Honeycomb Structure Nonwoven Reinforcing Fabric for Waterproof Membrane

A honeycomb structure, non-woven fabric technology, applied in the field of building waterproof engineering, can solve problems such as lap seal leakage, achieve the effects of enhancing peel strength, improving waterproof and anti-seepage performance, and simple manufacturing

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] The present invention will be further described below through specific examples.

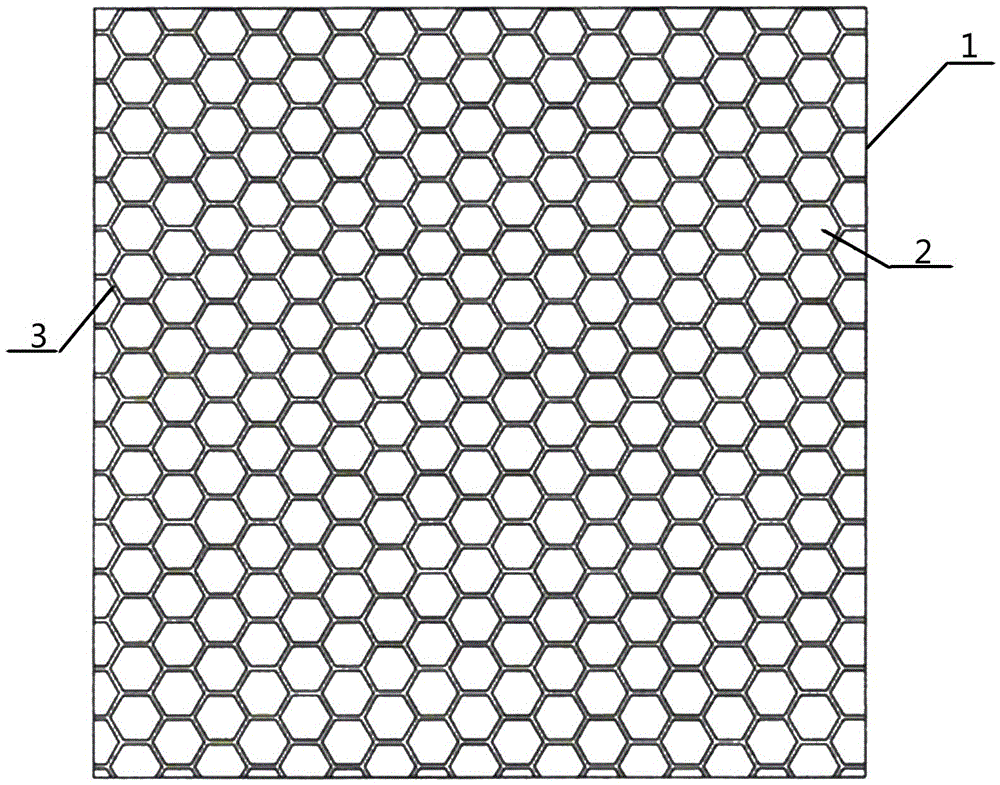

[0018] figure 1 The surface layer structure of the non-woven reinforced cloth with honeycomb structure is given. The non-woven reinforced cloth with honeycomb structure described in the present invention includes a non-woven reinforced cloth body 1 on which regular hexagonal solid sheets 2 are arranged and distributed, each A space is left between the edges of an adjacent regular hexagonal solid sheet 2 to form a concave-convex surface, which is connected by connecting fibers 3 to form a honeycomb network with a transparent space. In the present embodiment, the non-woven reinforced cloth 1 of the honeycomb structure has a convex thickness of the regular hexagonal solid sheet 2 on it of 0.4 mm, and the distance between the edges of each adjacent regular hexagonal solid 2 is 0.5 mm. The diameter of the fiber 3 connecting each pitch is 0.1 mm.

[0019] The above-mentioned non-woven reinfor...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com