Preparation method of an embedded diamond-based silicon carbide composite substrate

A composite substrate and silicon carbide-based technology, which is applied in chemical instruments and methods, gaseous chemical plating, metal material coating technology, etc. Matching problems, to achieve the effect of solving heat concentration, reducing interface thermal resistance, and high thermal conductivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

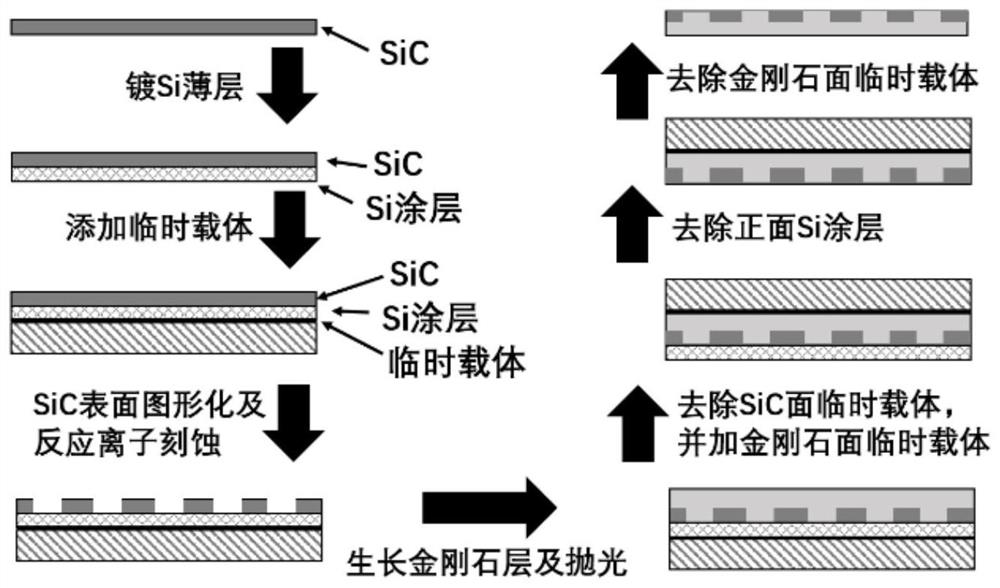

Embodiment 1

[0035] The magnetron sputtering technology was used to sputter for 0.5h under the conditions of power 100W, room temperature, chamber pressure 1Pa and self-bias voltage 300V, and a Si thin layer with a thickness of 200nm was plated. A high-temperature adhesive is coated on the Si thin layer, and the speed is maintained at 2000rpm for 6s. Attach a temporary carrier with exactly the same area as SiC on top of the thin Si layer. Afterwards, heat and cure in an oven, treat at 40°C for 2 hours, and then treat at 160°C for 2 hours. The SiC surface is patterned using mask and UV lithography, followed by CF 4 and O 2 Reactive ion etching is performed to remove the maskless SiC part and retain the SiC structure required by the design. Place the etched temporary carrier and SiC pattern in a microwave plasma vapor deposition system. Based on a two-inch substrate, the cavity pressure is 7.1kPa, the power is 4200W, and the deposition temperature is about 740°C, and CH is introduced int...

Embodiment 2

[0037] Magnetron sputtering technology was used under the conditions of power 400W, room temperature, chamber pressure 1Pa and self-bias voltage 200V for 5h, and a Si thin layer with a thickness of 2μm was deposited. Coat the high-temperature adhesive on the Si thin layer, and last 4s under the condition of rotating speed of 3000rpm. Attach a temporary carrier with exactly the same area as SiC on top of the thin Si layer. Afterwards, heat and cure in an oven, treat at 40°C for 2 hours, and then treat at 160°C for 2 hours. The SiC surface is patterned using mask and UV lithography, followed by CF 4 and O 2 Reactive ion etching is performed to remove the maskless SiC part and retain the SiC structure required by the design. Place the etched temporary carrier and SiC pattern in a microwave plasma vapor deposition system. Based on a two-inch substrate, the cavity pressure is 7.3kPa, the power is 4300W, and the deposition temperature is about 780°C, and CH is introduced into th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com