Petroleum-engine oil composition and application thereof

A technology for gasoline engine oil and composition, applied in the directions of lubricating composition, petroleum industry, etc., can solve problems such as poor anti-wear performance of gasoline engine oil, and achieve the effects of excellent anti-wear performance, good technical effect and good lubricity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

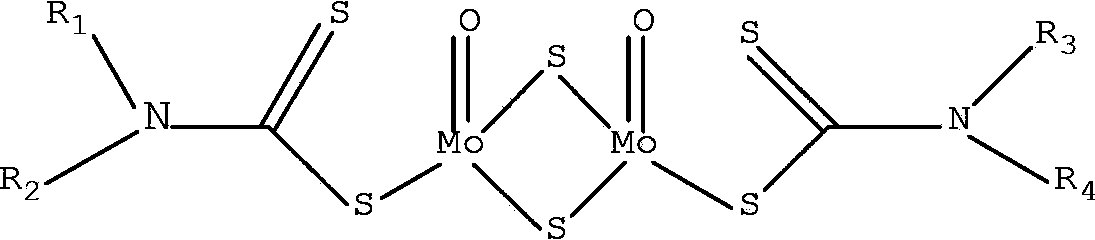

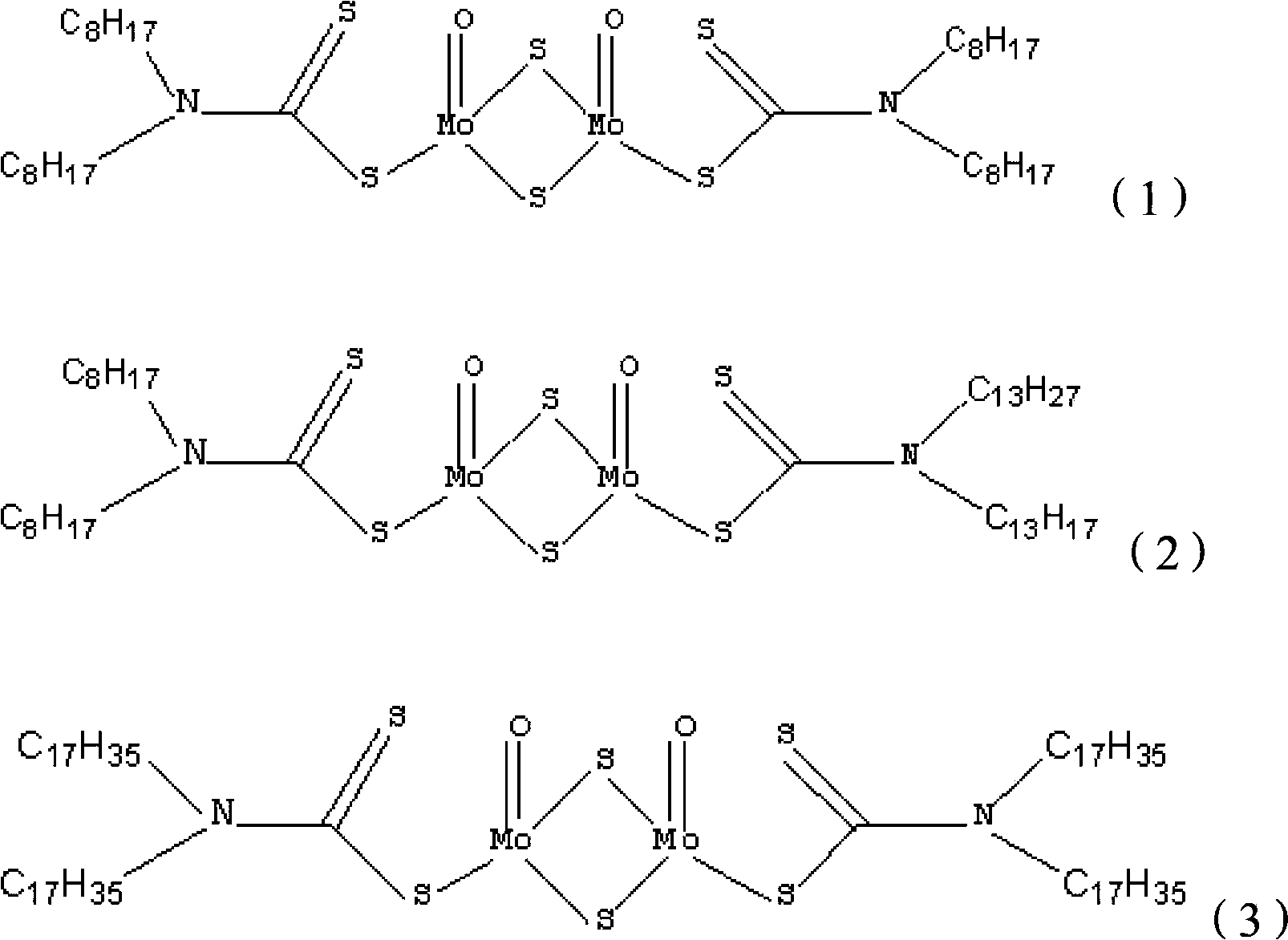

Method used

Image

Examples

Embodiment 1

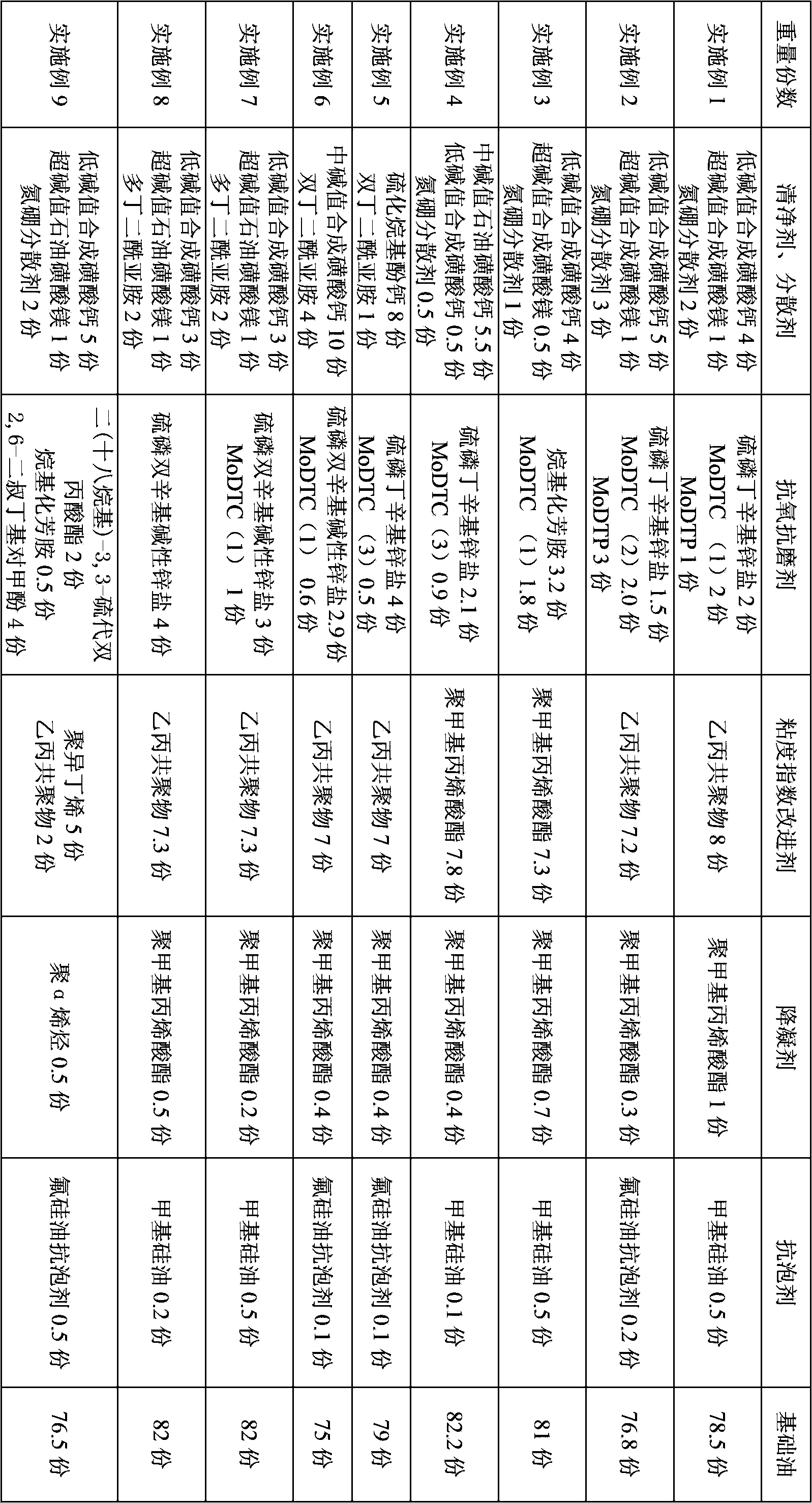

[0028] According to the parts by weight in Table 1, take by weighing respectively 4 grams of low-basic value synthetic calcium sulfonate, 1 gram of super-basic value synthetic magnesium sulfonate, 2 grams of nitrogen-boron dispersant, 2 grams of thiophosphobutyloctyl zinc salt, MoDTC 2 grams, 1 gram of MoDTP, 8 grams of ethylene-propylene copolymer, 1 gram of polymethacrylate, 0.5 grams of methyl silicone oil, 78.5 grams of American Petroleum Institute (API) Group III base oil, heated and stirred at 55 ° C for 1 hour to Completely homogeneous, prepared test oil for later use.

[0029]The anti-wear performance of the composition was evaluated by the determination method of SRV friction coefficient (Q / SH 037.08.044). The SRV friction coefficient test is to test the wear performance of the oil under the conditions of load 50N, temperature 90°C, time 1 hour, frequency 50Hz, stroke 0.5mm. It is required that the SRV friction coefficient of the oil is not greater than 0.07. The te...

Embodiment 2~15

[0034] Prepare the engine oil composition according to each step of [Example 1], but change the consumption and composition of each component. The composition of the engine oil composition is shown in Table 1, and the experimental results are shown in Table 2.

[0035] Table 1

[0036]

[0037] Continued Table 1

[0038]

[0039] Table 2

[0040] Example

[0041] The SRV friction coefficient must be no greater than 0.07 to meet the oil requirements of the engine manufacturer. From the experimental results in the table, it can be seen that the SRV coefficient of the oil does not meet the requirements when MoDTC is not included.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com