Patents

Literature

34results about How to "Stoichiometric ratio" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

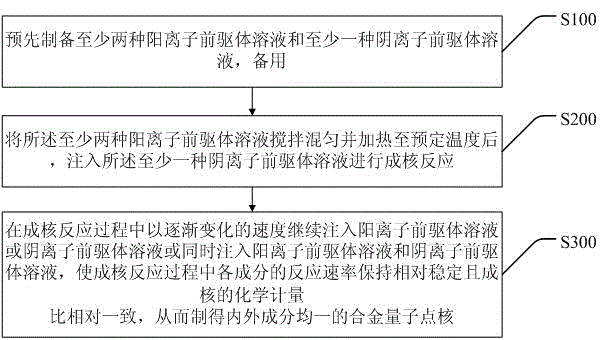

Alloy quantum dot core with uniform internal and external components and preparation method thereof

ActiveCN106590633ASolve for uniformitySolve efficiency problemsCadmium sulfidesNanoopticsReaction rateQuantum dot

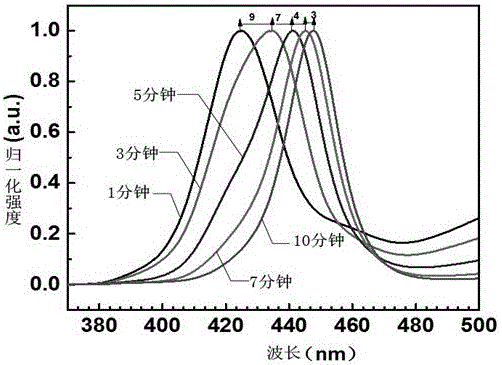

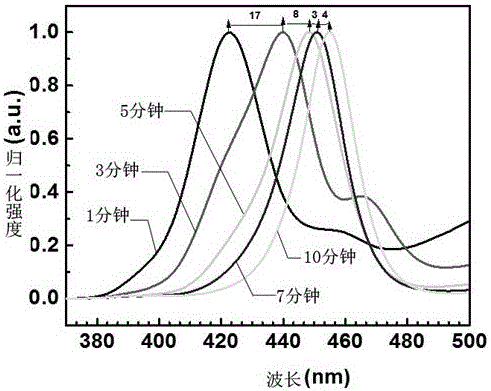

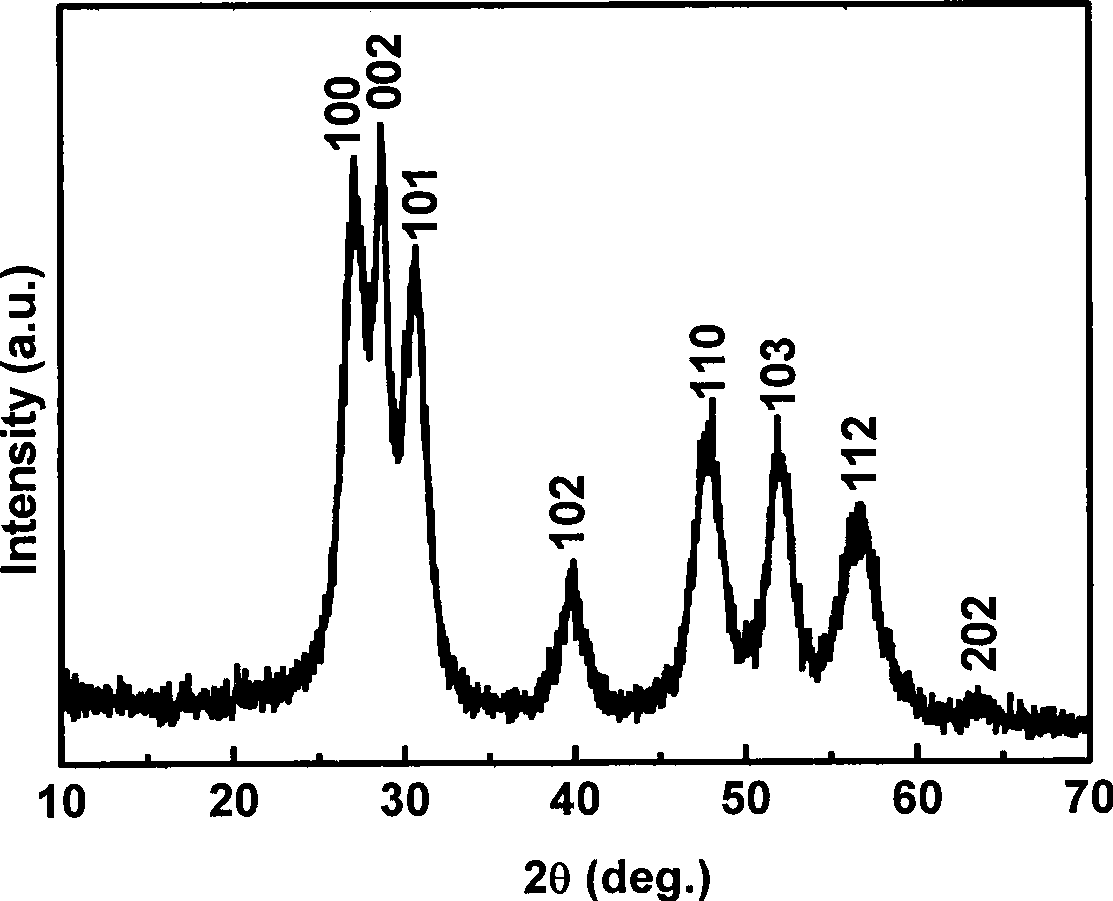

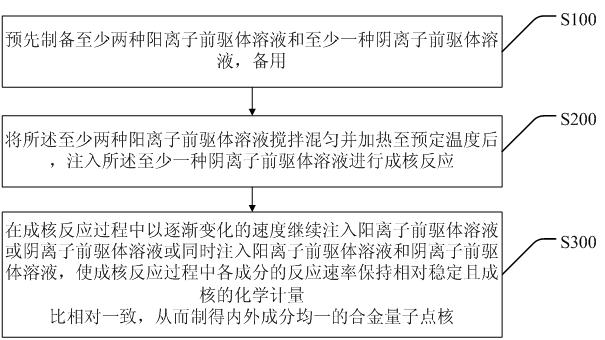

The invention discloses an alloy quantum dot core with uniform internal and external components and a preparation method thereof, wherein the method comprises the steps: stirring and mixing evenly at least two pre-prepared cationic precursor solutions, heating to a predetermined temperature, injecting at least one prepared anionic precursor solution, carrying out a nucleation reaction, continuing to inject the cationic precursor solutions or the anionic precursor solution or simultaneously inject the cationic precursor solutions and the anionic precursor solution at a gradually changed speed in the nucleation reaction process, making the reaction rate of all the components in the nucleation reaction process remained relatively stable and making the nucleation stoichiometric ratio relatively consistent, and thus obtaining the alloy quantum dot core with uniform internal and external components. By the method, the problems that an alloy quantum dot core has non-uniform internal and external components, low luminous efficiency and unstable wavelength and fluorescence intensity can be effectively solved, and the method provided by the invention has the advantages of simple operation, easy control, high repeatability and the like.

Owner:TCL CORPORATION

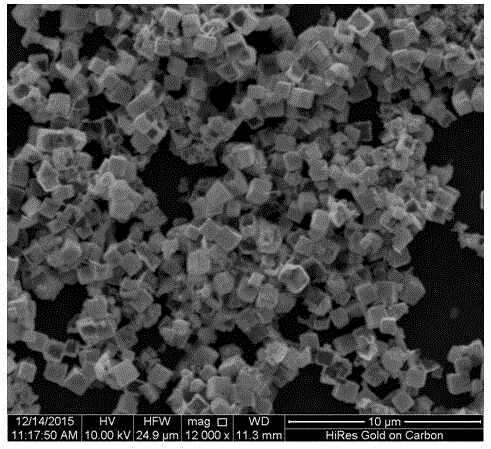

Method for preparing semi-conductor luminescent material manganese-doped zinc sulfide nano powder

InactiveCN101391802ANo protectionSave raw materialsZinc sulfidesLuminescent compositionsMANGANESE ACETATEFluorescence

The invention relates to a method for preparing semiconductor fluorescent material which is mixed with manganese, zinc sulphide and nanometer power. The method comprises the following steps: manganese acetate and zinc acetate are respectively weighted according to the mol ration of 1:99 or 3:97 or 5:95 to ensure that the amount of general matter of Zn<2+> and Mn<2+> is 0.01 mol; the two solid powder is mixed and dissolved with water to prepare 200 ml solution; 0.02 mol of sodium diethyldithiocarbamate powder is weighted and dissolved with water to prepare 200 mL solution; the two solutions are stirred and blended; the obtained precipitation is pumped and filtrated to obtain precursor Zn<1-x>Mn(DDTC)2, wherein, X is 0.01 or 0.03 or 0.05; 1.0 g of precursor Zn <1-x>Mn(DDTC)2 is put in a pot and placed in a muffle to be heated for 3 hours at the temperature of 300 DEG C, and then naturally cooled to the room temperature; finally Zn<1-x> MnxS of hexahedron phase is obtained. The invention solves defects such as complex operation, higher energy consumption, large kernels, many defects in crystals, plenty of water or organic solvent being polluted and wasted, long period, low productive rate, high cost and the like. The invention has the advantages of inexpensive and easy available raw materials, simple technique, low energy conservation, excellent semiconductor property and fluorescence property.

