Easy-care micro-foam film packaging paper material and preparation method thereof

A technology of micro-foaming and wrapping paper, applied in the field of materials, can solve the problems of affecting the service life of the bag, appearing bubbles in the lamination place, and difficulty in reducing costs, and achieves excellent oil barrier properties, increased lamination qualification rate, and good quality. Environmentally friendly effects

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

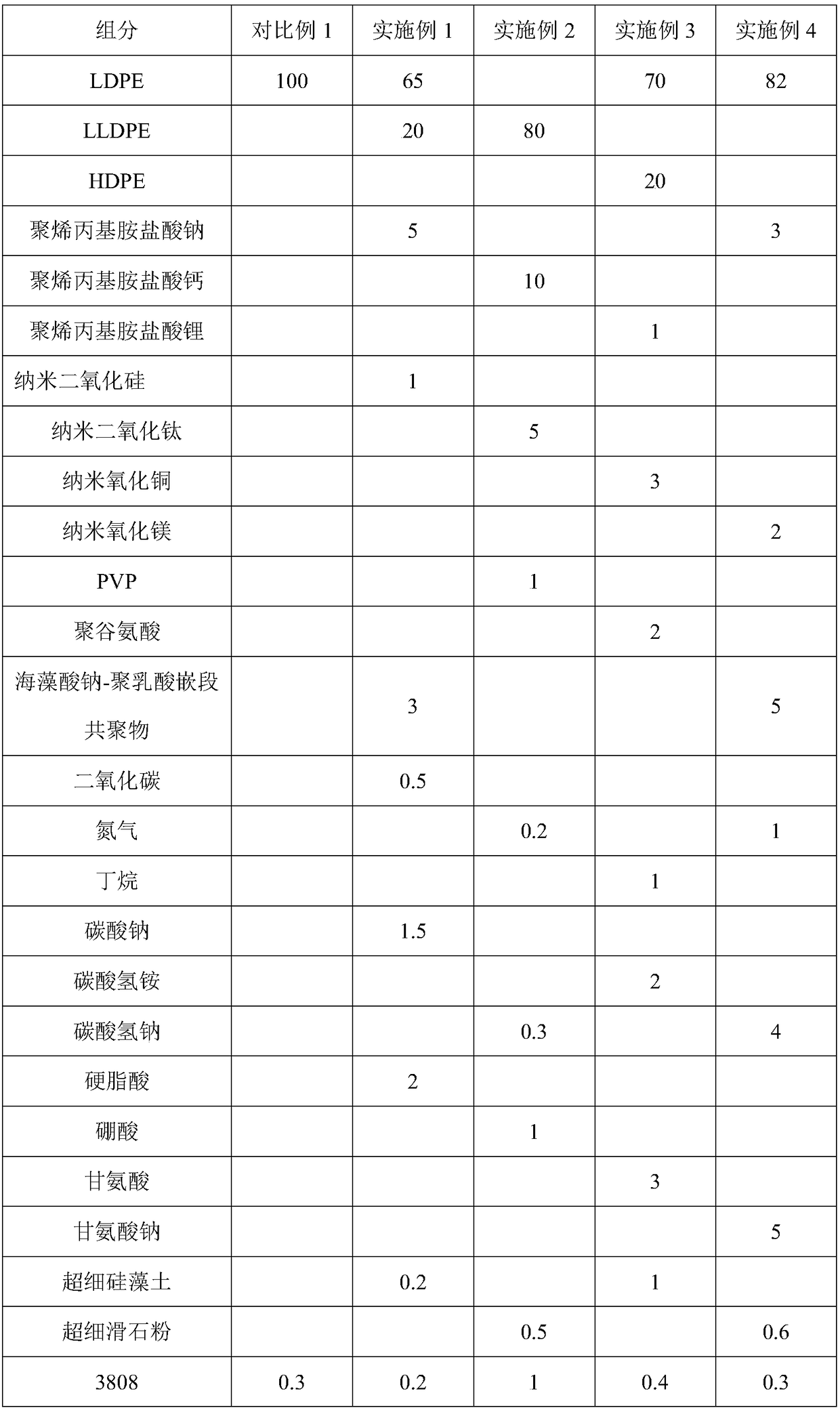

Embodiment 1

[0032] Step 1: Premix 5 parts of polyallylamine sodium hydrochloride, 1 part of nano-silica, and 3 parts of sodium alginate-polylactic acid block copolymer in a medium-speed mixer according to the parts by weight for 0.5-2 minutes, Finally, the mixture is added to the single-screw extruder through the hopper, and the amphiphilic composite masterbatch is obtained by extrusion and granulation;

[0033] Step 2, mix amphiphilic composite masterbatch with 65 parts of LDPE and 20 parts of LLDPE, 0.2 parts of ultrafine diatomaceous earth, 1.5 parts of sodium carbonate, 2 parts of stearic acid, other additives are 0.2 parts of photosensitizer 3808, antioxidant 1010 0.3 parts are added to the single-screw film extruder according to the parts by weight, and 0.5 parts of the physical foaming agent carbon dioxide are added to the extruder through the air inlet on the top of the barrel according to the parts by weight. , extruded and casted into a surface treatment-free foamed polyethylene...

Embodiment 2

[0037] Step 1: Premix 10 parts of polyallylamine calcium hydrochloride, 5 parts of nano-titanium dioxide, and 1 part of PVP in a medium-speed mixer for 0.5-2 minutes according to the parts by weight, and then add the mixture to the single-screw extrusion through the hopper In the machine, the amphiphilic composite masterbatch is obtained by extrusion and granulation;

[0038] Step 2: Mix amphiphilic composite masterbatch with 80 parts of LLDPE, 0.5 parts of superfine talcum powder, 0.3 parts of sodium bicarbonate, 1 part of boric acid, and other additives are 1 part of photosensitizer 3808 and 1 part of antioxidant 1010 according to weight The parts are added to the single-screw film extruder, and 0.2 parts of the physical foaming agent nitrogen is added to the extruder by metering the air inlet on the top of the barrel according to the parts by weight, and the extrusion flow is carried out at a temperature of 130-200 ° The surface treatment-free foamed polyethylene film is ex...

Embodiment 3

[0042] Step 1: Pre-mix 1 part of allylamine lithium hydrochloride, 3 parts of nano-copper oxide, and 2 parts of polyglutamic acid in a medium-speed mixer for 0.5-2 minutes according to the parts by weight, and then add the mixture to the unit through a hopper In the screw extruder, the amphiphilic composite masterbatch is obtained through extrusion and granulation;

[0043]Step 2, mix amphiphilic composite masterbatch with 70 parts of LDPE and 20 parts of HDPE, 1 part of ultrafine diatomaceous earth, 2 parts of ammonium bicarbonate, 3 parts of glycine, other additives are 0.4 parts of photosensitizer 3808, and 0.4 parts of antioxidant 1010 0.6 parts are added to the single-screw film extruder according to the parts by weight, and 1 part of the physical foaming agent butane is added to the extruder through the air inlet on the top of the barrel according to the parts by weight. , extruded and casted into a surface treatment-free foamed polyethylene film, and at the same time, t...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com