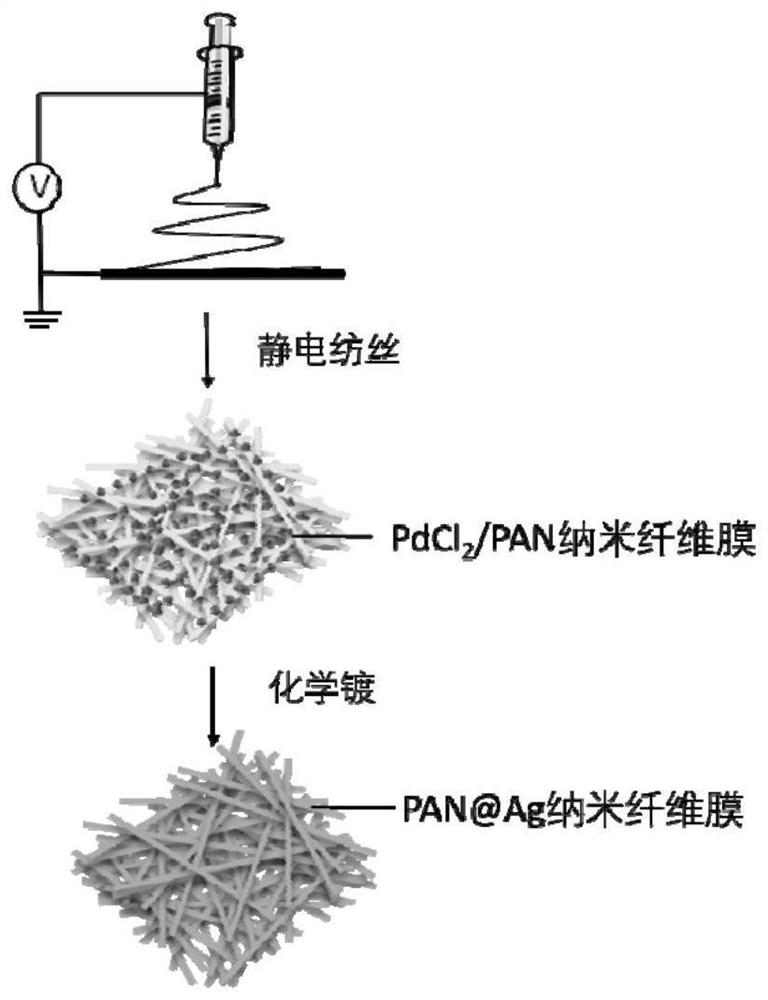

Method used

Image

Examples

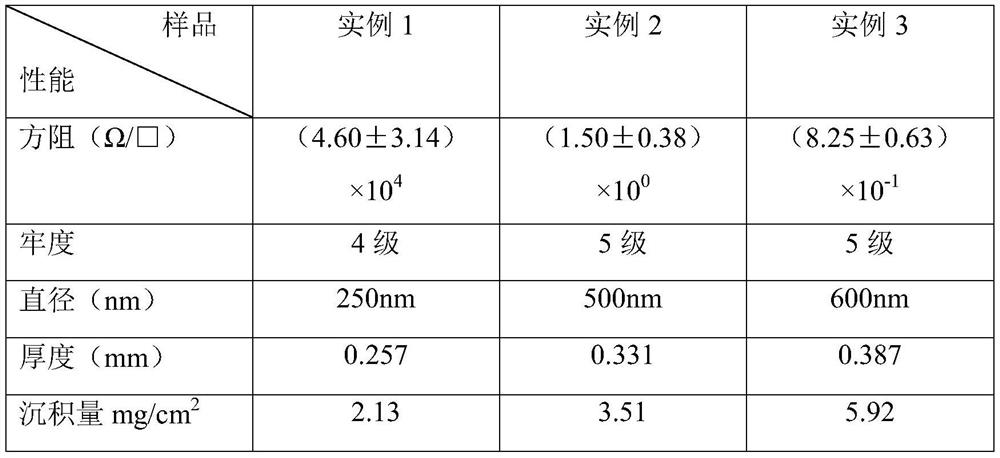

Embodiment 1

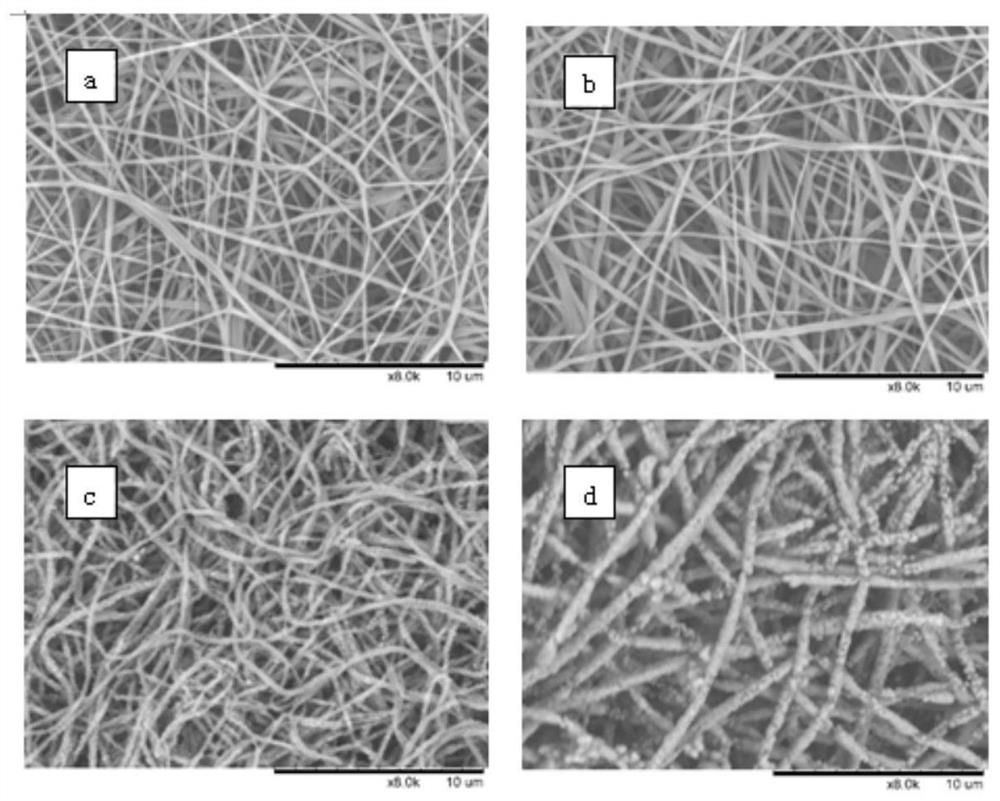

[0034] (1) Dissolve 1 mg of palladium chloride in DMF at room temperature for 8 hours to obtain PdCl with a concentration of 1 ppm 2 solution, adding PAN into the solution, magnetically stirring the spinning solution at 70° C. and 500 rpm for 4 hours until the PAN is completely dissolved to obtain a spinning solution of 8% wt PAN. Stand still for 5 minutes to remove the air bubbles in the solution to obtain a uniform and stable spinning solution.

[0035] (2) Electrospinning process parameters are: voltage 18kV, the distance from the needle of the spinning solution injector to the receiving plate of the rotating receiving system is 12cm, the diameter of the spinneret of the electrospinning device is 0.67-0.90mm, and the spinning speed is 6.5ml / h, the spinning time is 8h, the ambient temperature is 25°C, and the ambient humidity is 60%. A uniform nanofiber membrane was obtained by electrospinning, and a piece of electrospun nanofiber membrane with a size of 5*5cm was cut, with...

Embodiment 2

[0038] (1) Dissolve 1 mg of palladium chloride in DMF at room temperature for 8 hours to obtain PdCl with a concentration of 1 ppm 2 solution, adding PAN into the solution, magnetically stirring the spinning solution at 70° C. and 500 rpm for 4 hours until the PAN is completely dissolved to obtain a spinning solution of 8%wt PAN. Stand still for 5 minutes to remove the air bubbles in the solution to obtain a uniform and stable spinning solution.

