Patents

Literature

39results about How to "Uniform reaction rate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Water-soluble inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationPowder mixture

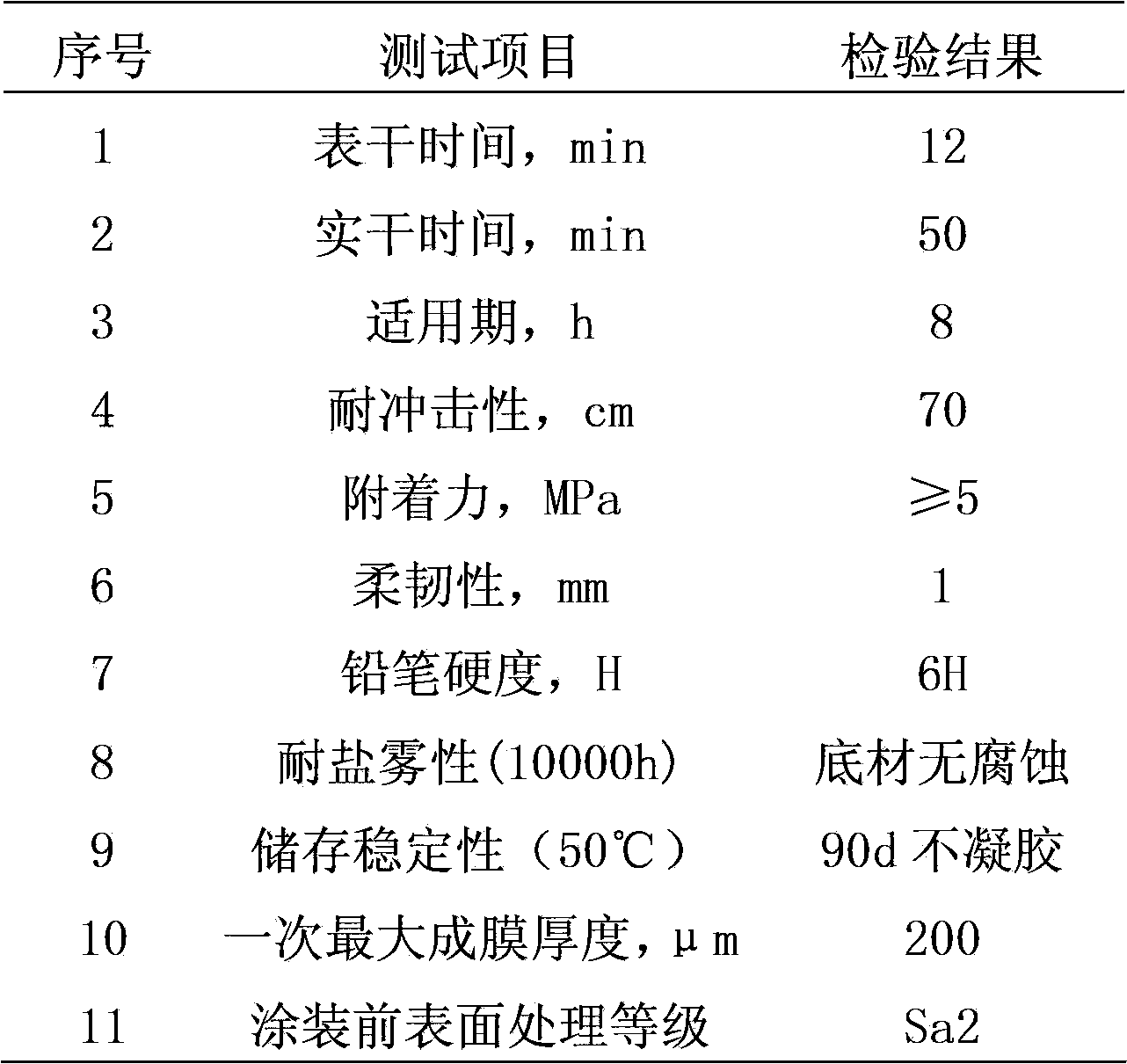

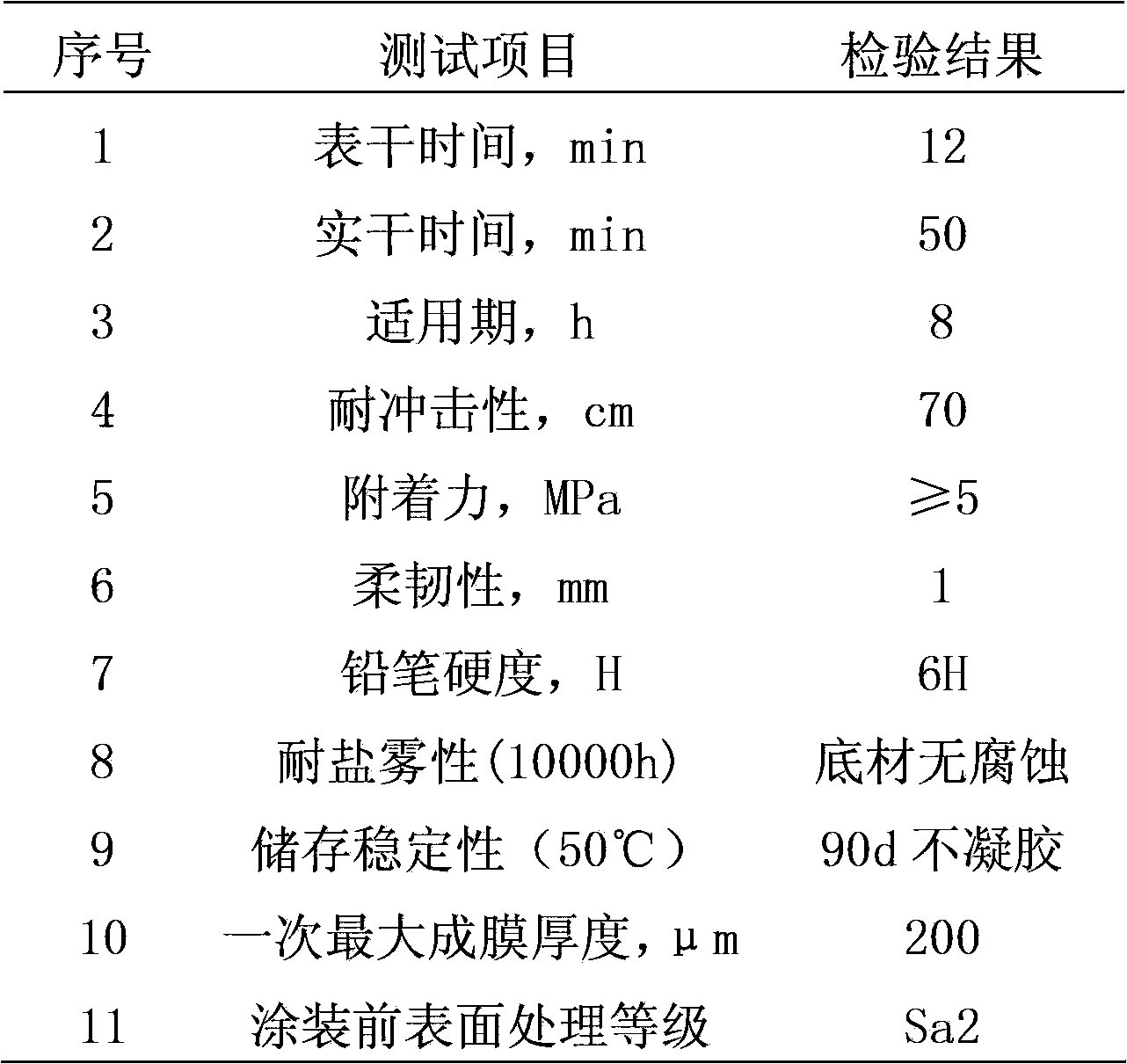

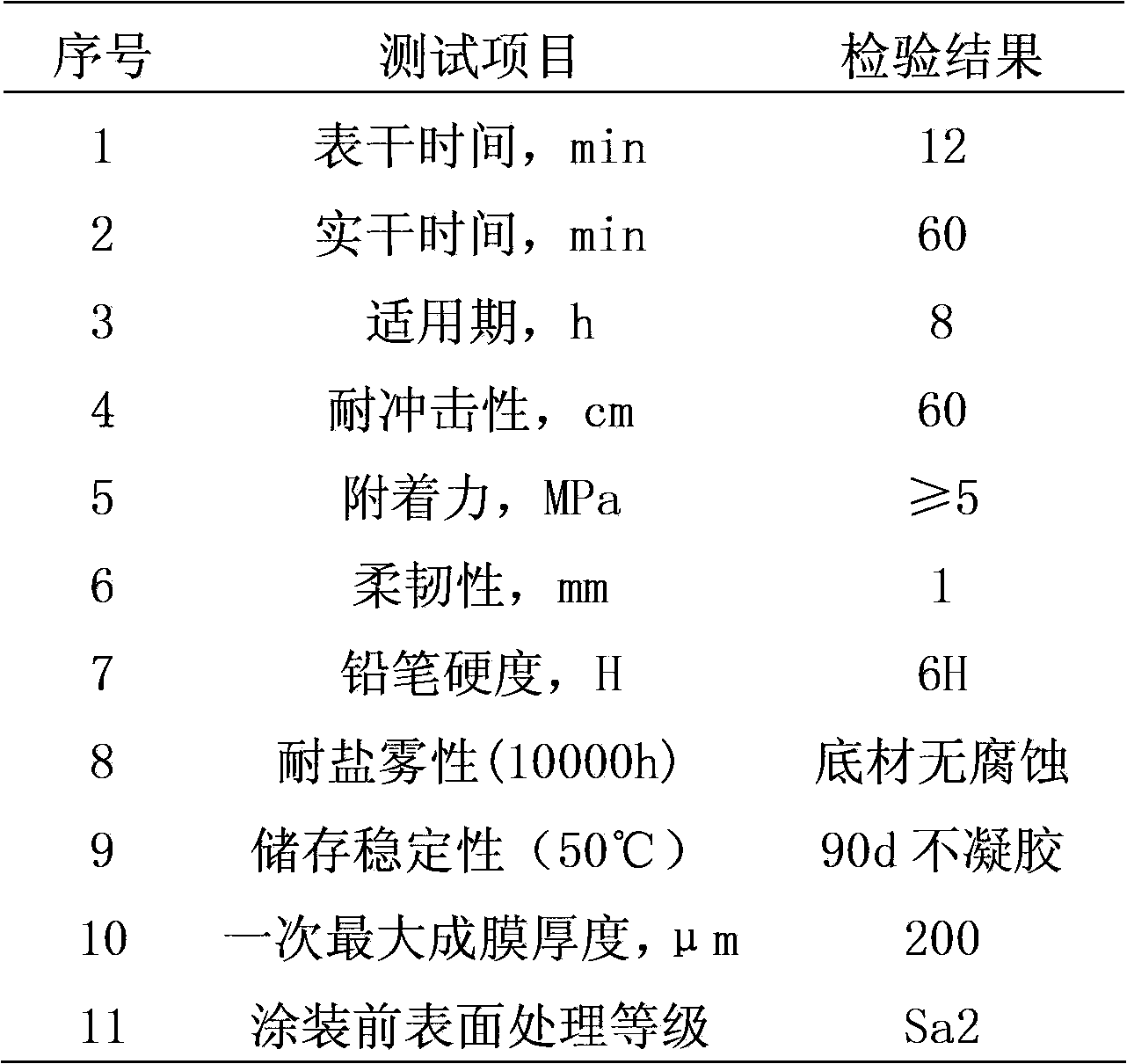

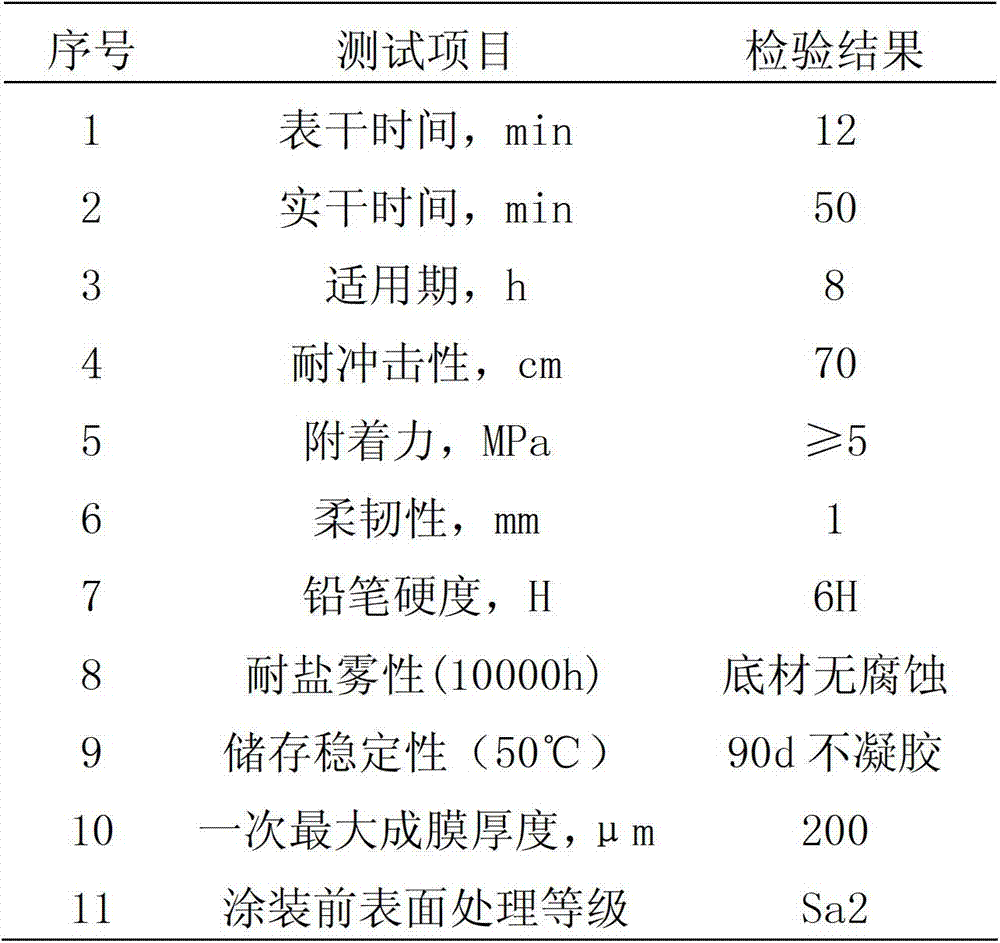

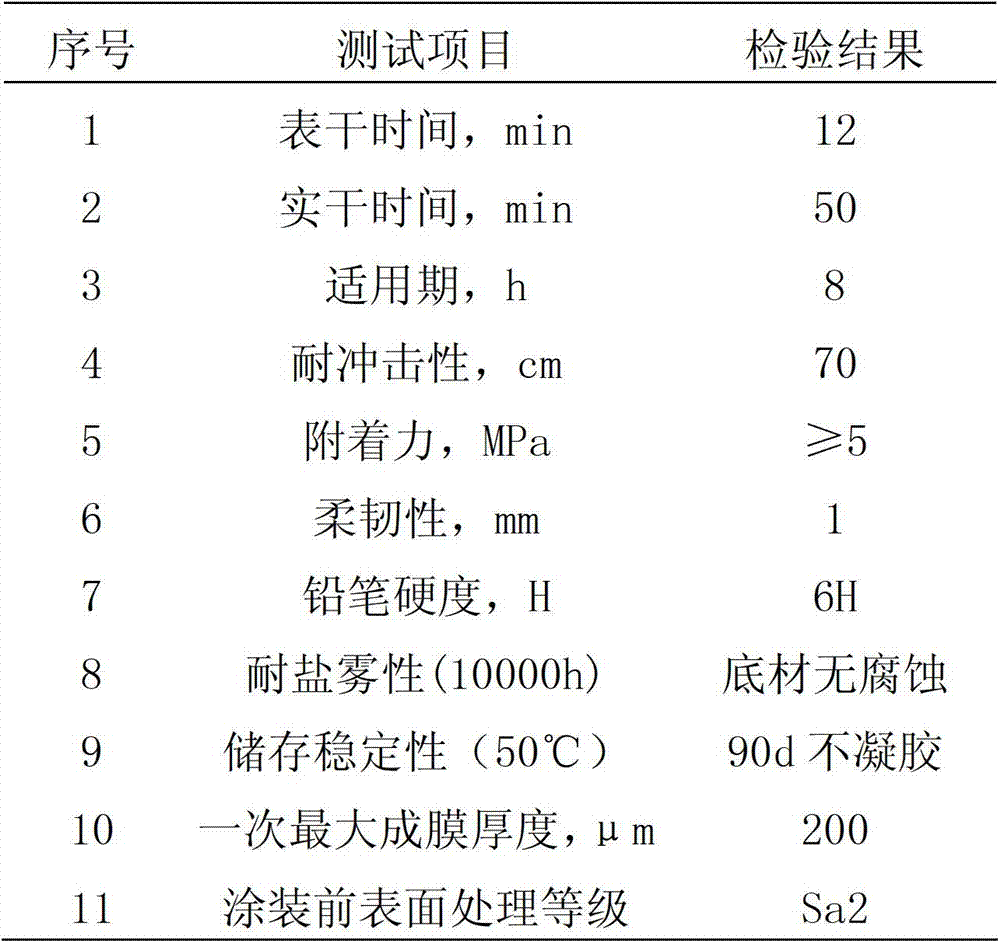

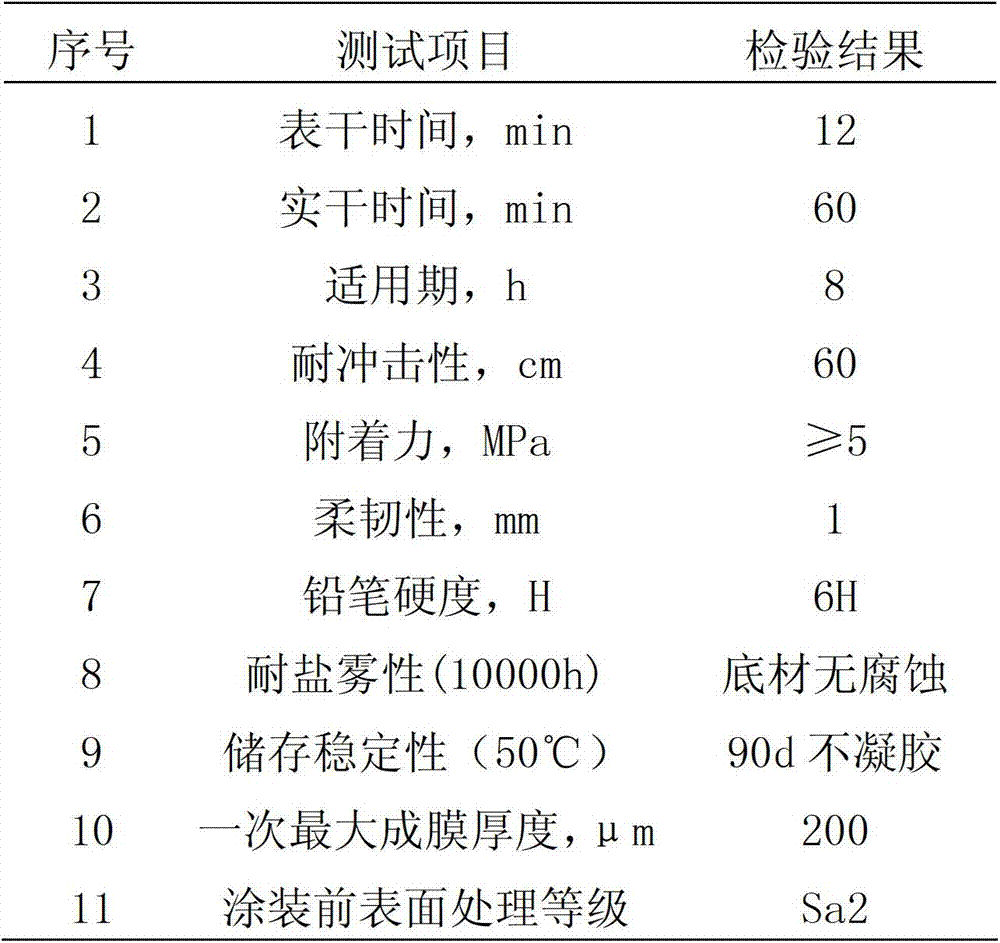

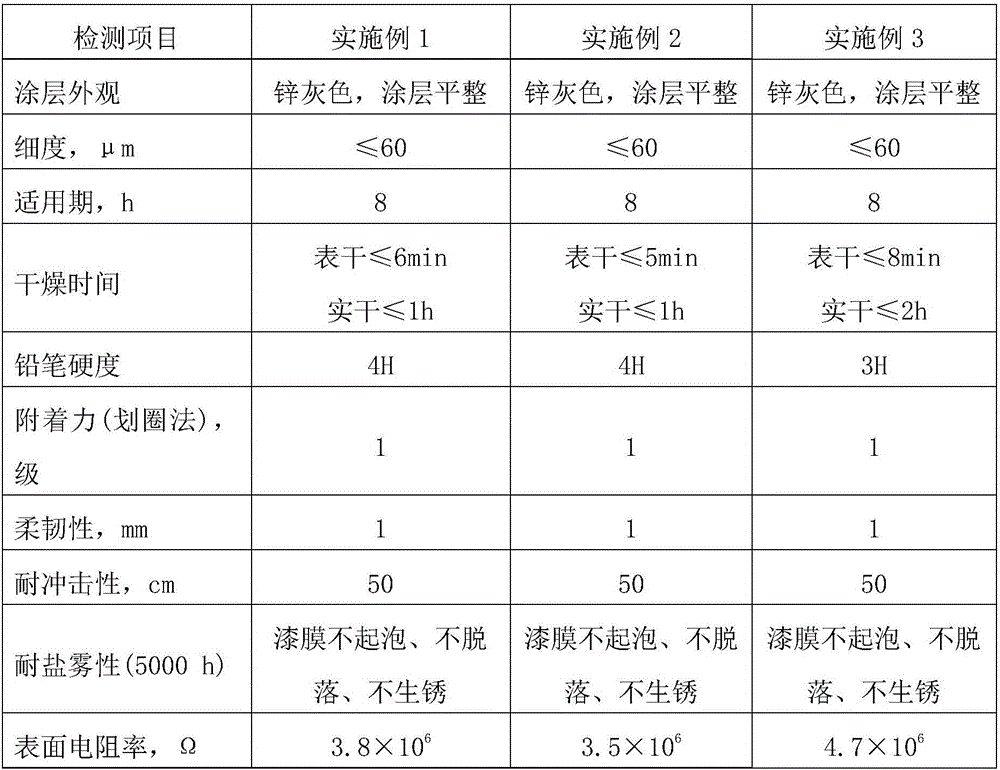

The invention provides a water-soluble inorganic zinc-rich paint and a preparation method thereof. The preparation method comprises the following steps: dropwise adding aluminum-modified silica sol into potassium silicate solution with low modulus, so as to obtain a high-modulus potassium silicate solution as a binder; and adding a catalyst, a siloxane oligomer and a modifier to ensure that the high-modulus potassium silicate solution are uniform in size distribution, and does not have gelatinization reaction for a long time, wherein after the high-modulus potassium silicate solution and a zinc powder mixture are stirred uniformly, the zinc-rich paint has the advantages that reaction rates of all parts of a coating are uniform, and no stress concentration phenomenon exist. Proved by experiments, the zinc-rich paint provided by the invention has no gel after being stored for 90 days at 50 DEG C, the thickness of a film formed once can reach 200 mu m, no cracking or bubbling phenomenon exists, construction can be carried out after the treatment level of the steel surface reaches Sa2, and the salt fog resistance of the coating can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

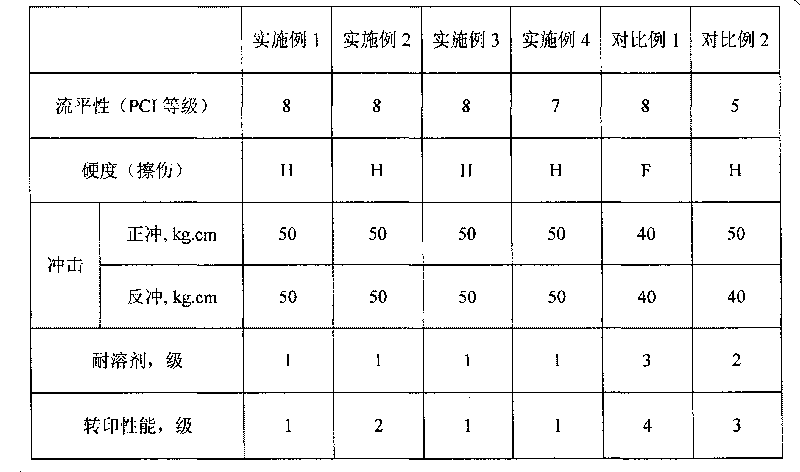

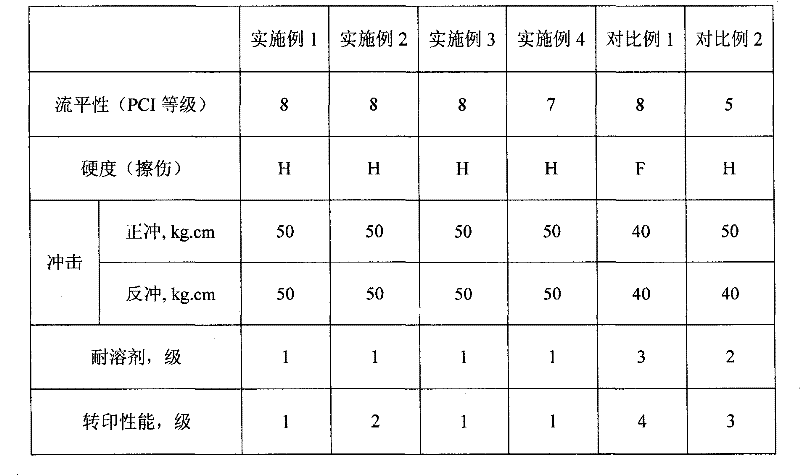

Polyester resin for mixed powder coating and preparation method thereof

ActiveCN101704945AUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsLow temperature curingAdipic acid

The invention relates to the field of powder coatings, in particular to a polyester resin for a mixed thermal transfer powder coating and a preparation method thereof. The polyester resin for the mixed thermal transfer powder coating comprises the following components and contents: 1 mole percent of acids, 1.05-1.20 mole percent of alcohols, 10-15wt% of trimellitic anhydride and 0.1-1.0wt% of recomposed onium salts, wherein the alcohols accounting for the total alcohol mol percent comprise 10-90 mol% of neopentyl glycol, 0-45 mol% of dimethyl-1,3-propanediol, 0-20 mol% of ethanediol, 10-25 mol% of diethylene glycol; and the acids accounting for the total acid mol percent comprise 80-100 mol% of terephthalic acid, 0-10 mol% of m-phthalic acid and 0-10 mol% of mol% of adipic acid. The functionality of the polyester resin is regulated according to the amount of the branched components of the trimellitic anhydride, thus the obtained cured film has better surface appearance, low temperature (160 DEG C) curing is realized, the curing percent of film coating at low temperature is high, the curing film has fine solvent resistance and the transfer-printed transfer printing film is clear, vivid and easy to tear.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

