Multifunctional fixed bed gasification furnace gas making device and gas making process

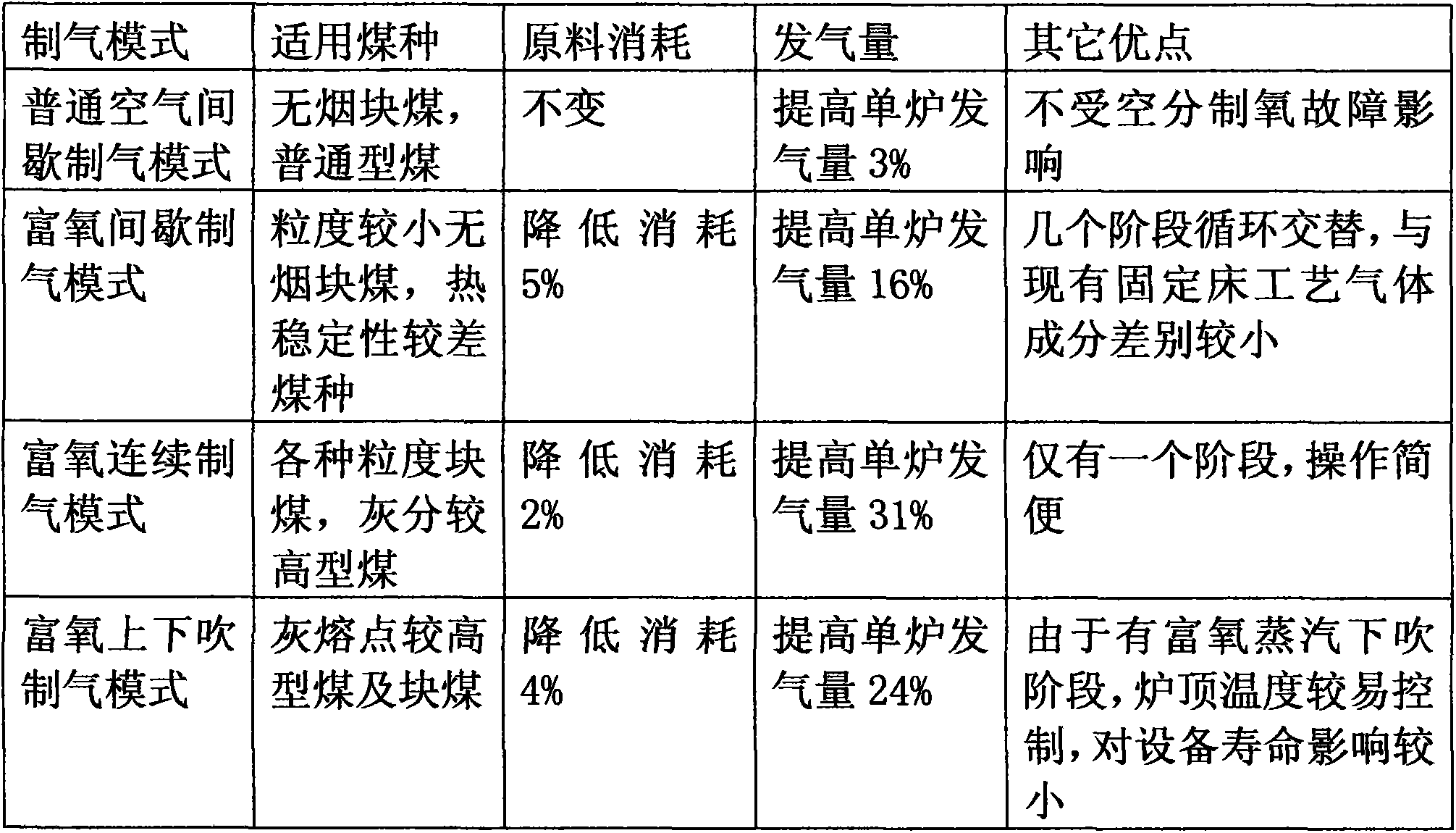

A technology for a gasifier and a fixed bed, which is applied in the field of a gas-making device and a gas-making process for a fixed-bed multi-purpose gasifier, can solve the problem of increasing the consumption of raw coal, the failure of the oxygen-enriched gas-making to work normally, and restricting the production of the fixed-bed gas-making furnace. Air volume etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

