Two-phase anaerobic fermentation method for kitchen waste

A technology for kitchen waste and anaerobic fermentation, applied in fermentation, biochemical equipment and methods, bioreactor/fermenter combination, etc., can solve problems such as inhibition, rot and odor, and reduction of anaerobic fermentation efficiency.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0098] The present invention will be described in further detail below in conjunction with the accompanying drawings and specific embodiments.

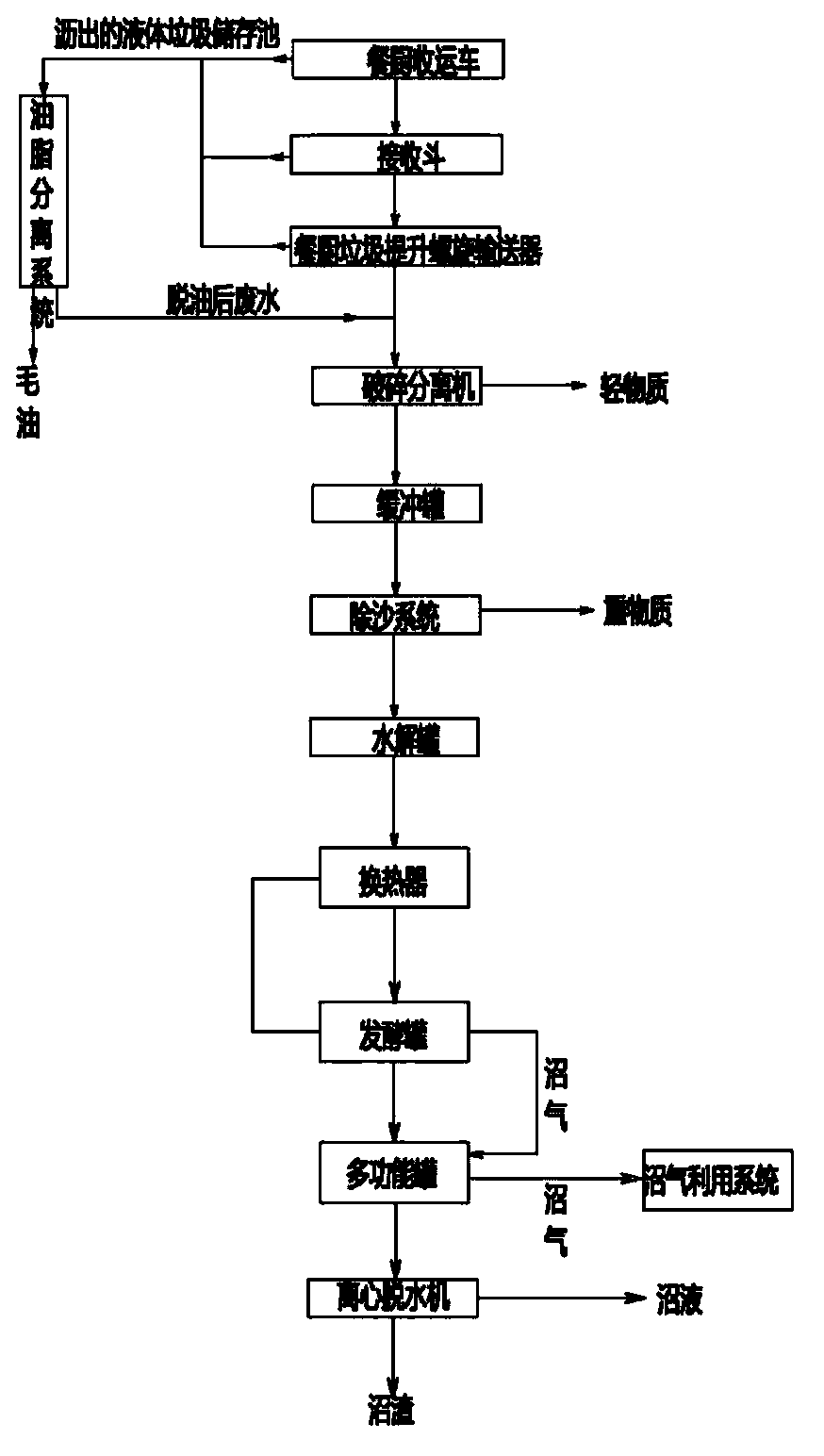

[0099] Such as figure 1 Shown, the food waste two-phase anaerobic fermentation method of the present invention comprises the following steps:

