Circulating system and method for improving biogas yield of biogas digester

A circulation system and biogas digester technology, applied in the field of aquaculture, can solve problems affecting biogas power generation, high cost, difficult operation of biogas digesters, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0041] In order to enable those skilled in the art to better understand the technical solutions in the present application, the technical solutions in the embodiments of the present application will be clearly and completely described below in conjunction with the accompanying drawings.

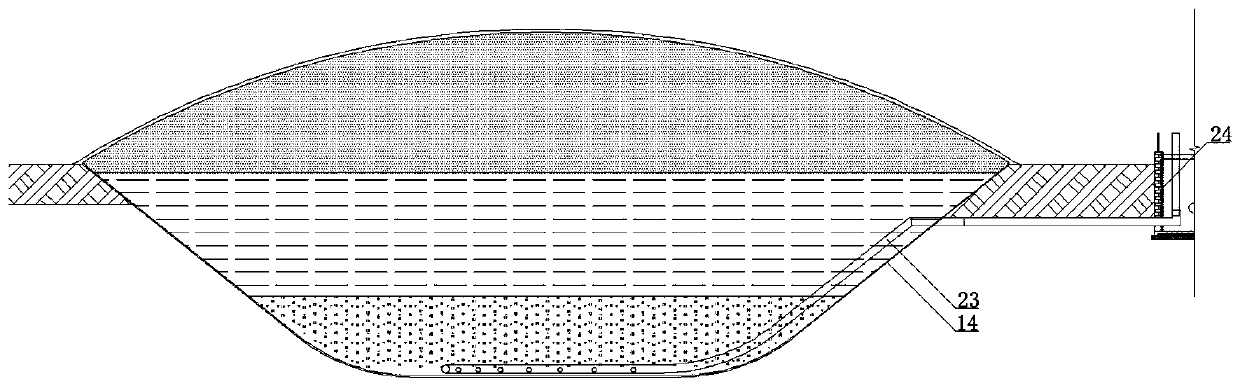

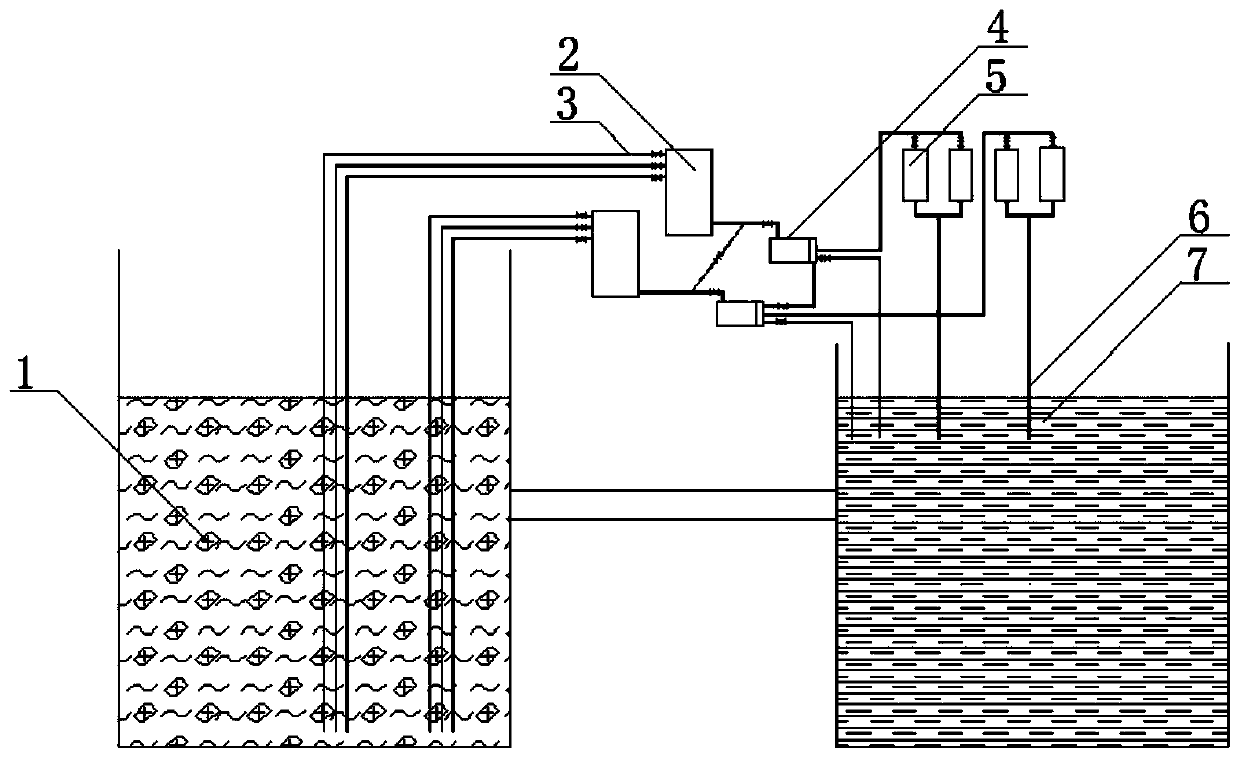

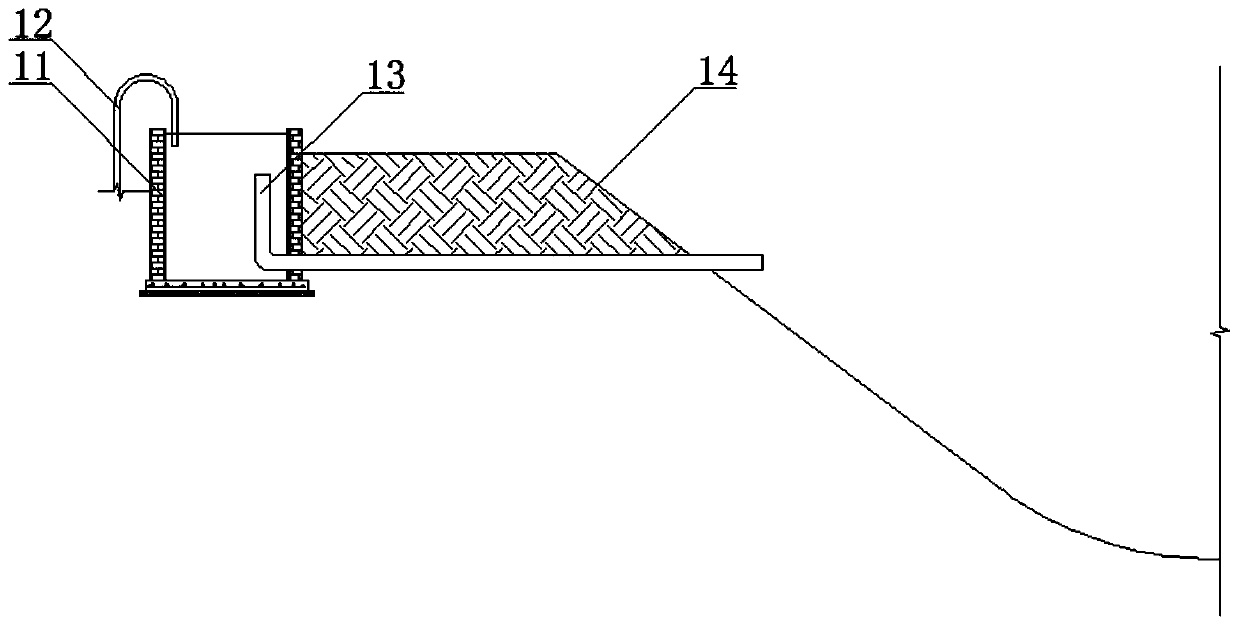

[0042] see Figure 1-8 , a circulation system for improving the gas production of a biogas digester, including a raw septic tank liquid 1, a backflush tank 7, a feed well 11, a biogas digester 14, a liquid outlet pipe well 17, a biogas well 20 and a plurality of The slag discharge well 24, the feed well 11, the biogas digester 14, and the discharge tube well 17 are made of 150 thick C20 concrete cushion, equipped with 12mm diameter rebar, single-layer mesh with a spacing of 200mm, and 240mm small cement bricks for the well wall For masonry, the inner diameter is 1500mm, the dam surface is 500mm, and the bottom, inner, top, and outer parts of the dam surface are exposed, and the 20mm thick wat...

PUM

| Property | Measurement | Unit |

|---|---|---|

| radius | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com