Elastic embossing warp knitted blanket and preparation method thereof

A technology for embossed printing and blankets, applied in blankets, warp knitting, dyeing and other directions, can solve the problems of poor toughness and elasticity of blankets, and achieve the effect of convenient care

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

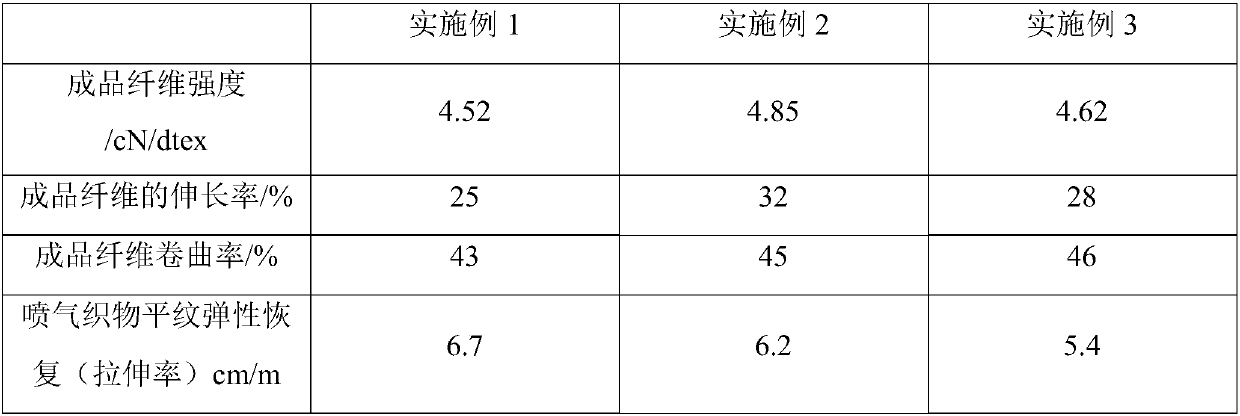

Embodiment 1

[0019] An elastic embossed printing warp knitted blanket, in parts by weight, said blanket comprises 12 parts of PET polyester, 5 parts of nylon, 35 parts of wool, 2 parts of corn fiber, 1 part of palm fiber, and 20 parts of polyester; said wool The fineness is 16 microns.

[0020] A preparation method for elastic embossed printing warp knitted blanket, comprising the following steps:

[0021] (1) Melt the PET polyester to obtain the as-spun fibers through the spinning box, the metering pump and the spinning assembly in turn, and the as-spun fibers are sequentially cooled, oiled, and wound to obtain POY filaments, wherein the production of the POY filaments is controlled The speed is 4200m / min;

[0022] (2) make described POY silk carry out drafting and twisting through first roller, heating source, cooling plate, twister and second roller successively, and after forming roller stable tension and oiling roller lubrication treatment, winding, The high elastic fiber is obtaine...

Embodiment 2

[0027] An elastic embossed printing warp-knitted blanket, in parts by weight, said blanket comprises 18 parts of PET polyester, 14 parts of nylon, 58 parts of wool, 8 parts of corn fiber, 5 parts of palm fiber, and 28 parts of polyester; said wool The fineness is 18 microns.

[0028] A preparation method for elastic embossed printing warp knitted blanket, comprising the following steps:

[0029] (1) Melt the PET polyester to obtain the as-spun fibers through the spinning box, the metering pump and the spinning assembly in turn, and the as-spun fibers are sequentially cooled, oiled, and wound to obtain POY filaments, wherein the production of the POY filaments is controlled The speed is 4600m / min;

[0030] (2) make described POY silk carry out drafting and twisting through first roller, heating source, cooling plate, twister and second roller successively, and after forming roller stable tension and oiling roller lubrication treatment, winding, That is to obtain the high elas...

Embodiment 3

[0035] An elastic embossed printing warp knitted blanket, in parts by weight, said blanket comprises 22 parts of PET polyester, 18 parts of nylon, 65 parts of wool, 11 parts of corn fiber, 7 parts of palm fiber, and 35 parts of polyester; said wool The fineness is 19 microns.

[0036] A preparation method for elastic embossed printing warp knitted blanket, comprising the following steps:

[0037] (1) Melt the PET polyester to obtain the as-spun fibers through the spinning box, the metering pump and the spinning assembly in turn, and the as-spun fibers are sequentially cooled, oiled, and wound to obtain POY filaments, wherein the production of the POY filaments is controlled The speed is 4800m / min;

[0038] (2) make described POY silk carry out drafting and twisting through first roller, heating source, cooling plate, twister and second roller successively, and after forming roller stable tension and oiling roller lubrication treatment, winding, The high elastic fiber is obta...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com