Owner:YANGZHOU UNIV

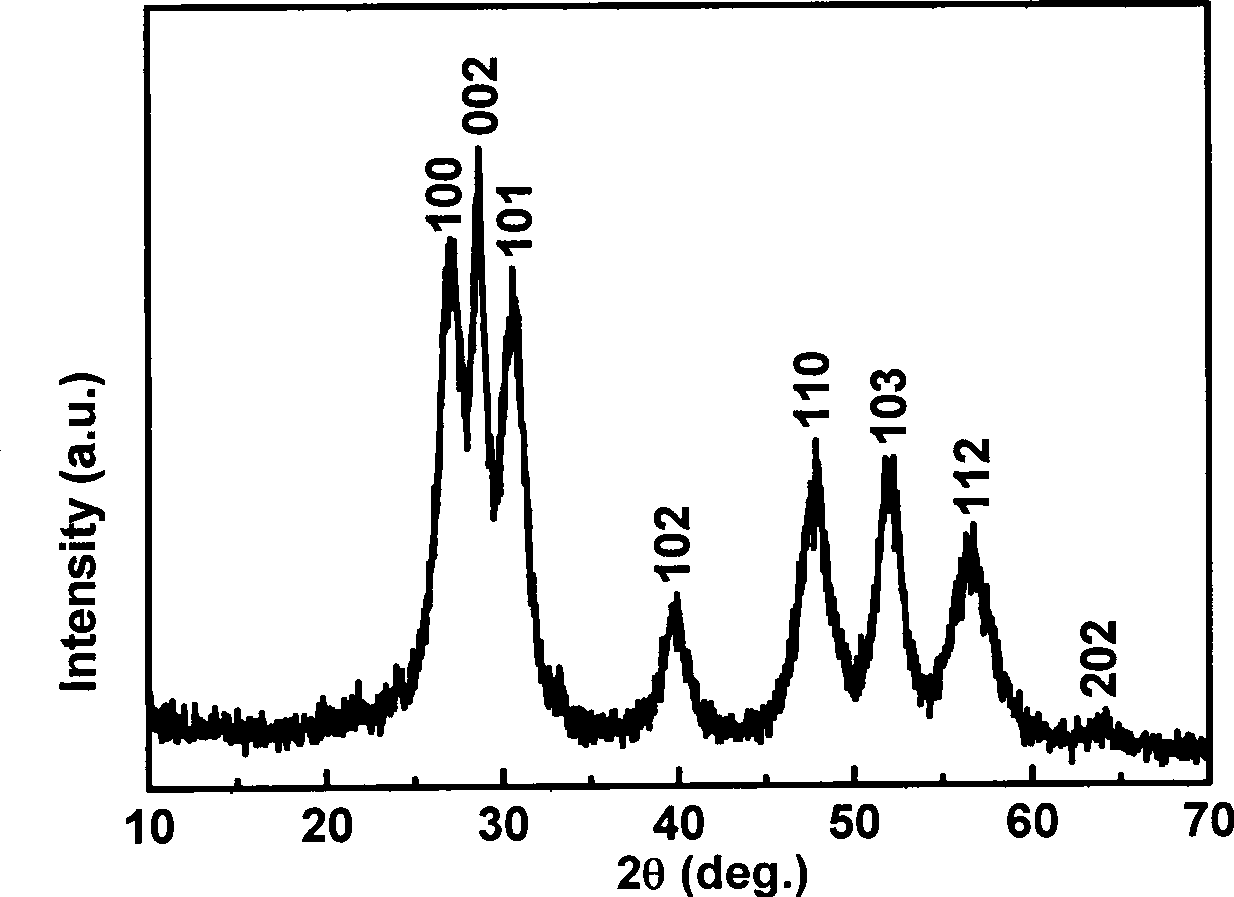

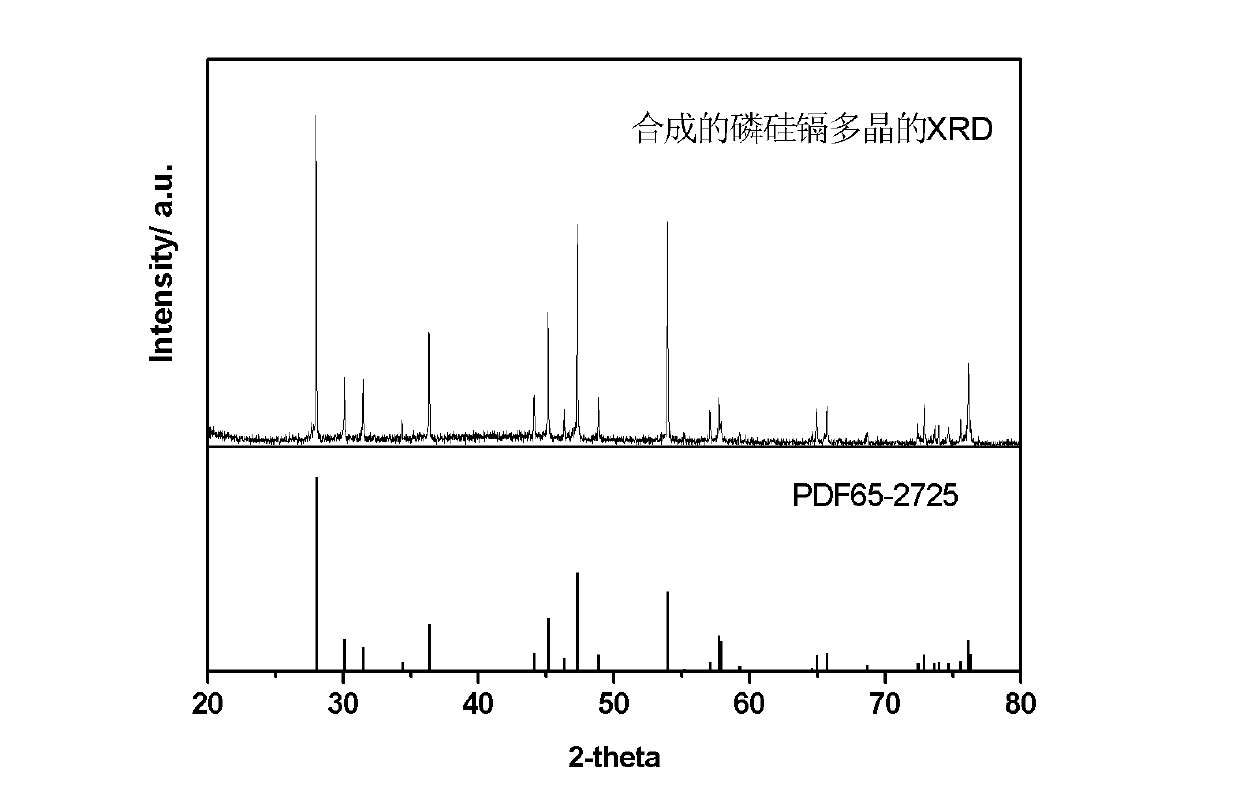

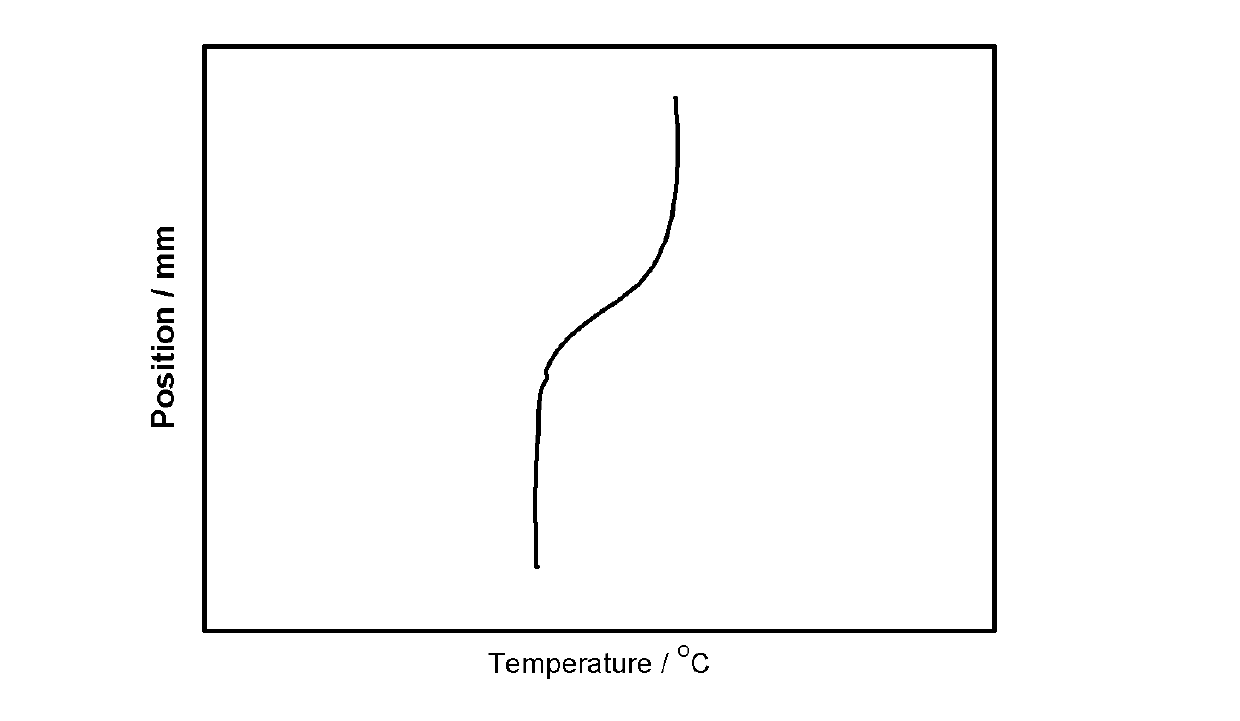

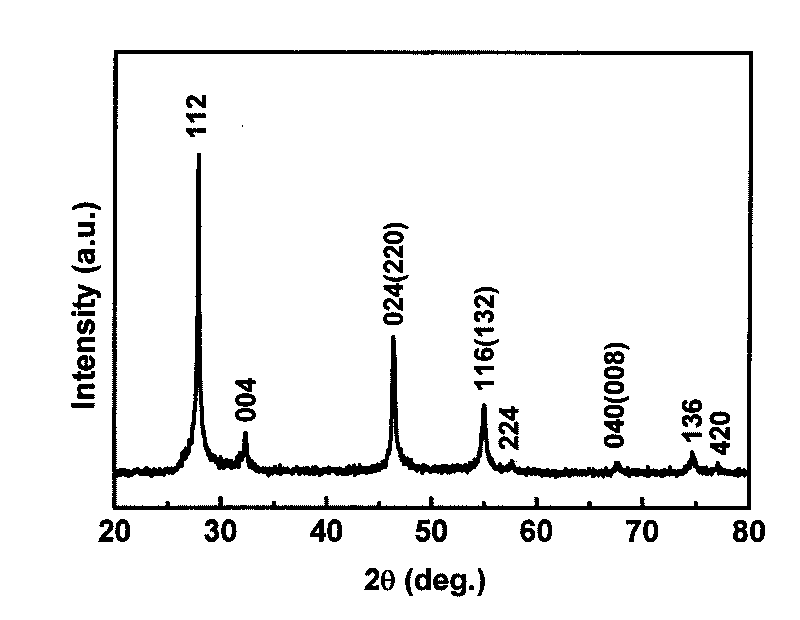

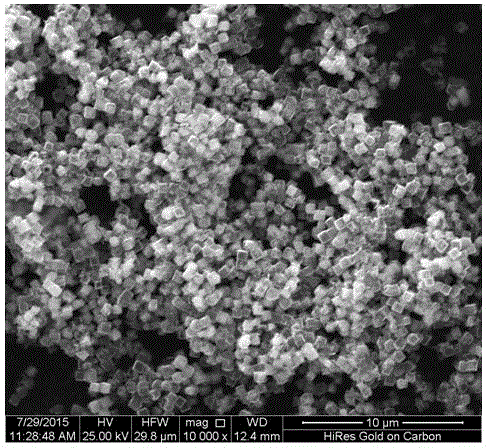

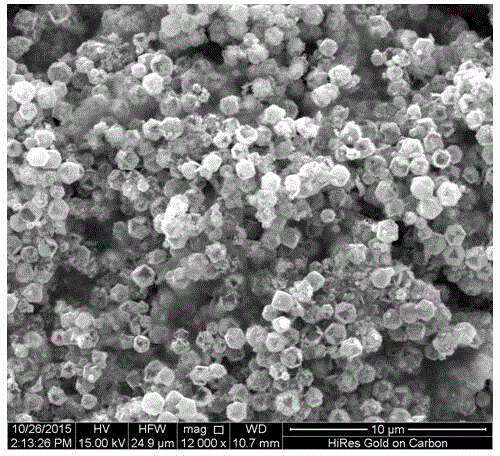

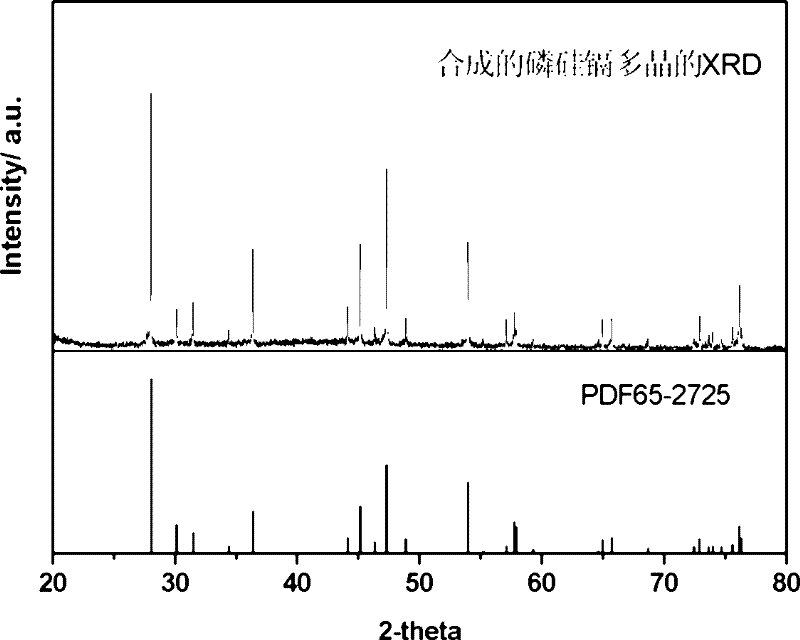

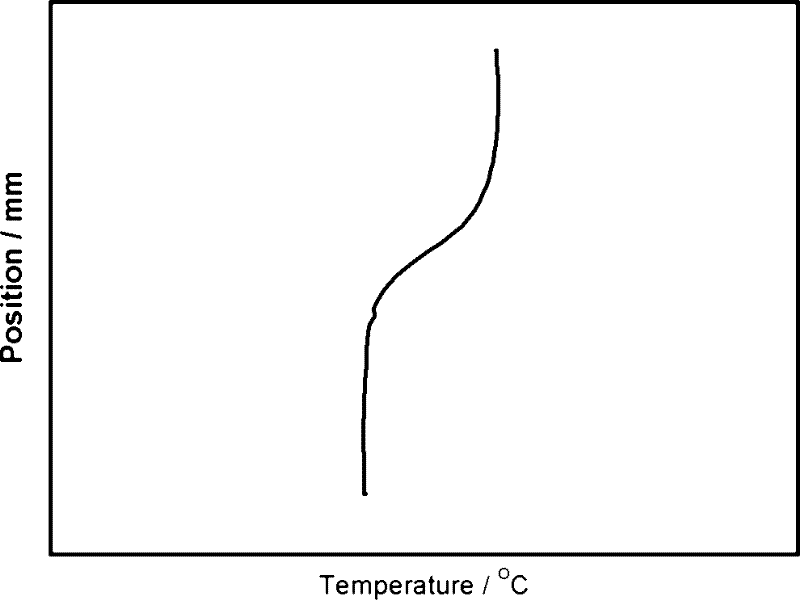

Method for growing phosphorus-silicon-cadmium single crystal

InactiveCN102168299AGood effectConvenient rotary controlPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationCrucible

The invention relates to a method for growing a phosphorus-silicon-cadmium single crystal. 1 part of silicon, 1 part of cadmium and 2-2.05 parts of phosphorus are synthesized into a phosphorus-silicon-cadmium polycrystal material, and the phosphorus-silicon-cadmium single crystal is grown by a crucible descending furnace by using a spontaneous nucleation growing method or oriented seed crystal growing method. The method comprises the following steps: directly filling the phosphorus-silicon-cadmium polycrystal material into a crucible, or filling the phosphorus-silicon-cadmium polycrystal material into the crucible after adding the seed crystal; putting the crucible into a silica tube, vacuumizing, and sealing the silica tube; putting the silica tube into a crucible descending furnace; and heating, descending the crucible, and finally cooling. The method provided by the invention can be used for preparing the high-purity high-quality phosphorus-silicon-cadmium single crystal.

Owner:SHANDONG UNIV

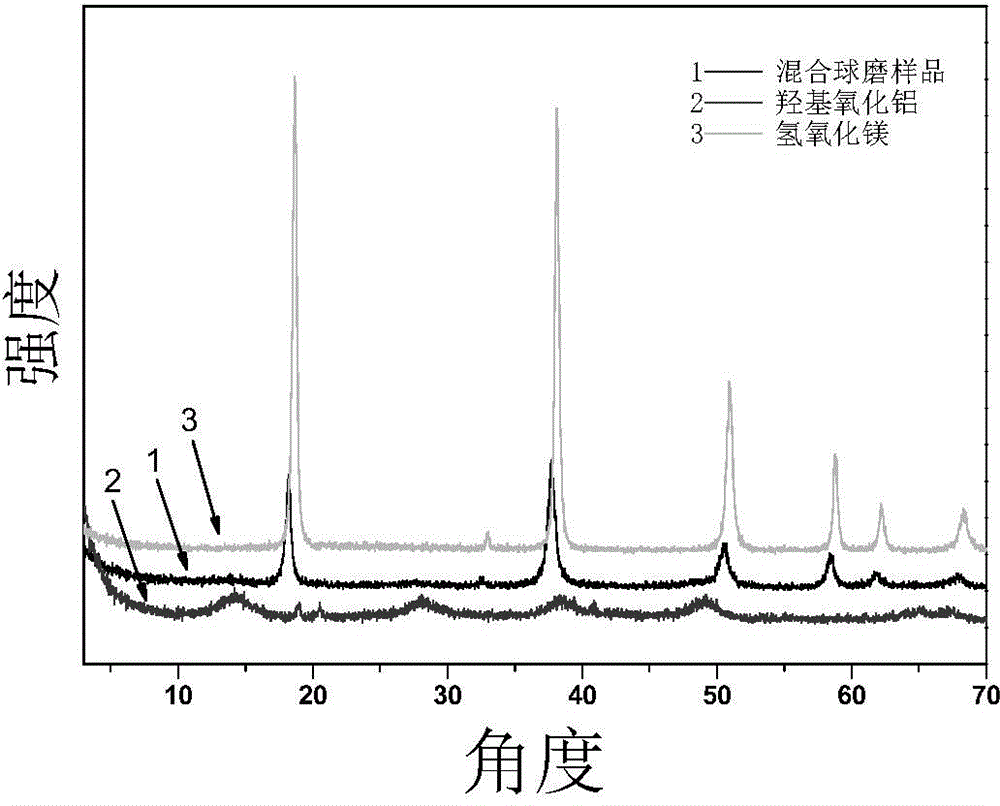

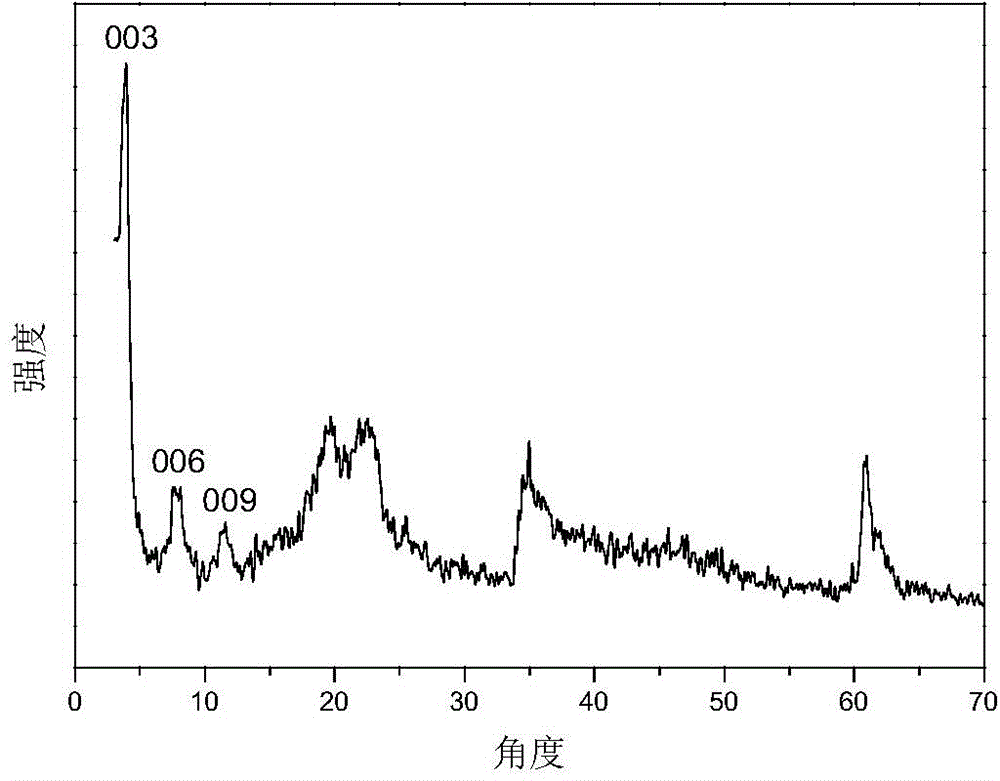

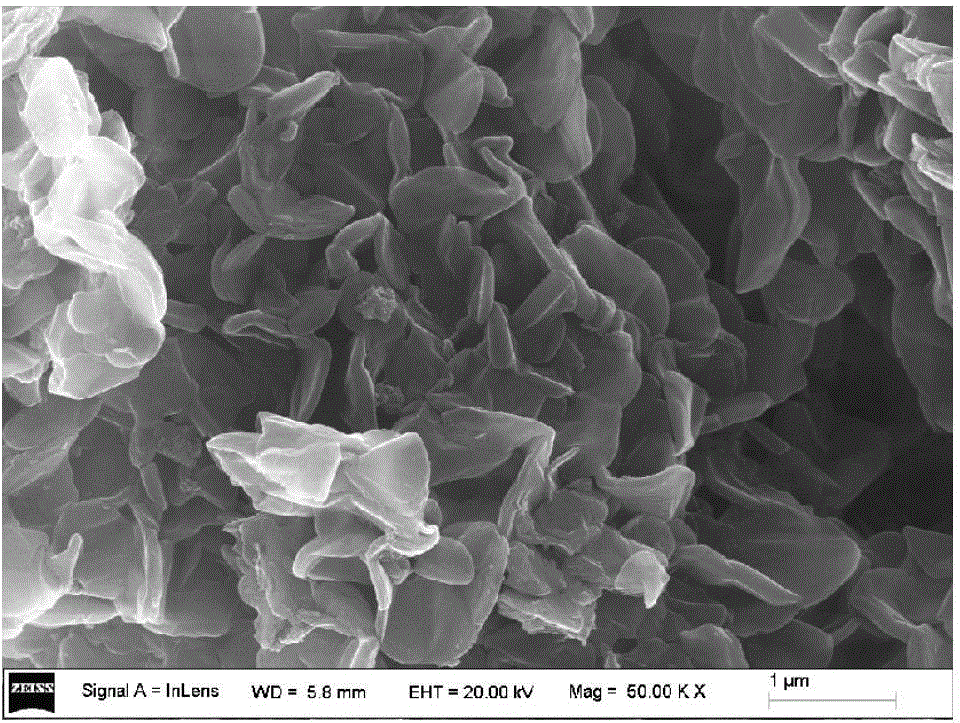

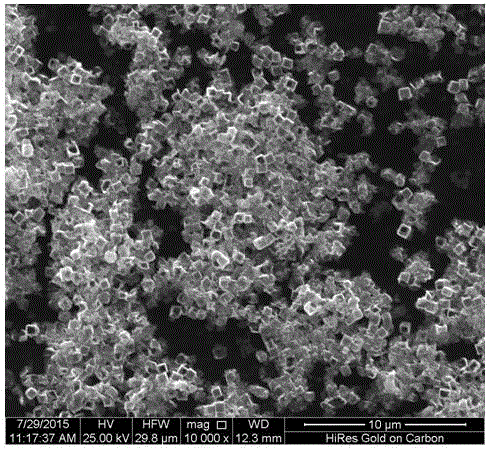

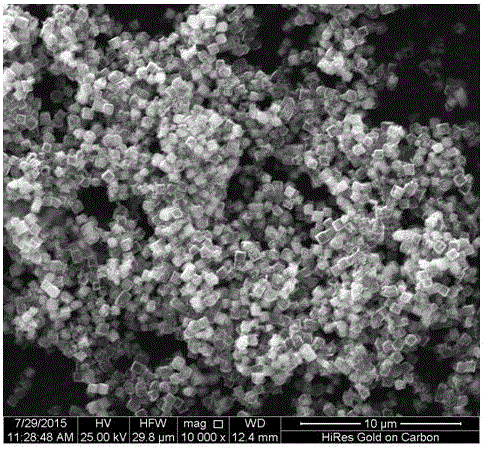

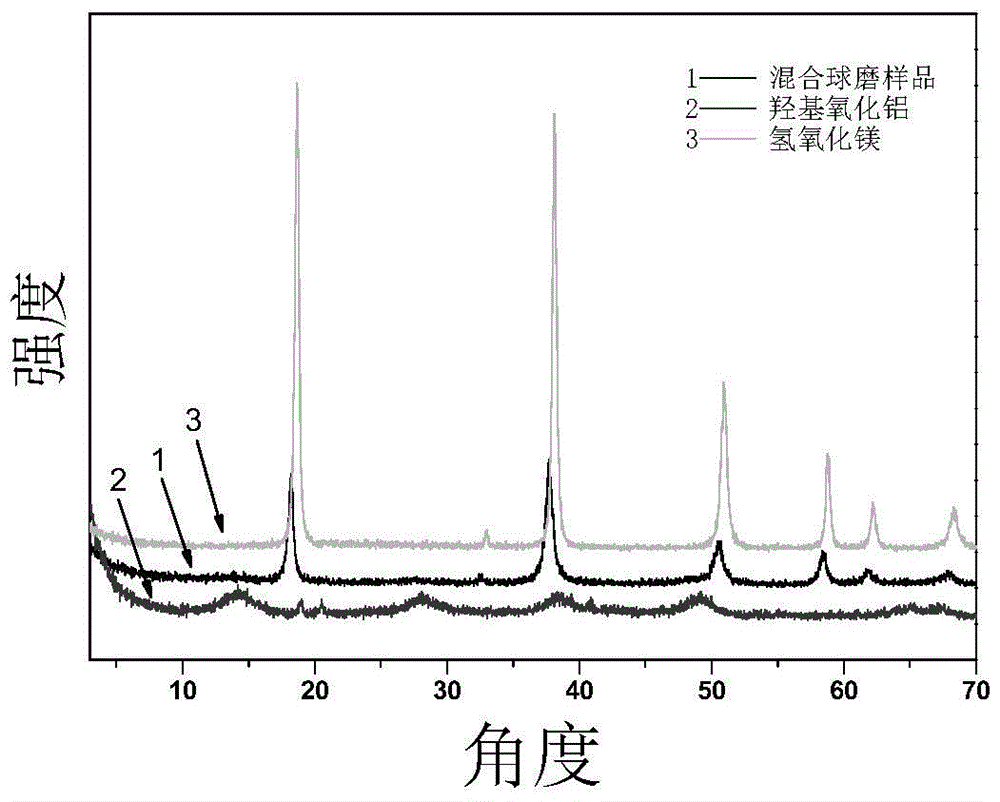

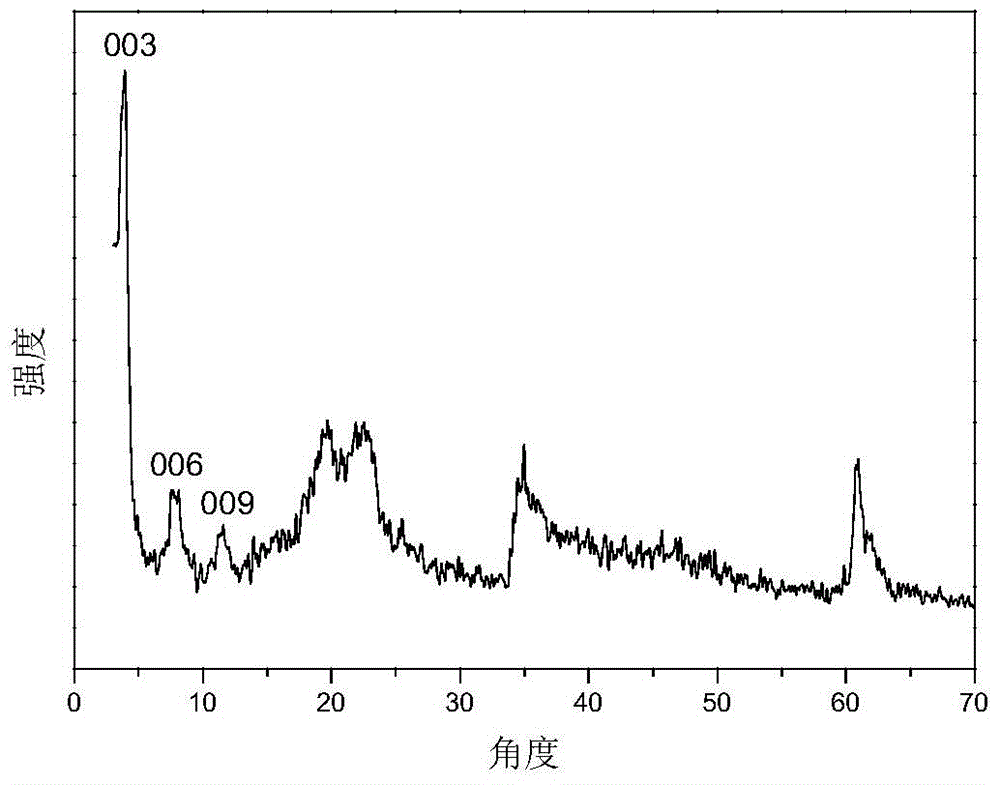

High pressure intercalation assembly method and application in preparation field of intercalation structure composite material

InactiveCN104860337AImprove solubilityAfter the reaction is completed, a large amount of water is required to wash the reaction fullyAluminium compoundsSolubilityWater source

The invention discloses a high pressure intercalation assembly method and application in preparation field of intercalation structure composite material. When preparing difficult soluble object intercalation hydrotalcite by using conventional method, object molecule solubility is extremely low, bivalence and trivalent metal salt solubility is relatively high, intercalation condition is not met in dynamics, and difficult soluble object intercalation hydrotalcite composite material cannot be prepared; if the raw material adopts the dissolubility salt for intercalation, the use amount of the object is excessive, a large amount of water is used for washing the reaction product after the reaction, the technology is complex, the water source is wasted and the environment pollution is generated. High temperature pressed mode is adopted for effectively improving solubility of the object; substep crystallization mode is adopted for guaranteeing sufficient reaction between the dissolved object molecule and the slowly ionized metallic oxide or hydroxide; the reaction system meets stoichiometric ratio and is the typical atom economy reaction, the technology is simple, no by-product is generated and the washing process is not required.

