Low-water-absorption good-appearance flame-retarding polyamide composition and preparation method thereof

A technology of polyamide composition and low water absorption, which is applied in the field of polyamide composition with low water absorption and good appearance and flame retardant and its preparation, which can solve the problems of easy warping and surface appearance of unconcerned materials, affecting product appearance, glass fiber Difficult to disperse and other problems, to achieve the effect of excellent mechanical properties, improved appearance, and no floating fibers on the surface

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

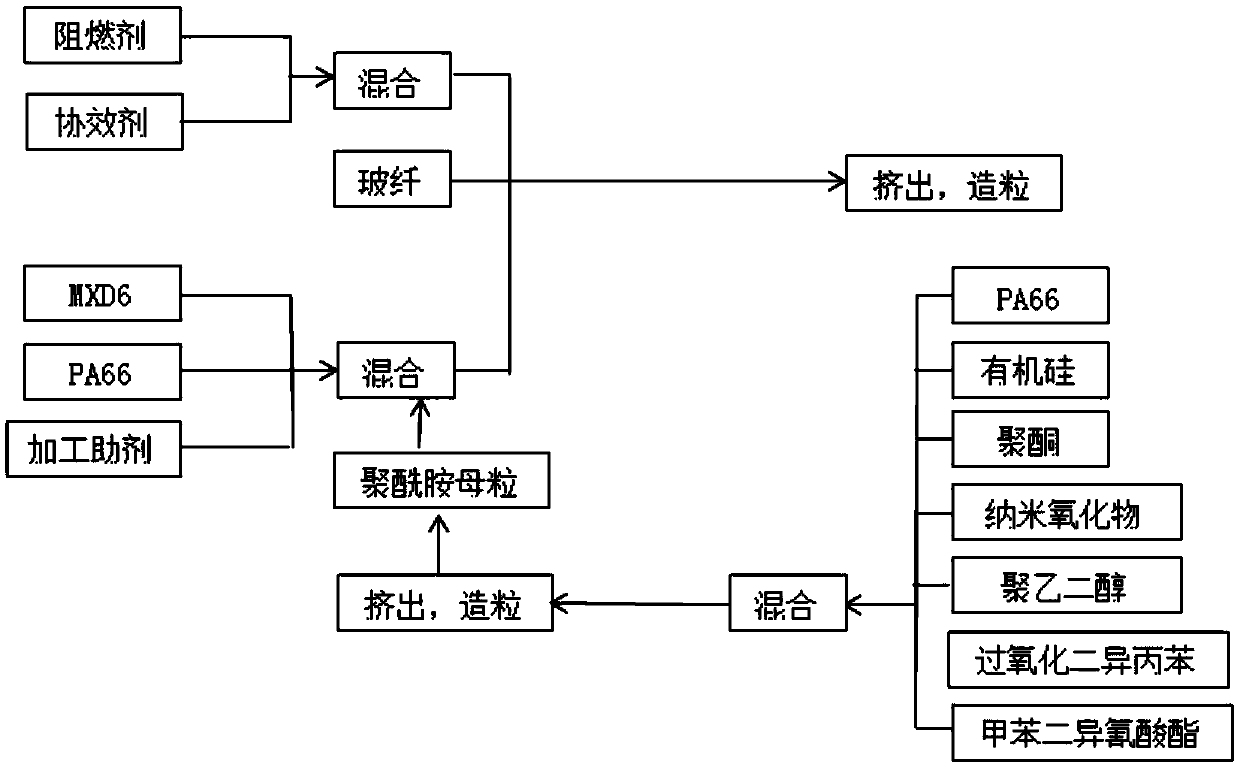

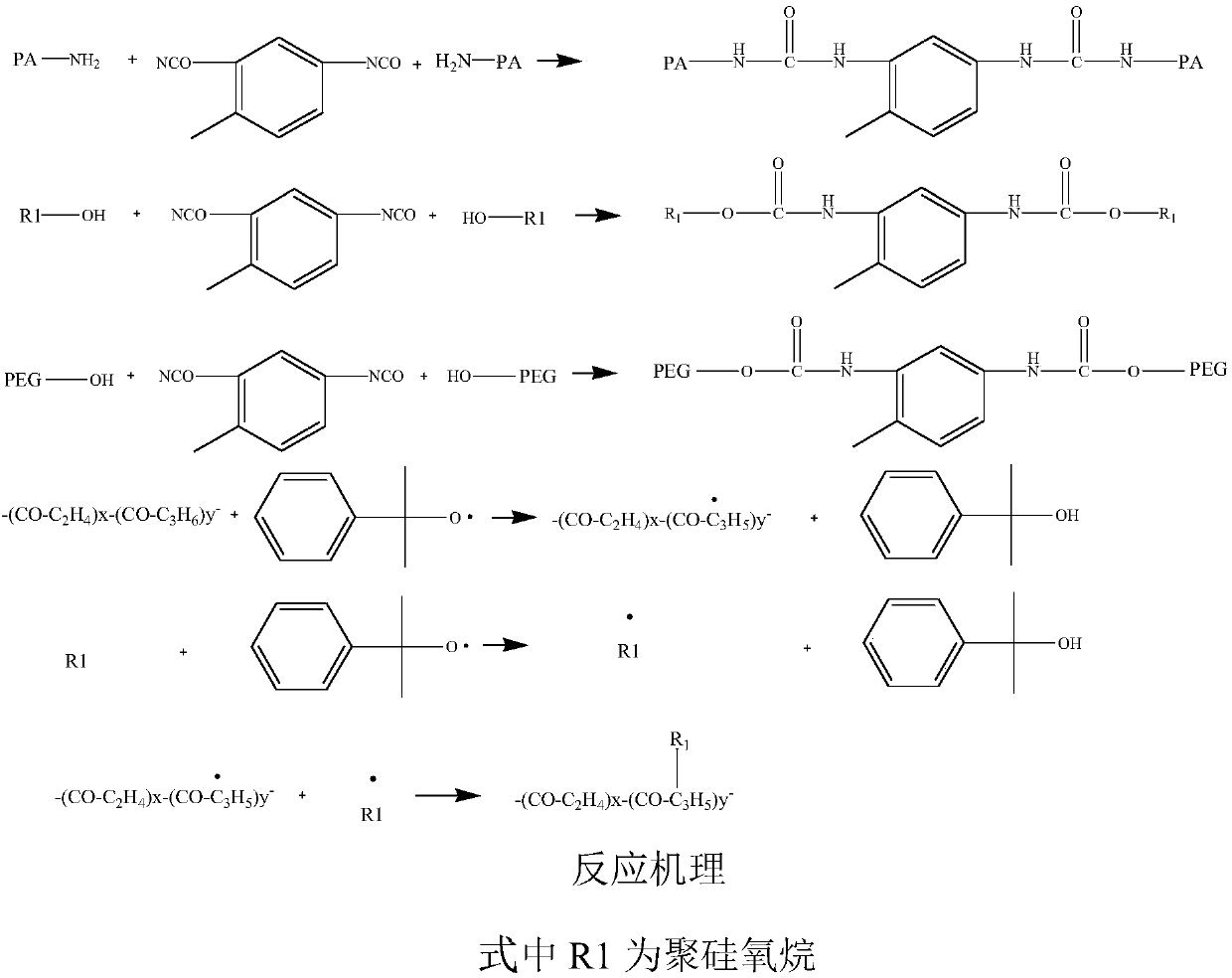

Method used

Image

Examples

Embodiment 1

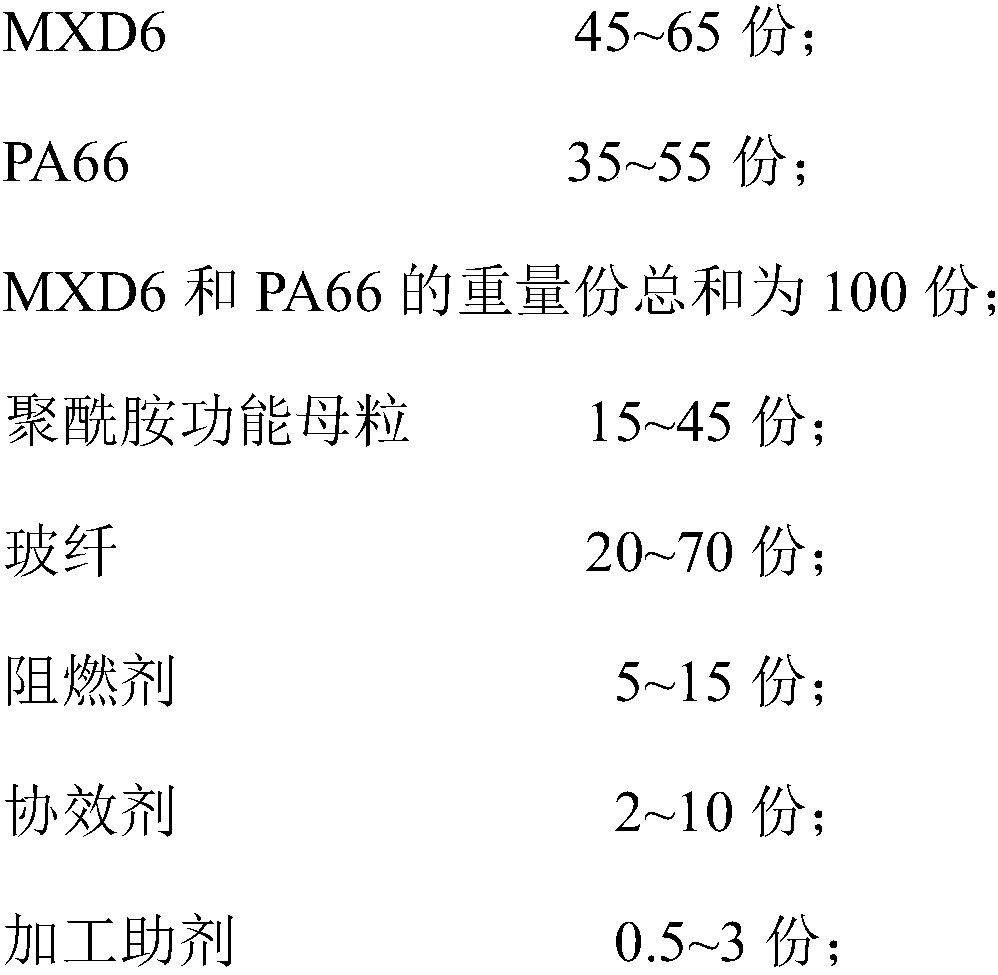

[0072] In this embodiment, a polyamide composition with low water absorption and good appearance and flame retardancy is prepared from the following raw materials in parts by weight:

[0073]

[0074] Wherein the polyamide functional master batch is made of the following raw materials in parts by weight:

[0075]

[0076]