Method for preparing naphthalene series water reducer

The invention provides a method for preparing a naphthalene series water reducer. The method comprises the following steps: sulfonation: carrying out a sulfonation reaction of naphthalene and concentrated sulfuric acid; hydrolysis: adding water into the sulfonation reaction product for hydrolysis, and hydrolyzing a by-product in the sulfonation reaction; condensation: adding poly formaldehyde and water into the hydrolysis reaction product for condensation; and neutralization: adjusting pH of the condensation reaction product to be 6-8, and drying to obtain the naphthalene series water reducer. The preparation method has the advantages of simple and stable production process and easily controlled parameters, and the prepared naphthalene series water reducer product has stable performance and good quality.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

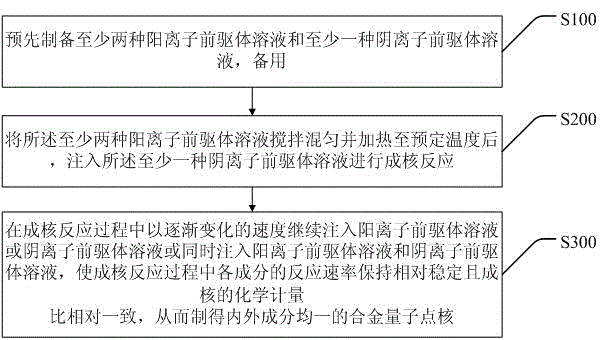

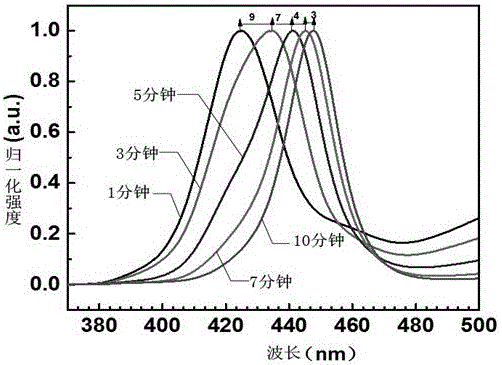

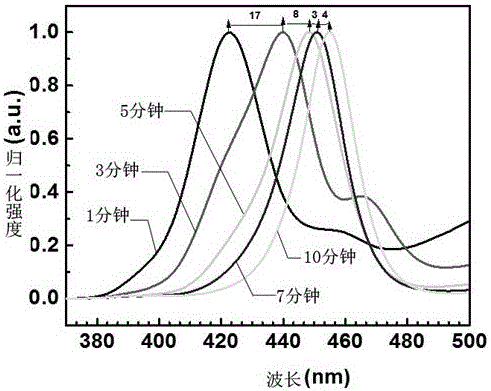

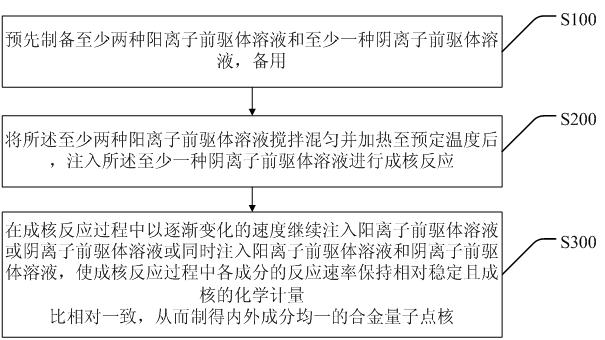

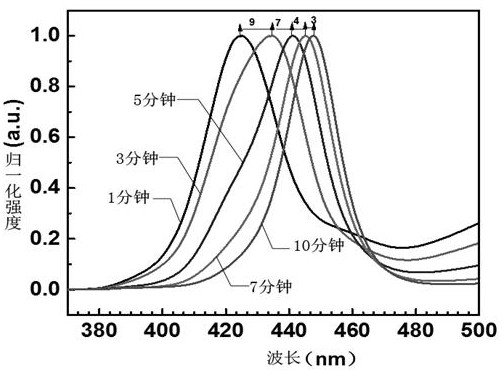

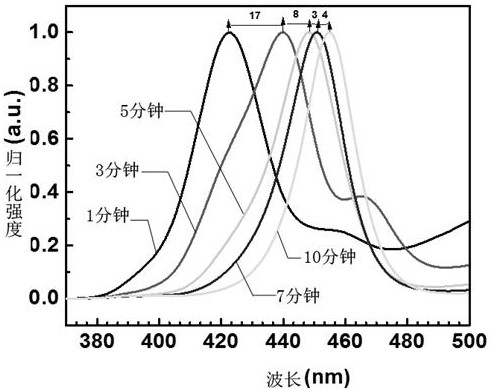

Alloy quantum dot core with uniform internal and external components and preparation method thereof

ActiveCN106590633ASolve for uniformitySolve efficiency problemsCadmium sulfidesNanoopticsReaction rateQuantum dot

The invention discloses an alloy quantum dot core with uniform internal and external components and a preparation method thereof, wherein the method comprises the steps: stirring and mixing evenly at least two pre-prepared cationic precursor solutions, heating to a predetermined temperature, injecting at least one prepared anionic precursor solution, carrying out a nucleation reaction, continuing to inject the cationic precursor solutions or the anionic precursor solution or simultaneously inject the cationic precursor solutions and the anionic precursor solution at a gradually changed speed in the nucleation reaction process, making the reaction rate of all the components in the nucleation reaction process remained relatively stable and making the nucleation stoichiometric ratio relatively consistent, and thus obtaining the alloy quantum dot core with uniform internal and external components. By the method, the problems that an alloy quantum dot core has non-uniform internal and external components, low luminous efficiency and unstable wavelength and fluorescence intensity can be effectively solved, and the method provided by the invention has the advantages of simple operation, easy control, high repeatability and the like.