Owner:BEIJING UNIV OF CHEM TECH

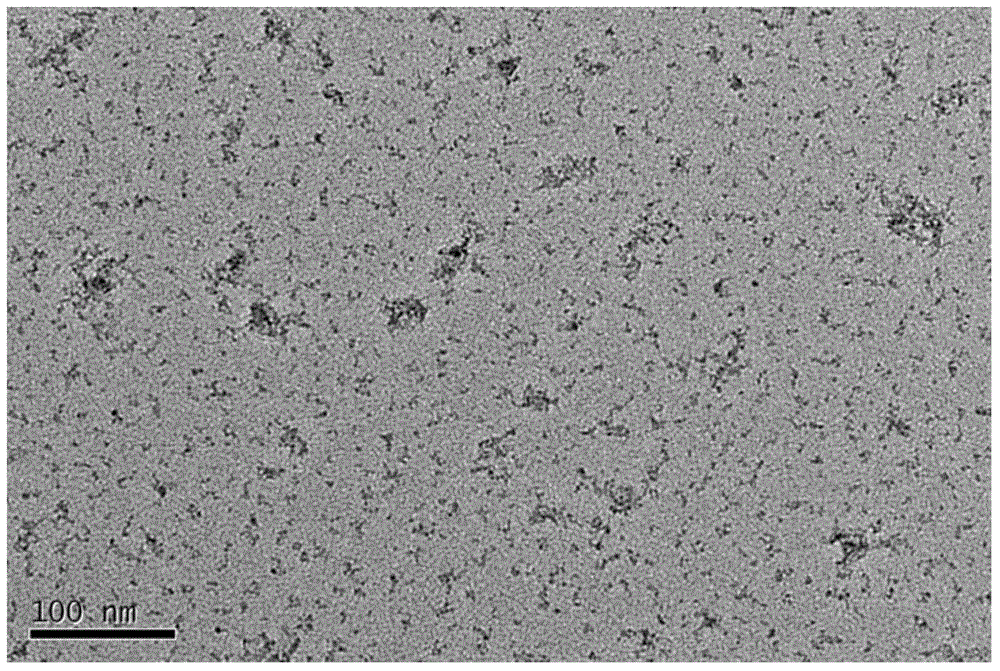

Ultrafine titanate nano powder and preparation method

ActiveCN103613125AInhibit hydrolysisNarrow particle size distributionMaterial nanotechnologyTitanium compoundsSolventBatch production

The invention discloses an ultrafine titanate nano powder and a preparation method. The method comprises the following steps: 1) taking an alcohol compound as a solvent, under the existence condition of a surfactant, reacting tetrabutyl titanate and barium hydroxide octahydrate or / and strontium oxide octahydrate to obatain a titanate nanoparticles sol; 2) adding water in the titanate nanoparticles sol, centrifuging to obtain the titanate deposition, and drying the deposition to obtain the titanate nano powder. The method has the advantages of high efficiency and energy saving, simple process and safety, can realize large batch production method of the titanate nano powder; and the method has universality to preparing nano powder with various perovskite type structure. The prepared powder has small granularity, good dispersibility, large specific surface area, high dimension uniformity, high chemical activity and wide application of electronic ceramic and chemical catalysis.

Owner:TSINGHUA UNIV

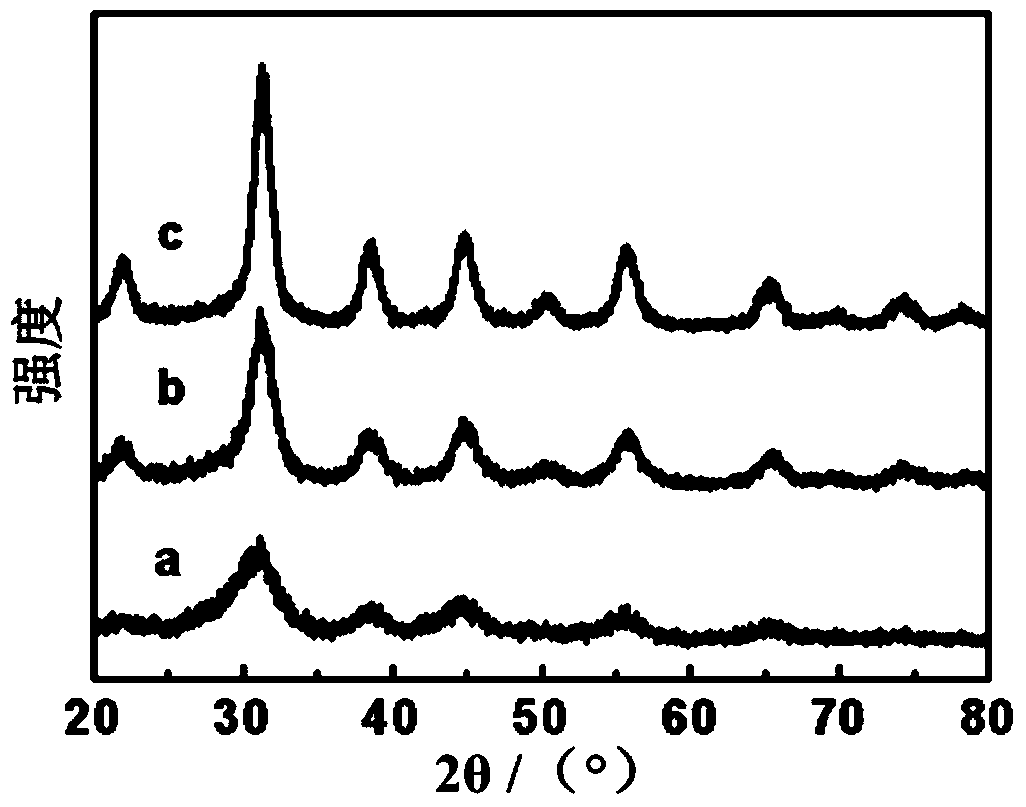

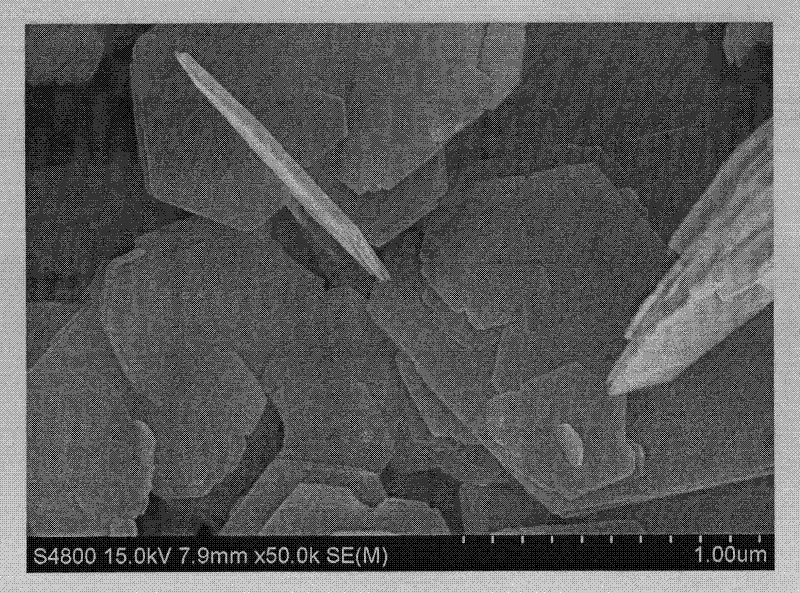

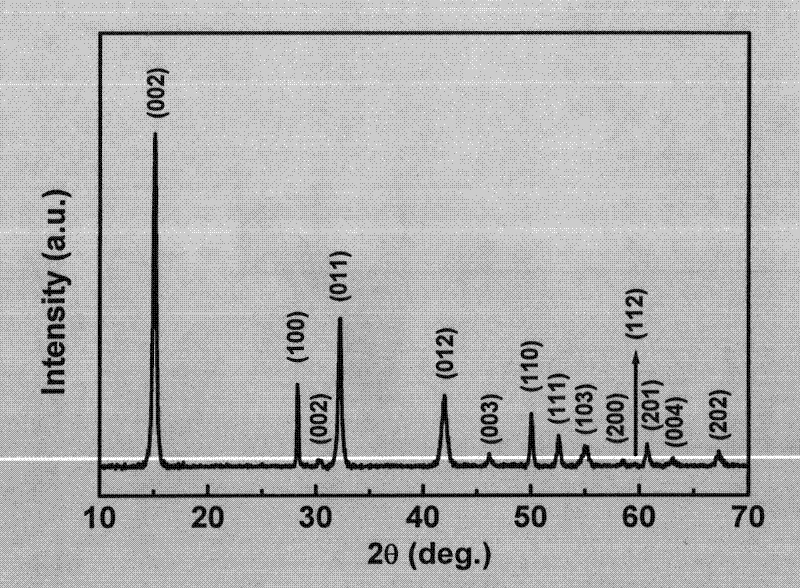

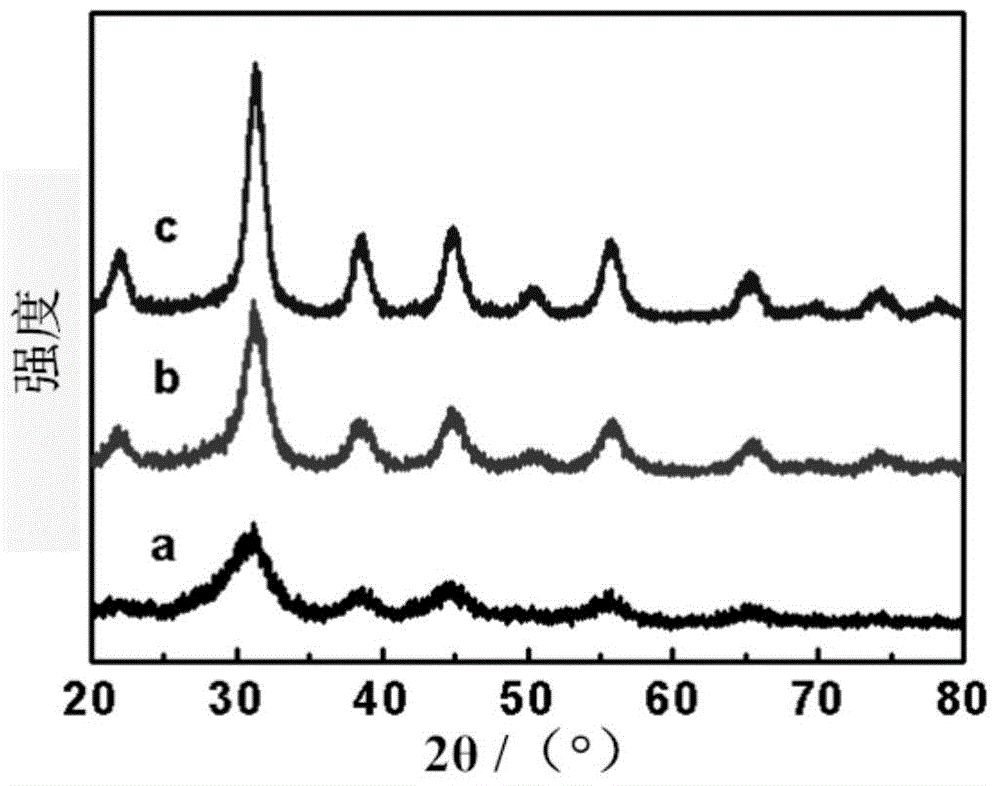

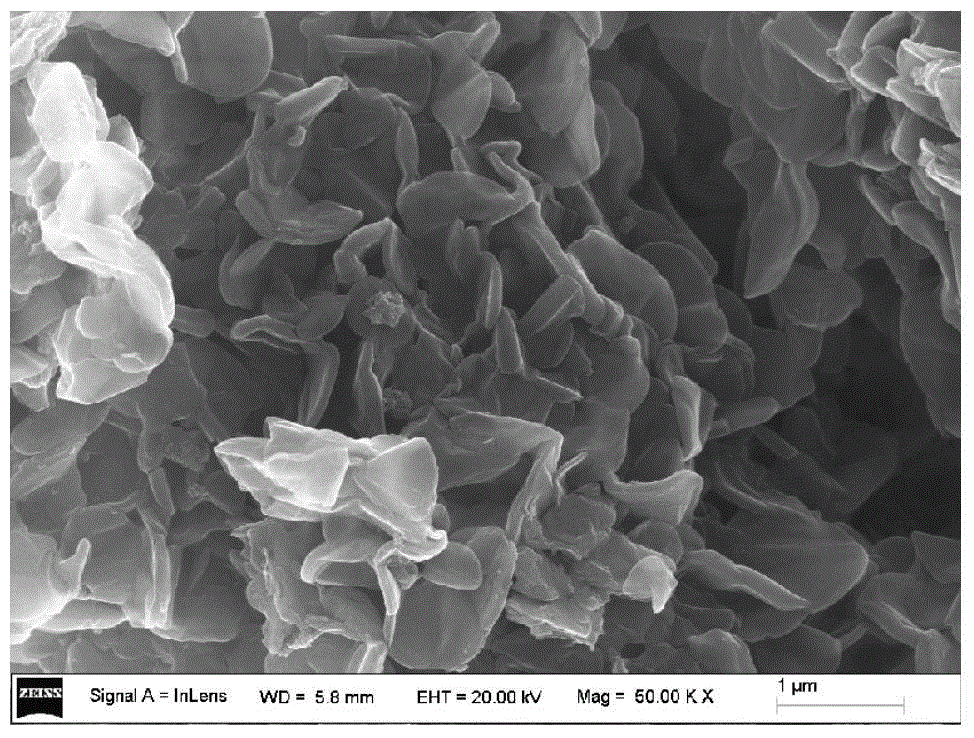

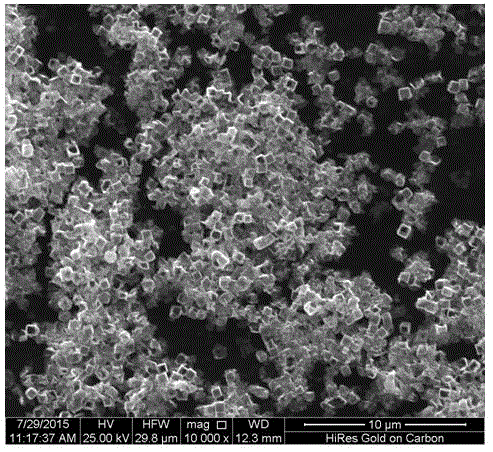

Method for preparing high-quality stannic sulfide nanosheet by use of single-source molecular precursor

The invention relates to a method for preparing a high-quality stannic sulfide nanosheet by use of single-source molecular precursor. The method comprises adding stannic chloride pentahydrate into anhydrous ethanol to prepare stannic chloride solution; dissolving sodium diethyldithiocarbamate powder in anhydrous ethanol to prepare sodium diethyldithiocarbamate solution; adding the stannic chloride solution into the sodium diethyldithiocarbamate solution, stirring, vacuum filtering and drying at 60 DEG C. to obtain a single-source molecular precursor Sn-(DDTC)4; putting the single-source molecular precursor Sn-(DDTC)4 into a high pressure vessel, and adding 2.5%-10% aqueous solution of acetic acid as solvent; and placing in an electric oven, heating at 180 DEG C. for 24 hours, cooling, vacuum filtering, washing by deionized water and anhydrous ethanol, and drying at 60 DEG C. to obtain yellow stannic sulfide powder. The invention overcomes the defects of an element direct reaction method and a chemical precipitation method, involves a low-toxicity easily-accessible single-source molecular precursor with reasonable price, simplifies the preparation process, and easily obtains a uniform-composition pure phase nanomaterial conforming to stoichiometric ratio. The obtained product has high crystallization degree and is nanosheet-like pure hexagonal phase stannic sulfide.

