One glass solution (OGS) capacitive touch screen and manufacturing method thereof

A technology of capacitive touch screen and manufacturing method, which is applied to the input/output process of electrical digital data processing, instruments, and data processing, etc., can solve the problems of only flat products, single product color, long processing flow, etc., and achieves simplified pattern process, Satisfy batch consistency and design flexible effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

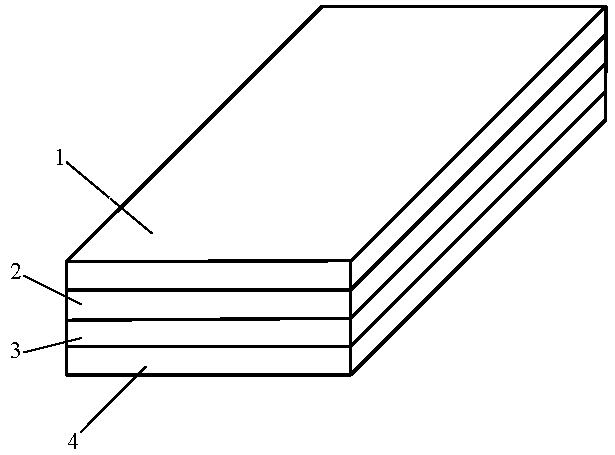

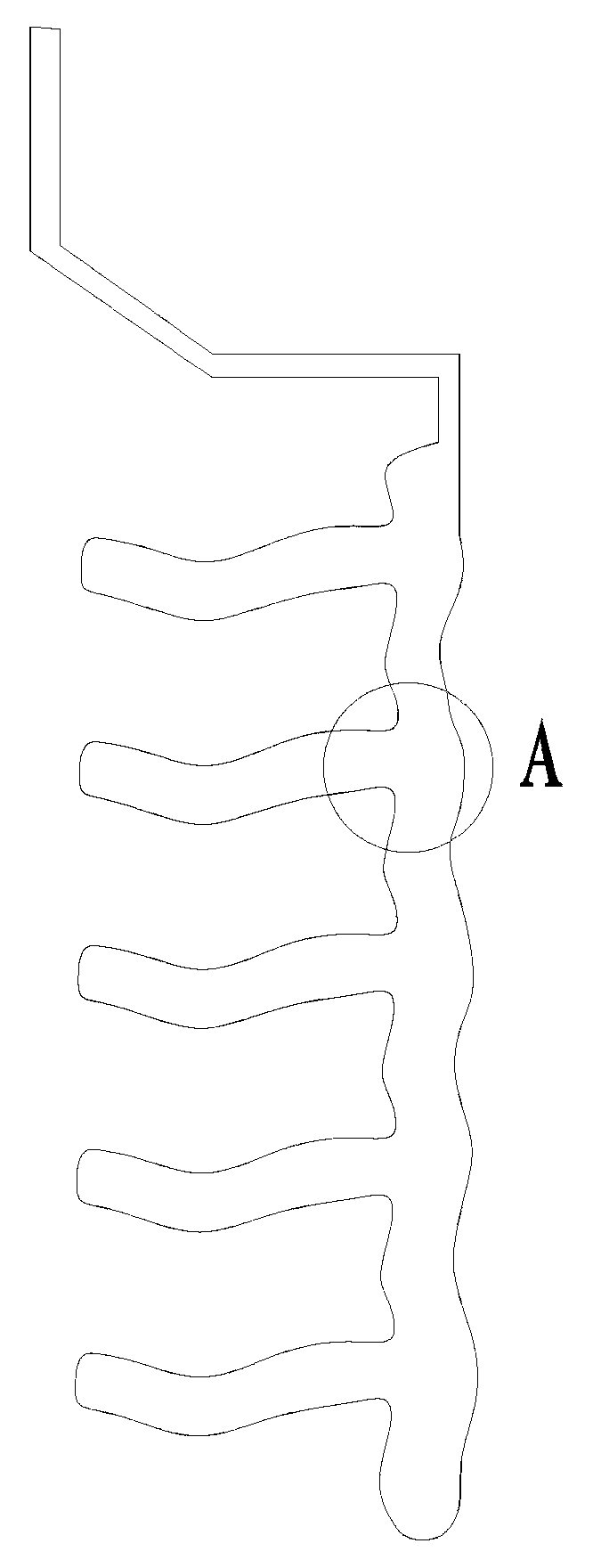

[0027] The invention discloses an OGS capacitive touch screen. see figure 1 , which includes: PET protective film 1 (also called high-temperature-resistant polyester film) stacked up and down, optical adhesive 2 (also called OCA), ITO functional sheet 3 (also called indium tin oxide), and pasted on ITO A flexible circuit board 4 (also known as FPC) on the upper or lower surface of the functional sheet. The ITO functional sheet displays images and receives external touch commands, and the flexible circuit board 4 connected to it transmits image data and touch commands, and the PET protective film attached to it plays a protective role in preventing scratches and bruises.