Owner:TCL CORPORATION

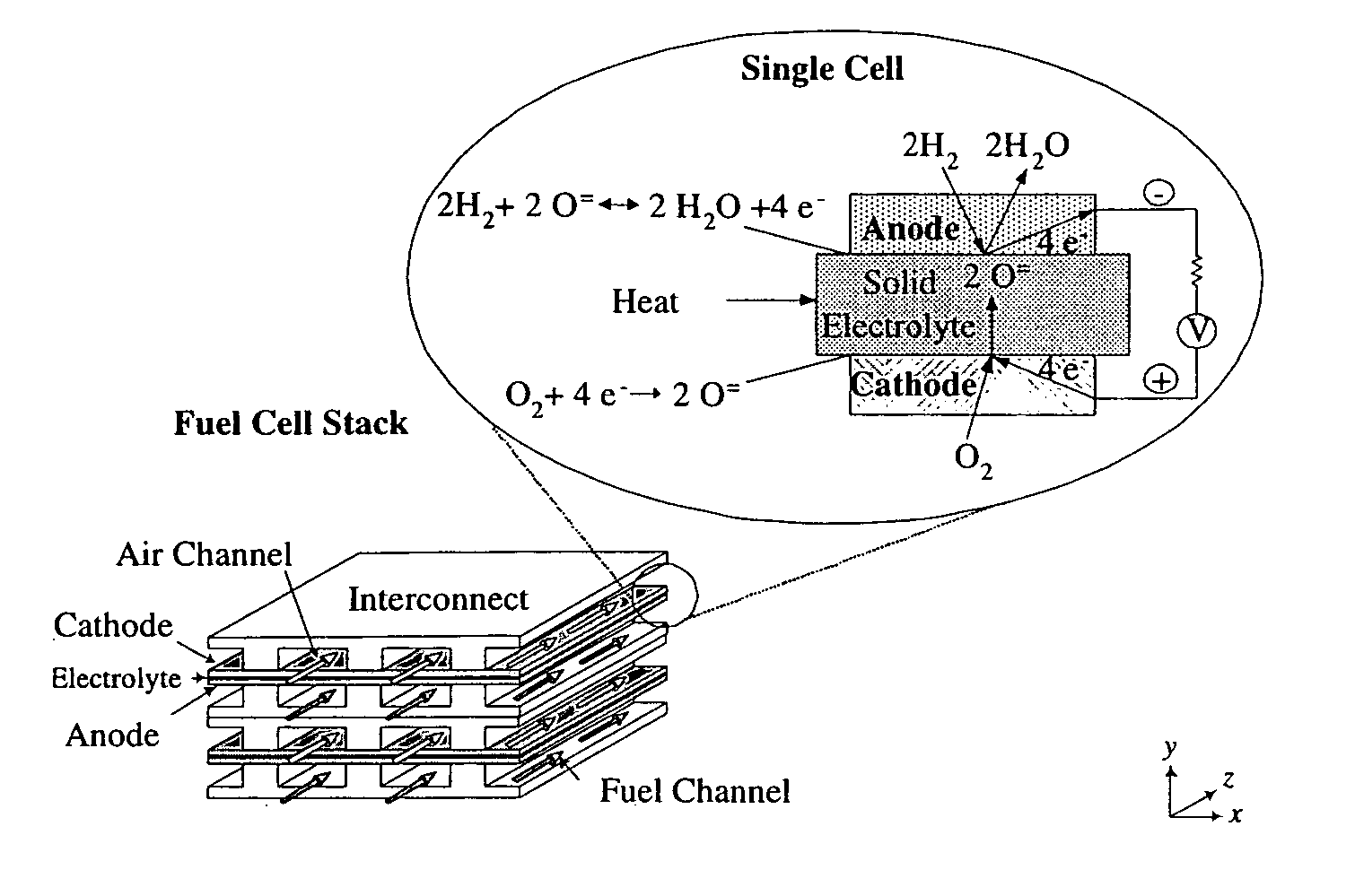

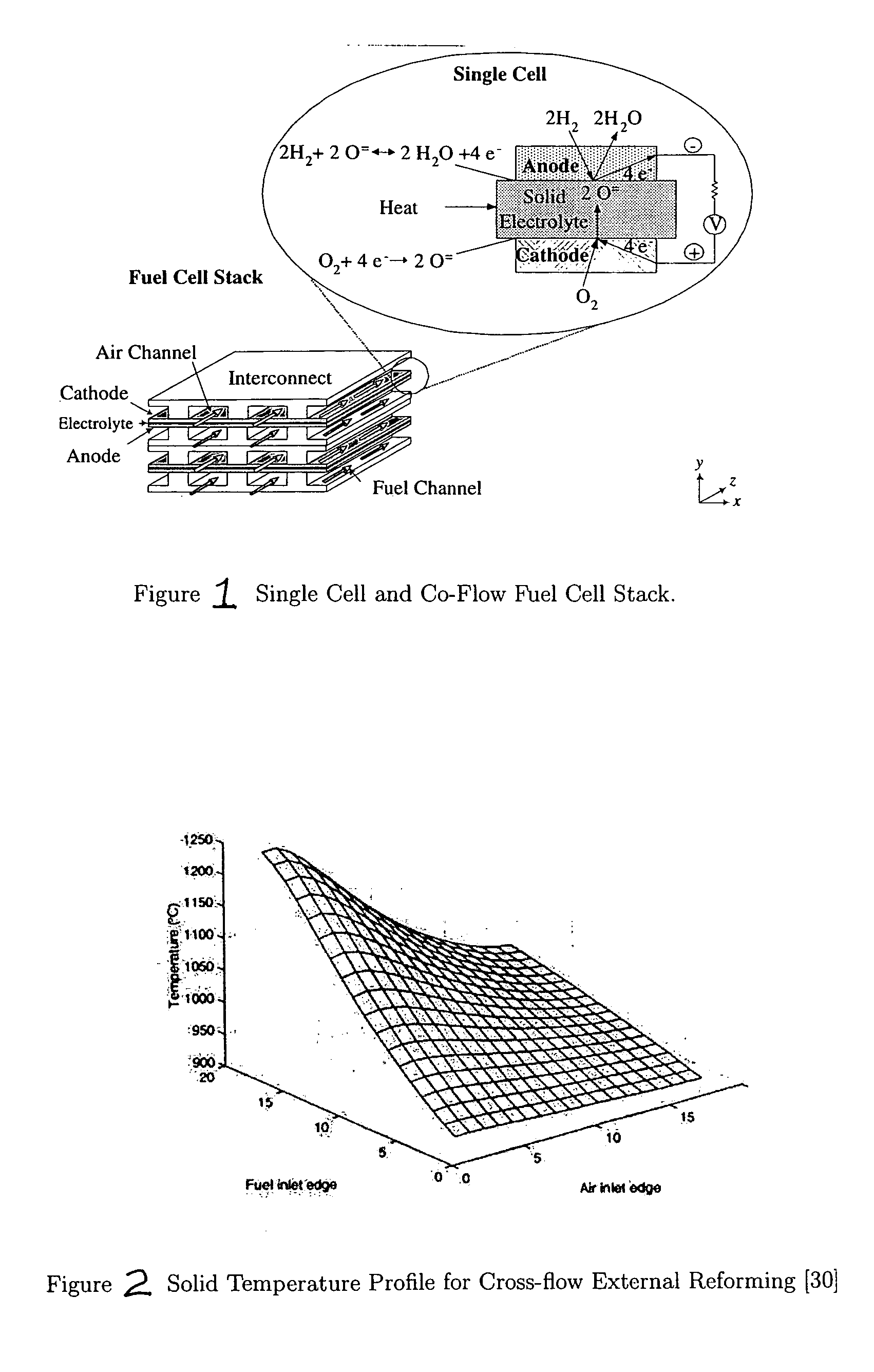

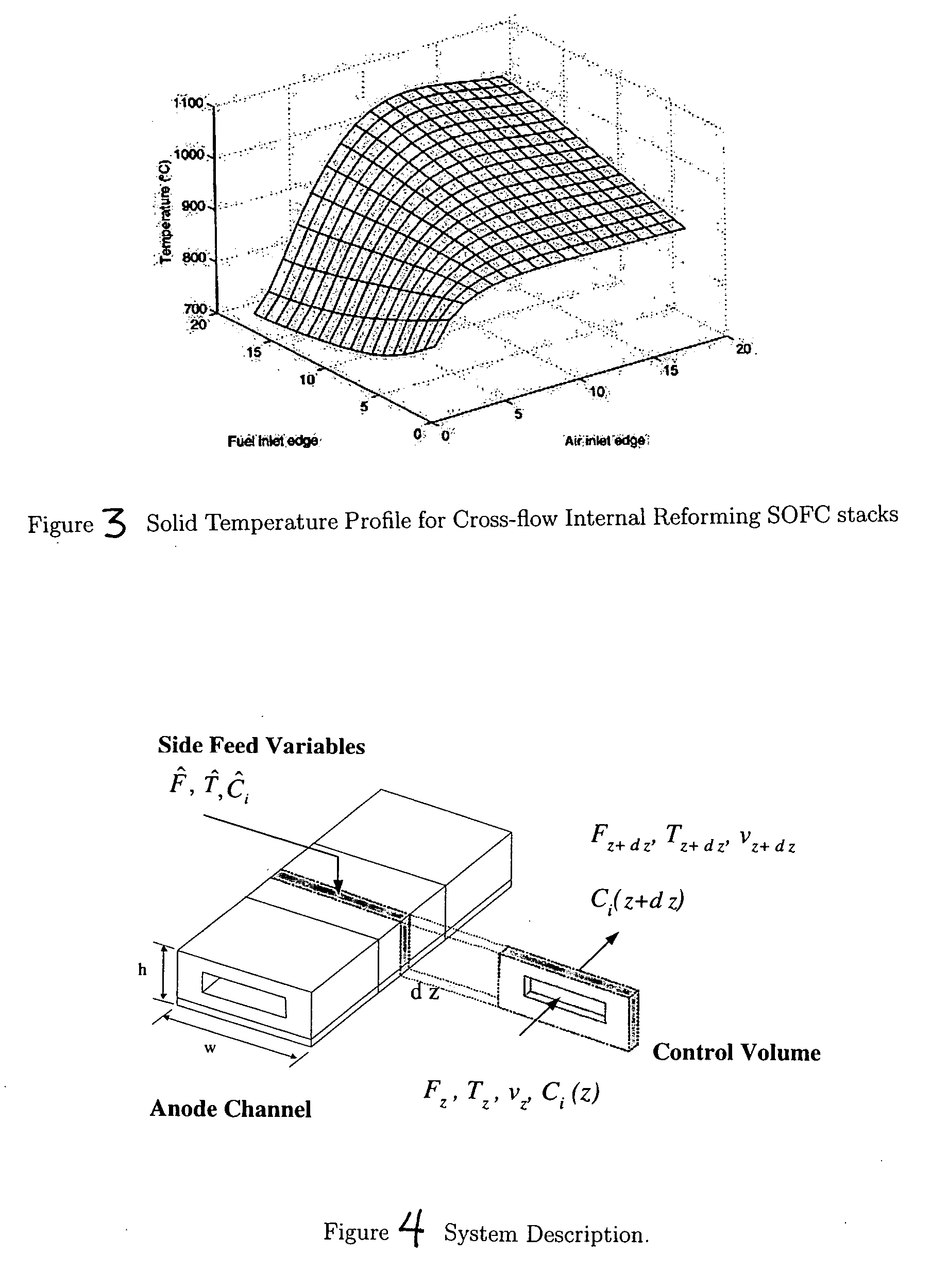

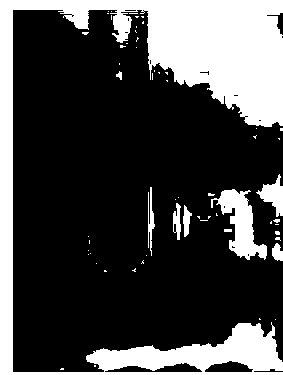

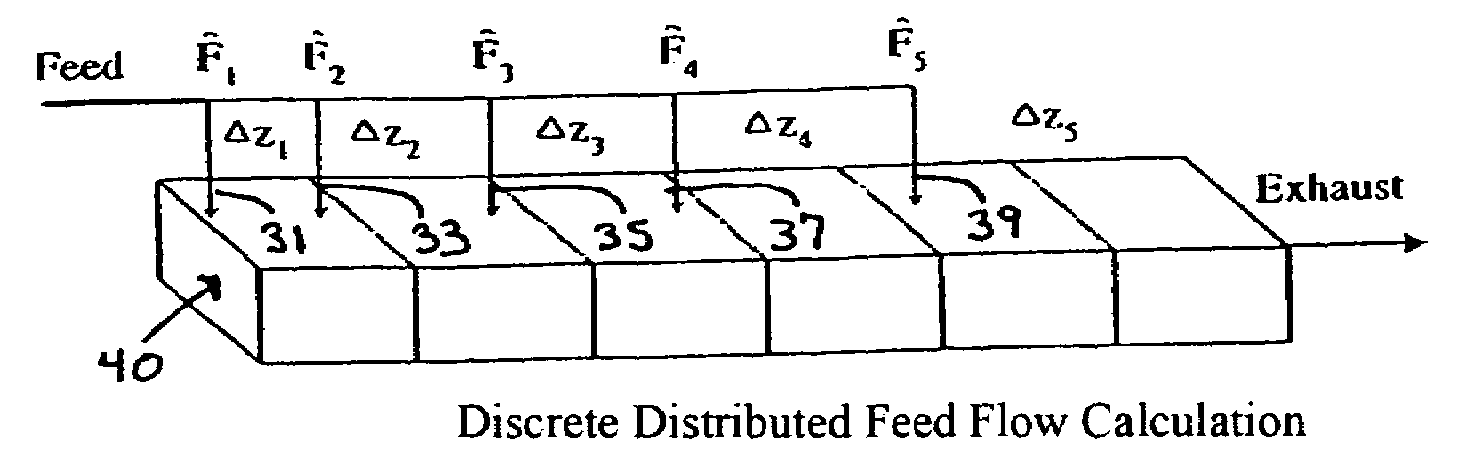

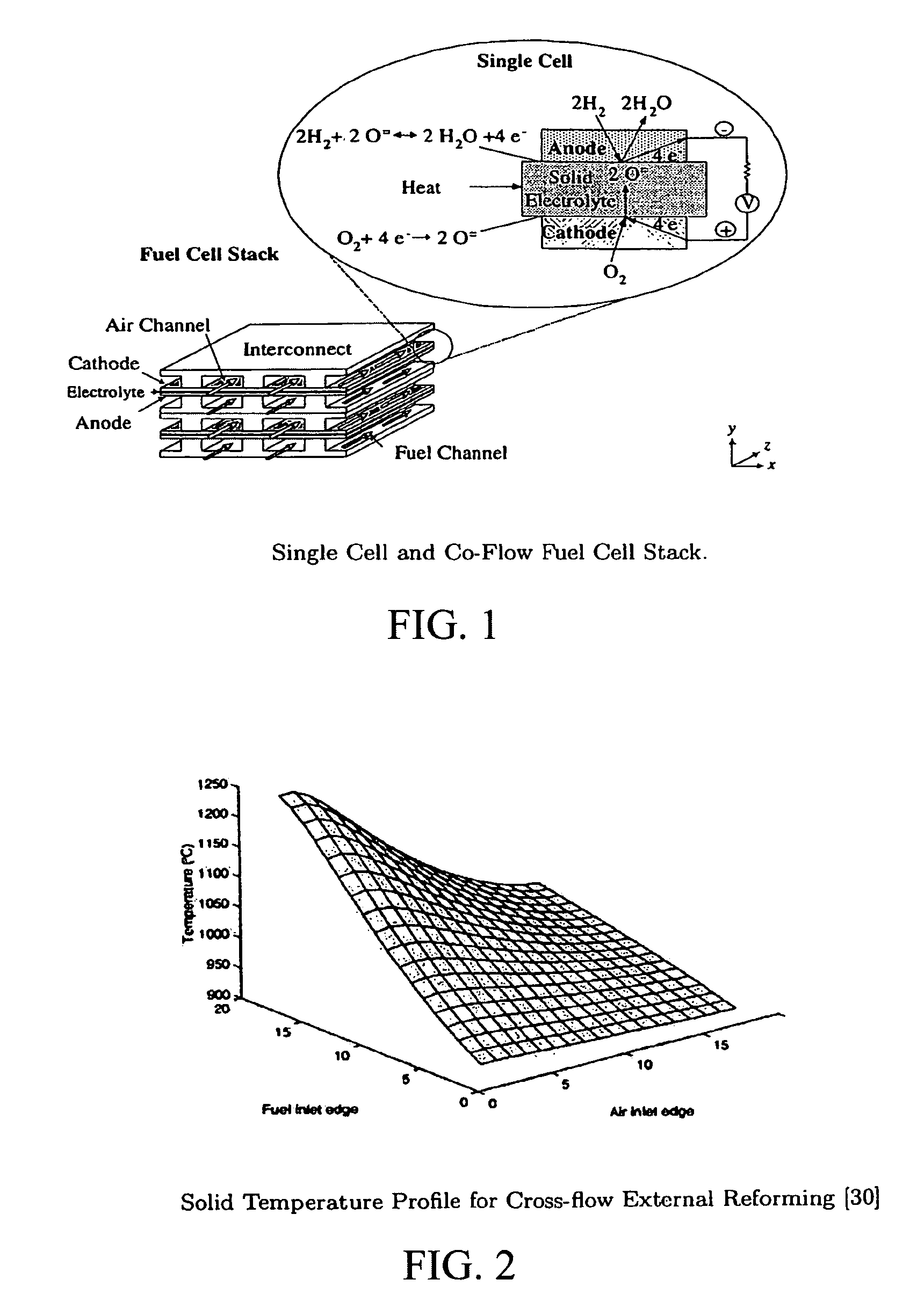

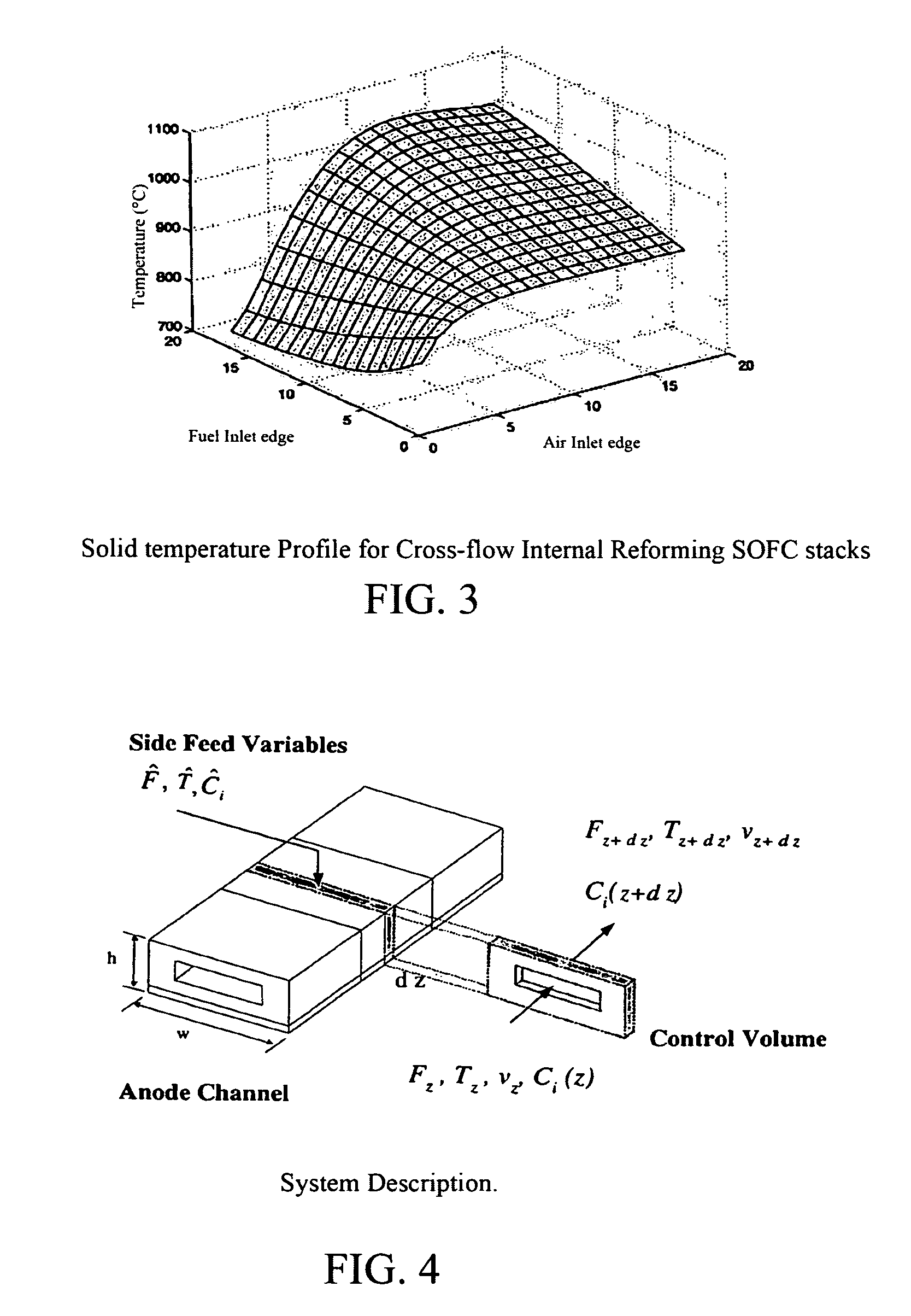

Distributed feed fuel cell stack

InactiveUS20050123821A1Improved thermal managementImprove power densityFuel cells groupingFuel cell auxillariesFuel cellsHeat generation

A fuel cell having a distributed fuel feed in which the heat generation profile can be better controlled. Fuel channel stack and system efficiency improvements are achieved.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

Aqueous alkali wet method corrosion technology for surface structure of solar cell

InactiveCN101431120ANo pollution in the processUniform reaction rateFinal product manufactureSemiconductor devicesEngineeringSolar cell

The invention relates to a solar cell surface processing technology, in particular to an alkaline solution wet etching technique of the surface structure of a solar cell. The technology comprises the following two operation processes of thinning and making herbs into wool. The concrete operation steps of the process of making herbs into wool are as follows: deionized water is added in a water tank of a cleaning device and a heating power supply is turned on; well weighed alkaline solids are poured according to the stipulated solution proportion and stirred evenly; slow release agent isopropyl alcohol is added and stirred evenly after the temperature is increased to the specified temperature; a well thinned silicon wafer is added for reaction. Compared with the existing method, the method can greatly improve the labor production efficiency, reduce the environmental pollution and increase the controllability of production operation.

Owner:展丰能源技术(上海)有限公司

Preparation method of polyaniline-polyacrylate compound

ActiveCN103897184AAchieve molecular level dispersionGood compatibilityAnti-corrosive paintsSolventAniline

The invention discloses a preparation method of a polyaniline-polyacrylate compound, and relates to the technical field of polyaniline synthesis. The preparation method comprises the following steps: firstly, enabling part of active solvent to be reacted with part of mixed monomers and initiator, then, heating the reacted mixed system, next, dropwise adding the other part of mixed monomers, initiator and active solvent, and carrying out preserved heat reaction until the reaction is ended; cooling the system generated through the reaction to 0-20 DEG C, adding aniline, uniformly stirring, then, dropwise adding an oxidative initiator solution, and then, reacting at normal temperature until the reaction is ended. Polyaniline and polyacrylate resin in the polyaniline-polyacrylate compound disclosed by the invention are formed into a molecular compound to be added into an anticorrosive coating, so that not only is the uniform dispersion of polyaniline in the coating realized, but also polyacrylate resin in the compound can be used for promoting the compatibility of the polyaniline and film forming materials in an anticorrosive coating, so that the long-acting corrosion resistance and environment friendliness of polyaniline in a heavy anticorrosive coating can be realized.

Owner:YANGZHOU UNIV

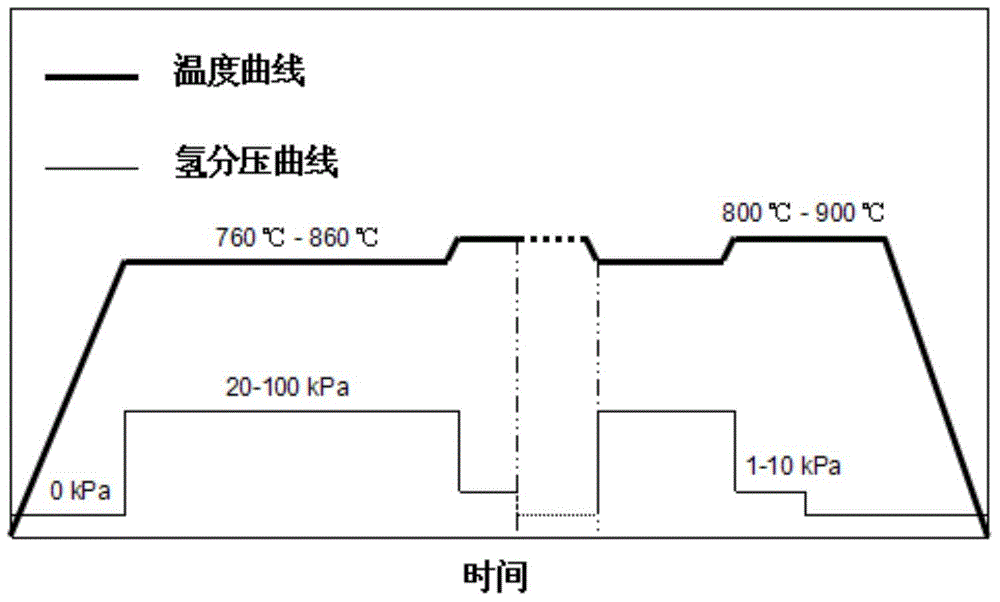

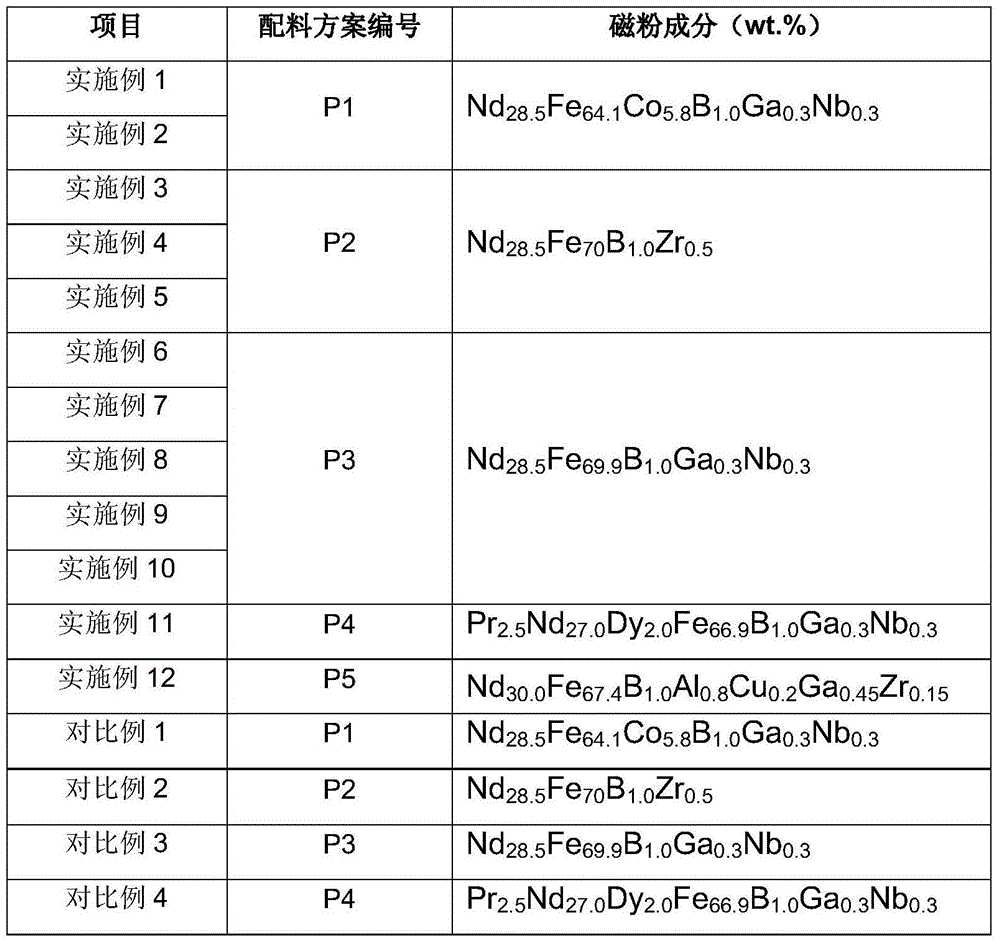

Preparing method of rare earth iron-boron-based anisotropy magnetic powder and prepared magnetic powder

ActiveCN104625079AImprove coercive forceLow costInorganic material magnetismMagnetic powderCoercivity

