Two-component acrylic structural adhesive for metal oily surface adhesion

A structural adhesive and surface bonding technology, applied in the direction of adhesive types, polyurea/polyurethane adhesives, adhesives, etc. Overcome the effect of slow curing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

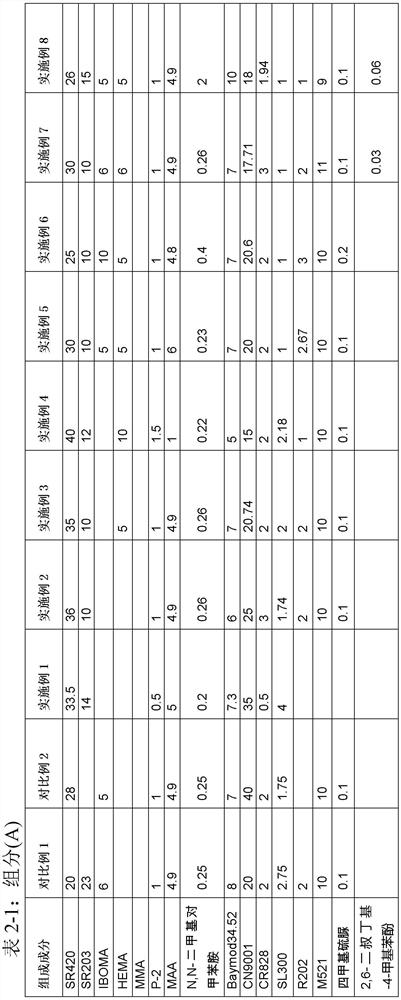

[0069] Examples and comparative examples provided below are provided to facilitate the understanding of the present invention, and these examples and comparative examples should not be construed as limiting the scope of the present invention. Unless otherwise indicated, all amounts are by weight, and the specific amount of each component is by weight.

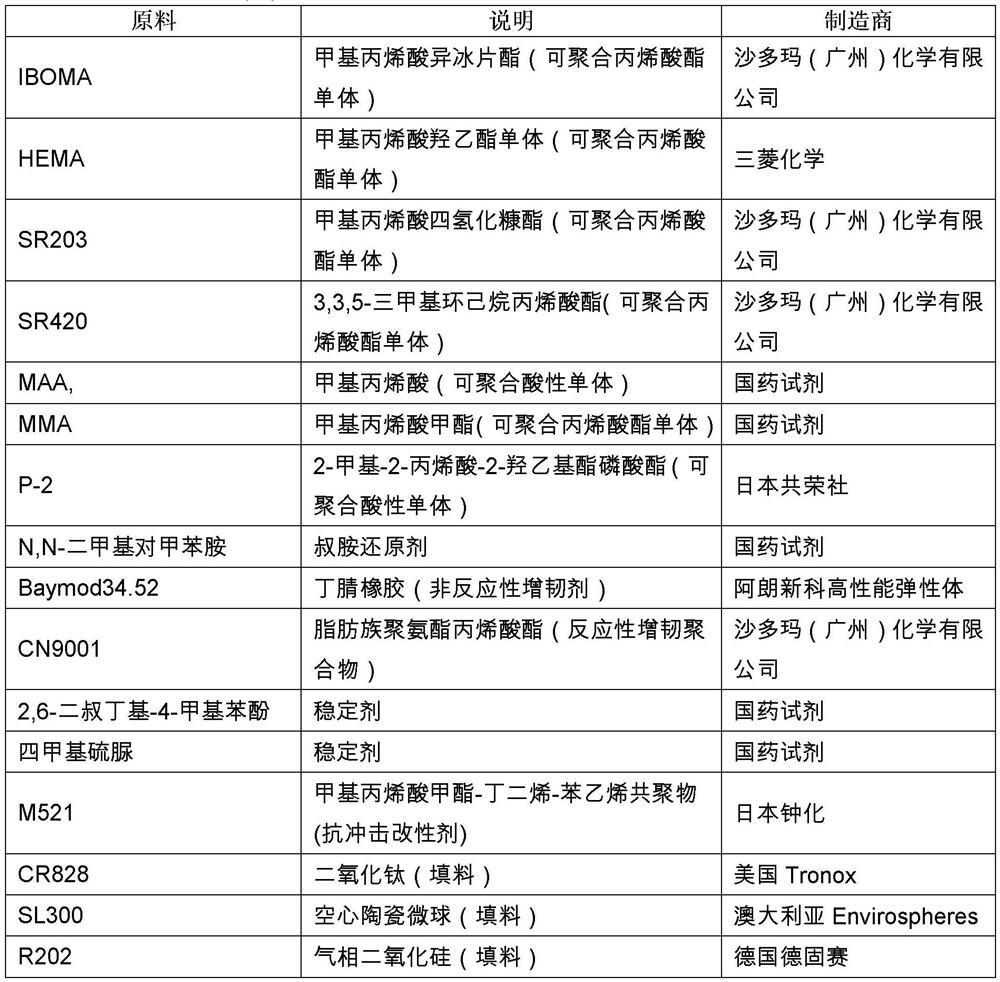

[0070] Raw materials used in Examples and Comparative Examples of the present invention are shown in Tables 1-1 and 1-2 below, and unless otherwise specified, these raw materials were used as they were without further treatment after purchase.

[0071] Table 1-1: Raw material list of component (A)

[0072]

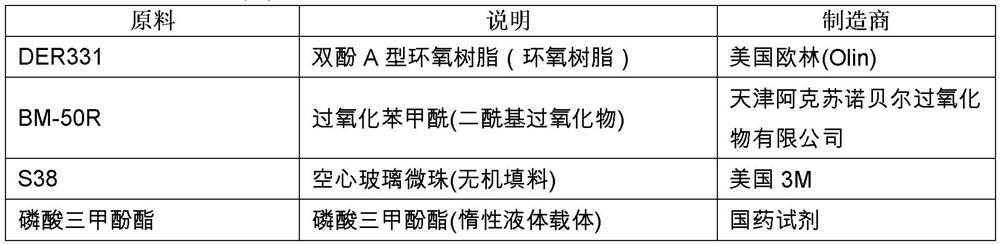

[0073] Table 1-2: Raw material list of component (B)

[0074]

[0075] testing method

[0076] Adhesive strength (i.e. T-peel adhesive strength) test method

[0077] According to the following method, the various structural adhesives obtained in the following examples and comparative examples were tested with r...

PUM

| Property | Measurement | Unit |

|---|---|---|

| peel strength | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com