[0077] Among them, the intrinsic viscosity of MXD6 is 0.8; the intrinsic viscosity of PA66 is 2.7; the glass fiber is E-type glass fiber; the flame retardant is dialkyl hypophosphite; the synergist is zinc borate; the silicone is polydimethyl / methyl Phenylsiloxane, the number-average molecular weight is 2,000,000; the nano-oxide is nano-zinc oxide; the processing aid is N,N'-bis-(3-(3,5- A mixture of di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4-di-tert-butylphenyl)phosphite, 2,4-dihydroxybenzophenone and γ- Aminopropyltriethoxysilane.

[0078] The preparation method of the above-mentioned low water absorption and good ap...

Embodiment 2

[0084] In this embodiment, a polyamide composition with low water absorption and good appearance and flame retardancy is prepared from the following raw materials in parts by weight:

[0085]

[0086] Wherein the polyamide functional master batch is made of the following raw materials in parts by weight:

[0087]

[0088] Among them, the intrinsic viscosity of MXD6 is 0.7; the intrinsic viscosity of PA66 is 3.2; the glass fiber is E-type glass fiber; the flame retardant is dialkyl hypophosphite and melamine polyphosphate with a weight ratio of 9:1; the synergist is a weight ratio 4:1 zinc borate and aluminum hydroxide; silicone is polydimethyl / methylphenylsiloxane with a number average molecular weight of 3,000,000; nano oxide is nano zirconia; processing aid is a weight ratio of 1: 1:1:0.5 of N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4-di-tert-butylbenzene base) a mixture of phosphite, zinc stearate and gamma-aminopropyltrime...

Embodiment 3

[0091] In this embodiment, a polyamide composition with low water absorption and good appearance and flame retardancy is prepared from the following raw materials in parts by weight:

[0092]

[0093] Wherein the polyamide functional master batch is made of the following raw materials in parts by weight:

[0094]

[0095]

[0096] Among them, the intrinsic viscosity of MXD6 is 1.2; the intrinsic viscosity of PA66 is 3.0; the glass fiber is E-type glass fiber; the flame retardant is dialkyl hypophosphite and melamine polyphosphate with a weight ratio of 9:1; the synergist is a weight ratio 3:1 zinc borate and magnesium hydroxide; silicone is polydimethyl / methylphenylsiloxane with a number average molecular weight of 2,000,000; nano oxide is nano iron oxide; processing aid is a weight ratio of 1: 2:2:1:0.5 N,N'-bis-(3-(3,5-di-tert-butyl-4-hydroxyphenyl)propionyl)hexamethylenediamine, tris(2,4-di-tert-butyl A mixture of phosphite, rosin ester wax, calcium stearate and N...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com