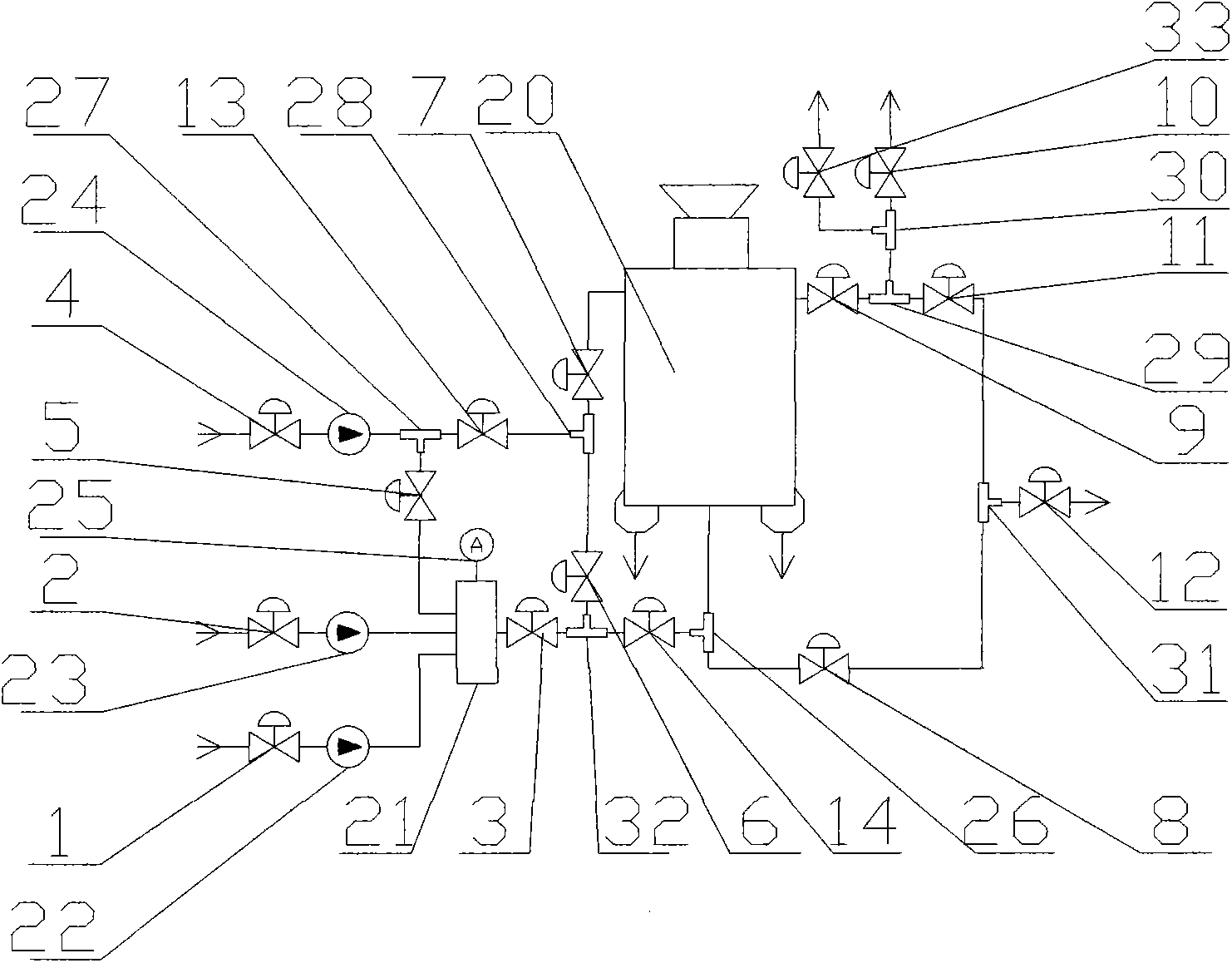

Method used

Image

Examples

Embodiment 1

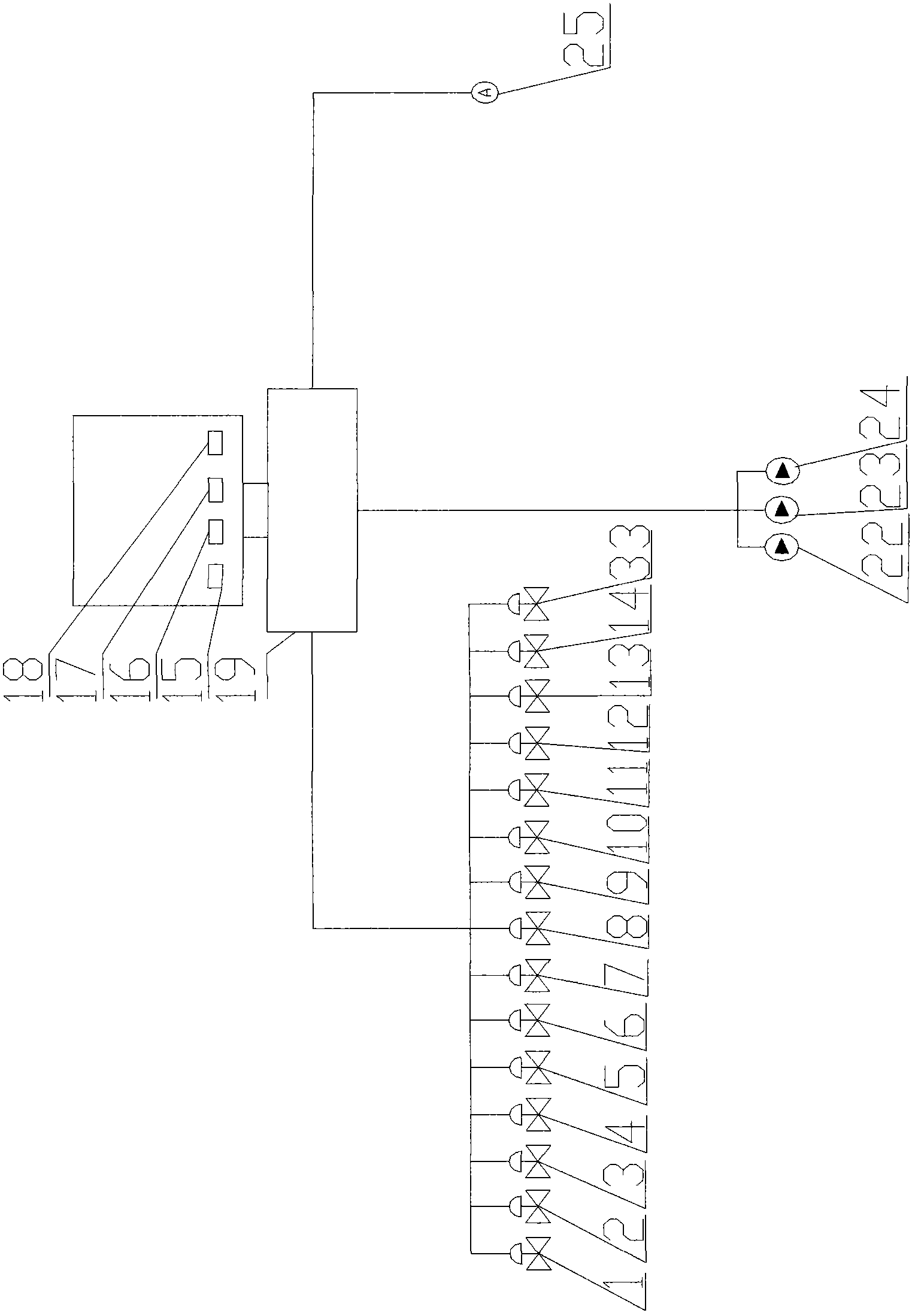

[0054] When the ordinary air intermittent gas production mode is required, press the ordinary air intermittent gas production mode button 15, the program-controlled valve is controlled by the DCS microcomputer control system 19, and the ordinary air intermittent gas production mode is started. The ordinary air intermittent gas production mode includes two The second blowing stage, the blowing stage, the blowing stage, the blowing stage and the blowing stage;

[0055] a. The second blowing stage: through the DCS microcomputer control system 19, the fourth program-controlled valve 4, the thirteenth program-controlled valve 13, the sixth program-controlled valve 6, the fourteenth program-controlled valve 14, the ninth program-controlled valve 9, and the eleventh program-controlled valve The program-controlled valve 11 and the twelfth program-controlled valve 12 are opened, and the steam with a pressure of 54KPa enters the bottom of the gasifier 20 through the fourth program-contro...

Embodiment 2

[0061] When the oxygen-enriched intermittent gas production mode is required, press the oxygen-enriched intermittent gas production mode button 16 to control the program-controlled valve through the DCS microcomputer control system 19 to start the oxygen-enriched intermittent gas production mode. The oxygen-enriched intermittent gas production mode includes Oxygen secondary blowing stage, oxygen-enriched blowing stage, oxygen-enriched blowing stage, oxygen-enriched upward blowing stage and oxygen-enriched blowing stage;