Owner:YANGZHOU UNIV

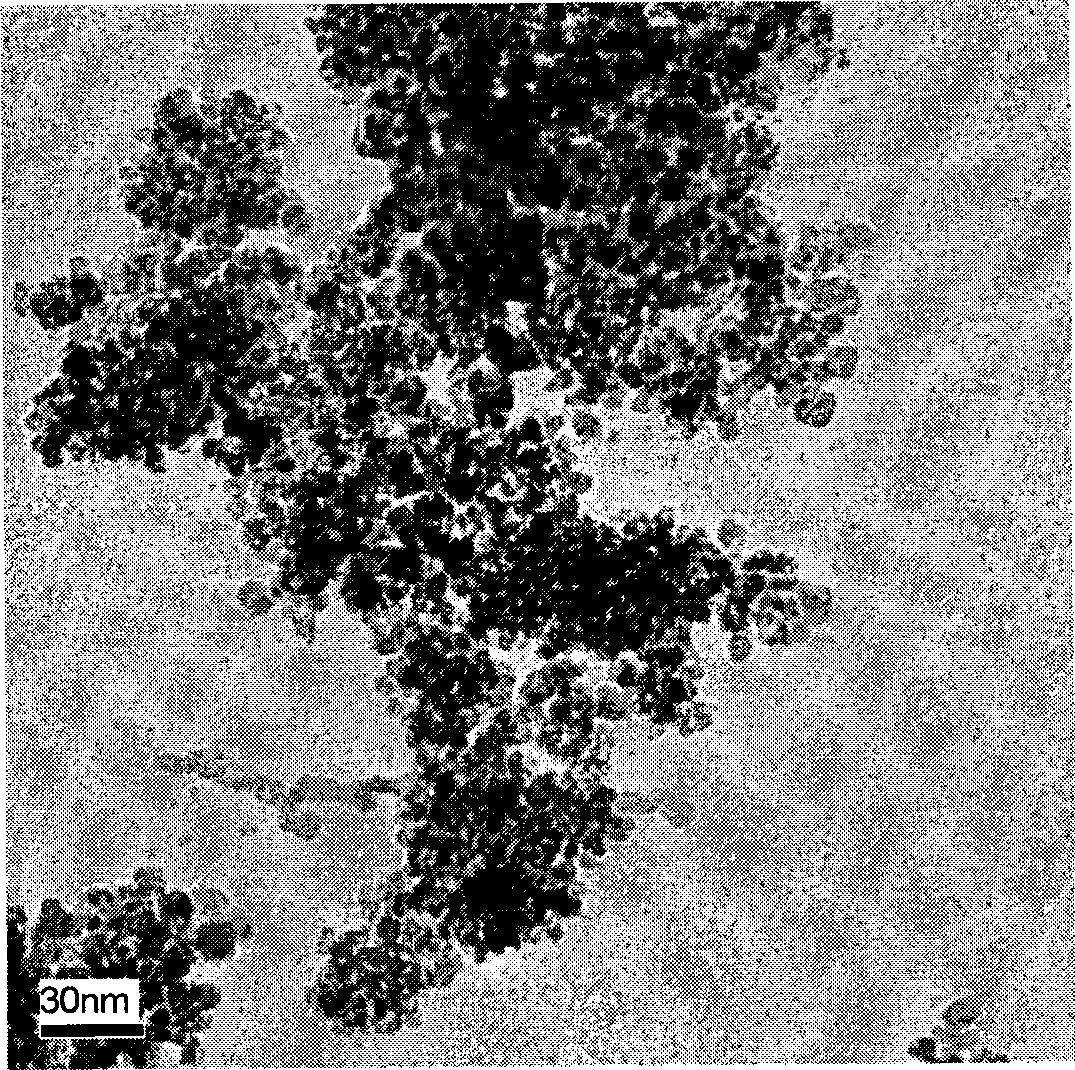

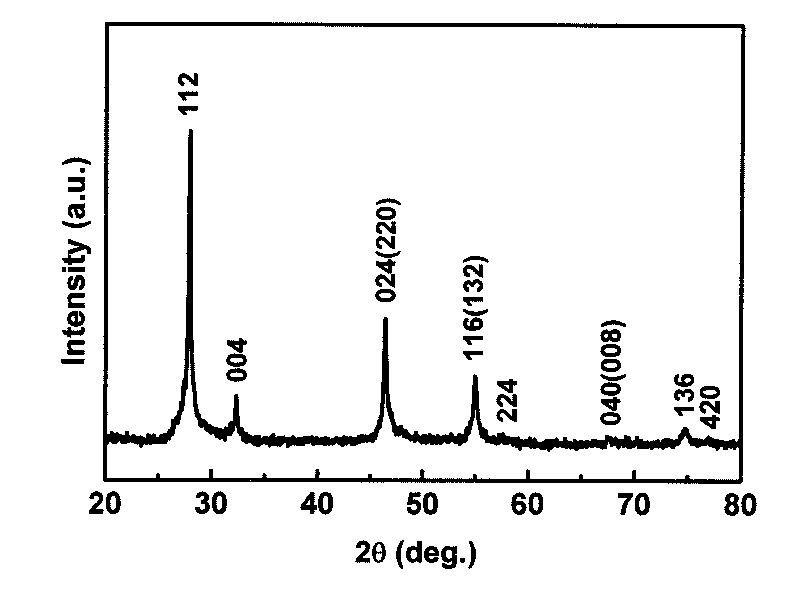

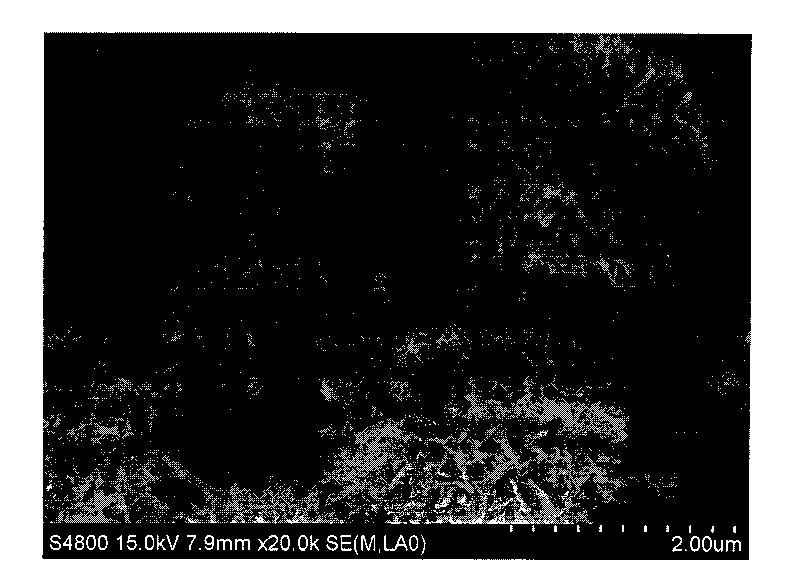

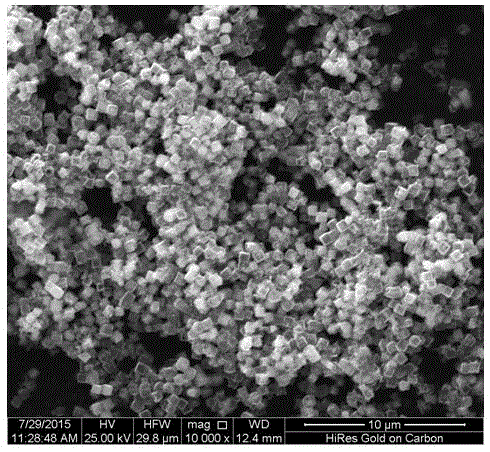

Method for preparing high-quality copper indium sulfide by employing single-source molecular precursor

InactiveCN101734712ASave raw materialsRaw materials are easy to getGallium/indium/thallium compoundsSolubilityGas phase

The invention relates to a method for preparing high-quality copper indium sulfide by employing a single-source molecular precursor. The method comprises the following steps: mixing copper chloride and indium chloride powder to prepare a solution, and preparing sodium diethyl dithiocarbamate powder into a solution; adding the former solution to the latter solution slowly in the way of stirring, filtering and drying precipitate, putting the obtained product into an autoclave and adding ethanol used as a solvent; sealing the autoclave and then placing the autoclave in an electric dry oven, heating and cooling naturally, washing with deionized water and absolute ethyl alcohol, and finally drying to obtain black copper indium sulfide powder. The invention solves the defaults of a gas phase method and a liquid phase method of expensive equipment, complex process operation, low yield, and the uniformity of the inner and outer composition of the product and the generation of a core-shell structure which are caused by the relatively larger solubility difference of the multi-source precursor in solvent. The invention has the advantages of cheap and easily obtained raw materials, no toxic H2S gas or vacuum environment, and simple process, and can obtain pure tetragonal phase copper indium sulfide with sea urchin-like morphology and high degree of crystallinity.

Owner:YANGZHOU UNIV

Synthesis method for selenium germanium gallium barium polycrystal and growth method for selenium germanium gallium barium monocrystal

ActiveCN110144624AAvoid corrosionAvoid explosionPolycrystalline material growthFrom frozen solutionsSingle phaseChemistry

The invention discloses a synthesis method for a selenium germanium gallium barium polycrystal and a growth method for a selenium germanium gallium barium monocrystal. The growth of the polycrystal comprises the following steps: putting elemental Ga, elemental Ba and elemental Ge into a PBN boat; then placing the PBN boat at one end of a quartz tube and placing elemental Se at the other end of thequartz tube; conducting vacuumizing, and then carrying out heat sealing; and then putting the quartz tube into a horizontal double-temperature-region resistor furnace for synthesizing, so as to obtain a high-purity single-phase selenium germanium gallium barium polycrystal raw material, wherein the yield of the raw material is greater than 99%. The growth of the selenium germanium gallium bariummonocrystal comprises the following steps: adding the selenium germanium gallium barium polycrystal into a crystal growth crucible and vertically placing the crystal growth crucible into a quartz tube; conducting vacuumizing, and then carrying out heat sealing; and then putting the quartz tube into a vertical double-temperature-region resistor furnace, so as to obtain the selenium germanium gallium barium monocrystal after the growth of the monocrystal is finished. The selenium germanium gallium barium monocrystal obtained by the method disclosed by the invention has the advantages of few defects, high infrared band transmission rate and the like and can be used as a far infrared laser frequency conversion material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Method for synthesizing LiXSe2 polycrystalline compound and mono-crystal

InactiveCN108277536AThe stoichiometric ratio matchesReduce lossesPolycrystalline material growthFrom frozen solutionsChemical compositionSteam pressure

The invention relates to a preparation method of LiXSe2 polycrystalline compound and mono-crystal. The preparation method comprises the following steps: filling Li, In, Ga and Sa monomers into an inner-layer crucible and a quartz crucible and packaging in vacuum; filling the crucibles into a swinging furnace and carrying out heat preservation and swinging at the temperature above the smelting point of the LiXSe2 compound; then cooling to room temperature. The obtained LiXSe2 (X is equal to In / Ga / InyGa1-y) compound meets a stoichiometric ratio. By controlling the temperature, the Li, In, Ga andSa monomers are subjected to compound reaction at temprature close to smelting points of the Li and the Se under relatively low steam pressure of the Li and the Se, so as to obtain Li2Se, InxSey andGaxSey compounds and the like and fix the chemical activity of the Li and the Se and reduce the loss of Li and Se components; the deviation of the stoichiometric ratio of chemical components of the LiXSe2 mono-crystal (X is equal to In / Ga / InyGa1-y) obtained by the growth of the polycrystalline raw material LiXSe2 (X is equal to In / Ga / InyGa1-y) obtained by the invention can be controlled within 5 percent.

Owner:NORTHWESTERN POLYTECHNICAL UNIV

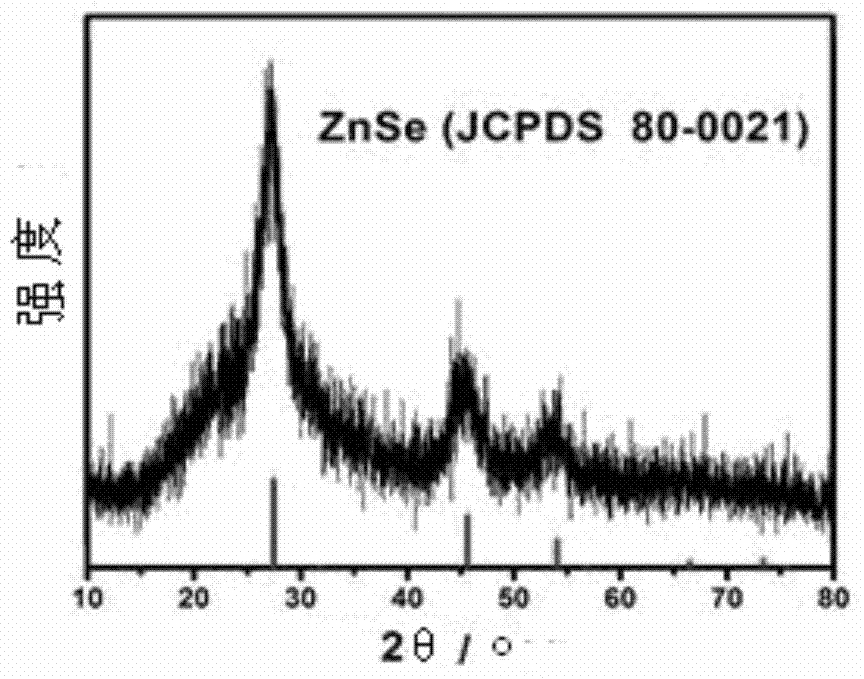

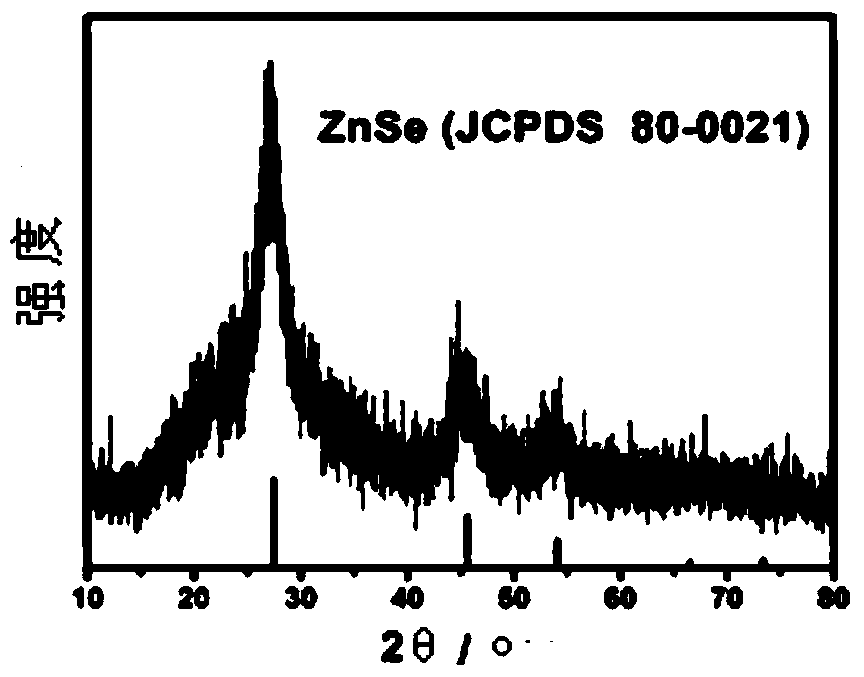

Preparation method of ZnSe nanocrystal, ZnSe nanocrystal and preparation method of ZnSe buffer layer

ActiveCN104495762AQuality improvementImprove stabilityMaterial nanotechnologyFinal product manufactureSodium borohydrideStearic acid

The invention discloses a preparation method of ZnSe nanocrystal. The preparation method of the ZnSe nanocrystal comprises the following steps: S1, preparing selenium precursor solution, namely preparing a reaction solution by utilizing oleylamine, a selenium simple substance and a reducing agent, heating and reacting, and thus the selenium precursor solution is obtained, wherein concentration of the selenium precursor solution in the reaction solution is 0.25-1.5mol / L, the mole ratio of the reducing agent to the selenium simple substance is more than 1:1, and the reducing agent is dimethylamine borane or sodium borohydride; S2, preparing a zinc precursor solution, namely dispersing a zinc source in a reaction solvent to obtain the zinc precursor solution, wherein mole ratio of the zinc source to the selenium simple substance is 1:(1-1.5), and the reaction solvent is oleylamine or a mixed solvent of octadecene and stearic acid; and S3, preparing ZnSe nanocrystal, namely heating the zinc precursor solution obtained in the step S2 to 150-350 DEG C in an anhydrous oxygen-free system, then injecting the selenium precursor solution obtained in the step S1 into the zinc precursor solution, and reacting for at least 10 minutes, and thus the ZnSe nanocrystal is obtained. By adopting the preparation method of the ZnSe nanocrystal, high-quality ZnSe nanocrystal can be prepared.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

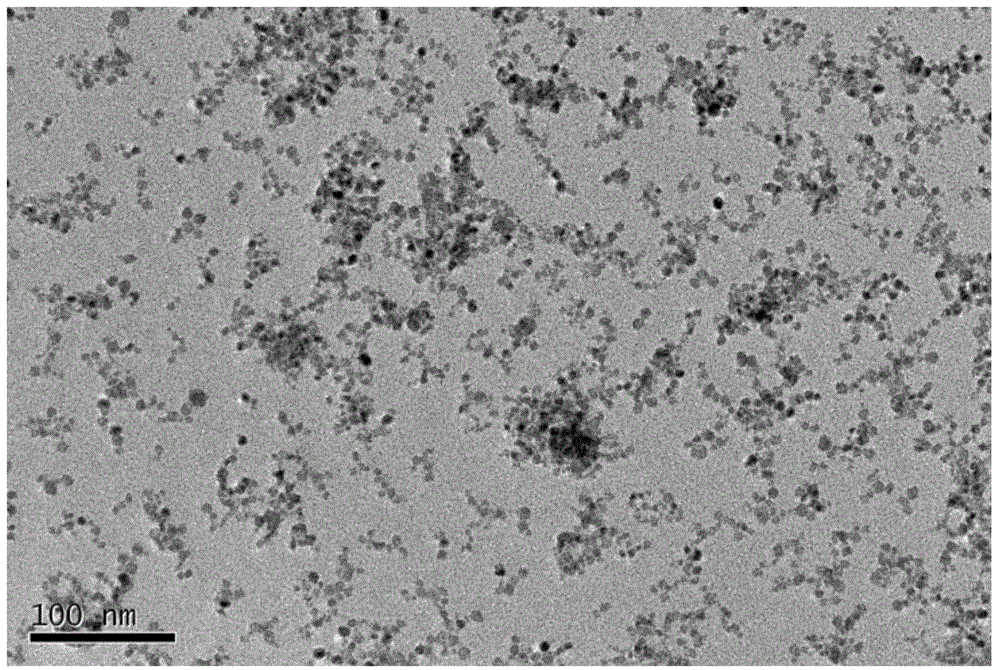

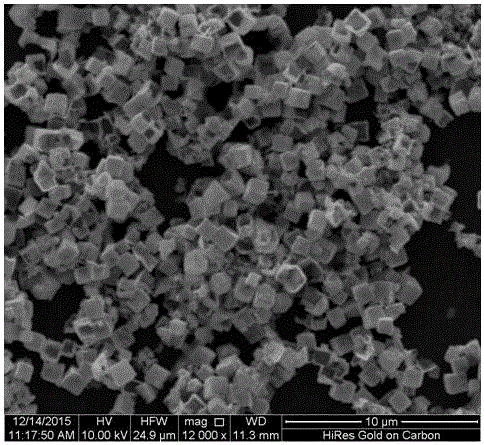

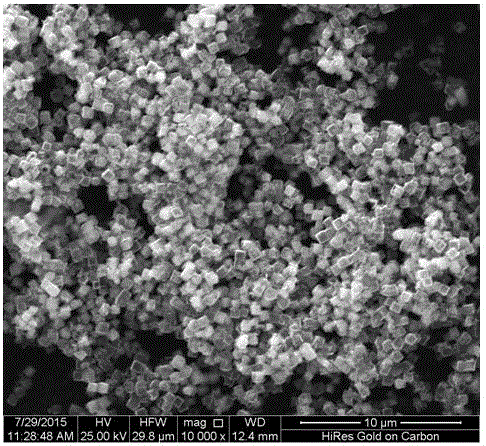

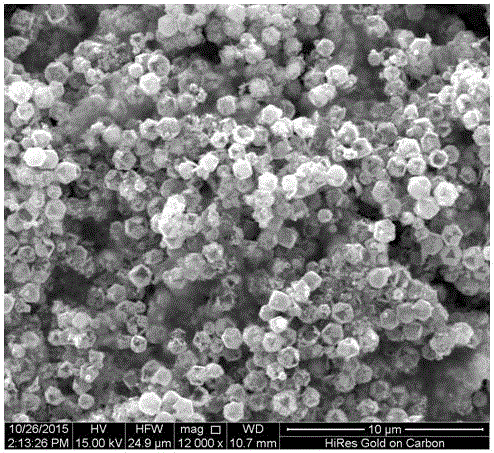

Preparation method of hollow PtPd nanometer material

InactiveCN105537616AStoichiometric ratioExact copy of topographyTransportation and packagingMetal-working apparatusAlcoholCopper

The invention discloses a preparation method of a hollow PtPd nanometer material, comprising the following steps: (1) uniformly dispersing cuprous oxide to low mass molecule alcohol, adding a low mass molecule alcohol solution containing PtCl6(2-) and PdCl4(2-) while stirring, and carrying out ultrasonic stirring and mixing; (2) dripping a mixed solution obtained in step (1) to water, and carrying out stirring reaction for 30-60min at the temperature of 20-25 DEG C; (3) transferring a reaction system in the step (2) to a heating device and heating to 60-65 DEG C at the heating rate of 1-3 DEG C / min, and continuing to react for 90-120min at current temperature; and (4) removing a cuprous oxide core after reaction is completed so as to obtain the hollow PtPd nanometer material. The hollow PtPd nanometer material prepared by adopting the method can meet the stoichiometric ratio of reactants, and can uniformly and precisely copy the morphology of a cuprous oxide template.