The invention discloses a preparing method of rare earth iron-boron-based anisotropy magnetic powder and the prepared magnetic powder. The method comprises the steps that rare earth iron-boron alloy particles are subjected to HDDR processing, the rare earth iron-boron alloy particles obtained after HDDR processing is subjected to HDDR processing again, and accordingly the high-coercivity rare earth iron-boron-based anisotropy magnetic powder is obtained. The coercivity of the rare earth iron-boron-based anisotropy magnetic powder can be greatly improved, magnetic powder cost cannot be increased, and the residual magnetism and the maximum magnetic energy product of the magnetic powder cannot be lowered greatly.

Owner:BEIKUANG MAGNETS FUYANG CO LTD

Additive for silicon wafer alkali liquor texturing

PendingCN112877784AImprove photoelectric conversion rateUniform reaction ratePolycrystalline material growthAfter-treatment detailsAlcoholSilicic acid

The invention provides an additive for silicon wafer alkali liquor texturing, and belongs to the technical field of photovoltaics. The mass percent of each component is as follows: 0.5%-15% of a buffer component, 0.5%-10% of a dispersing component, 0.1%-8% of a suede adjusting component A, 0.01%-5% of a suede adjusting component B and the balance of water. The obtained texturing additive can be applied to diamond wire cutting single crystal alkali liquor texturing and can also be applied to diamond wire polycrystal alkali liquor rough texturing. Compared with traditional alcohol added components, the additive has the advantages of no toxicity, no volatilization, uniform reaction rate, no piebaldness and excellent foam control effect. The staying and separating time of bubbles on the surface of the silicon wafer can be controlled by adjusting the proportion of the suede adjusting components A and B, and the alkali suede making effect is enhanced. After the single crystal is applied, the silicon wafer has high photoelectric conversion rate. After the polycrystal is applied, the conversion efficiency can be improved by combining the existing black silicic acid texturing technology.

Owner:武汉宜田科技发展有限公司

Distributed feed fuel cell stack

InactiveUS7632596B2Improved thermal distribution and mass and thermal integrationImproved thermal managementFuel cells groupingFuel cell auxillariesFuel cellsNuclear engineering

A fuel cell having a distributed fuel feed in which the heat generation profile can be better controlled. Fuel channel stack and system efficiency improvements are achieved.

Owner:ILLINOIS INSTITUTE OF TECHNOLOGY

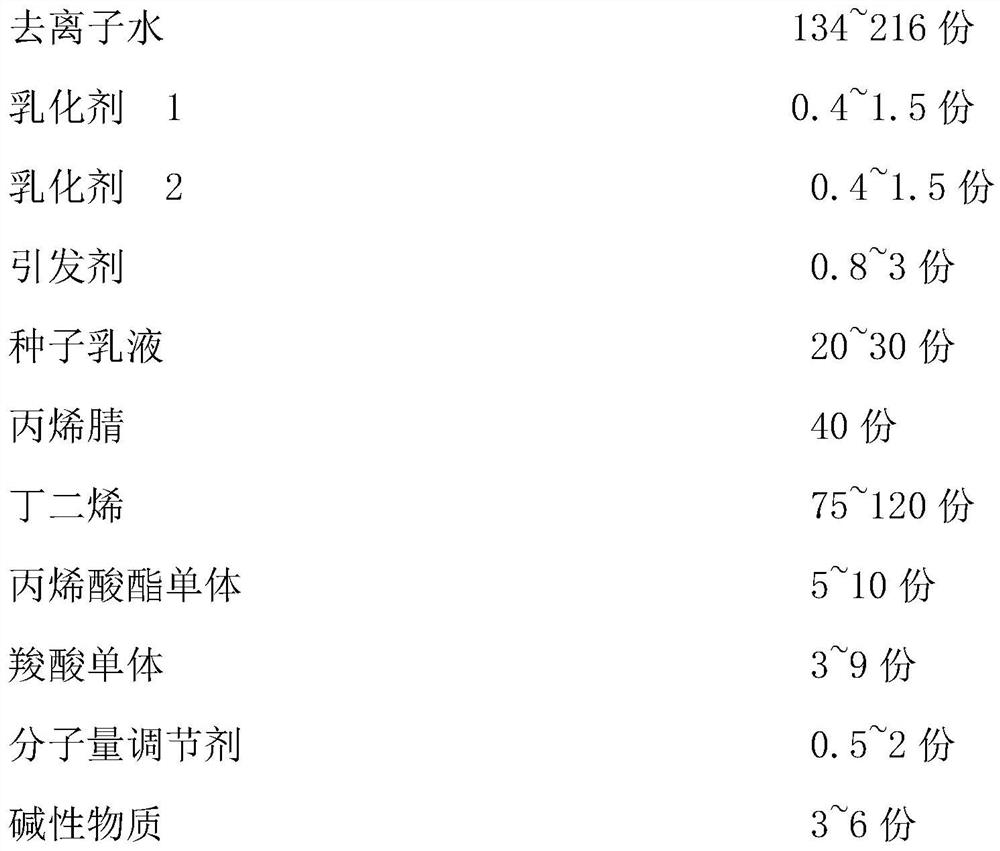

Preparation method of carboxylic butadiene-acrylonitrile latex

The invention belongs to the technical field of emulsion polymerization, and relates to a preparation method of carboxylic butadiene-acrylonitrile latex. A seed emulsion polymerization technology is adopted, and the preparation method comprises the steps of vacuumizing a polymerization kettle, adding deionized water, an emulsifier 1, an emulsifier 2, a seed emulsion and an initiator, carrying out gradient heating at the temperature of 25-60 DEG C, starting to dropwise add a mixture solution of acrylonitrile, butadiene, a carboxylic acid monomer and a molecular weight regulator for free radical emulsion polymerization for 6-9 hours, heating to 75 DEG C, keeping the temperature for 2 hours, cooling, adjusting the pH value of a reaction product to 6-8 by using an alkaline substance, and filtering to obtain carboxylic butadiene-acrylonitrile latex. Compared with the prior art, the carboxylic butadiene-acrylonitrile latex provided by the invention has excellent stability. The carboxylic butadiene-acrylonitrile latex is good in flowability, and is suitable for dipping gloves, medical examination gloves, thin (unlined) gloves and the like. The gradient heating process is adopted, the reaction condition is mild, the monomer is dropwise added, the temperature runaway phenomenon and the condensation product generation are effectively controlled, and the process is easy to control.