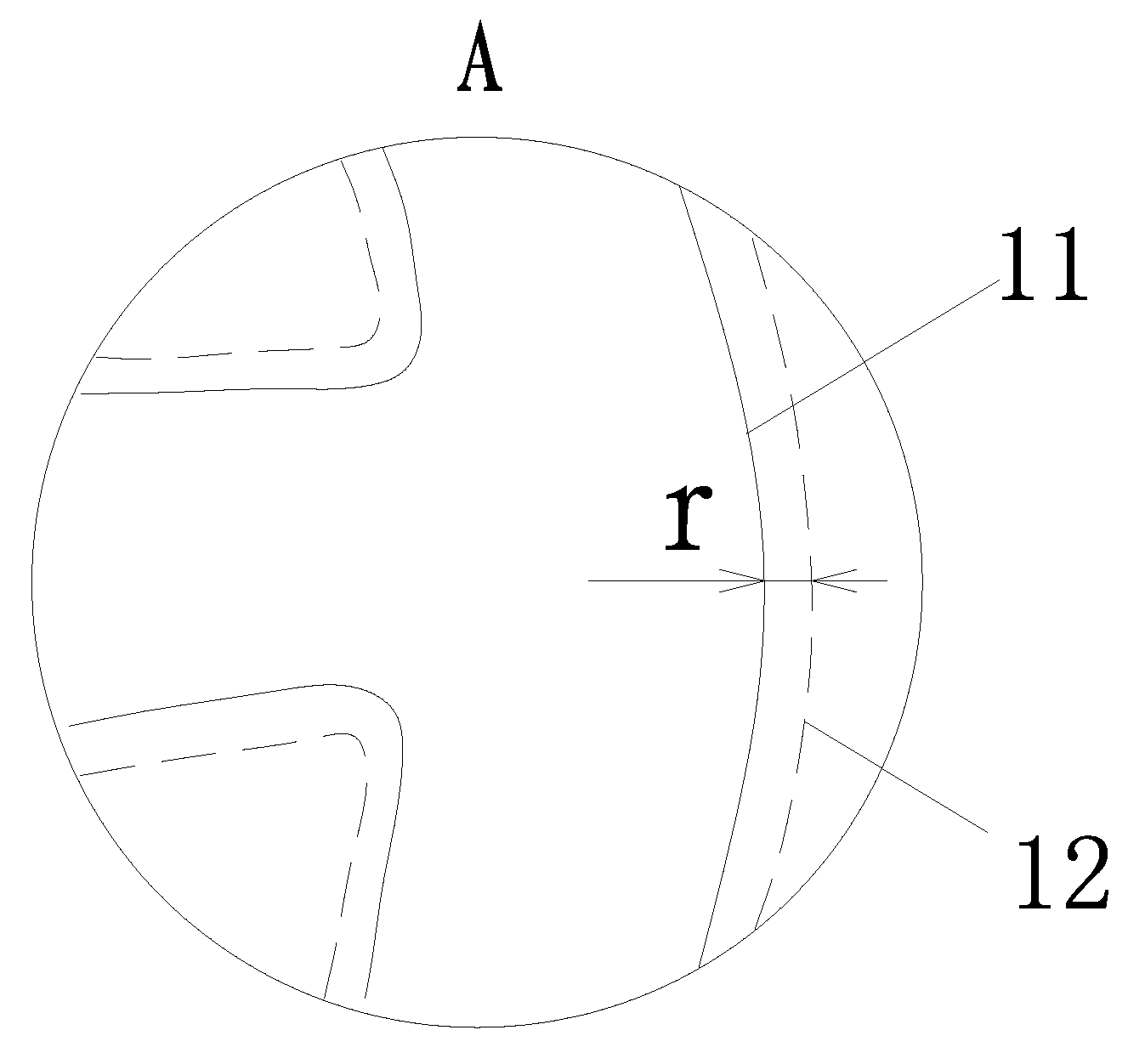

[0028] In a preferred embodiment, a circle of colored layers is screen-printed around the lower surface of the PET protective film. This layer can be a solid color block, such as a black frame, a red frame, a metallic color frame, etc., or it can be a variety of colorful patterns. In the past, the OGS colo...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com