Owner:重庆稳稳科技有限公司

Method for growing phosphorus-silicon-cadmium single crystal

InactiveCN102168299BGood effectConvenient rotary controlPolycrystalline material growthFrom frozen solutionsSpontaneous nucleationCrucible

The invention relates to a method for growing a phosphorus-silicon-cadmium single crystal. 1 part of silicon, 1 part of cadmium and 2-2.05 parts of phosphorus are synthesized into a phosphorus-silicon-cadmium polycrystal material, and the phosphorus-silicon-cadmium single crystal is grown by a crucible descending furnace by using a spontaneous nucleation growing method or oriented seed crystal growing method. The method comprises the following steps: directly filling the phosphorus-silicon-cadmium polycrystal material into a crucible, or filling the phosphorus-silicon-cadmium polycrystal material into the crucible after adding the seed crystal; putting the crucible into a silica tube, vacuumizing, and sealing the silica tube; putting the silica tube into a crucible descending furnace; andheating, descending the crucible, and finally cooling. The method provided by the invention can be used for preparing the high-purity high-quality phosphorus-silicon-cadmium single crystal.

Owner:SHANDONG UNIV

A kind of ultrafine titanate nanopowder and preparation method thereof

ActiveCN103613125BAvoid hydrolysisAvoid formingMaterial nanotechnologyTitanium compoundsSolventBarium hydroxide

Owner:TSINGHUA UNIV

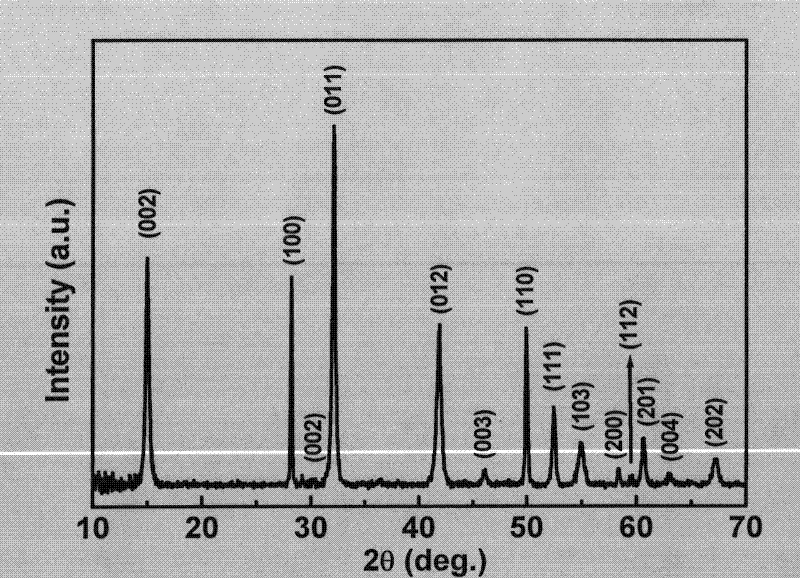

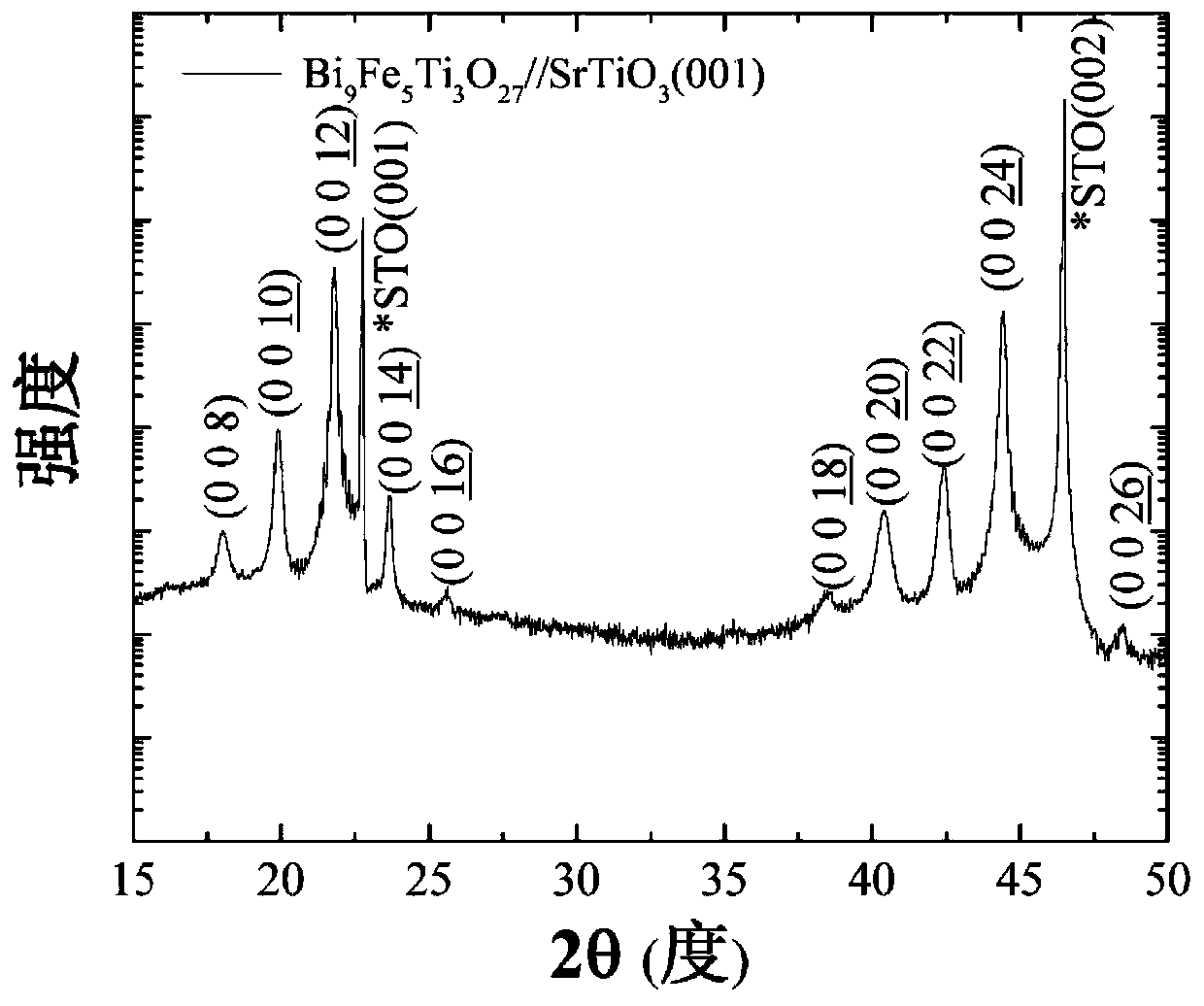

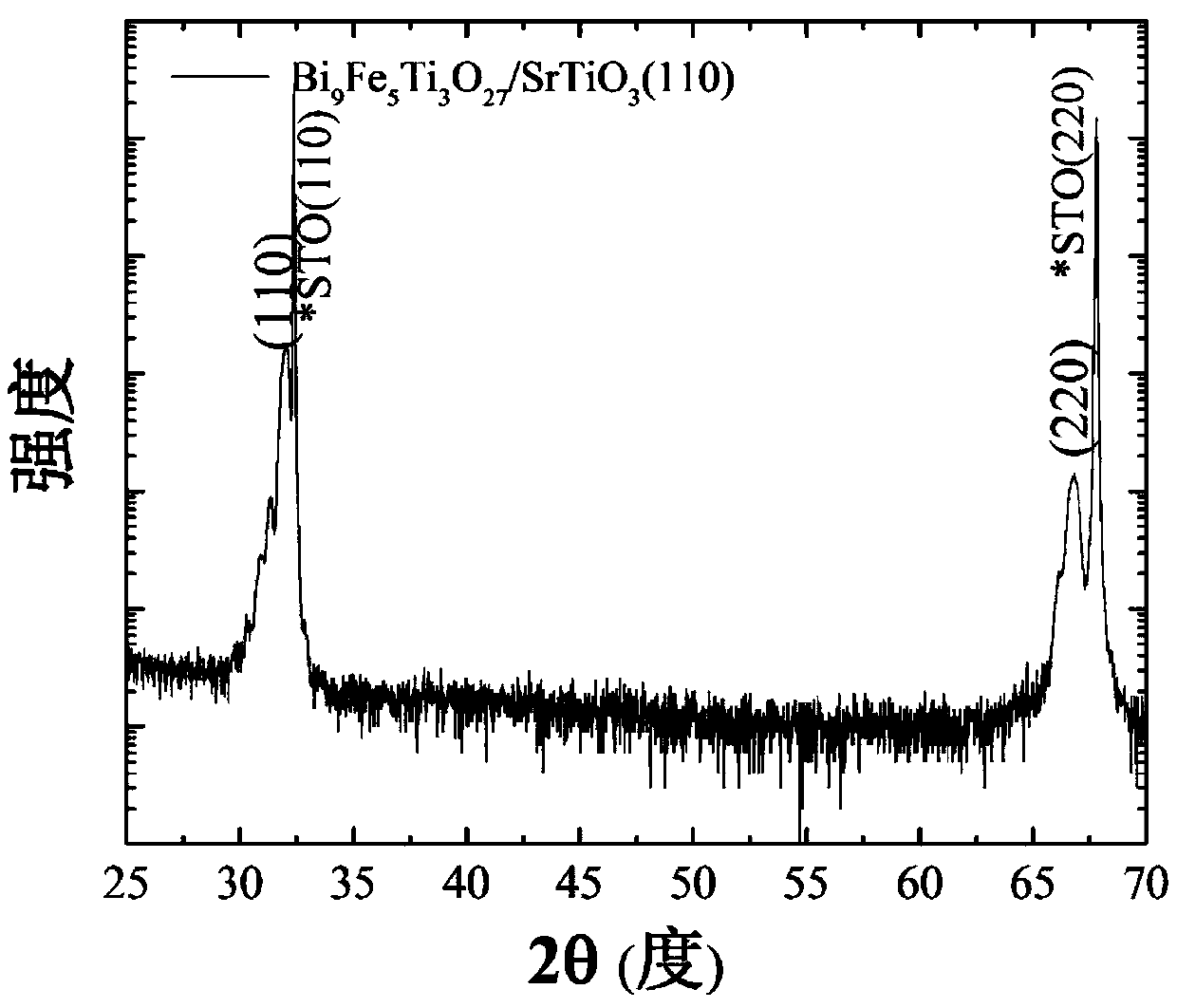

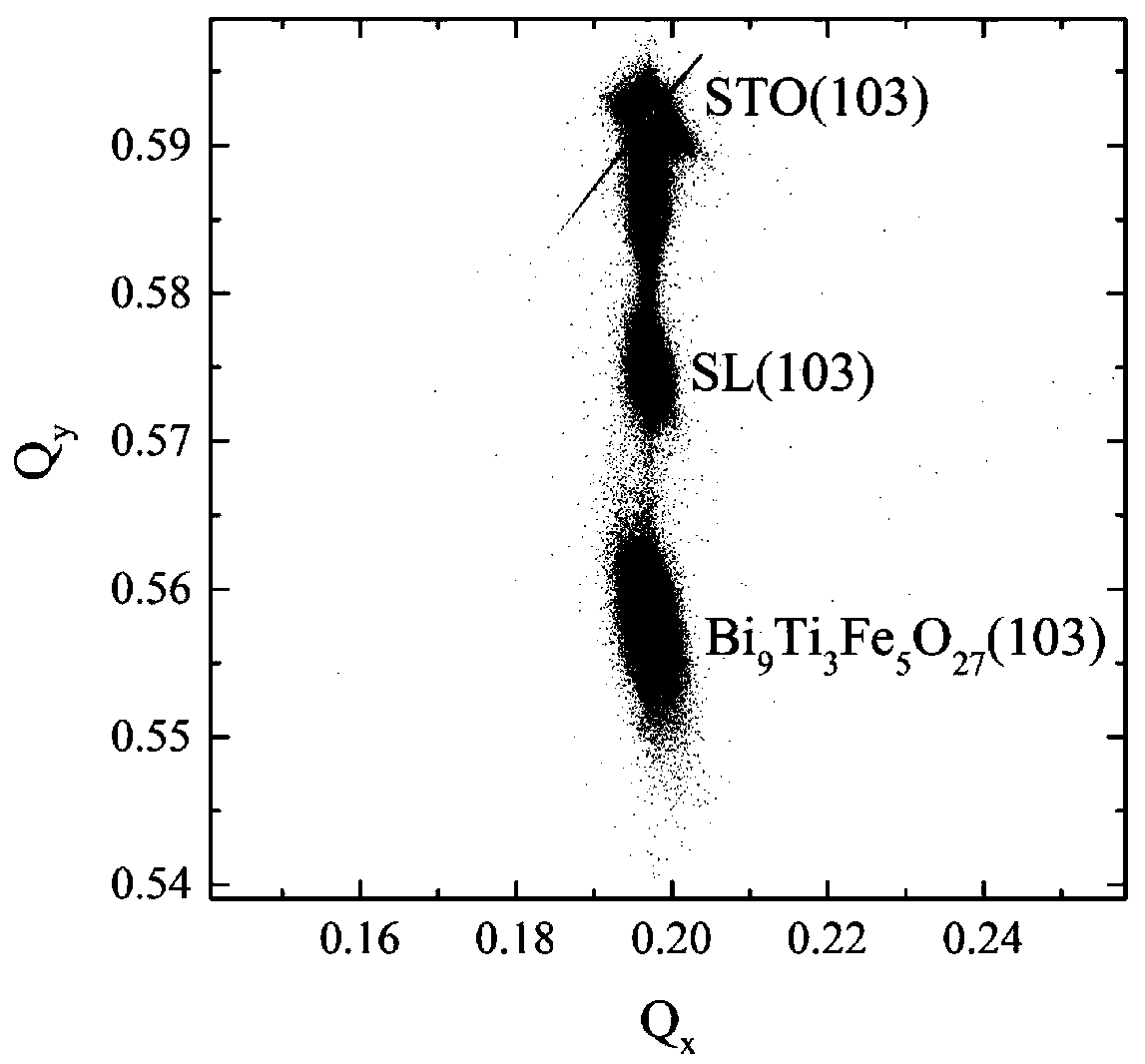

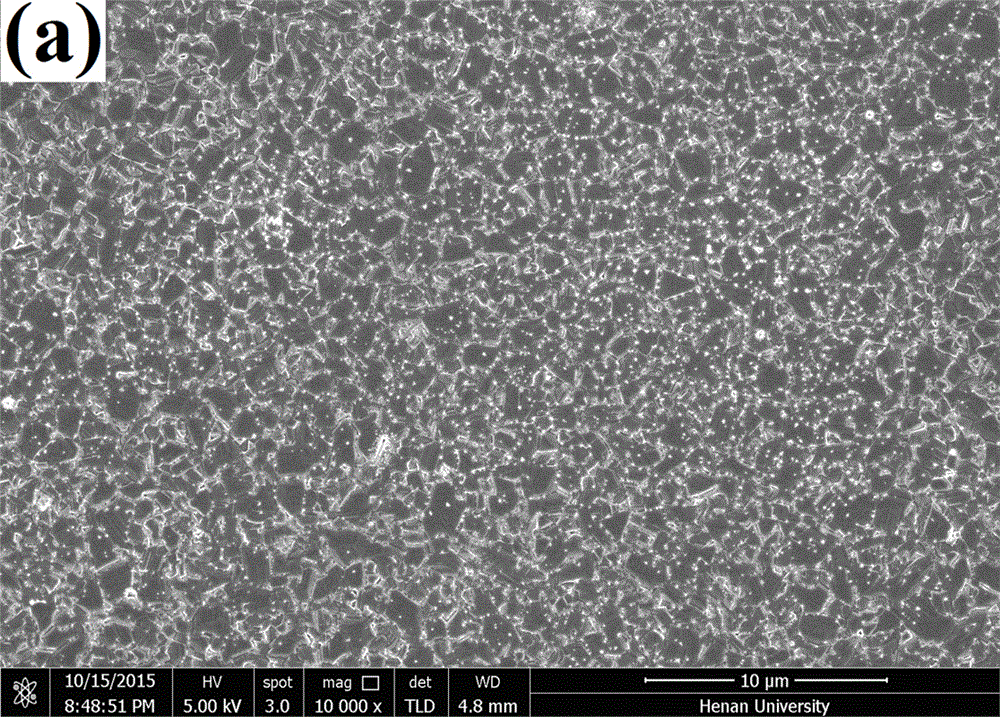

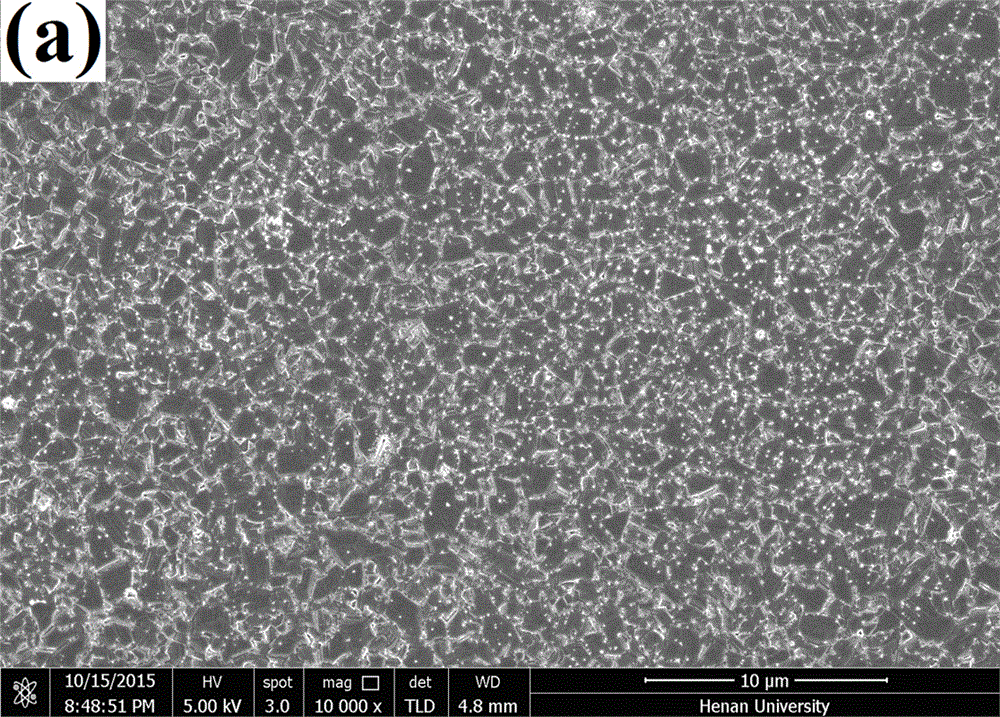

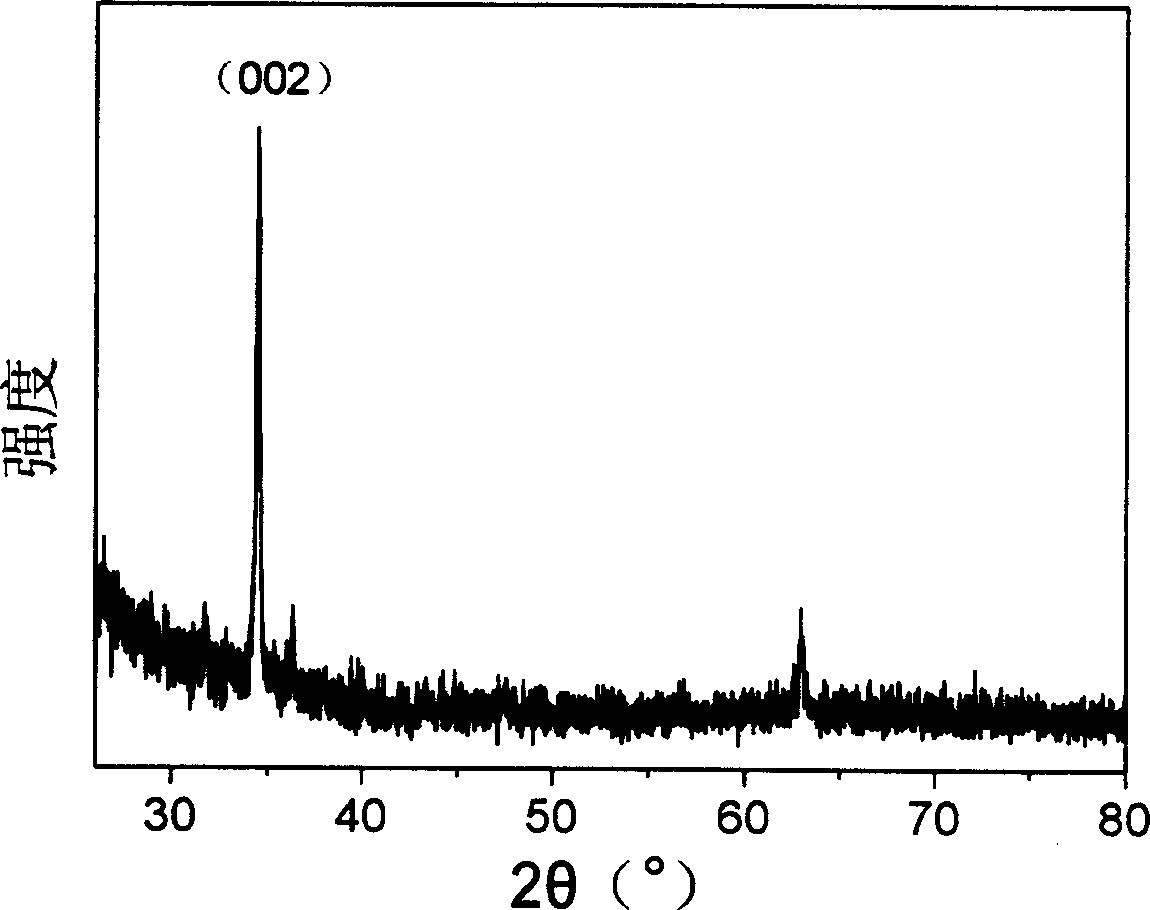

a bi 9 ti 3 fe 5 o 27 Layered multiferroic epitaxial thin film and preparation method thereof

ActiveCN108018525BQuality improvementImprove crystal qualityVacuum evaporation coatingSputtering coatingMetallurgyPhysical chemistry

The invention relates to a Bi9Ti3Fe5O27 laminated iron-rich epitaxial film and a preparation method thereof. The film is prepared through a pulsed laser deposition method, and the chemical constitution of the film is Bi9Ti3Fe5O27. The Bi9Ti3Fe5O27 laminated iron-rich epitaxial film has high phase purity, excellent ferroelectric properties and considerable ferromagnetism, is an excellent room temperature iron-rich film material and is quite beneficial for research and development and popularization of novel iron-rich films.

