Alloy quantum dot core with uniform internal and external components and preparation method thereof

A technology of quantum dots and alloys, applied in the field of quantum dots, can solve the problems of low luminous efficiency, poor repeatability, uneven composition inside and outside the core of alloy quantum dots, etc., and achieve the effect of high repeatability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

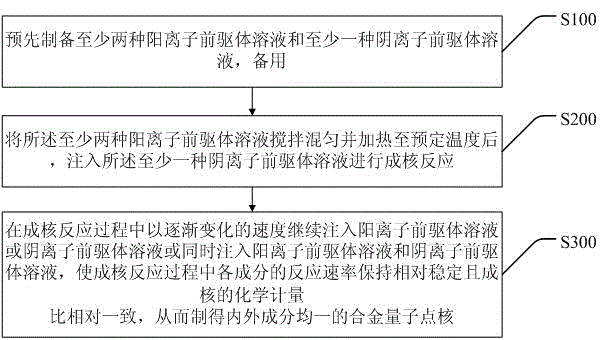

Method used

Image

Examples

Embodiment 1

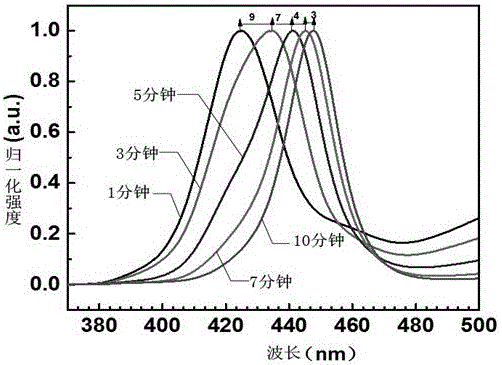

[0051] To obtain Cd with uniform internal and external components x Zn 1-x S alloy quantum dot core as an example

[0052] 1. Cadmium Oleate Cd(OA) 2 Preparation of precursors:

[0053] Add 0.2 mmol of cadmium oxide (CdO), 0.5 ml of oleic acid (OA) and 5 ml of octadecene (ODE) into a three-necked flask. First vacuumize at room temperature for 30 mins, then heat to 180°C and exhaust argon for 60 mins, and then maintain Vacuum at 180°C for 30 mins, and cool to room temperature for later use.

[0054] 2. Preparation of zinc oleate Zn(OA)2 precursor:

[0055] Add zinc acetate Zn(Ac) into the three-necked flask 2 1.8 mmol, 1 ml of oleic acid (OA) and 5 ml of octadecene (ODE) were first vacuumed at room temperature for 30 mins, then heated to 180°C to exhaust argon for 60 mins, then vacuumed at 180°C for 30 mins, cooled to room temperature for later use.

[0056] 3. Preparation of sulfur (S) precursor:

[0057] Add 13 mg of S to 1 ml of octadecene (ODE), heat at 230 °C for 2...

Embodiment 2

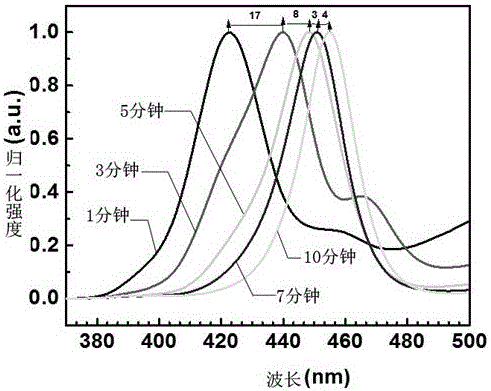

[0061] To obtain Cd with uniform internal and external components x Zn 1-x Se alloy quantum dot core as an example

[0062] 1. Cadmium Oleate Cd(OA) 2 Preparation of precursors:

[0063] Add 0.2 mmol of cadmium oxide (CdO), 0.5 ml of oleic acid (OA) and 5 ml of octadecene (ODE) into a three-necked flask. First vacuumize at room temperature for 30 mins, then heat to 180°C and exhaust argon for 60 mins, and then maintain Vacuum at 180°C for 30 mins, and cool to room temperature for later use.

[0064] 2. Preparation of zinc oleate Zn(OA)2 precursor:

[0065] Add zinc acetate Zn(Ac) into the three-necked flask 2 1.8 mmol, 1 ml of oleic acid (OA), and 5 ml of octadecene (ODE) were first vacuumed at room temperature for 30 mins, then heated to 180°C and exhausted with argon for 60 mins, then vacuumed at 180°C for 30 mins, cooled to room temperature for later use.

[0066] 3. Preparation of Selenium (Se) Precursor:

[0067] Weighing 25 mg of Se was added to 1 ml of octadecen...

Embodiment 3

[0071] To obtain Cd with uniform internal and external components x Zn 1-x S y Se 1-y Alloy quantum dot core as an example

[0072] 1. Cadmium Oleate Cd(OA) 2 Preparation of precursors:

[0073] Add 0.2 mmol of cadmium oxide (CdO), 0.5 ml of oleic acid (OA) and 5 ml of octadecene (ODE) into a three-necked flask. First vacuumize at room temperature for 30 mins, then heat to 180°C and exhaust argon for 60 mins, and then maintain Vacuum at 180°C for 30 mins, and cool to room temperature for later use.

[0074] 2. Preparation of zinc oleate Zn(OA)2 precursor:

[0075] Add zinc acetate Zn(Ac) into the three-necked flask 2 3.6 mmol, 1 ml of oleic acid (OA) and 5 ml of octadecene (ODE) were first vacuumed at room temperature for 30 mins, then heated to 180°C and exhausted with argon for 60 mins, then vacuumed at 180°C for 30 mins, cooled to room temperature for later use.

[0076] 3. Preparation of sulfur (S) precursor 1:

[0077] Add 20 mg of S to 1 ml of octadecene (ODE) ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com