Method for preparing high-quality copper indium sulfide by employing single-source molecular precursor

An indium copper sulfide and precursor technology, applied in chemical instruments and methods, inorganic chemistry, gallium/indium/thallium compounds, etc., can solve the problems of uneven composition inside and outside, difficult to meet the requirements of high-purity raw materials for photovoltaic devices, etc. The production equipment and process are simple, the raw materials are cheap, and the reaction temperature and energy consumption are low.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

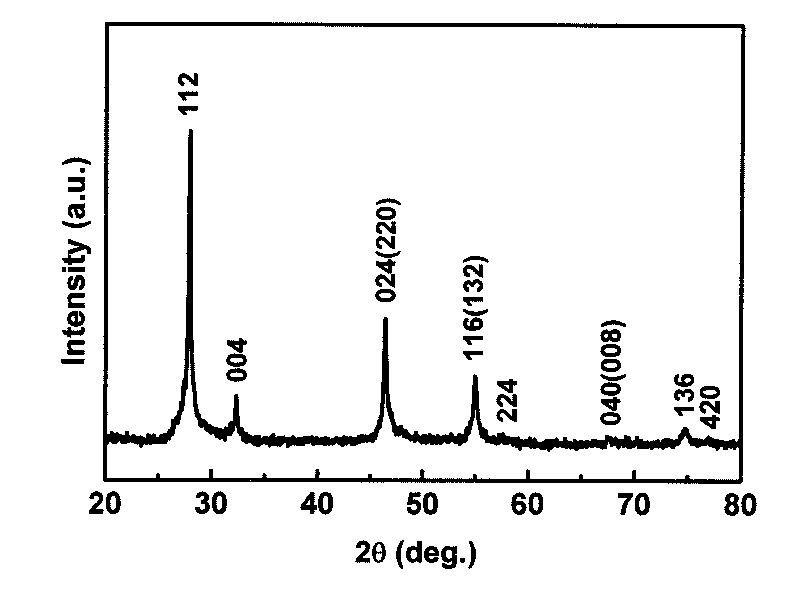

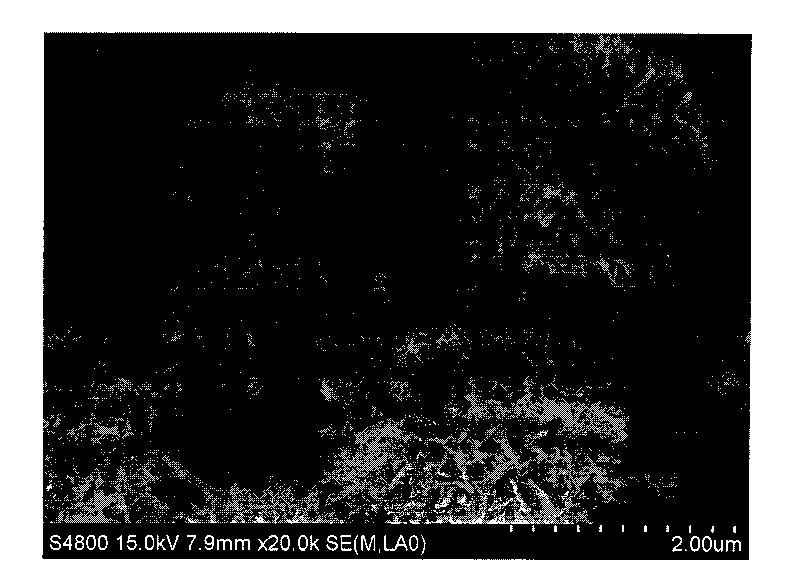

[0025] 1. Weigh 4mmol of copper chloride and indium chloride powder respectively, mix the two solid powders, add water to dissolve, and make a 200mL solution; 2. Weigh 20mmol of sodium diethyldithiocarbamate (abbreviation: Na-DDTC ) powder, dissolved in water, and made into 200mL solution; 3. Slowly add the mixed solution of copper chloride and indium chloride prepared in step (1) to the Na-DDTC solution prepared in step (2) under stirring, and keep at room temperature Stir for 5 hours, then filter the resulting precipitate, and dry it in an oven at 60°C for 12 hours to obtain the precursor CuIn-(DDTC) 5 ; 4. Take 0.5g precursor CuIn-(DDTC) 5 Put it into a polytetrafluoroethylene-lined autoclave with a capacity of 40mL, add 32mL of ethanol as a solvent, seal the autoclave and place it in an electric oven, heat it at 180°C for 12 hours, then stop heating and let it cool naturally After reaching room temperature, the resulting precipitate was suction-filtered, washed several ti...