Owner:江苏先进无机材料研究院

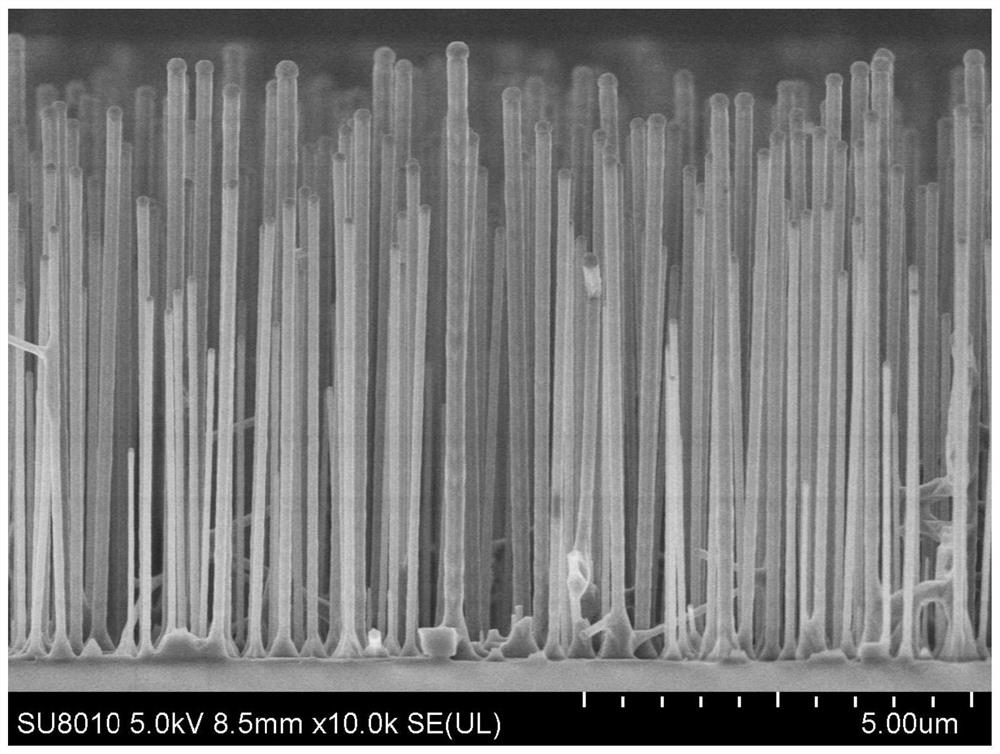

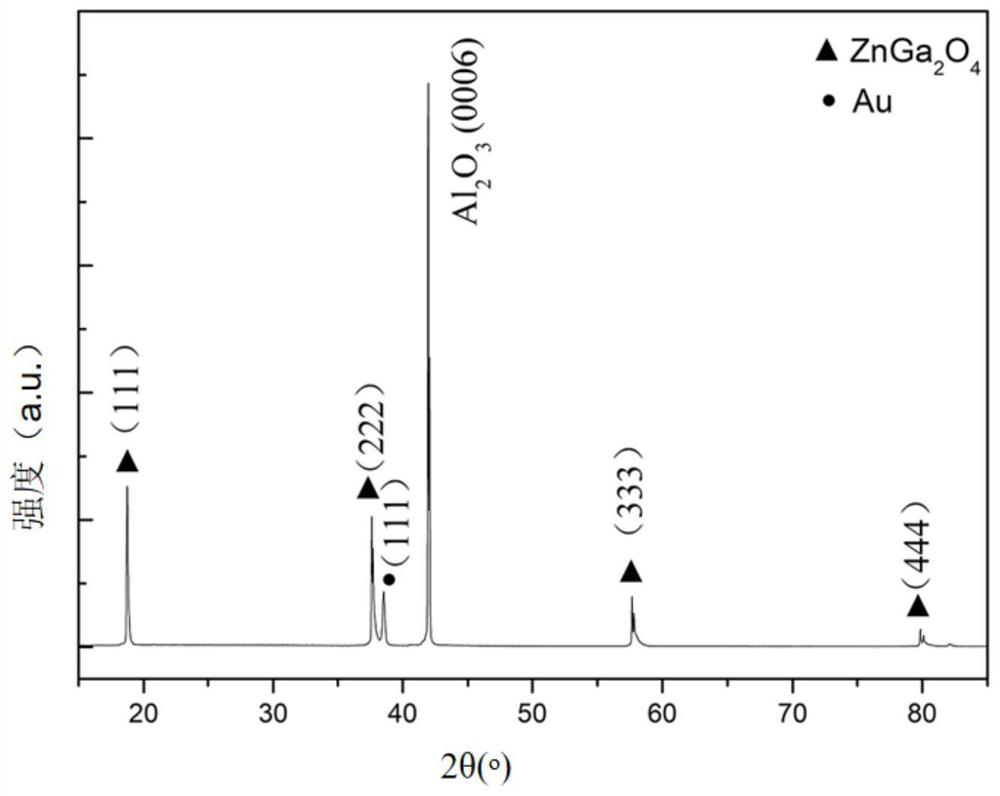

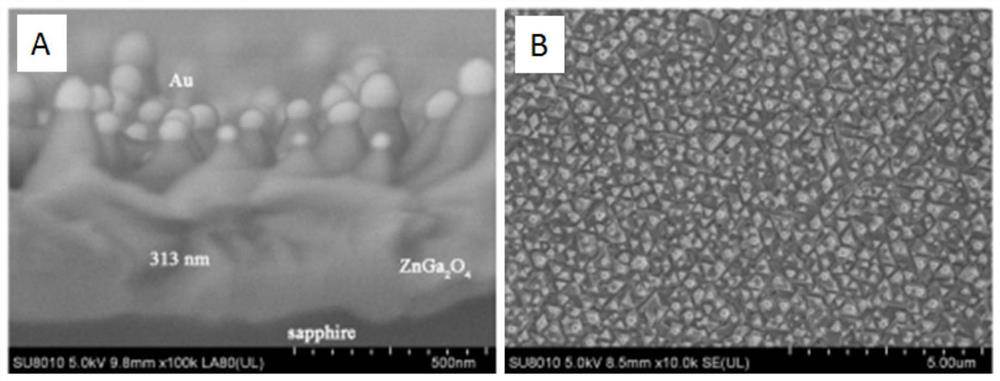

Zinc gallate nano material as well as preparation method and application thereof

PendingCN113443647AOrderly rowsStoichiometric ratioGallium/indium/thallium compoundsNanoopticsNanowireSemiconductor materials

The invention discloses a zinc gallate nano material as well as a preparation method and application thereof. The zinc gallate nano material has a nanowire structure which is cross-linked at the bottom and is vertically arranged in order. The zinc gallate nano material has a good application prospect as a semiconductor material and / or a luminescent material, and can be widely applied to the fields of ultraviolet detectors, fluorescent luminescent powder, gas sensors and the like.

Owner:FUJIAN INST OF RES ON THE STRUCTURE OF MATTER CHINESE ACAD OF SCI +1

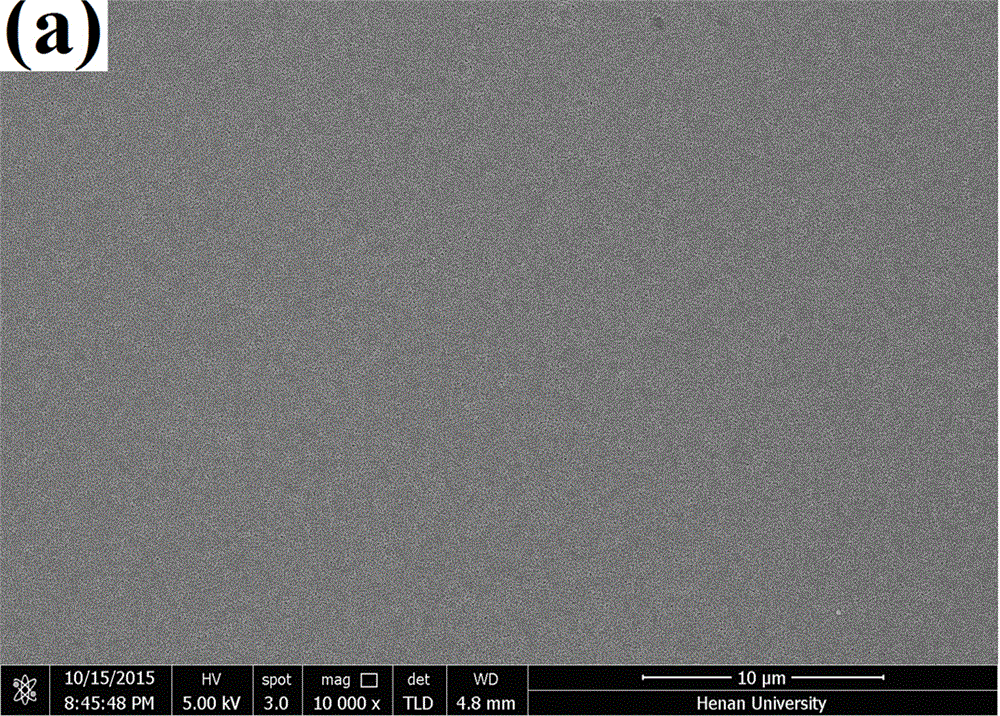

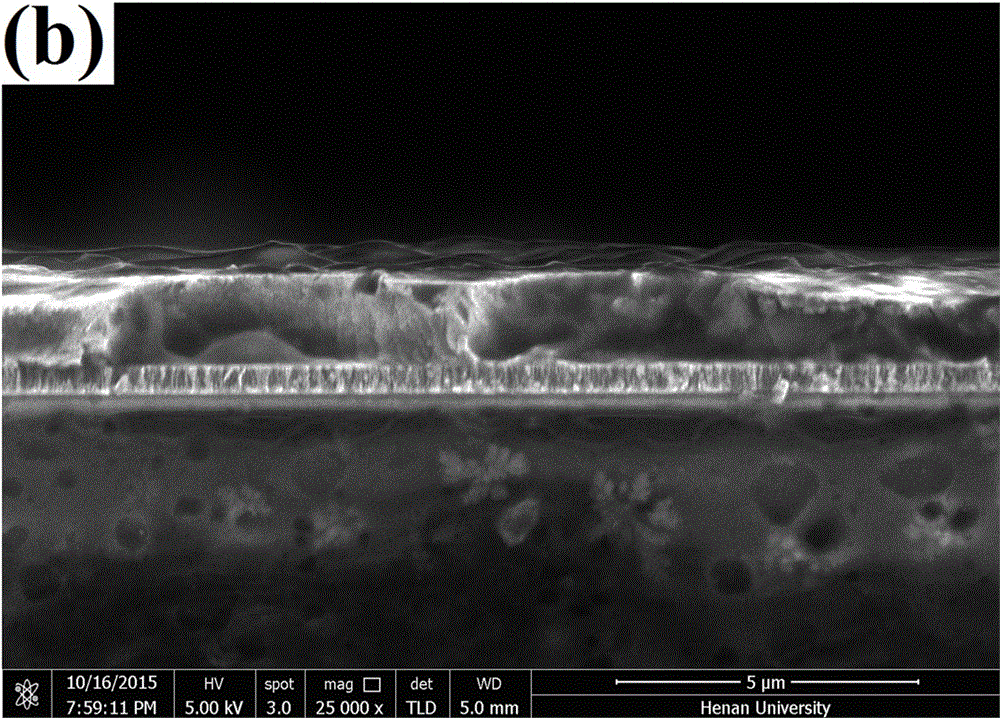

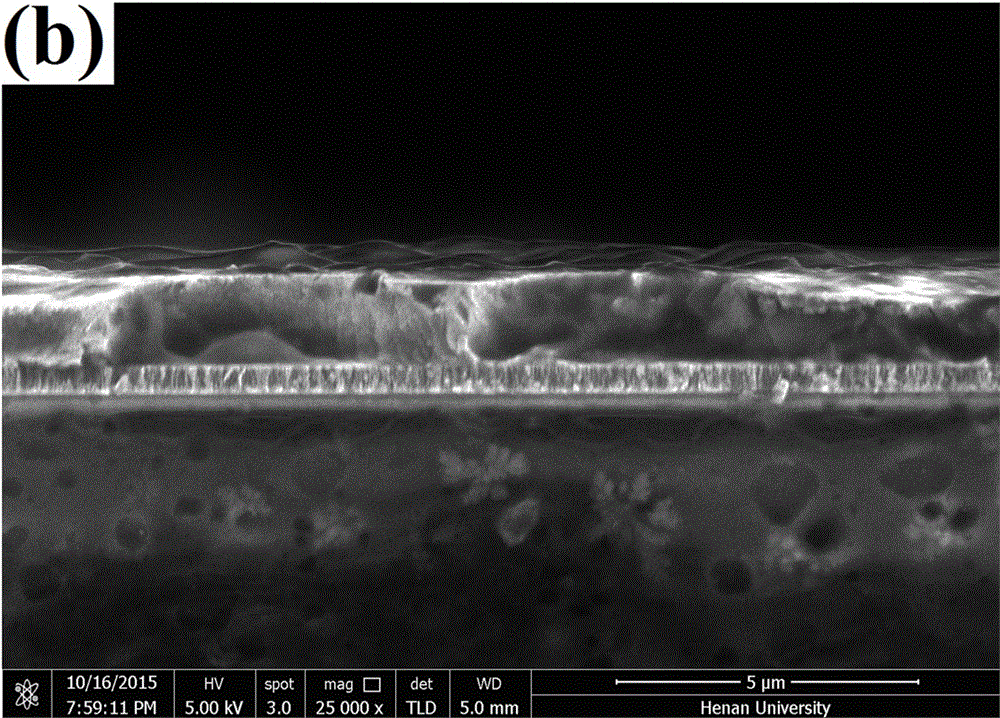

Method for preparing CIGS thin-film solar cell absorption layer employing co-sputtering method

InactiveCN105870255AAvoid lostStoichiometric ratioFinal product manufacturePhotovoltaic energy generationIndiumNitrogen gas

The invention belongs to a method for preparing a CIGS thin-film solar cell absorption layer employing a co-sputtering method. The method comprises the steps as follows: (1) a substrate is provided, radio-frequency sputtering is carried out by a copper indium gallium selenide target, meanwhile, DC sputtering is carried out by an indium target and a copper indium gallium selenide preformed layer is prepared in a co-sputtering manner; and (2) the copper indium gallium selenide preformed layer is put into a quick annealing furnace, is selenized under nitrogen protection for twice and is naturally cooled to a room temperature to obtain the CIGS thin-film solar cell absorption layer. By a technological approach of carrying out sputtering by a standard CIGS quaternary target, large-scale industrial production is facilitated; the loss of an indium element caused by the standard CIGS quaternary target in the sputtering process can be effectively avoided through the method; and a CIGS absorption layer material in accordance with the stoichiometric ratio can be obtained. Annealing treatment is carried out on the prepared CIGS absorption layer through a two-step heating method; the selenylation completeness and crystallinity can be further strengthened; and the high-quality CIGS with a uniform surface and a consistent thickness can be obtained.

Owner:HENAN UNIVERSITY

A kind of co-sputtering method prepares the method for absorbing layer of cigs thin film solar cell

InactiveCN105870255BAvoid lostStoichiometric ratioFinal product manufacturePhotovoltaic energy generationIndiumFree cooling

The invention belongs to a method for preparing a CIGS thin-film solar cell absorption layer employing a co-sputtering method. The method comprises the steps as follows: (1) a substrate is provided, radio-frequency sputtering is carried out by a copper indium gallium selenide target, meanwhile, DC sputtering is carried out by an indium target and a copper indium gallium selenide preformed layer is prepared in a co-sputtering manner; and (2) the copper indium gallium selenide preformed layer is put into a quick annealing furnace, is selenized under nitrogen protection for twice and is naturally cooled to a room temperature to obtain the CIGS thin-film solar cell absorption layer. By a technological approach of carrying out sputtering by a standard CIGS quaternary target, large-scale industrial production is facilitated; the loss of an indium element caused by the standard CIGS quaternary target in the sputtering process can be effectively avoided through the method; and a CIGS absorption layer material in accordance with the stoichiometric ratio can be obtained. Annealing treatment is carried out on the prepared CIGS absorption layer through a two-step heating method; the selenylation completeness and crystallinity can be further strengthened; and the high-quality CIGS with a uniform surface and a consistent thickness can be obtained.

Owner:HENAN UNIVERSITY

A method for preparing hollow ptpd nanomaterials using cuprous oxide as a template

ActiveCN105537617BExact copy of topographyStoichiometric ratioTransportation and packagingMetal-working apparatusCopper oxideAqueous solution

The invention discloses a method for preparing hollow PtPd nanomaterials using cuprous oxide as a template, comprising the following steps: (1) uniformly dispersing cuprous oxide in water, adding PtCl62‒ and PdCl42 under stirring conditions at 20-25°C ‒ aqueous solution, stirred and reacted at this temperature for 30-60min; (2) Move the reaction system in step (1) into a heating device and heat it to 60-65°C at a heating rate of 1-3°C / min, and continue at this temperature React for 90‑120 min; (3) After the reaction is completed, the cuprous oxide nucleus is removed to obtain a hollow PtPd nanomaterial. The hollow PtPd nanomaterial obtained by the present invention not only accurately replicates the morphology of the cuprous oxide template, but also makes the atomic ratio Pt / Pd of the hollow PtPd nanomaterial similar to the atomic ratio Pt / Pd in the reaction solution, which conforms to the stoichiometric ratio of the reactants , to achieve precise composition control.