Owner:SHANGHAI CHANGFA NEW MATERIAL CO LTD

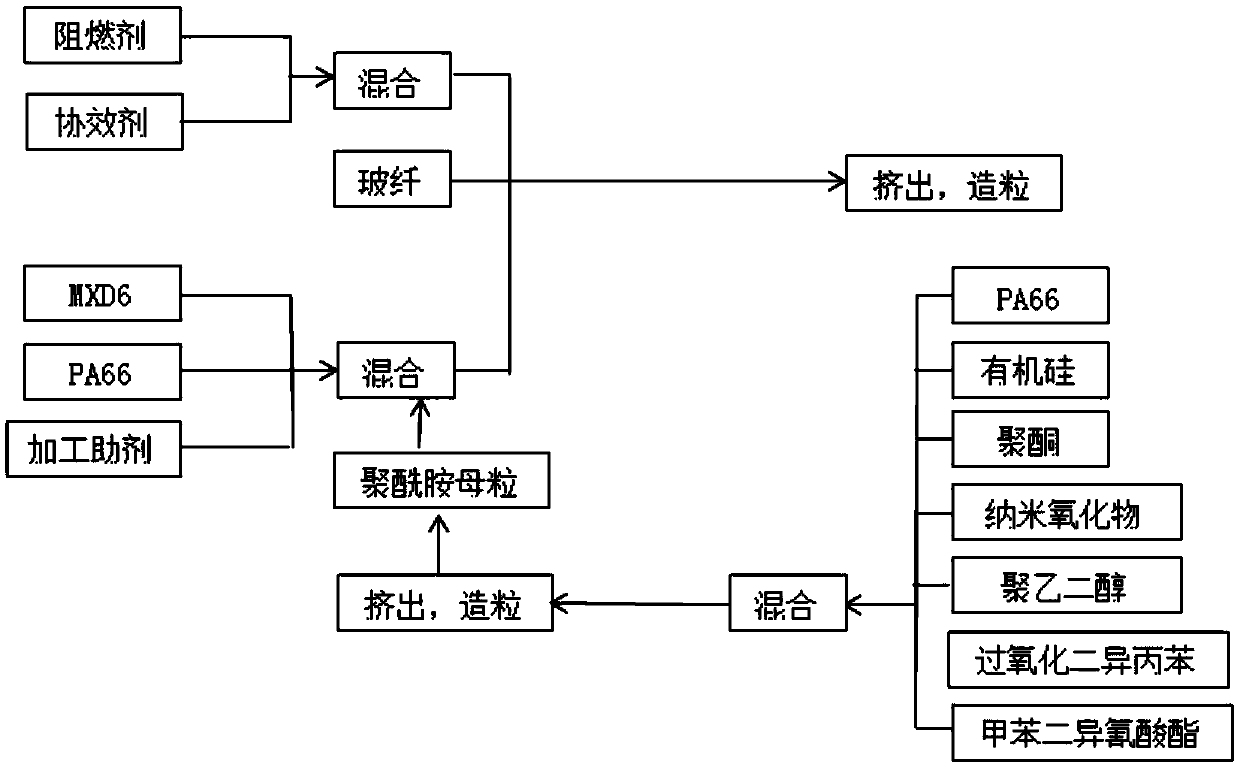

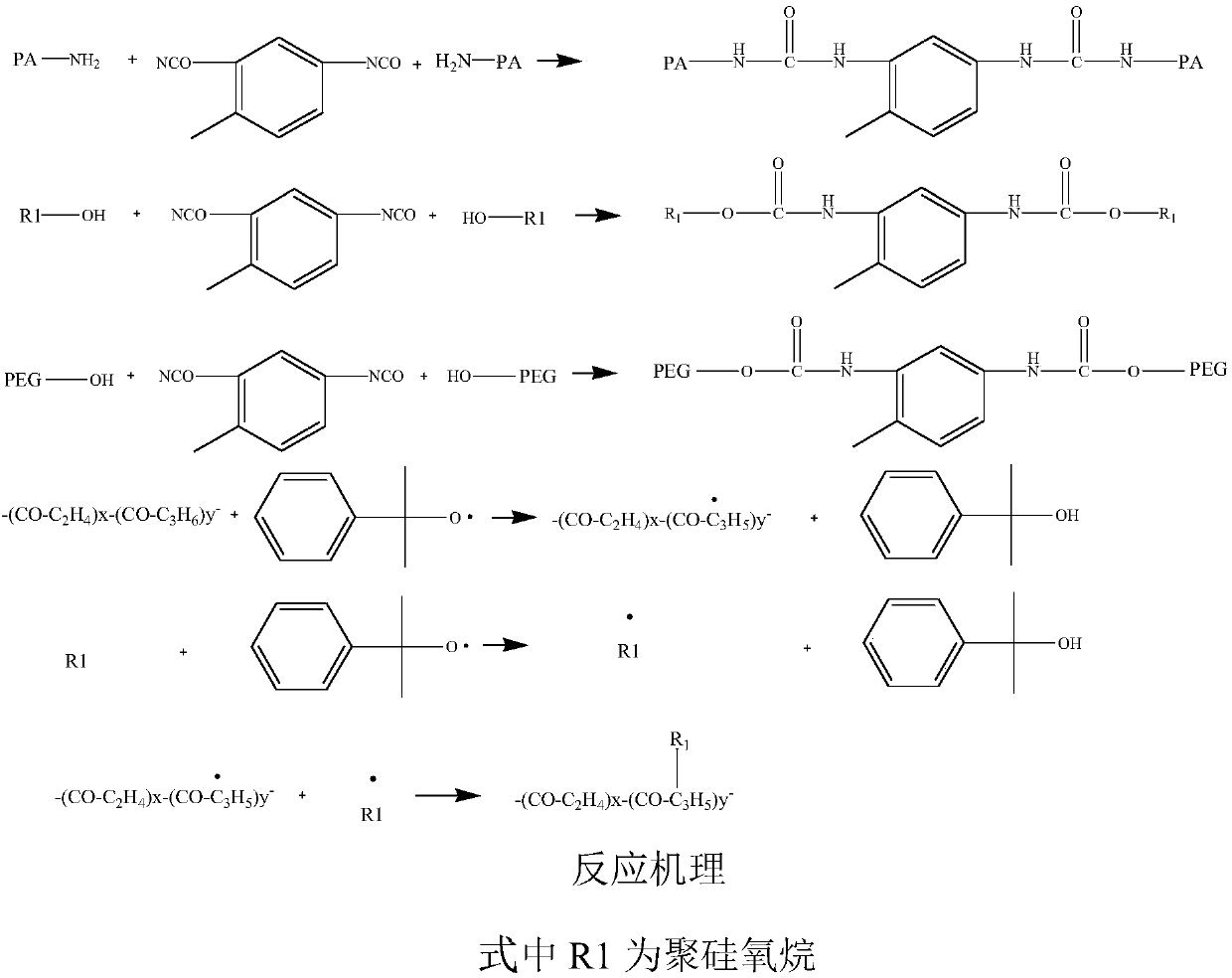

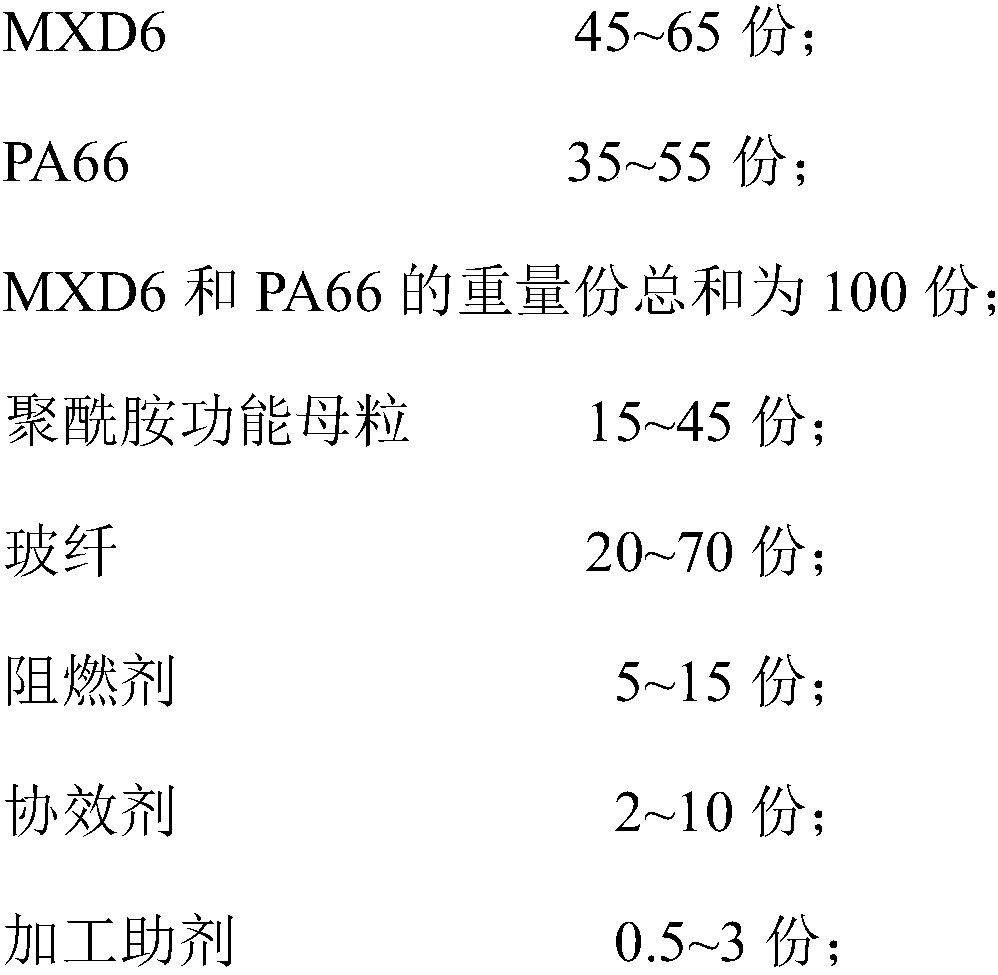

Low-water-absorption good-appearance flame-retarding polyamide composition and preparation method thereof

Owner:GUANGDONG ALDEX NEW MATERIAL CO LTD

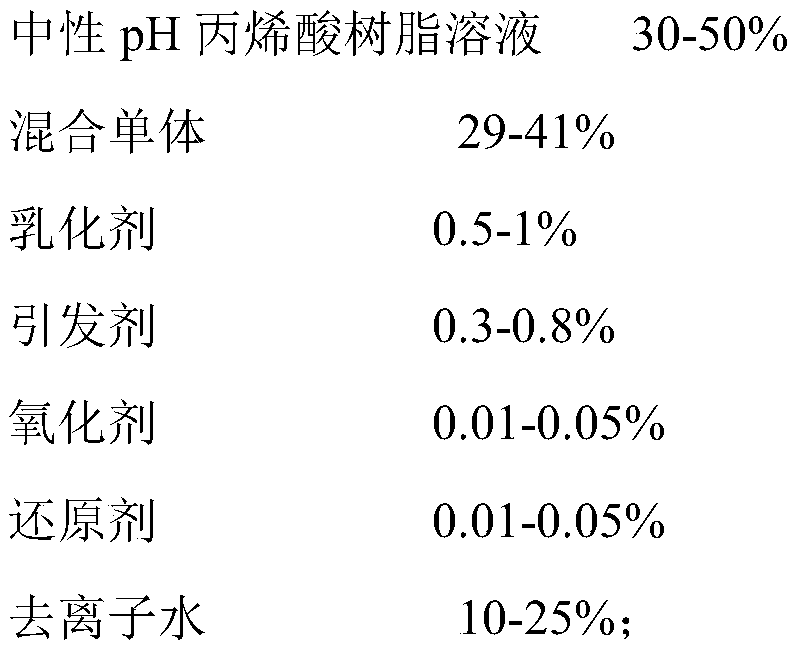

Anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from same

ActiveCN107033288AImprove defoaming abilityStrong anti-foaming abilityPaper coatingCorrosion-inhibiting/anti-oxidant agent additionCardboardHot stamping

The invention relates to the technical field of coating varnish, in particular to anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from the same. The anti-oxidation emulsion is prepared from raw materials in percentage by weight as follows: 30%-50% of an acrylic resin solution with neutral pH, 29%-41% of mixed monomers, 0.5%-1% of an emulsifier, 0.3%-0.8% of an initiator, 0.01%-0.05% of an oxidizing agent, 0.01%-0.05% of a reducing agent and 10%-25% of deionized water, and the sum of the raw materials in percentage by mass is 100%. According to the anti-oxidation emulsion, possibly existing acid-base substances can be reduced, the probability of oxidation is reduced, and hot stamping foil is not prone to oxidation; the anti-oxidation waterborne coating varnish prepared from the anti-oxidation emulsion contains no organic solvents, is low in content of VOCs (volatile organic chemicals) or free of VOCs, is environment-friendly, non-toxic and anti-oxidation, and is suitable for surface lustering of substrates, prone to hot stamping oxidation, of black cardboards, blackened paper, coated black paper and the like.

