Calcium carbide powder molding equipment

A technology of molding equipment and calcium carbide powder, which is applied in the direction of material molding presses, presses, manufacturing tools, etc., can solve the problems of high processing costs, etc., and achieve the effect of improving service life and preventing damage by rolling

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

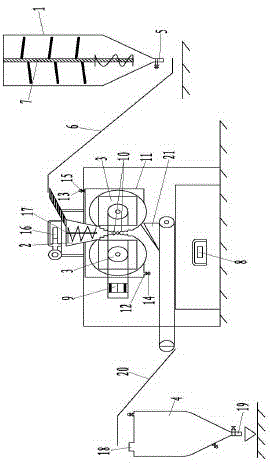

Image

Examples

example 1

[0046] Calcium carbide powder, calcium carbonate, talcum powder, polyethylene acetate emulsion and borax are proportioned by weight percentage: calcium carbide powder: 100; calcium carbonate: 10; talcum powder: 5; polyethylene acetate emulsion: 2; borax: 1.

[0047] In this embodiment, the generation time of calcium carbide powder is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons.

example 2

[0049] Proportion calcium carbide powder, calcium carbonate, talcum powder, polyethylene acetate emulsion and borax by weight percentage: calcium carbide

[0050] Powder: 100; Calcium Carbonate: 15; Talc: 15; Polyvinyl Acetate Emulsion: 3; Borax: 1.5.

[0051] In this embodiment, the generation time of calcium carbide powder is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons.

example 3

[0053] Proportion calcium carbide powder, calcium carbonate, talcum powder, polyethylene acetate emulsion and borax by weight percentage: calcium carbide

[0054] Powder: 100; Calcium Carbonate: 30; Talc: 15; Polyvinyl Acetate Emulsion: 5; Borax: 2.

[0055] In this embodiment, the generation time of calcium carbide powder is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com