[0039] (2) Electrospinning process parameters are: voltage 18kV, the distance from the needle of the spinning solution injector to the receiving plate of the rotating receiving system is 12cm, the diameter of the spinneret of the electrospinning device is 0.67-0.90mm, and the spinning speed is 6.5ml / h, the spinning time is 8h, the ambient temperature is 25°C, and the ambient humidity is 60%. The nanofiber membrane was obtained by electrospinning, and a piece of electrospun nanofiber membrane with a size of 5*5cm was cut, with a mass...

Embodiment 3

[0042] (1) Dissolve 1 mg of palladium chloride in DMF at room temperature for 8 hours to obtain PdCl with a concentration of 1 ppm 2 solution, adding acrylonitrile into the solution, magnetically stirring the spinning solution at 70° C. and 500 rpm for 4 hours until PAN was completely dissolved to obtain a spinning solution of 8% wt acrylonitrile. Stand still for 5 minutes to remove the air bubbles in the solution to obtain a uniform and stable spinning solution.

[0043] (2) Electrospinning process parameters are: voltage 18kV, the distance from the needle of the spinning solution injector to the receiving plate of the rotating receiving system is 12cm, the diameter of the spinneret of the electrospinning device is 0.67-0.90mm, and the spinning speed is 6.5ml / h, the spinning time is 8h, the ambient temperature is 25°C, and the ambient humidity is 60%. The nanofiber membrane was obtained by electrospinning, and a piece of electrospun nanofiber membrane with a size of 5*5cm wa...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com