Owner:GUANGDONG YINGKE GRP CO LTD

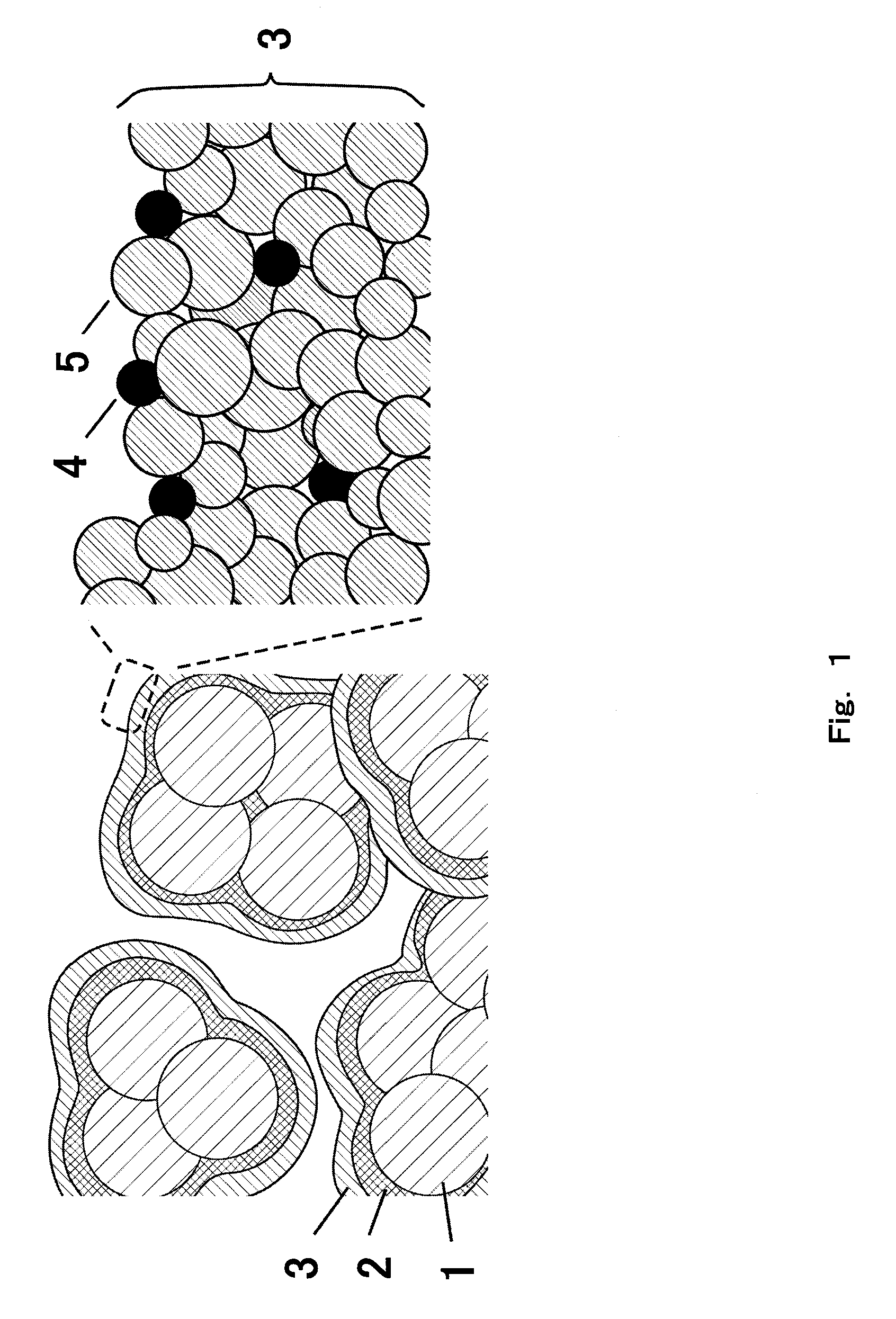

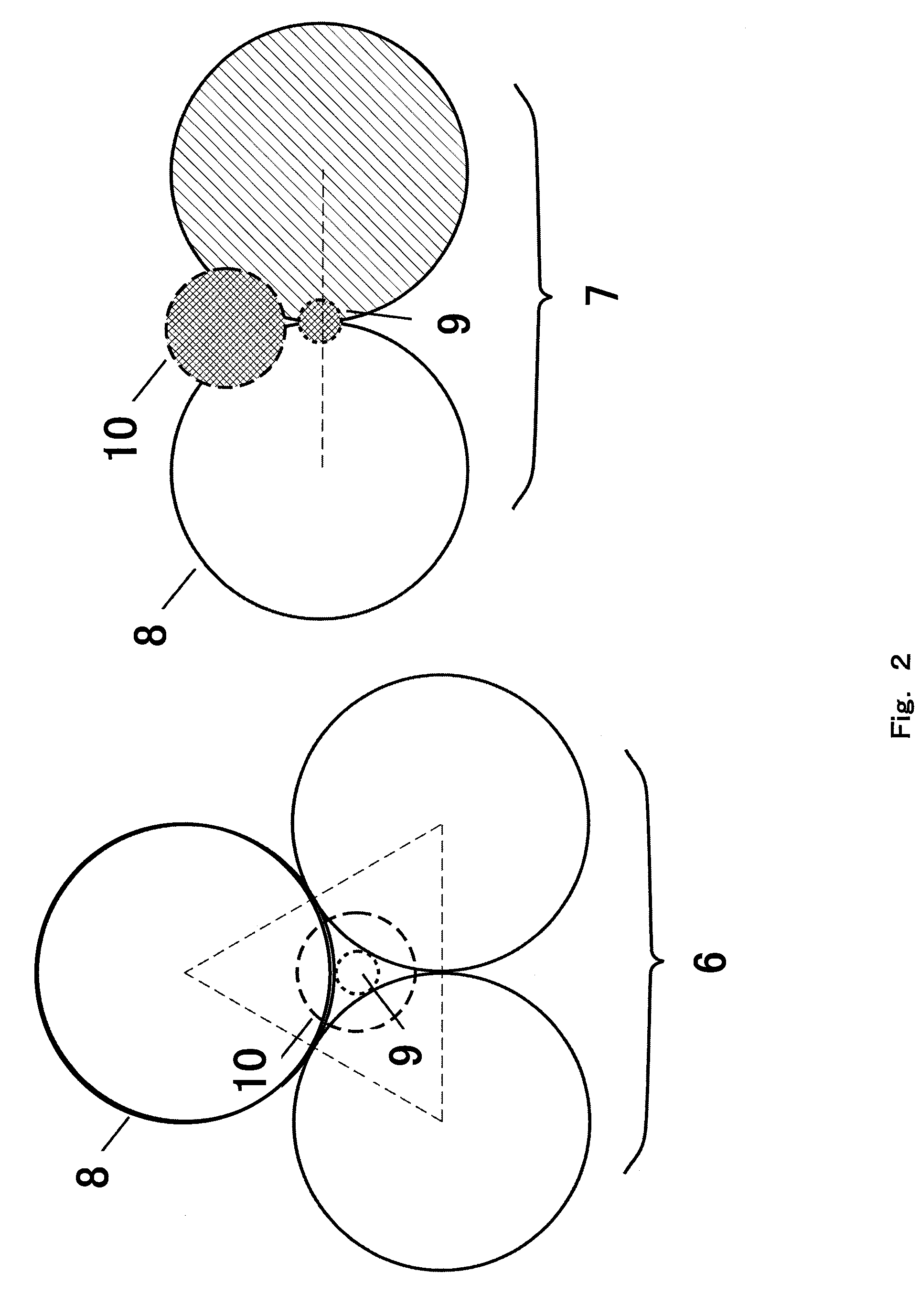

Fuel cell comprising oxygen electrode with surface nanostructure

InactiveUS20100104915A1Uniform reaction rateAccurate operationActive material electrodesSolid electrolyte fuel cellsCarbon NanoparticlesNanometre

The present invention is aimed to realize, in a fuel cell with an oxygen electrode (a catalytic electrode), both catalytic function and immobilization of the catalyst nanoparticles when the catalyst nanoparticles are very small nanoparticles in the size of 1-3 nm.Oxygen electrode used in the fuel cell according to the present invention is an oxygen electrode comprising a plurality of carbon particles, a carbon thin-film, and surface nanostructure, wherein the carbon particles are bonded to one another with the carbon thin-film 2, the surface nanostructure is formed on the surface of the carbon thin-film, the surface nanostructure comprises catalyst nanoparticles made of platinum (Pt) and carbon nanoparticles, diameter of each of the carbon particles is 30 nm or more and 100 nm or less, diameter of the catalyst nanoparticle is 1.7 nm or more and 3.1 nm or less, and diameter of the carbon nanoparticle is 1.0 nm or more and 11.2 nm or less. According to this combination of these elements, the catalyst nanoparticles are confined within three-dimensional structure to be formed by the carbon nanoparticles and are immobilized without losing space which allows any reactant to be accessed to the surface of the catalyst nanoparticles.

Owner:PANASONIC CORP

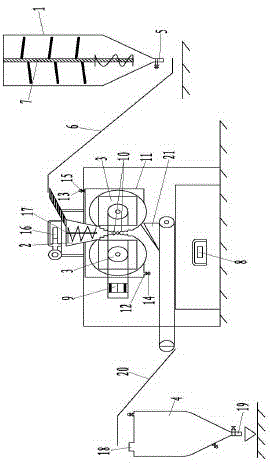

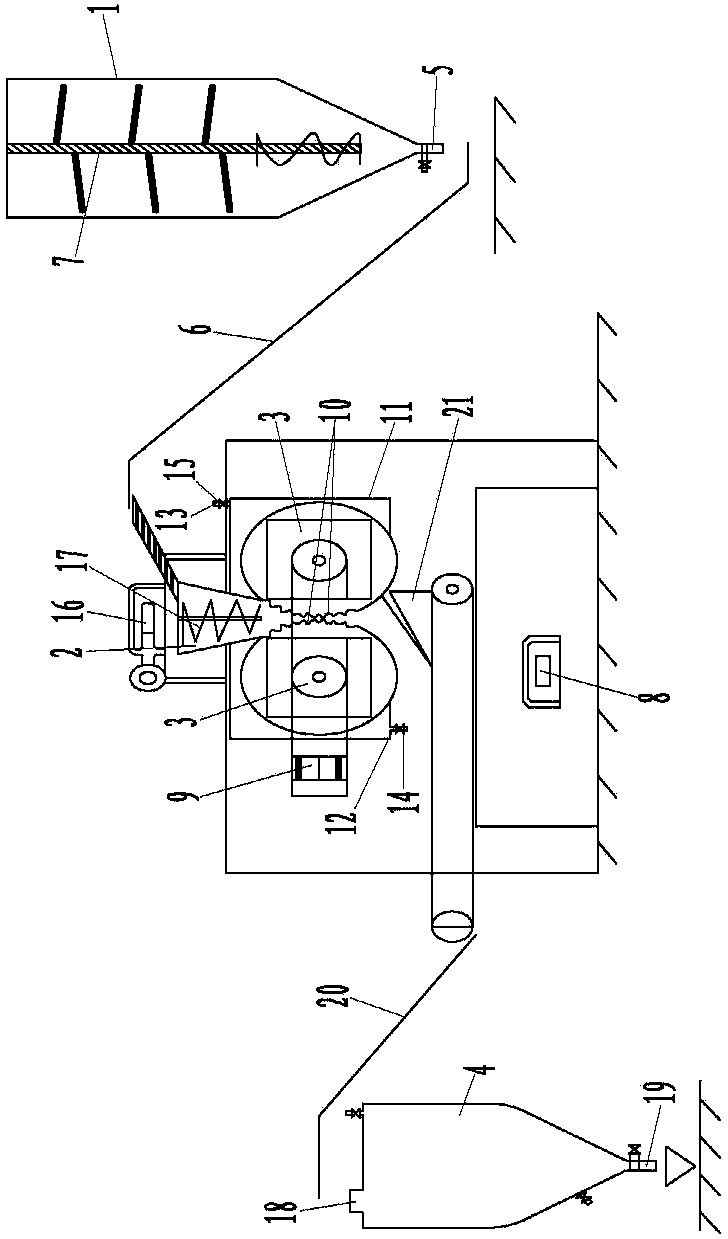

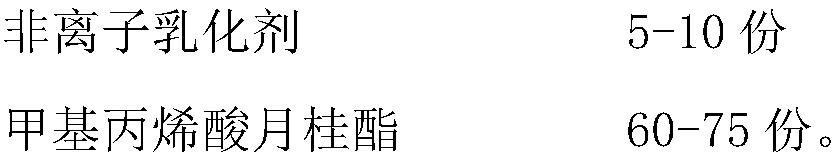

Calcium carbide powder molding equipment

The invention discloses calcium carbide powder molding equipment. The calcium carbide powder molding equipment comprises a taper hopper, wherein two extrusion dies which are driven by power equipment to rotate in opposite directions and are extruded mutually are arranged below the taper hopper; an outlet in the lower end of the taper hopper directly faces the extruded parts of the two extrusion dies; a plurality of concave dies are arranged on the outer surfaces of the two extrusion dies; the two extrusion dies are both mounted in a protection casing provided with an inner cavity filled with nitrogen. The calcium carbide powder molding equipment can be used for safely preparing calcium carbide balls or calcium carbide blocks and inhibits flying of calcium carbide powder dust, the prepared calcium carbide balls or calcium carbide blocks are put into an acetylene production kettle for recycling, the reaction rate is uniform, the amount of gas evolution is high, and the economic benefit is increased.

Owner:郭蓉

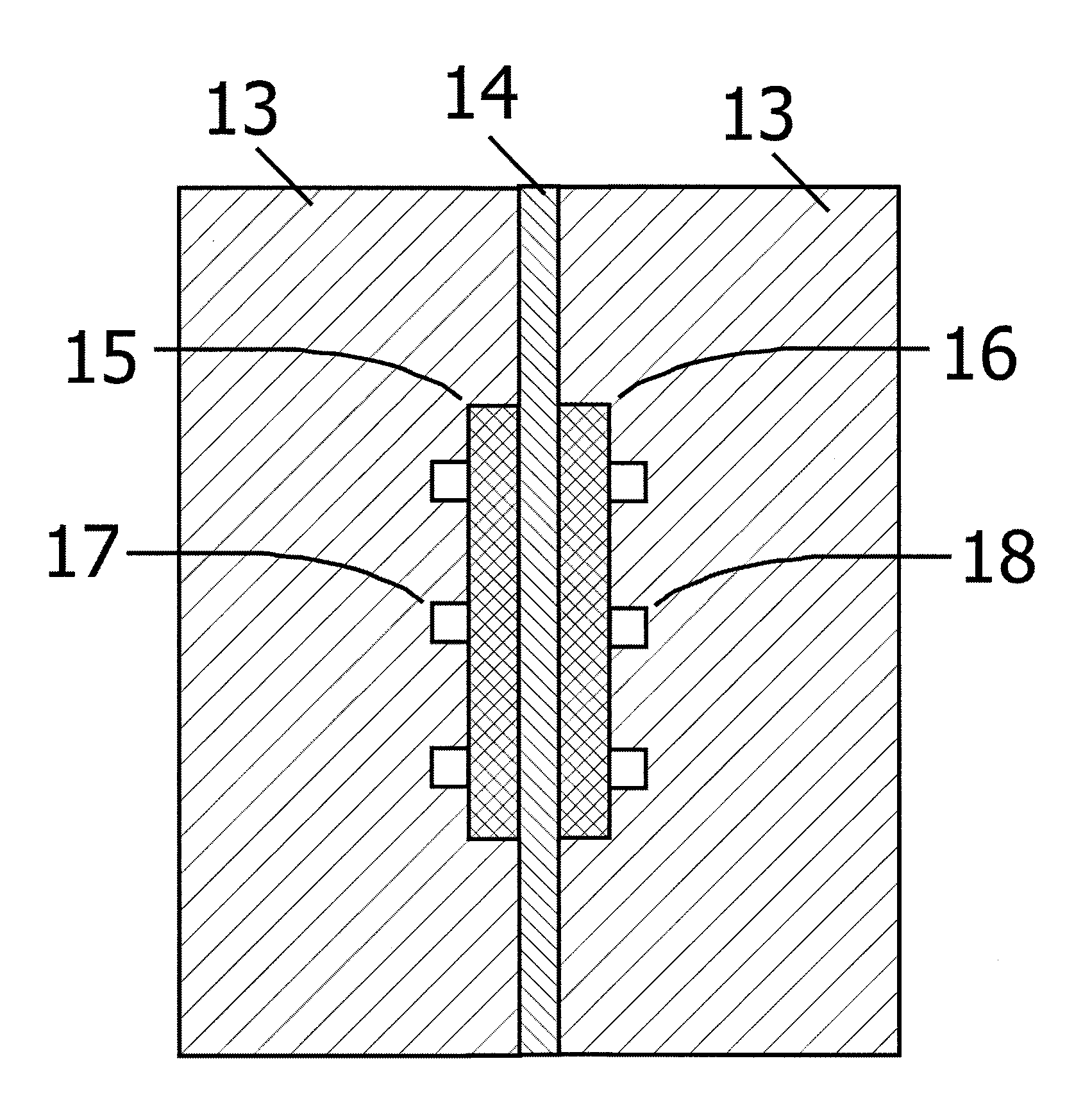

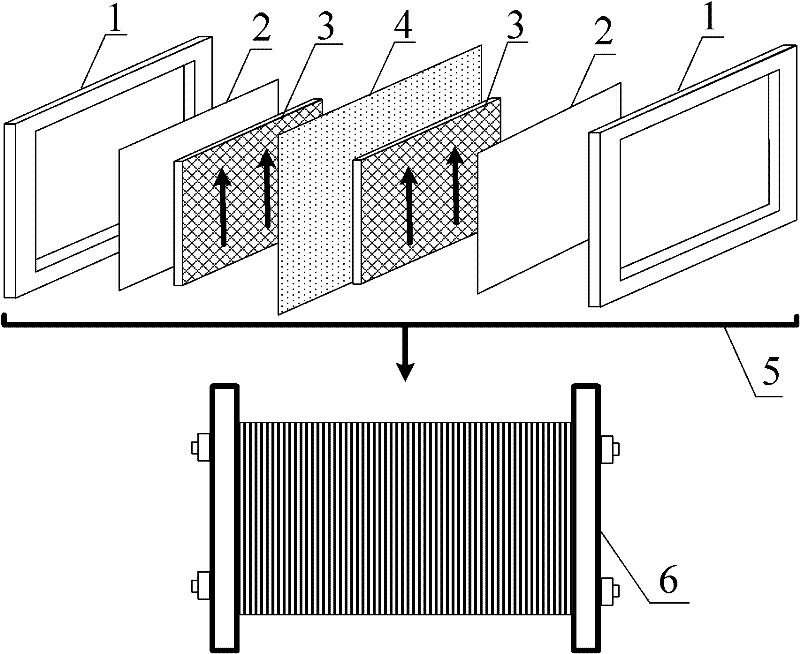

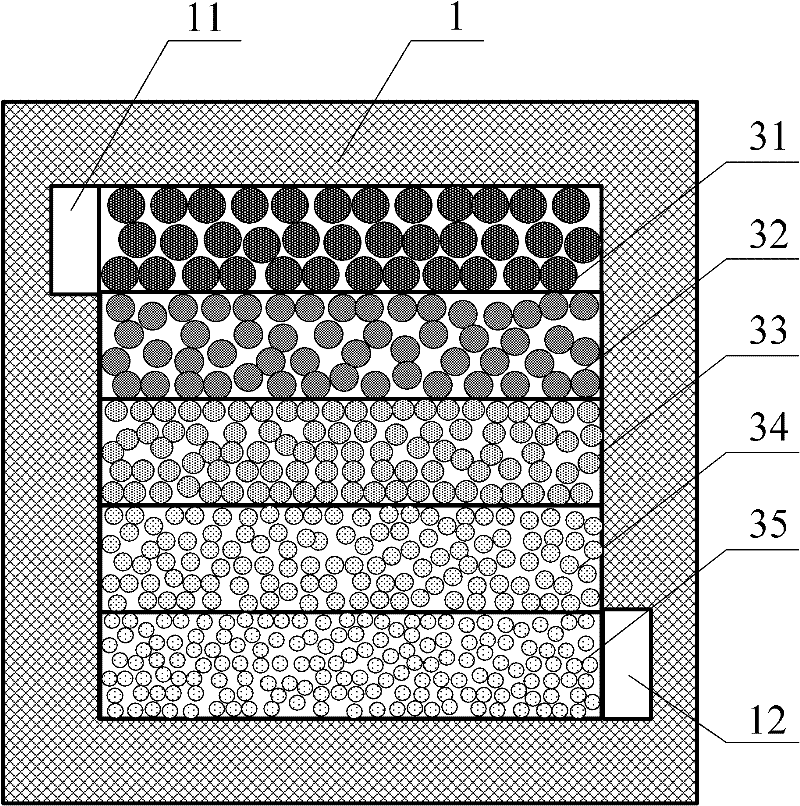

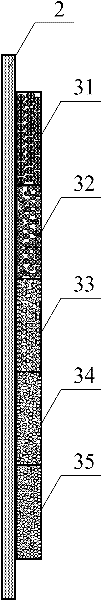

Flow battery, flow battery stack and flow battery system

ActiveCN102290591AThe concentration of the reacting species decreasesUniform reaction rateFuel cells groupingCell electrodesFlow cellReaction rate

The invention provides a redox flow cell, a redox flow cell stack and a redox flow cell system, wherein the redox flow cell comprises flow frames (1), collector plates (2), an ion exchange membrane and electrodes (3); each flow frame (1) is provided with a middle passage, a liquid inlet (11) and a liquid outlet (12), and the liquid inlet (11) and the liquid outlet (12) communicate with the middle passage; the collector plates (2) are arranged in the middle passages of the flow frames (1); the ion exchange membrane is arranged between the collector plates (2), and electrolyte-containing cavities are defined by the ion exchange membrane and the collector plates (2); and the electrodes (3) are arranged in the cavities, and are so arranged that the specific surface areas are gradually enlarged along the flowing direction of electrolyte from the liquid inlets (11) to the liquid outlets (12). The invention effectively solves the problem that the reaction rate and the reaction-produced heat at each part of the electrode are ununiform because the concentration of the reaction substances in the electrolyte is gradually decreased as reaction goes on, consequently, polarization is effectively reduced in the processes of charge and discharge, the charge-discharge performance of the cell is enhanced, and the service life of the cell is prolonged.