Embodiment 2

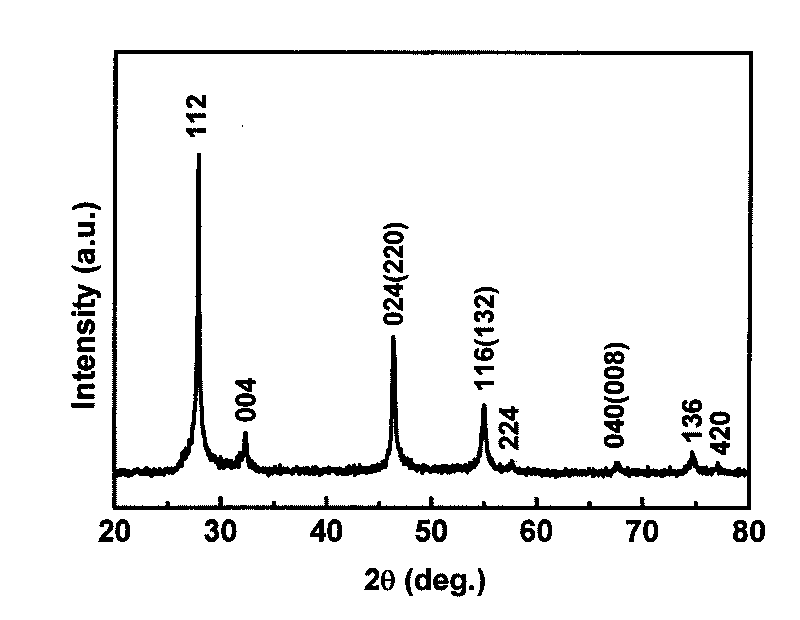

[0032] 1. Weigh 4mmol of copper chloride and indium chloride powder respectively, mix the two solid powders, add water to dissolve, and make a 200mL solution; 2. Weigh 20mmol of sodium diethyldithiocarbamate (abbreviation: Na-DDTC ) powder, dissolved in water, and made into 200mL solution; 3. Slowly add the mixed solution of copper chloride and indium chloride prepared in step (1) to the Na-DDTC solution prepared in step (2) under stirring, and keep at room temperature Stir for 5 hours, then filter the resulting precipitate, and dry it in an oven at 60°C for 12 hours to obtain the precursor CuIn-(DDTC) 5 ; 4. Take 0.5g precursor CuIn-(DDTC) 5Put it into a polytetrafluoroethylene-lined autoclave with a capacity of 40mL, add 32mL of ethanol as a solvent, seal the autoclave and place it in an electric oven, heat at 180°C for 36 hours, then stop heating and let it cool naturally After reaching room temperature, the resulting precipitate was suction-filtered, washed several times ...

Embodiment 3

[0039] 1. Weigh 4mmol of copper chloride and indium chloride powder respectively, mix the two solid powders, add water to dissolve, and make a 200mL solution; 2. Weigh 20mmol of sodium diethyldithiocarbamate (abbreviation: Na-DDTC ) powder, dissolved in water, and made into 200mL solution; 3. Slowly add the mixed solution of copper chloride and indium chloride prepared in step (1) to the Na-DDTC solution prepared in step (2) under stirring, and keep at room temperature Stir for 5 hours, then filter the resulting precipitate, and dry it in an oven at 60°C for 12 hours to obtain the precursor CuIn-(DDTC) 5 ; 4. Take 0.5g precursor CuIn-(DDTC) 5 Put it into a polytetrafluoroethylene-lined autoclave with a capacity of 40mL, add 32mL of ethanol as a solvent, seal the autoclave and place it in an electric oven, heat at 190°C for 36 hours, then stop heating and let it cool naturally After reaching room temperature, the resulting precipitate was suction-filtered, washed several times...

PUM

| Property | Measurement | Unit |

|---|---|---|

| diameter | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com