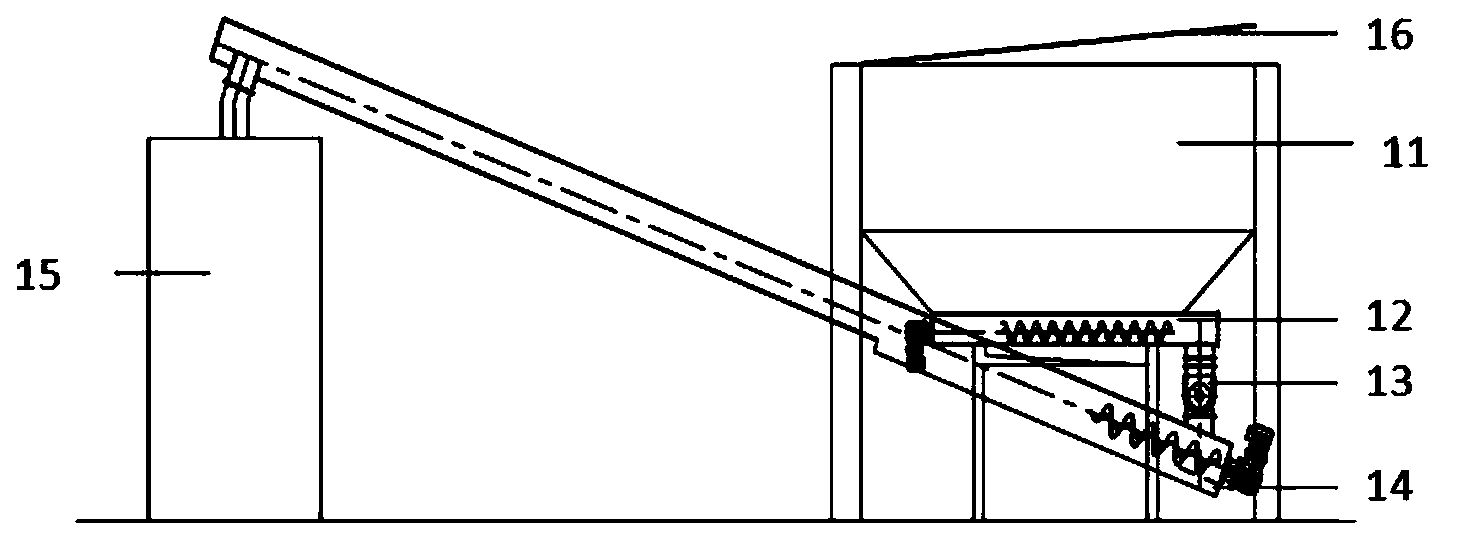

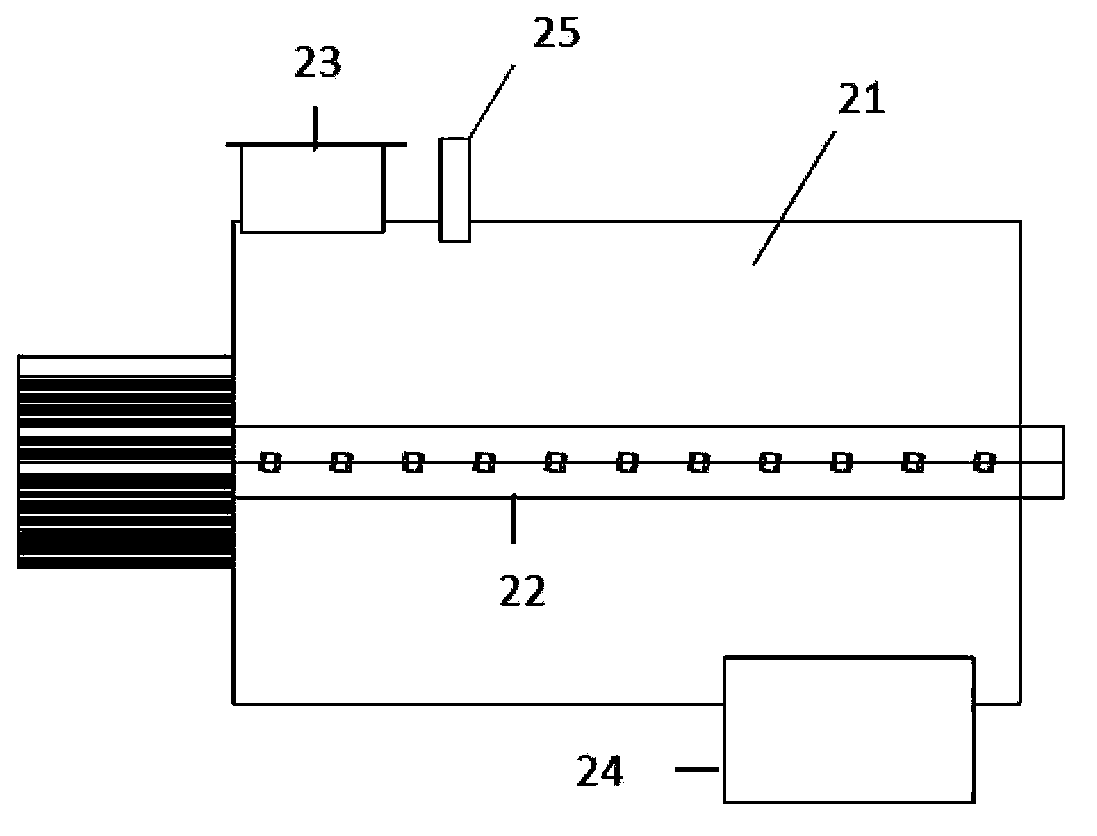

[0100] 1) Pour the kitchen waste into the receiving hopper of the receiving and conveying system through the garbage transport vehicle, and intercept the materials with a diameter larger than the longitudinal shaftless screw conveyor in the receiving hopper through the longitudinal shaftless screw conveyor at the bottom of the receiving hopper, and the diameter The food waste smaller than the vertical shaftless screw conveyor is transported to the horizontal shaftless screw conveyor, and then transported to the lifting screw conveyor through the horizontal shaftless screw conveyor, and the food waste is transported to the material crushing and separation system by the lifting screw conveyor ;...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com