Owner:CHONGQING UNIV OF ARTS & SCI

A high-voltage intercalation assembly method and its application in the field of preparation of intercalation structure composite materials

InactiveCN104860337BImprove solubilityAfter the reaction is completed, a large amount of water is required to wash the reaction fullyAluminium compoundsSolubilityWater source

The invention discloses a high pressure intercalation assembly method and application in preparation field of intercalation structure composite material. When preparing difficult soluble object intercalation hydrotalcite by using conventional method, object molecule solubility is extremely low, bivalence and trivalent metal salt solubility is relatively high, intercalation condition is not met in dynamics, and difficult soluble object intercalation hydrotalcite composite material cannot be prepared; if the raw material adopts the dissolubility salt for intercalation, the use amount of the object is excessive, a large amount of water is used for washing the reaction product after the reaction, the technology is complex, the water source is wasted and the environment pollution is generated. High temperature pressed mode is adopted for effectively improving solubility of the object; substep crystallization mode is adopted for guaranteeing sufficient reaction between the dissolved object molecule and the slowly ionized metallic oxide or hydroxide; the reaction system meets stoichiometric ratio and is the typical atom economy reaction, the technology is simple, no by-product is generated and the washing process is not required.

Owner:BEIJING UNIV OF CHEM TECH

Method for preparing nanometer zinc oxide thin film using high temperature oxidation

InactiveCN1733973APromote crystallizationOxidation process is simple and easyVacuum evaporation coatingSputtering coatingOxygen vacancyZno nanoparticles

The preparation method for nano zinc oxide thin membrane by oxygenating zine sulfide at high temperature. Wherein, preparing the thin membrane with common electron-beam evaporation method in Muffle furnace; whole process is simple, convenient and controllable and can avoid oxygen vacancy and zinc interstice and other defects the product has well performance.

Owner:SHANGHAI INST OF OPTICS & FINE MECHANICS CHINESE ACAD OF SCI

Preparation method of znse nanocrystal, preparation method of znse nanocrystal and znse buffer layer

ActiveCN104495762BQuality improvementImprove stabilityMaterial nanotechnologyFinal product manufactureStearic acidFatty acid

The invention discloses a preparation method of ZnSe nanocrystal. The preparation method of the ZnSe nanocrystal comprises the following steps: S1, preparing selenium precursor solution, namely preparing a reaction solution by utilizing oleylamine, a selenium simple substance and a reducing agent, heating and reacting, and thus the selenium precursor solution is obtained, wherein concentration of the selenium precursor solution in the reaction solution is 0.25-1.5mol / L, the mole ratio of the reducing agent to the selenium simple substance is more than 1:1, and the reducing agent is dimethylamine borane or sodium borohydride; S2, preparing a zinc precursor solution, namely dispersing a zinc source in a reaction solvent to obtain the zinc precursor solution, wherein mole ratio of the zinc source to the selenium simple substance is 1:(1-1.5), and the reaction solvent is oleylamine or a mixed solvent of octadecene and stearic acid; and S3, preparing ZnSe nanocrystal, namely heating the zinc precursor solution obtained in the step S2 to 150-350 DEG C in an anhydrous oxygen-free system, then injecting the selenium precursor solution obtained in the step S1 into the zinc precursor solution, and reacting for at least 10 minutes, and thus the ZnSe nanocrystal is obtained. By adopting the preparation method of the ZnSe nanocrystal, high-quality ZnSe nanocrystal can be prepared.

Owner:SHENZHEN DANBANG INVESTMENT GROUP

a baga 4 the se 7 Polycrystalline synthesis device and synthesis method

ActiveCN109930203BAvoid corrosionAvoid explosionPolycrystalline material growthSingle crystal growth detailsSynthesis methodsPhysical chemistry

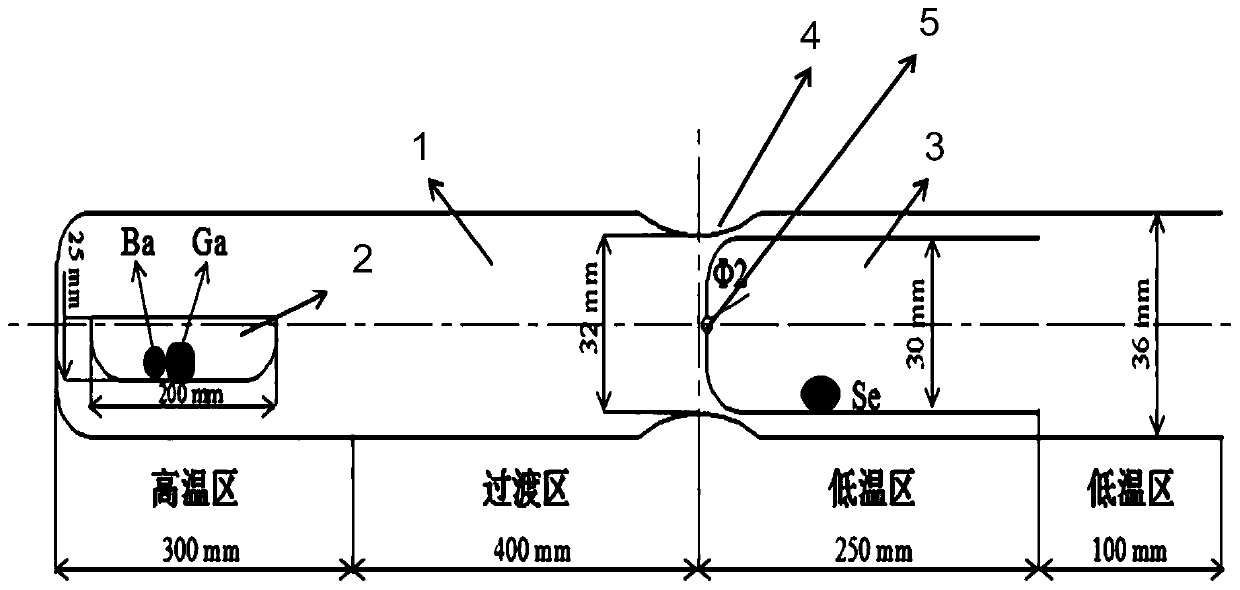

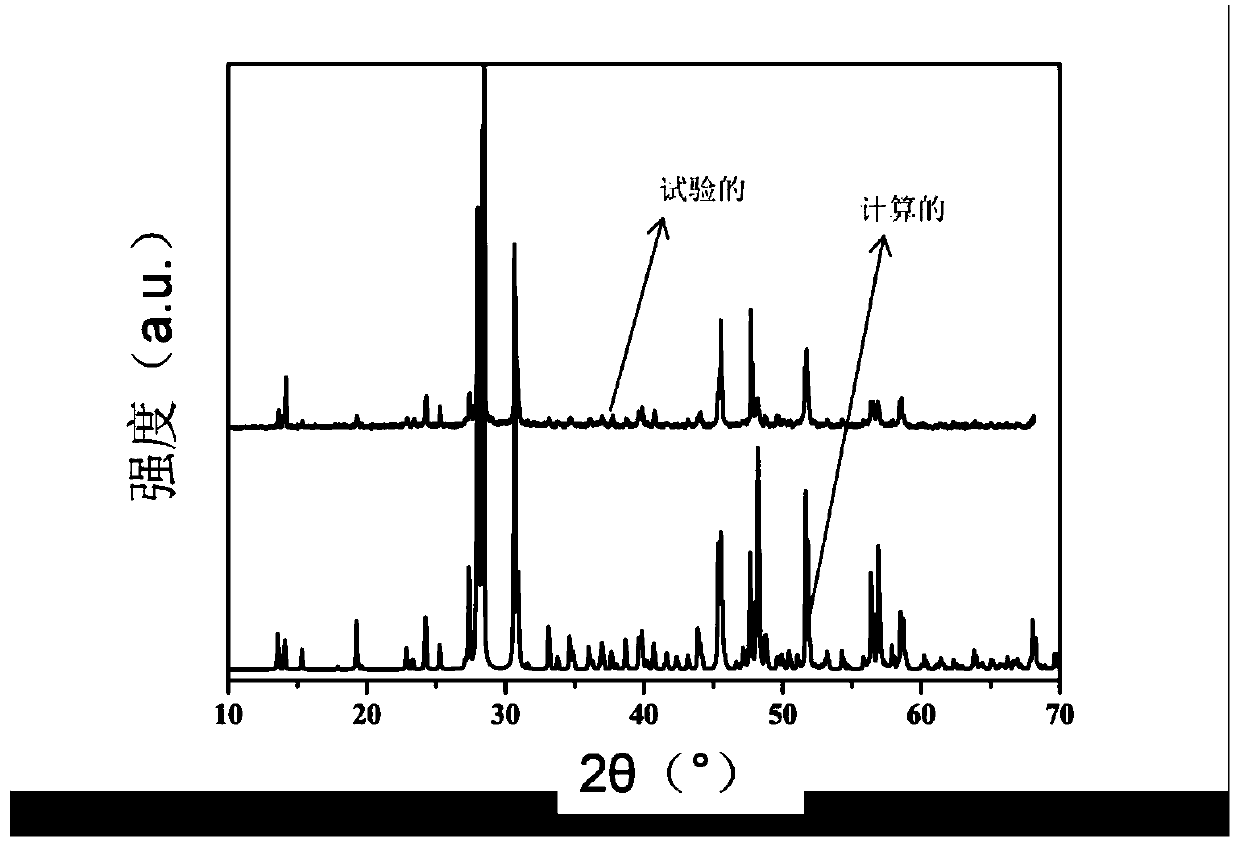

The invention discloses a synthesis device and a synthesis method for BaGa4Se7 polycrystal, the synthesis device comprises a vapor phase transmission quartz tube (1), a boron nitride boat (2) and a quartz small tube (3); the vapor phase transmission quartz tube (1) is a quartz tube closed at one end, the middle tube wall of the quartz tube is concaved toward the inside of the tube to form an annular groove (4), and the annular groove divides the vapor phase transmission quartz tube into two parts, a transition zone and a high temperature zone are in turn arranged in the part from the annular groove is to the closed end, and a low temperature zone is arranged in the part from the annular groove to the open end; the boron nitride boat is used for holding high purity elemental barium and gallium, and is placed in the high temperature zone of the vapor phase transmission quartz tube (1), the quartz small tube is used for holding elemental selenium and is placed in the low temperature zoneof the vapor phase transmission quartz tube (1), the quartz tube is closed at one end, and the closed end is provided with a small hole (5). The BaGa4Se7 polycrystal is synthesized by gas phase transmission reaction of selenium vapor, the yield is more than 99%, and 200g of a high-purity polycrystalline raw material can be synthesized in a single time.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

An alloy quantum dot core with uniform internal and external components and its preparation method

ActiveCN106590633BUniform composition inside and outsideUniform reaction rateCadmium sulfidesNanoopticsChemical physicsReaction rate

The invention discloses an alloy quantum dot core with uniform internal and external components and a preparation method thereof, wherein the method comprises: stirring and mixing the pre-prepared at least two cation precursor solutions and heating them to a predetermined temperature, injecting the prepared At least one anion precursor solution of the nucleation reaction is carried out by continuing to inject the cation precursor solution or the anion precursor solution or simultaneously injecting the cation precursor solution and the anion precursor solution at a gradually changing speed during the nucleation reaction, so that the nucleation reaction During the process, the reaction rate of each component remains relatively stable and the stoichiometric ratio of nucleation is relatively consistent, thereby preparing an alloy quantum dot nucleus with uniform internal and external components. The method of the invention effectively solves the problems of inhomogeneity of the inner and outer components of the alloy quantum dot core, low luminous efficiency, unstable wavelength and fluorescence intensity, and the method provided by the invention has the advantages of simple operation, easy regulation, and high repeatability.

Owner:TCL CORPORATION

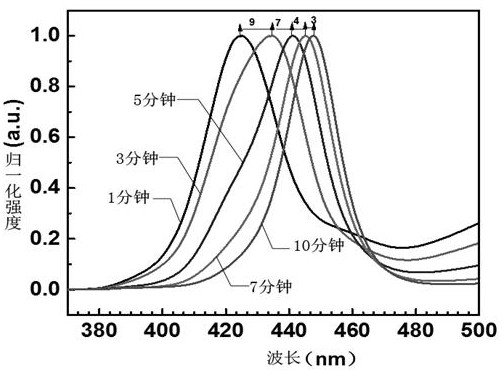

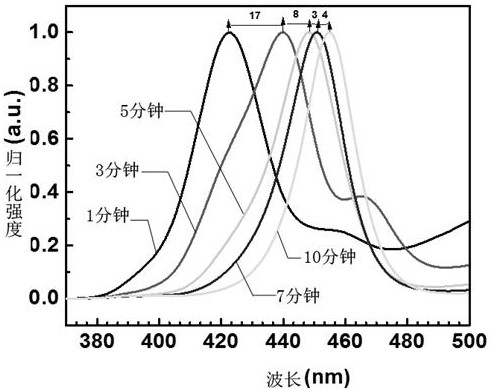

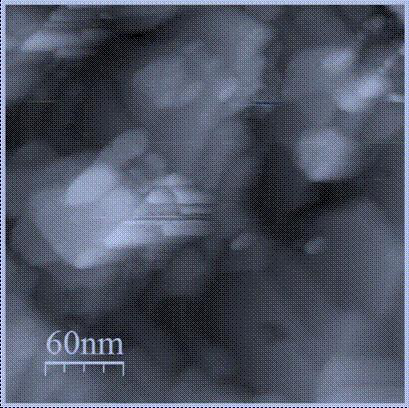

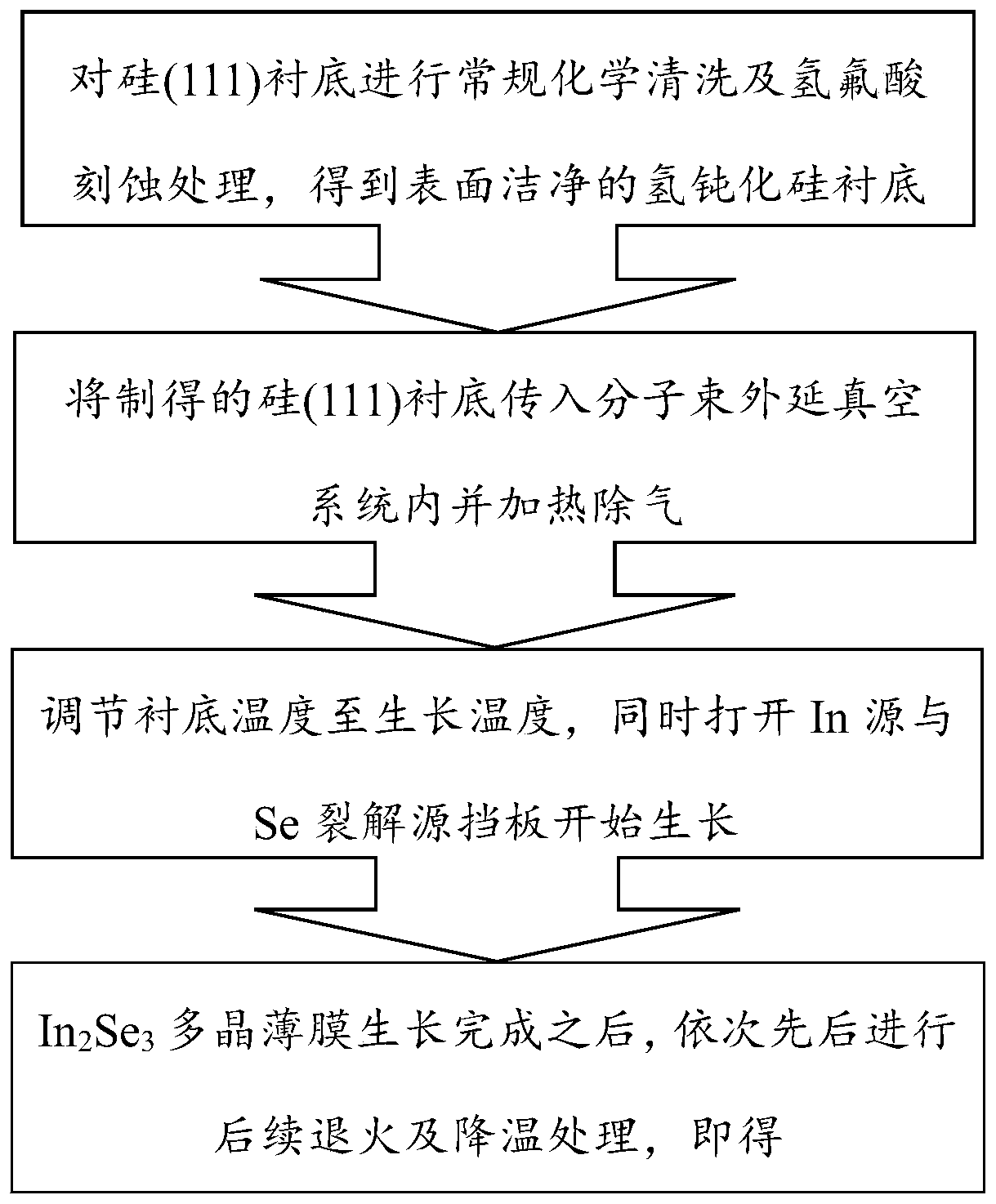

Method for preparing large-area beta-phase indium selenide single crystal film

ActiveCN111211041AReduce mismatchPromote growthFinal product manufactureSemiconductor/solid-state device manufacturingIndiumBeam source

The invention relates to a method for preparing a large-area beta-phase In2Se3 single crystal film. The method comprises the following steps that: 1) chemical cleaning and chemical corrosion treatmentare carried out on a silicon substrate with crystal orientation of (111), so that a hydrogen-passivated silicon substrate with a clean surface can be obtained; 2) the prepared silicon substrate is transferred into a molecular beam epitaxy system, heating is performed to 180 DEG C, and degassing is performed until the vacuum degree of the system is superior to 8*10 <-10 > mbar; (3) the substrate naturally cools to a growth temperature range after the substrate is degassed, and meanwhile, an In beam source and a Se beam source are opened to grow and synthesize an In2Se3 polycrystalline film; (4) the temperature of the substrate is immediately raised to 300-350 DEG C after the growth of the polycrystalline film is finished, and subsequent annealing is carried out for 5 minutes; and 5) heating is immediately stopped after annealing is finished, and the substrate naturally cools to room temperature, so that a high-quality beta-phase In2Se3 single crystal film can be obtained. According tothe method for growing the beta-phase In2Se3 thin film, the molecular beam epitaxy technology is combined with the subsequent in-situ annealing process, and the large-area high-quality beta-phase In2Se3 single crystal thin film can be prepared on the hydrogen-passivated silicon substrate at a low temperature.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