Owner:DONGFANG ELECTRIC (CHENGDU) HYDROGEN FUEL CELL TECH CO LTD

Polyester resin for hybrid powder coating and preparation method thereof

ActiveCN101704945BUniform reaction rateGood solvent resistancePowdery paintsPolyester coatingsHybrid typeLow temperature curing

The present invention relates to the field of powder coatings, in particular to a polyester resin for hybrid thermal transfer powder coatings and a preparation method thereof. The polyester resin for hybrid thermal transfer powder coatings includes the following components and content: polyester resin The molar ratio of acid / alcohol is 1 / 1.05-1.20; Wherein the content of each alcohol accounts for the percentage of total alcohol mole number respectively: neopentyl glycol 10-90mol%; 2 methyl 1,3 propanediol 0-45mol%; Glycol 0-20mol%; diethylene glycol 10-25mol%; wherein the content of each acid accounts for the percentage of total acid moles: terephthalic acid 80-100mol%; isophthalic acid 0-10mol%; Acid 0-10mol%; Trimellitic anhydride accounts for 10-15wt% of polyester resin total amount; Compound onium salts account for 0.1-1.0wt% of polyester resin total amount, and the branching component of this polyester resin is passed trimellitic anhydride Adjust the functionality of the polyester resin by adjusting the amount of the polyester resin, the obtained cured film has a better surface appearance, and realizes low-temperature (160°C) curing, and the low-temperature curing rate of the coating film is high, and the cured film has good solvent resistance. The final transfer film is clear and realistic and easy to tear off the paper.

Owner:HUANGSHAN SHENJIAN NEW MATERIAL CO LTD

Aqueous high-modulus inorganic zinc-rich coating added with catalyst

InactiveCN107841166AUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsAnti-corrosive paintsColloidal particleCoating

The invention relates to an aqueous high-modulus inorganic zinc-rich coating added with a catalyst and a preparation method thereof. The coating is prepared by mixing a lithium silicate solution, water, aluminum-modified silica sol, tetraethylammonium hydroxide, dodecyl glycol amide, a silane coupling agent, a silicone-acrylate emulsion and low-lead zinc powder. According to the aqueous high-modulus inorganic zinc-rich coating added with the catalyst, the tetraethylammonium hydroxide catalyst is added into the coating and is used for catalyzing reaction between the lithium silicate solution and the aluminum-modified silica sol, so that the uniformity of the colloid particles after reaction is improved.

Owner:林家天

Calcium carbide powder forming equipment and process for machining calcium carbide powder into calcium carbide balls or blocks

InactiveCN104228110AConvenient mixing and conveyingEasy to transportShaping pressPowder mixtureNitrogen

The invention discloses calcium carbide powder forming equipment and a process for machining calcium carbide powder into calcium carbide balls or blocks. The equipment comprises a taper hopper. A pair of extrusion dies is disposed below the taper hopper. The extrusion dies are driven by power equipment to rotate along opposite directions and extrude each other. The lower-end outlet of the taper hopper faces directly to the extruding part of the two extrusion dies. A plurality of female dies are disposed on the outer surface of each extrusion die. The two extrusion dies are mounted in the cavity, filled with nitrogen, of a protective shell. Collected calcium carbide powder and mixed materials are mixed and then fed into the taper hopper, and the calcium carbide powder mixture enters the extrusion dies and is extruded by the female dies of the two extrusion dies to form the calcium carbide balls or blocks. By the calcium carbide powder forming equipment, the calcium carbide balls or blocks can be manufactured safely, calcium carbide powder dust flying is inhibited, the manufactured calcium carbide balls or blocks can be reused in acetylene generating kettles, even reaction speed and high gas generating quantity, and economical benefits are increased.

Owner:亿绿兰德(北京)技术有限公司

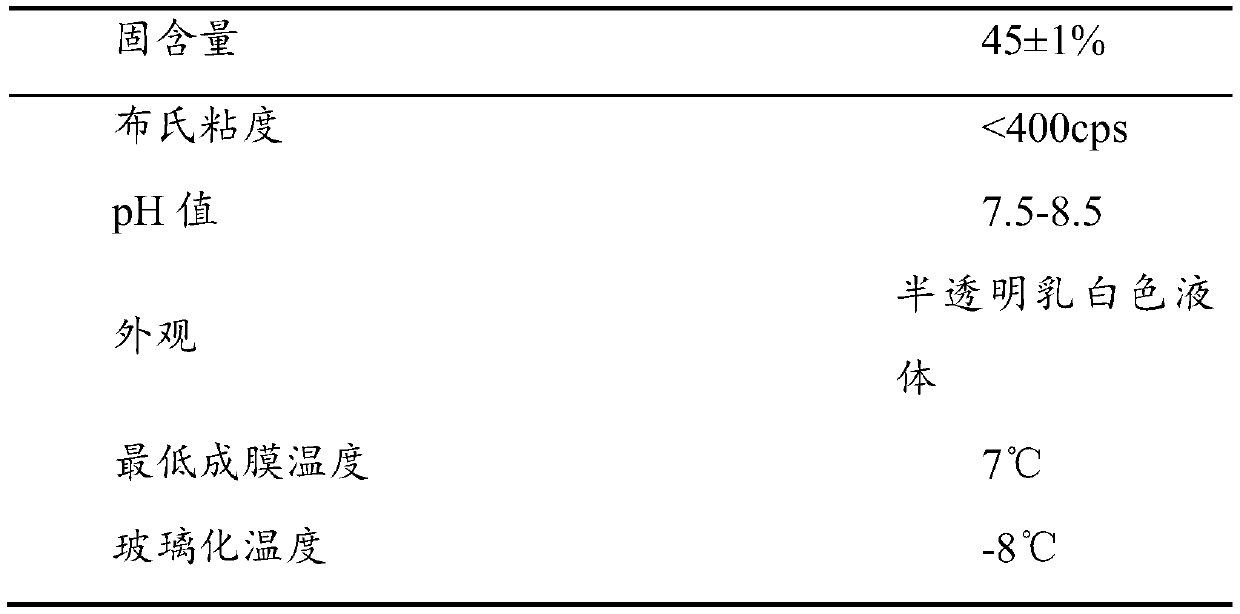

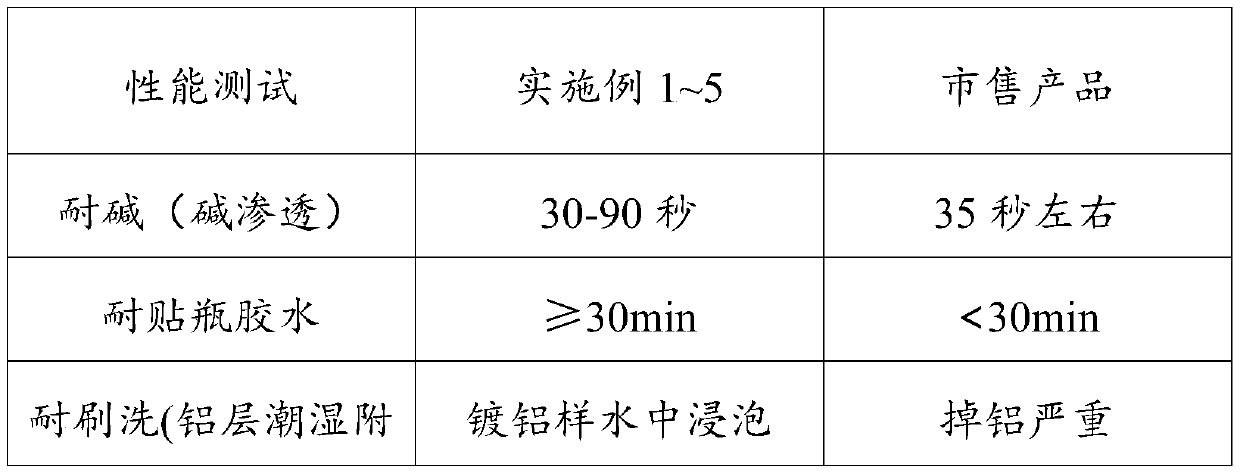

Water-based emulsion for beer label and preparation method thereof

The invention belongs to the technical field of labels, and particularly discloses a water-based emulsion for a beer label and a preparation method thereof. The water-based emulsion is prepared from the following components in parts by weight: a phase A of 80-150 parts of acrylic resin and 250-350 parts of deionized water, a phase B of 1-10 parts of a reactive emulsifier and 3-5 parts of deionizedwater, a phase C of 0.5-1.5 parts of an initiator and 1-15 parts of deionized water, a phase D of 10-25 parts of a compound composed of diacetone acrylamide and adipic acid dihydrazide and 5-15 partsof deionized water, a phase E of 250-400 parts of mixed reactants and a phase E1 of 20-40 parts of mixed reactants, wherein the mass ratio of the diacetone acrylamide to the adipic acid dihydrazide is 2-3:1. The water-based emulsion belongs to the self-crosslinking type and has excellent alkali resistance, adhesive force and bottle sticking glue resistant performance, the problems that in the prior art, a beer label coating is poor in alkali resistance, poor in bottle sticking glue resistance and poor in water resistance, the wet adhesive force is poor, and an original coating is low in viscosity and difficult to clean can be solved, the water-based emulsion can be better recycled and is more environmentally friendly, and the pollution to the environment is reduced.

Owner:广州富思德化工科技有限公司

Nickel-free hole sealing agent for improving compactness of aluminum alloy anode oxide film and preparation method of nickel-free hole sealing agent

InactiveCN105200495AImprove antioxidant capacityRaise sub> <sup>2-<</sup> Surface reaction electrolytic coatingReaction rateZirconium oxychloride

The invention provides a nickel-free hole sealing agent for improving the compactness of an aluminum alloy anode oxide film. The nickel-free hole sealing agent is prepared from, by weight, 8-8.5 parts of magnesium acetate, 19-20 parts of triethanolamine, 3-3.2 parts of ammonium acetate, a proper amount of deionized water, 0.2-0.4 part of zirconium oxychloride, 1.1-1.2 parts of lithium stannate, 0.3-0.4 part of vitamin E, 0.4-0.5 part of titanyl sulfate, 0.4-0.5 part of lithium silicate, 2.6-2.8 parts of lauryl fluorine heptyl propyl trimethoxysilane, 1-1.2 parts of tetrabutyl titanate, 45-48 parts of ethyl alcohol, 8.6-9 parts of ammonium hydroxide and 0.3-0.4 part of fluorine-containing surfactant. Due to the fact that zirconium oxychloride, lithium stannate, vitamin E and titanyl sulfate are adopted, the nickel-free hole sealing agent can permeate to the bottom of a gap, the reaction rate is even, the compactness of the oxide film can be greatly improved, and corrosion resistance is greatly improved.

Owner:MAANSHAN JIECHUANG PLASTIC TECH CO LTD

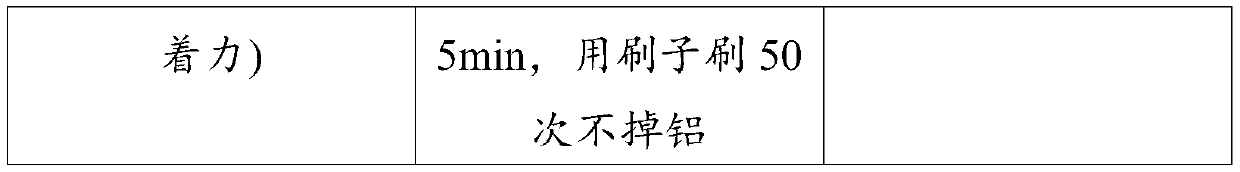

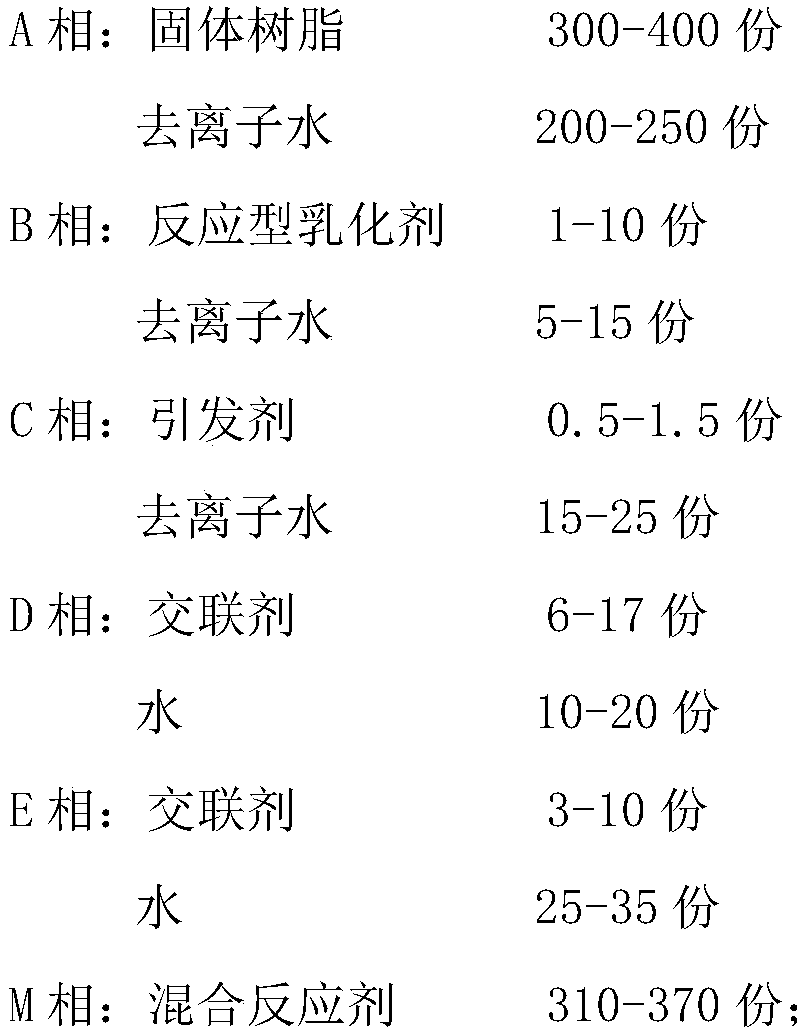

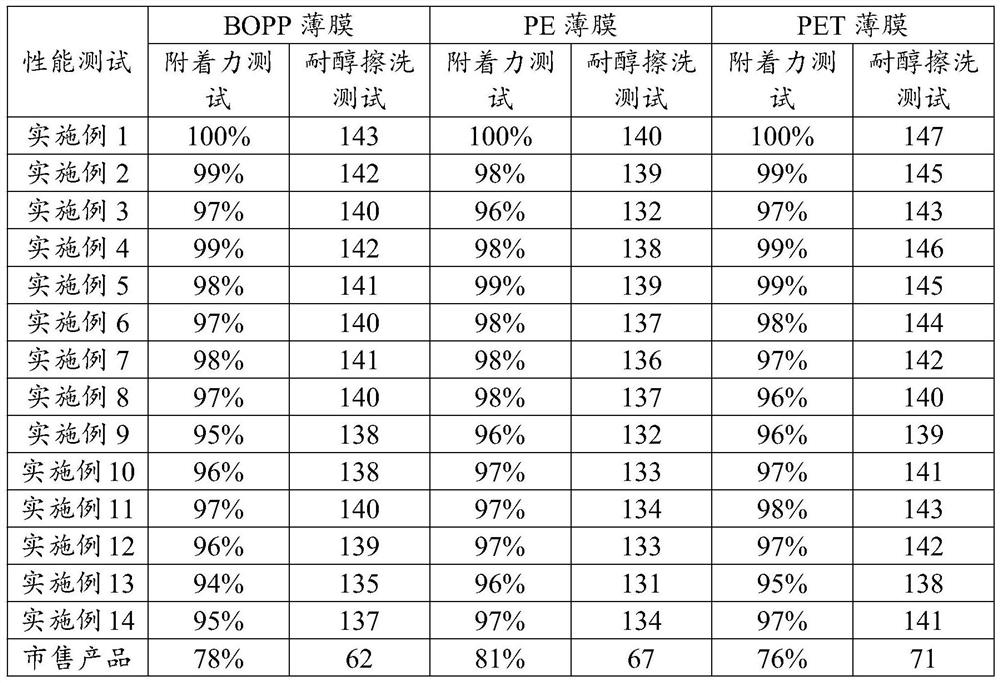

A special aqueous emulsion for plastic film ink and preparation method thereof

The invention belongs to the technical field of ink emulsion, and in particular relates to a special water-based emulsion for plastic film ink and a preparation method thereof. The water-based emulsion includes the following raw materials in parts by weight: Phase A: 300-400 parts of solid resin, 200-250 parts of deionized water; Phase B: 1-10 parts of reactive emulsifier, 5-15 parts of deionized water; Phase C: 0.5-1.5 parts of initiator, 15-25 parts of deionized water; Phase D: 6-17 parts of crosslinking agent, 10 parts of water ‑20 parts; E phase: 3‑10 parts of crosslinking agent, 25‑35 parts of water; M phase: 310‑370 parts of mixed reaction agent. The water-based emulsion of the present invention has excellent adhesion to non-absorbent substrates PE, BOPP, and PET; the preparation method is easy to operate, and the prepared water-based emulsion has excellent adhesion to films by strictly controlling the addition time and reaction temperature of each raw material. Adhesion, chemical resistance and physical resistance.

