Convex and concave curtain wall plate

A sheet and curtain wall technology, applied in the field of convex curtain wall sheets, can solve the problems of sheet deformation, breakage, and volume increase, and achieve the effect of thin sheet shape, large contact area, and not easy to break

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

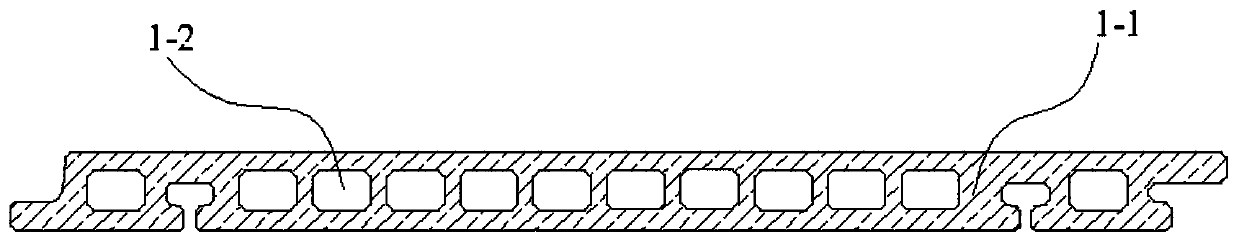

[0063] The raw material slurry used to prepare the pendant plate 1 is processed by a wet forming process, a semi-finished plate with a specific shape is obtained by high-pressure extrusion molding of the raw slurry, and the semi-finished plate is sintered at a high temperature to obtain a solidified and shaped pendant plate 1. Or the dry powder molding process is used to process the raw material dry powder used to prepare the pendant plate 1, and the raw material dry powder is extruded in a specific mold under high pressure, and then kiln fired to obtain a solidified and shaped pendant plate 1. Can choose clay, dry pottery powder, china clay, dry china clay or ultra-high performance concrete (Ultra-High Performance Fibre Reinforced Concrete, UHPC for short) slurry, UHPC dry powder as raw materials. The finished pendant plate 1 is a solid plate with raised clamping blocks 2 integrally formed on the surface. Different shapes of molds can be used according to actual construction ne...

