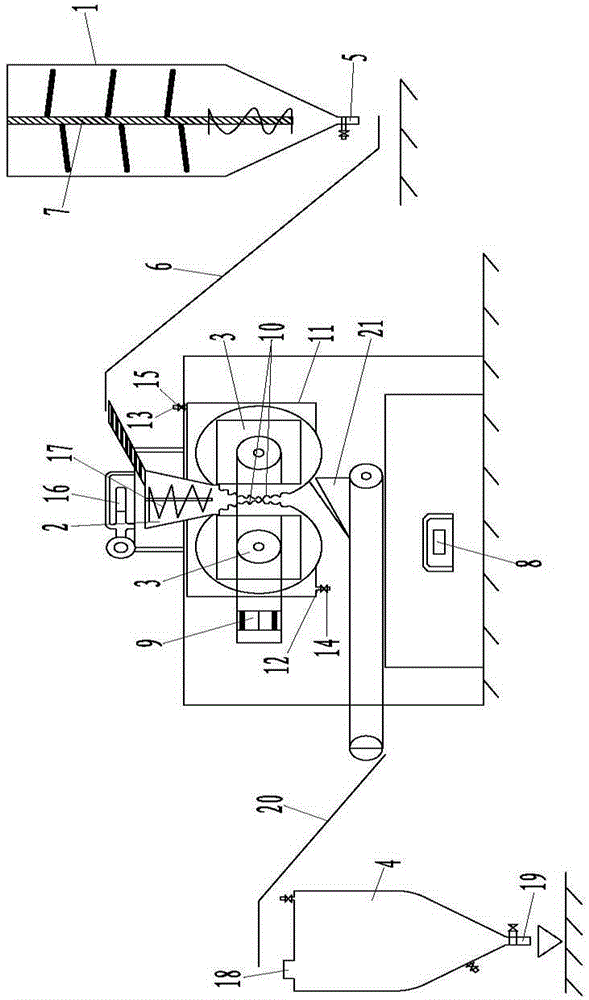

The process of processing calcium carbide powder into calcium carbide balls or blocks by using calcium carbide powder forming equipment

A molding equipment, calcium carbide powder technology, applied in material molding presses, manufacturing tools, presses, etc., can solve the problems of excessive calcium carbide powder dust, fast reaction speed, large contact area, etc., to prevent damage by rolling, The effect of improving the service life

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

example 1

[0042] Calcium carbide powder, calcium carbonate, talcum powder, polyethylene acetate emulsion and borax are proportioned by weight percentage: calcium carbide powder: 100; calcium carbonate: 10; talcum powder: 5; polyethylene acetate emulsion: 2; borax: 1.

[0043] The generation time of the calcium carbide powder in this embodiment is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons;

[0044] generation time

example 2

[0046] Calcium carbide powder, calcium carbonate, talcum powder, polyethylene acetate emulsion and borax are proportioned by weight percentage: calcium carbide powder: 100; calcium carbonate: 15; talcum powder: 15; polyethylene acetate emulsion: 3; borax: 1.5.

[0047] In this embodiment, the generation time of calcium carbide powder is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons;

[0048] generation time

example 3

[0050] Calcium carbide powder, talcum powder, polyethylene acetate emulsion and borax are proportioned by weight percentage: calcium carbide powder: 100; calcium carbonate: 30; talcum powder: 15; polyethylene acetate emulsion: 5; borax: 2.

[0051] In this embodiment, the generation time of calcium carbide powder is 12h-36h, and the static pressure provided by the hydraulic system is 150-300 tons;

[0052] generation time

[0053] The above data shows that through high pressure (usually above 200), the compactness of calcium carbide powder can be improved, so in terms of mechanical properties, the compressive strength will be higher, and it is not easy to break when doing the anti-drop test. Anti-drop test: Drop the formed calcium carbide block from a height of 2m in a free fall. The ground is cement or slate. Judging by the crushing condition after dropping the ground, the anti-fall strength is based on the fact that the calcium carbide powder block or ball is on th...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com