Mechanical thin film keyboard

A thin-film keyboard and mechanical technology, applied to electrical components, electric switches, emergency springs, etc., can solve the problems of high cost, heavy volume, etc., and achieve the effects of long life, high sensitivity, and increased mechanical feel

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

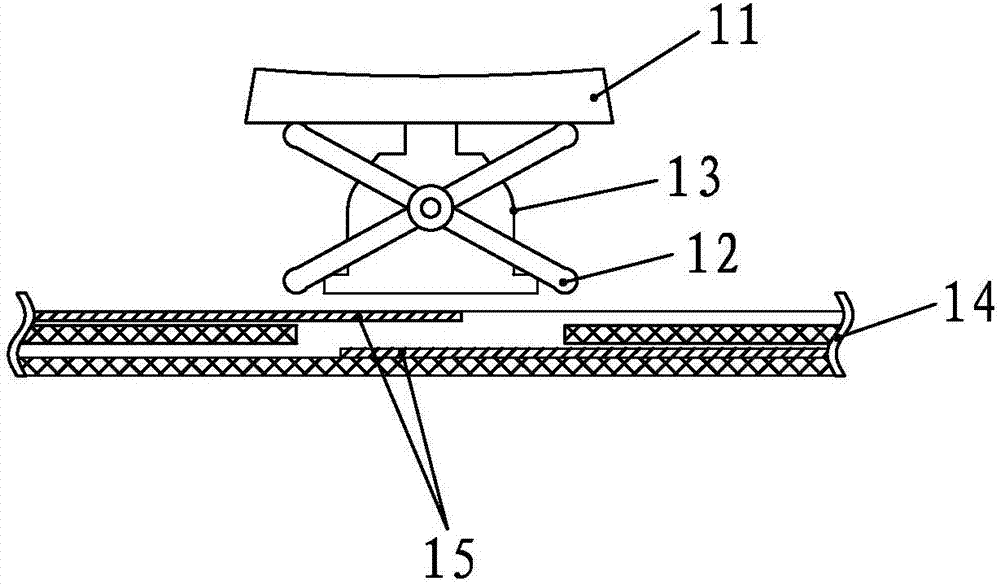

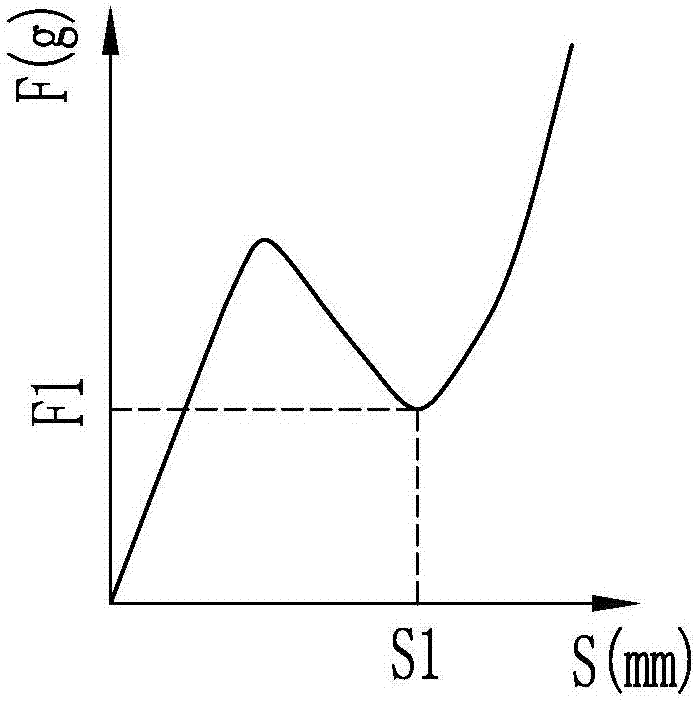

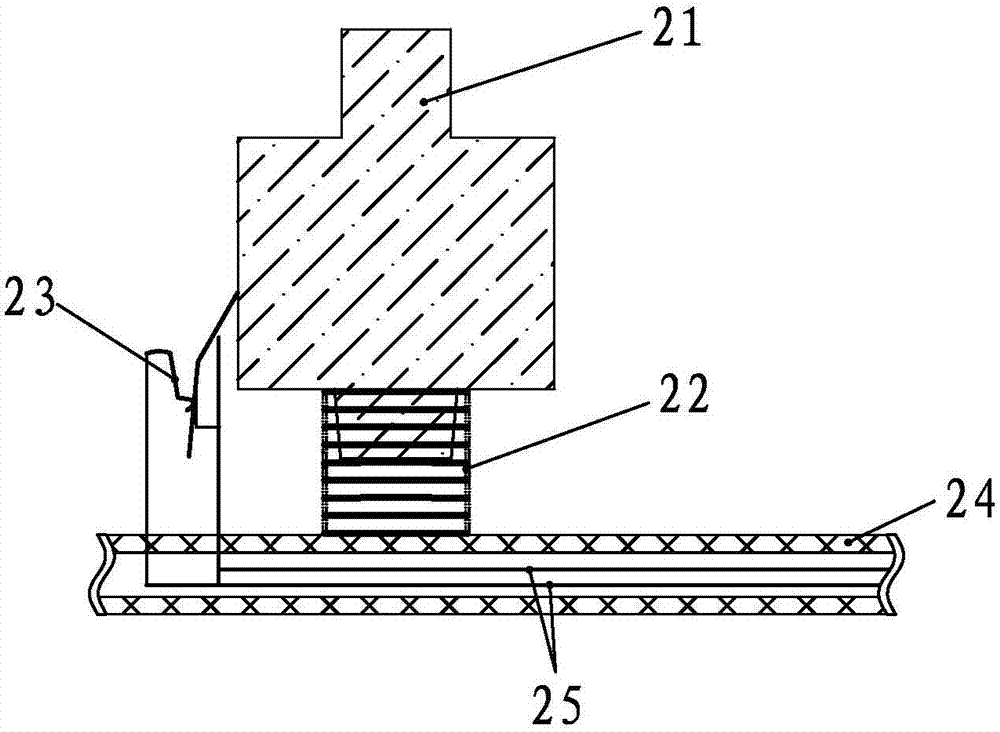

[0036] refer to Figure 5 , the mechanical membrane keyboard provided by the present invention includes: a metal support layer as a supporting base layer; a thin film circuit layer 31 bonded to the metal support layer, and the thin film circuit layer 31 is provided with electrode contact points for internal conduction of the thin film circuit layer 31 The conduction of the line; the X-shaped bracket 32 arranged on one side of the thin film circuit layer 31; one end of the X-shaped bracket 32 is fixedly connected to the metal support layer, and the other end is fixedly connected to the keycap 33; the inner side of the keycap 33 is provided with a corresponding thin film circuit The inverted bowl-shaped silicone button 34 of the layer 31, the mouth of the silicone button 34 is installed on the inside of the keycap 33, and the top of the silicone button 34 protrudes corresponding to the thin film circuit layer 31; There is a linear spring 35, by pressing the key cap 33 and th...

Embodiment 2

[0039]On the basis of the structure of the mechanical membrane keyboard described in Embodiment 1 above, a first electrode is provided in the top protrusion of the silicone button 34, and a second electrode and a conductive circuit connecting the second electrode are provided in the thin film circuit layer 31. , so as to obtain a capacitive mechanical membrane keyboard to further realize non-contact conduction and improve its durability and comfortable operation; when pressing the silicone button 34, by changing the distance between the first electrode and the second electrode to change The capacitance value between the first electrode and the second electrode, so that the conduction of the conductive circuit can be realized through the change of the capacitance value.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com