Owner:杨康营 +1

A variable volume soil gas collection device and its application method

ActiveCN109374366BSolve spending moneyReduce experiment costWithdrawing sample devicesEarth material testingSoil gasCellular respiration

A variable-volume soil gas collection device and its use method relate to a soil gas collection device and its use method. The purpose of the present invention is to solve the problem that a plurality of branching units need to be configured when measuring soil respiration to change the measurement volume, resulting in huge cost. The soil gas collection device with variable volume consists of a hard cabin, a soft cabin, a gas conduit and a valve. Methods: 1. Soil loading and device assembly; 2. Equilibrium gas environment; 3. Injecting air; 4. Gas reaction process; 5. Taking gas samples; 6. Gas sample analysis. Advantages: within the limit of the maximum volume range, the volume in the cabin can be continuously changed. It solves the cost of volume switching and reduces the cost of experiments. The invention is mainly used for soil gas collection.

Owner:NORTHEAST INST OF GEOGRAPHY & AGRIECOLOGY C A S

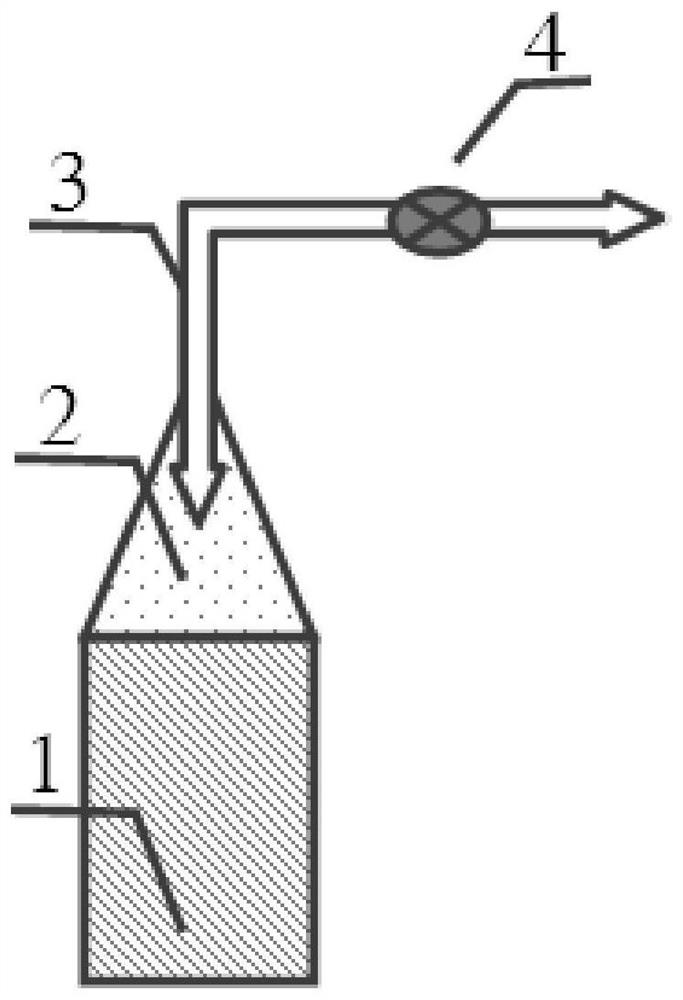

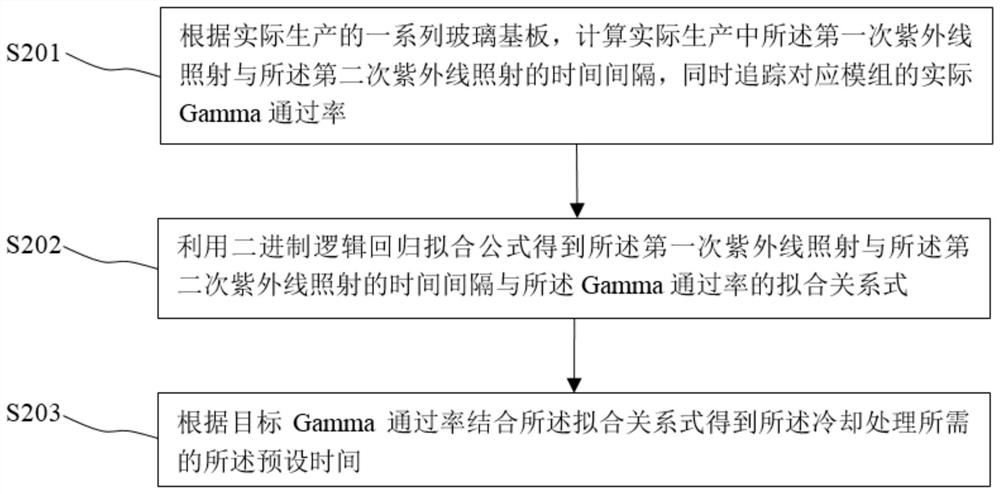

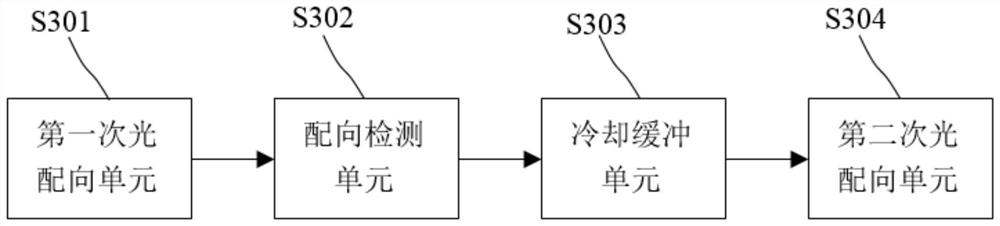

Optical alignment method and system for improving gamma pass rate

ActiveCN109212838BGamma pass rate increasedImprove pass rateNon-linear opticsOptical alignmentMaterials science

The present application provides a photo-alignment method and system for improving the Gamma pass rate. The method includes the following steps: firstly applying a voltage to the liquid crystal panel to be aligned, and irradiating the liquid crystal panel with ultraviolet light for the first time, so that in the first preliminary At a set temperature, the photosensitive monomer moves to the alignment substrate, and a polymerization reaction occurs to form a polymer; and then the liquid crystal panel is cooled to a second preset temperature within a preset time, wherein the preset time is passed according to Gamma Finally, at the second preset temperature, the liquid crystal panel is irradiated with ultraviolet rays for the second time, so that the photosensitive monomer and the alignment substrate form an alignment film, so that the liquid crystal molecules are in a preset Angular alignment.

Owner:SUZHOU CHINA STAR OPTOELECTRONICS TECH CO LTD

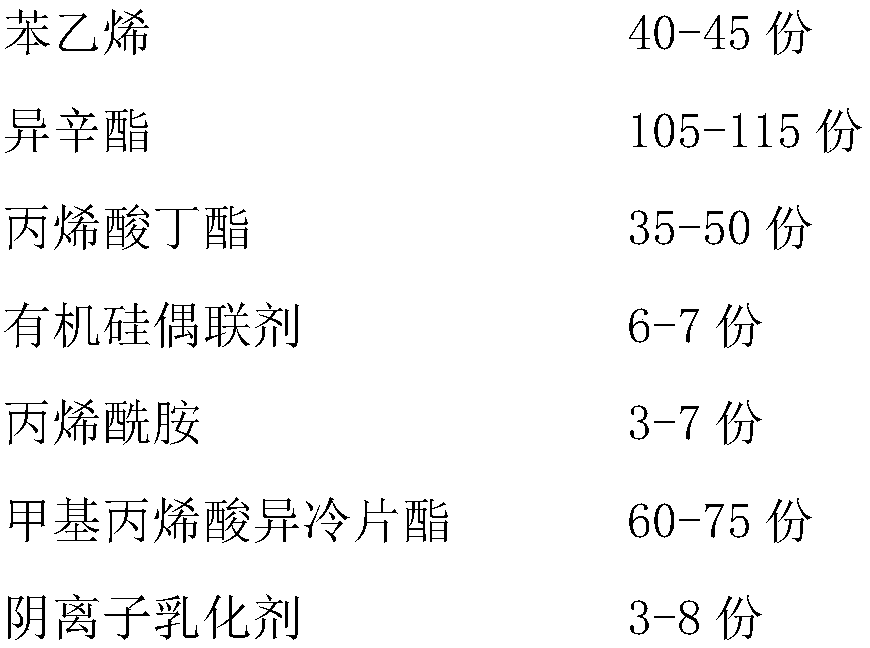

High-adhesive-force emulsion for cigarette packet film and preparation method of high-adhesive-force emulsion

PendingCN114316148AStrong adhesionImprove adhesionCoatingsPolymer sciencePolyethylene terephthalate glycol

The invention discloses a high-adhesion emulsion for a cigarette packet film and a preparation method thereof, and the high-adhesion emulsion is composed of the following raw materials: acrylic resin, a cationic emulsifier, an anionic emulsifier, 1, 2, 4-trimethyl-1, 3-pentanediol monoisobutyrate, an emulsifier, a dispersant, a thickener, a thickener and a solvent. The water-based acrylic resin is prepared from 1, 6-hexanediol diacrylate, a first monomer, a second monomer, a third monomer, a fourth monomer, a fifth monomer, a nonionic emulsifier, a silane coupling agent, an initiator, dimethyl maleic anhydride, ethylene glycol, ethylenediamine, adipic dihydrazide and deionized water. The preparation method is simple and convenient to operate, by strictly controlling the adding time, the reaction time and the reaction temperature of all the raw materials, the reaction rate balance in the early stage and the later stage of the emulsion preparation process can be kept, the conversion rate and the stability of the reaction can be improved, and the prepared emulsion has excellent adhesive force and chemical resistance to a cigarette packet film; and the adhesive force to non-absorbent substrates such as BOPP (biaxially-oriented polypropylene), PP (polypropylene), PVC (polyvinyl chloride), PE (polyethylene) and PET (polyethylene terephthalate) plastic films is excellent.

Owner:广州富思德化工科技有限公司

A kind of anti-oxidation emulsion and the anti-oxidation water-based coating varnish prepared by using it

ActiveCN107033288BImprove defoaming abilityStrong anti-foaming abilityPaper coatingCorrosion-inhibiting/anti-oxidant agent additionWater basedCardboard

The invention relates to the technical field of coating varnish, in particular to anti-oxidation emulsion and anti-oxidation waterborne coating varnish prepared from the same. The anti-oxidation emulsion is prepared from raw materials in percentage by weight as follows: 30%-50% of an acrylic resin solution with neutral pH, 29%-41% of mixed monomers, 0.5%-1% of an emulsifier, 0.3%-0.8% of an initiator, 0.01%-0.05% of an oxidizing agent, 0.01%-0.05% of a reducing agent and 10%-25% of deionized water, and the sum of the raw materials in percentage by mass is 100%. According to the anti-oxidation emulsion, possibly existing acid-base substances can be reduced, the probability of oxidation is reduced, and hot stamping foil is not prone to oxidation; the anti-oxidation waterborne coating varnish prepared from the anti-oxidation emulsion contains no organic solvents, is low in content of VOCs (volatile organic chemicals) or free of VOCs, is environment-friendly, non-toxic and anti-oxidation, and is suitable for surface lustering of substrates, prone to hot stamping oxidation, of black cardboards, blackened paper, coated black paper and the like.

Owner:GUANGDONG YINGKE GRP CO LTD

A kind of water-based inorganic zinc-rich paint and preparation method thereof

ActiveCN103788734BUniform particle size distributionUniform reaction rateAlkali metal silicate coatingsStress concentrationOligomer

The invention provides a water-based inorganic zinc-rich paint and a preparation method thereof. The zinc-rich coating uses a high-modulus potassium silicate solution obtained by dropping aluminum-modified silica sol in a low-modulus potassium silicate solution as a binder, and adds catalysts, siloxane oligomers, The modifying agent makes the particle size distribution of the high modulus potassium silicate solution uniform, and the gelation reaction does not occur for a long time. The reaction rate of each part of the layer is uniform, and the advantages of no stress concentration occur. Experiments have proved that the zinc-rich coating of the present invention does not gel after being stored at 50°C for 90 days; the thickness of one-time film formation can reach 200 μm, without cracking and peeling; the steel surface treatment grade can reach Sa2 and can be applied; the coating’s salt spray resistance can reach 10000 hours.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

A kind of preparation method of naphthalene series water reducing agent

The invention provides a method for preparing a naphthalene series water reducer. The method comprises the following steps: sulfonation: carrying out a sulfonation reaction of naphthalene and concentrated sulfuric acid; hydrolysis: adding water into the sulfonation reaction product for hydrolysis, and hydrolyzing a by-product in the sulfonation reaction; condensation: adding poly formaldehyde and water into the hydrolysis reaction product for condensation; and neutralization: adjusting pH of the condensation reaction product to be 6-8, and drying to obtain the naphthalene series water reducer. The preparation method has the advantages of simple and stable production process and easily controlled parameters, and the prepared naphthalene series water reducer product has stable performance and good quality.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

A kind of antistatic paint on steel structure surface and preparation method thereof

InactiveCN103788726BGood for condensationIncrease crosslink densityElectrically-conductive paintsCarbon nanotubeSlurry

The invention provides a antistatic paint for a steel structure surface and a preparation method thereof. The paint is prepared by mixing zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry in a mass ratio of 3:1-5:1. The ethyl orthosilicate in the ethyl orthosilicate slurry is subjected to hydrolytic condensation under the action of a catalyst, and a furfural-furfuryl alcohol resin is added as a modifier into the zinc-aluminum alloy powder slurry. After the zinc-aluminum alloy powder slurry and ethyl orthosilicate slurry are mixed, the furfural-furfuryl alcohol resin is cured to release water molecules when meeting with acid so as to promote the further condensation of the ethyl orthosilicate hydrolytic condensation substances, and the furfural-furfuryl alcohol resin and the zinc-aluminum alloy powder react to form a interpenetrating network, thereby enhancing the crosslinking density between the paint and the steel structure substrate surface and increasing the wettability and adhesive force of the coating for the substrate.Preferably, a carbon nanotube dispersion solution and conductive mica powder can be added into the zinc-aluminum alloy powder slurry to correspondingly improve the antistatic property of the obtained coating. Therefore, the protective paint is suitable for various steel storage tank internal and external walls, large bridges, ships, offshore oil drilling platforms and other steel structure surfaces.

Owner:CENT RES INST OF BUILDING & CONSTR CO LTD MCC GRP +2

An alloy quantum dot core with uniform internal and external components and its preparation method

ActiveCN106590633BUniform composition inside and outsideUniform reaction rateCadmium sulfidesNanoopticsChemical physicsReaction rate

The invention discloses an alloy quantum dot core with uniform internal and external components and a preparation method thereof, wherein the method comprises: stirring and mixing the pre-prepared at least two cation precursor solutions and heating them to a predetermined temperature, injecting the prepared At least one anion precursor solution of the nucleation reaction is carried out by continuing to inject the cation precursor solution or the anion precursor solution or simultaneously injecting the cation precursor solution and the anion precursor solution at a gradually changing speed during the nucleation reaction, so that the nucleation reaction During the process, the reaction rate of each component remains relatively stable and the stoichiometric ratio of nucleation is relatively consistent, thereby preparing an alloy quantum dot nucleus with uniform internal and external components. The method of the invention effectively solves the problems of inhomogeneity of the inner and outer components of the alloy quantum dot core, low luminous efficiency, unstable wavelength and fluorescence intensity, and the method provided by the invention has the advantages of simple operation, easy regulation, and high repeatability.

Owner:TCL CORPORATION

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com