Polyester resin for mixed powder coating and preparation method thereof

A polyester resin and powder coating technology, applied in powder coatings, polyester coatings, coatings, etc., can solve the problems of poor solvent resistance of cured films and low curing rate at low temperatures

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

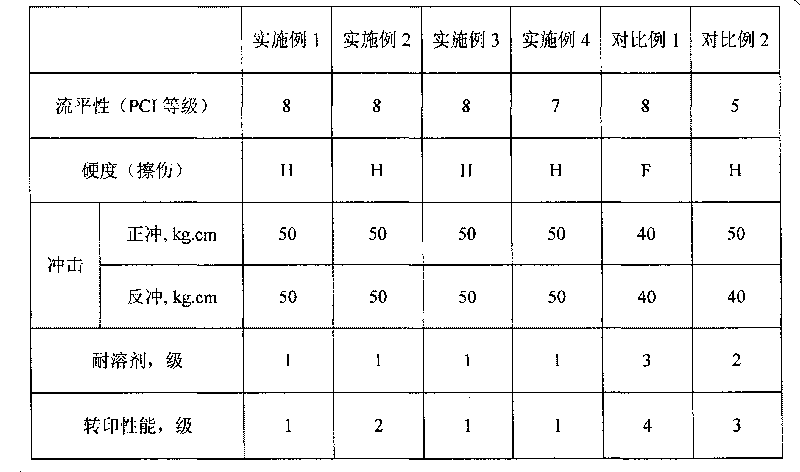

Examples

Embodiment 1

[0029] a. Esterification process: In the synthesis reaction vessel, the temperature of the kettle is raised to 100°C, and 10.81mol of ethylene glycol, 10.75mol of diethylene glycol, 10.78mol of 2-methyl-1,3-propanediol, 21.54 mol of neopentyl glycol, 44.28mol of terephthalic acid, 2.35mol of isophthalic acid, 2.33mol of adipic acid, and 0.07mol of monobutyltin oxide. Nitrogen is used for reaction protection, and the temperature of the material is gradually heated to 245°C, and the reaction is continued at this temperature until no distillate is formed. When the top temperature of the reactor drops to 75°C, sampling and analysis are performed. The linearity of the terminal hydroxyl group The acid value of the polyester resin prepolymer is 12.8mgKOH / g; the molar ratio of acid / alcohol in the reactant is 1 / 1.10;

[0030] b. Vacuum process: react the above reactants under negative pressure at a vacuum degree of about 50mmHg and a temperature of 240°C until the acid value is 3.5mgKO...

Embodiment 2

[0036] a. Esterification process: In the synthesis reaction vessel, the temperature of the kettle is raised to 100°C, and 8.06mol of ethylene glycol, 8.02mol of diethylene glycol, 21.67mol of 2-methyl-1,3-propanediol, 16.15 mol of neopentyl glycol, 44.28mol of terephthalic acid, 2.35mol of isophthalic acid, 2.33mol of adipic acid, and 0.06mol of monobutyltin oxide. Nitrogen is used for reaction protection, and the temperature of the material is gradually heated to 245°C, and the reaction is continued at this temperature until no distillate is formed. When the top temperature of the reactor drops to 75°C, sampling and analysis are performed. The linearity of the terminal hydroxyl group The acid value of the polyester resin prepolymer is 13.1mgKOH / g, and the molar ratio of acid / alcohol in the reactant is 1 / 1.10;

[0037] b. Vacuum process: react the above reactants under negative pressure at a vacuum degree of about 50mmHg and a temperature of 240°C until the acid value is 3.2mg...

Embodiment 3

[0043] (a) Esterification process: In the synthesis reaction vessel, the temperature of the kettle is raised to 100° C., and 15.38 mol of diethylene glycol, 46.06 mol of neopentyl glycol, 51.20 mol of terephthalic acid, and 0.07 mol of mono For butyl tin oxide, after feeding the materials, seal the kettle and raise the temperature, and at the same time fill it with nitrogen for reaction protection, gradually heat the temperature of the materials to 245°C, and keep the temperature at this temperature to continue the reaction until no distillate is produced. Sampling analysis was carried out when the tank top temperature dropped to 75°C. The acid value of the hydroxyl-terminated linear polyester resin prepolymer was 5.4mgKOH / g; the molar ratio of acid / alcohol in the reactant was 1 / 1.20;

[0044] (b) Vacuum process: react the above-mentioned reactant under negative pressure at a vacuum degree of about 50mmHg and a temperature of 230°C until the acid value is 1.0mgKOH / g;

[0045] ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

| acid value | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com