[0062] a. Oxygen-enriched secondary blowing stage: through the DCS microcomputer control system 19, the fourth program-controlled valve 4, the thirteenth program-controlled valve 13, the sixth program-controlled valve 6, the fourteenth program-controlled valve 14, the ninth program-controlled valve 9, the The eleventh program-controlled valve 11 and the twelfth program-controlled valve 12 are opened, and the steam with a pressure of 54KPa enters the gasifier 2...

Embodiment 3

[0068] When the oxygen-enriched continuous gas production mode is required, press the oxygen-enriched continuous gas production mode button 17 to control the program-controlled valve through the DCS microcomputer control system 19 to start the oxygen-enriched continuous gas production mode. The oxygen-enriched continuous gas production mode includes Oxygen continuous upward blowing stage;

[0069] a. Oxygen-enriched continuous upward blowing stage: DCS microcomputer control system 19 controls the first program-controlled valve 1, the second program-controlled valve 2, the third program-controlled valve 3, the fourth program-controlled valve 4, the fifth program-controlled valve 5, and the fourteenth program-controlled valve 14. The ninth program-controlled valve 9, the eleventh program-controlled valve 11 and the twelfth program-controlled valve 12 are opened, the air with a pressure of 45KPa enters the buffer tank 21 through the second program-controlled valve 2, and the oxyge...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com