Embodiment 2

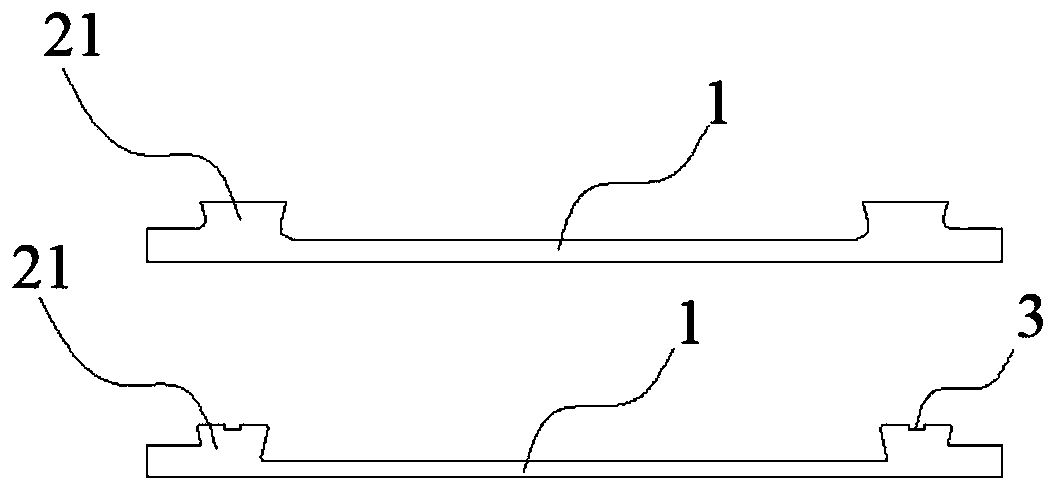

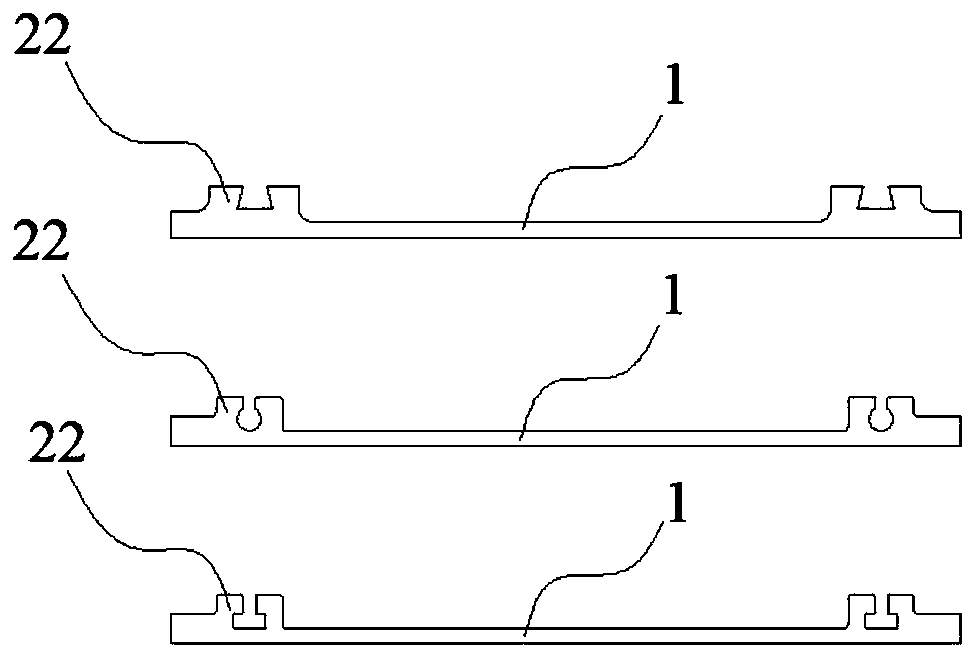

[0067] In this embodiment, clay slurry is used as the raw material for the plate, and a solid ceramic plate 11 is prepared according to the method provided in Example 1. The four corners of the surface of the ceramic plate 11 are respectively integrally formed with dovetail clamps 21, the cross section of which is wide at the top and narrow at the bottom. Dovetail type, the corner of the joint between the clamping block and the plate body is 75°. The rear view of pottery plate 11 is as Figure 8 shown in a. Compared with the traditional hollow ceramic plate, the solid ceramic plate 11 used in this embodiment avoids technical problems such as damage to the plate structure due to humid air and rain and snow entering the ceramic plate cavity and causing safety hazards.

[0068] A pendant connector 4 that can be closely attached to the dovetail clamp block 21 of the ceramic plate 11 and surface-contacted is provided. The pendant connector 4 can be selected from metal profiles, stampe...

Embodiment 3

[0073] In this embodiment, dry pottery powder is used as the raw material of the plate, and a solid ceramic plate 11 is prepared according to the method provided in Example 1. A set of opposite sides on the surface of the ceramic plate 11 are respectively integrally formed with dovetail clamping blocks 21, the cross section of which is upper, wide and lower. Narrow dovetail shape, the corner of the joint between the clamp block and the plate body is 75°, the two ends of the dovetail clamp block 21 are provided with reserved fastener holes 3, the rear view of the ceramic plate 11 is as follows Picture 14 Shown.

[0074] A pendant connector 4 that can be closely attached to the dovetail clamp block 21 of the ceramic plate 11 and surface-contacted is provided. The pendant connector 4 can be selected from metal profiles, stamped metal parts or other non-metallic materials that can be used for external hanging structures. The pendant connector 4 of this embodiment is an aluminum alloy...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Inclination | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com