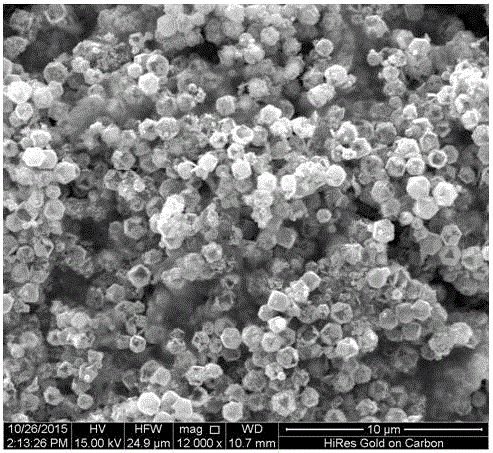

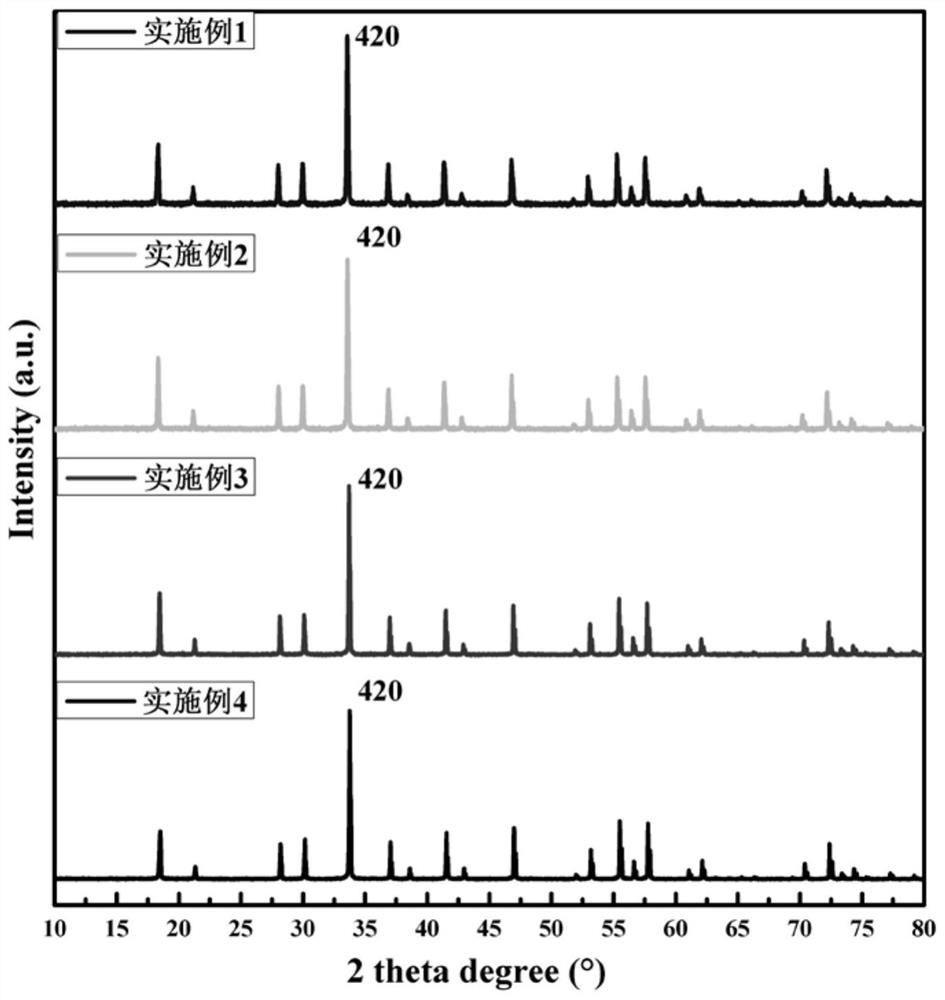

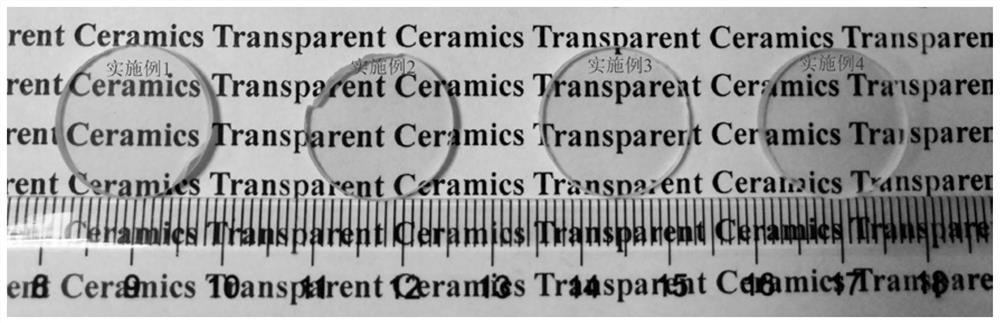

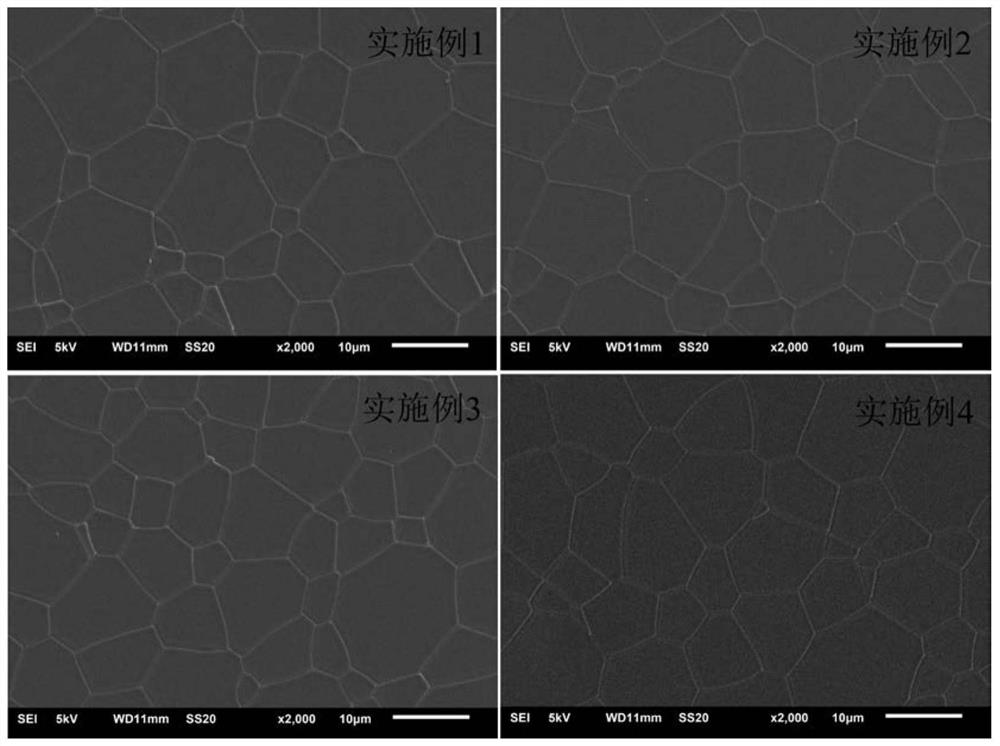

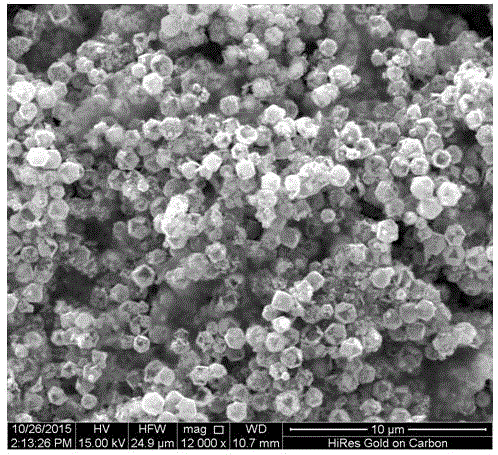

A method for preparing YAG transparent ceramics by adopting core-shell structure powder

The invention discloses a method for preparing YAG transparent ceramics by adopting a core-shell structure powder. The specific steps are: Y(NO 3 ) 3 solution added to Al 2 O 3 In the suspension, the precipitating agent is urea, the amount of ions added meets the stoichiometric ratio of Y:Al=3:5, the reaction temperature is 50-80°C; the pH of the slurry is adjusted by urea to 8.8-9.1, and the solid content is 35-60vol. %; the slurry is directly filtered without washing to obtain a core-shell structure powder; the powder is dried at a constant temperature, and the dried powder is calcined; the calcined powder is ball-milled, dried, and sieved; first dry pressed and then cooled Isostatic pressing, then calcining the green body in a muffle furnace; vacuum sintering the ceramic green body; annealing, grinding and polishing, to obtain YAG transparent ceramics. The present invention adopts precipitation method + non-washing method to prepare core-shell structure precursor powder, no waste ions in the product, high powder yield, high purity, and small particle size; the preparation process is simple and easy to operate, the sintering temperature is low, and the cost is low.

Owner:XUZHOU NORMAL UNIVERSITY

Method for preparing hollow PtPd nano material with cuprous oxide as template

ActiveCN105537617APrecise control of ingredientsExact copy of topographyTransportation and packagingMetal-working apparatusAqueous solutionAtomic ratio

The invention discloses a method for preparing a hollow PtPdnano material with cuprous oxide as a template. The method comprises the following steps that (1) the cuprous oxide is uniformly dispersed into water, an aqueous solution containing PtCl<6><2-> and PdCl<4><2-> is added under the stirring condition at the temperature of 20-25 DEG C, and a stirring reaction is conducted for 30-60 minutes at the temperature; (2) the reaction system in the step (1) is moved into a heating device and heated to the temperature of 60-65 DEG C at the heating speed of 1-3 DEG C / min, and the reaction continues to be conducted for 90-120 minutes at the temperature; and (3) after the reaction is finished, cuprous oxide cores are removed, and the hollow PtPd nano material is obtained. According to the hollow PtPd nano material obtained through the method, the shape of the cuprous oxide template is accurately duplicated, the atomic ratio Pt / Pd of the nano PtPd nano material is made to be close to the atomic ratio Pt / Pd of the reaction solution, the requirement for the stoichiometric ratio of reactants is met, and accurate component controlling is achieved.

Owner:CHONGQING UNIV OF ARTS & SCI

A kind of preparation method of hollow ptpd nanometer material

InactiveCN105537616BStoichiometric ratioExact copy of topographyTransportation and packagingMetal-working apparatusAlcoholCopper oxide

Owner:重庆稳稳科技有限公司

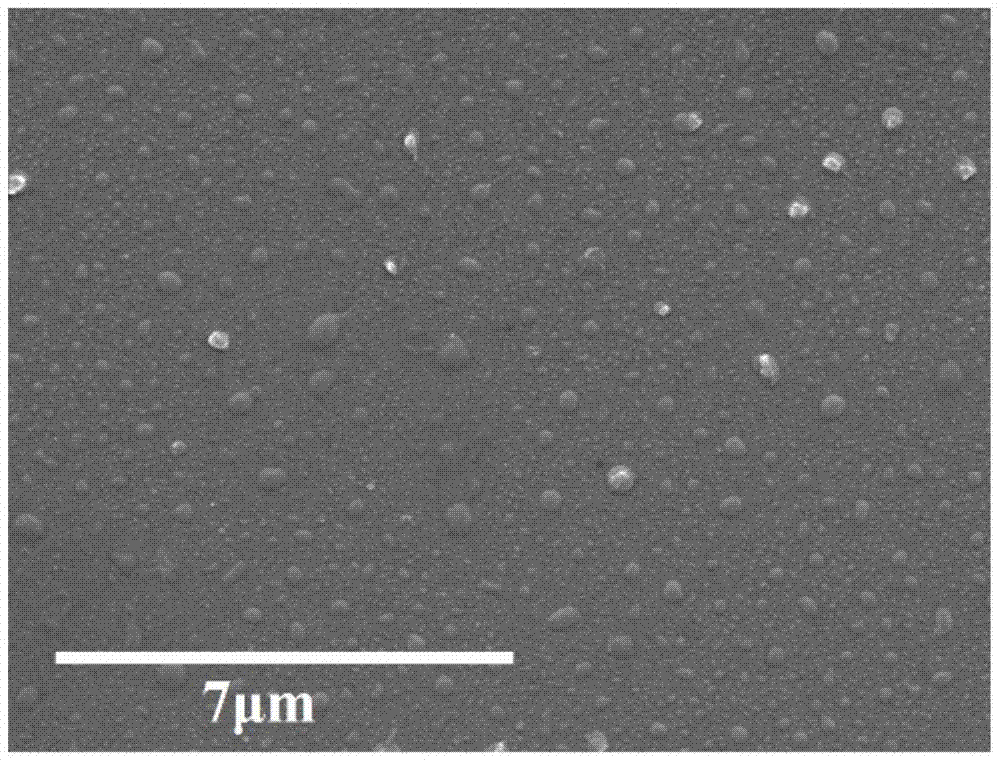

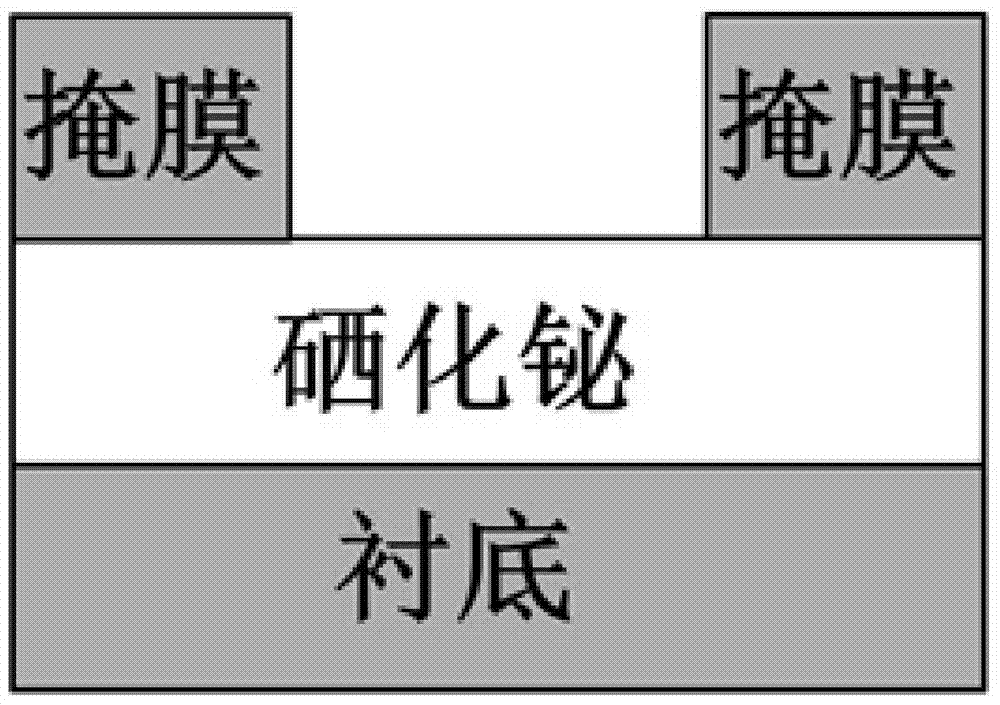

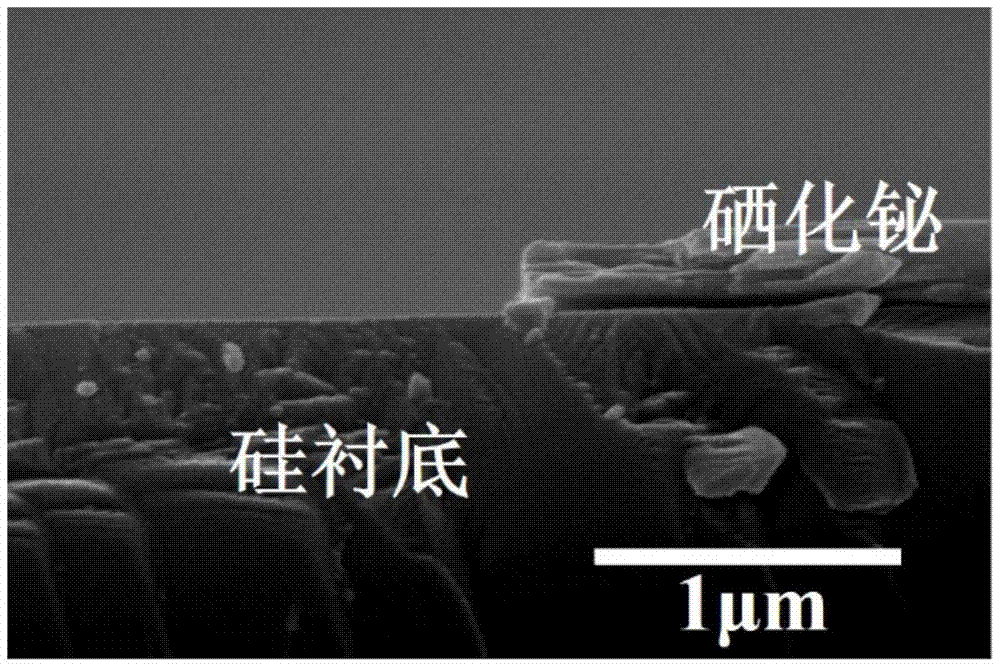

A kind of chemical etching method of bismuth selenide material

ActiveCN105543980BSimple processEasy to operatePolycrystalline material growthAfter-treatment detailsPotassiumChemical measurement

The present invention relates to a chemical etching method for bismuth selenide material, which comprises the following steps: (1) making a mask: the mask is a photolithography mask, which is made by standard photolithography technology and attached to a silicon substrate (2) preparation of etchant: the etchant is a potassium dichromate complex acid solution, and its preparation method is that the following components are mixed according to a certain proportion, and the volume percentage Be 9% potassium dichromate saturated aqueous solution, the concentrated hydrochloric acid that volume percentage is 48%, the concentrated sulfuric acid that volume percentage is 98%; (3) etching: utilize the potassium dichromate compound acid solution that step (3) makes The etchant is used to etch the bismuth selenide material attached to the photolithography mask prepared in the attaching step (1). The invention has the advantages of simple process, convenient operation, low cost and remarkable effect. The surface of the etched bismuth selenide material is smooth, conforms to the stoichiometric ratio, and the etching rate is easy to control.

Owner:UNIV OF ELECTRONICS SCI & TECH OF CHINA

Prep.of strontium titanate barium ceramic target

InactiveCN1250482CWith superfineHigh superfineVacuum evaporation coatingSputtering coatingStrontium titanateRadio frequency magnetron sputtering

The present invention belongs to the field of material preparation technology. The preparation of strontium barium carbonate ceramic target includes the steps of: making the water solution of titanium tetrachloride, water solution of strontium chloride, water solution of barium chloride and water solution of oxalic acid react in controlled pH value to obtain strontium barium titanium oxalate precipitate; washing, filtering, stoving and thermally decomposing the precipitate to obtain composite strontium barium carbonate powder; pretreating, ball milling and presintering the powder; re-milling, pressing in hydraulic press and isostatic forming; and final sintering in Siliconit furnace to obtain strontium barium carbonate ceramic target. The prepared powder has high purity, fine size, high homogeneity and high activity and can meet the requirement for RF magnetically controlled sputtering and the target of the present invention has excellent application foreground.

Owner:SHANGHAI JIAO TONG UNIV

A kind of synthetic method of selenium germanium gallium barium polycrystal and the growth method of selenium germanium gallium barium single crystal

ActiveCN110144624BAvoid corrosionAvoid explosionPolycrystalline material growthFrom frozen solutionsFrequency conversionPhysical chemistry

The invention discloses a synthesis method for a selenium germanium gallium barium polycrystal and a growth method for a selenium germanium gallium barium monocrystal. The growth of the polycrystal comprises the following steps: putting elemental Ga, elemental Ba and elemental Ge into a PBN boat; then placing the PBN boat at one end of a quartz tube and placing elemental Se at the other end of thequartz tube; conducting vacuumizing, and then carrying out heat sealing; and then putting the quartz tube into a horizontal double-temperature-region resistor furnace for synthesizing, so as to obtain a high-purity single-phase selenium germanium gallium barium polycrystal raw material, wherein the yield of the raw material is greater than 99%. The growth of the selenium germanium gallium bariummonocrystal comprises the following steps: adding the selenium germanium gallium barium polycrystal into a crystal growth crucible and vertically placing the crystal growth crucible into a quartz tube; conducting vacuumizing, and then carrying out heat sealing; and then putting the quartz tube into a vertical double-temperature-region resistor furnace, so as to obtain the selenium germanium gallium barium monocrystal after the growth of the monocrystal is finished. The selenium germanium gallium barium monocrystal obtained by the method disclosed by the invention has the advantages of few defects, high infrared band transmission rate and the like and can be used as a far infrared laser frequency conversion material.

Owner:TECHNICAL INST OF PHYSICS & CHEMISTRY - CHINESE ACAD OF SCI

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com