A kind of ultrafine titanate nanopowder and preparation method thereof

A nano-powder, titanate technology, applied in nanotechnology, nanotechnology, chemical instruments and methods, etc., can solve problems such as growth and particle agglomeration, and achieve uniform particle size distribution, good dispersion, and strong operability. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0041] Embodiment 1, preparation average particle diameter is the barium titanate nanopowder of 2.8nm

[0042] Accurately weigh barium hydroxide octahydrate (Ba(OH) 2 ·8H 2O) 7.8868g (the molar ratio to tetrabutyl titanate is 1:1), polyethylene glycol (weight average molecular weight 3000) 0.58g (10% of the mass of theoretically synthesized barium titanate), tetrabutyl titanate Esters 8.54g (the molar concentration in diethylene glycol is 0.625mol / L), measure 40ml of diethylene glycol and place them in a three-necked bottle, add a reflux device, react at 160°C for 2 hours and then naturally Cool to room temperature. Add 10 times the volume of deionized water to the cooled sol, and centrifuge to obtain barium titanate precipitate. Then, the precipitated part of barium titanate was washed and centrifuged three times with absolute ethanol, and dried in an oven at 60°C to obtain completely crystallized nano barium titanate powder.

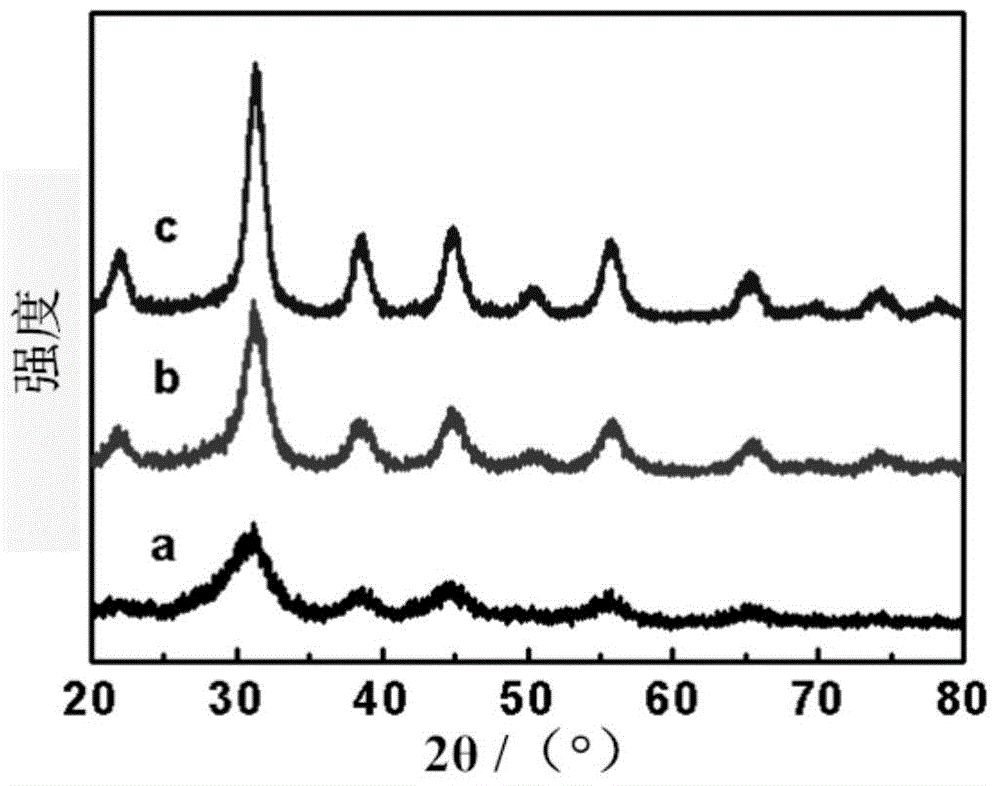

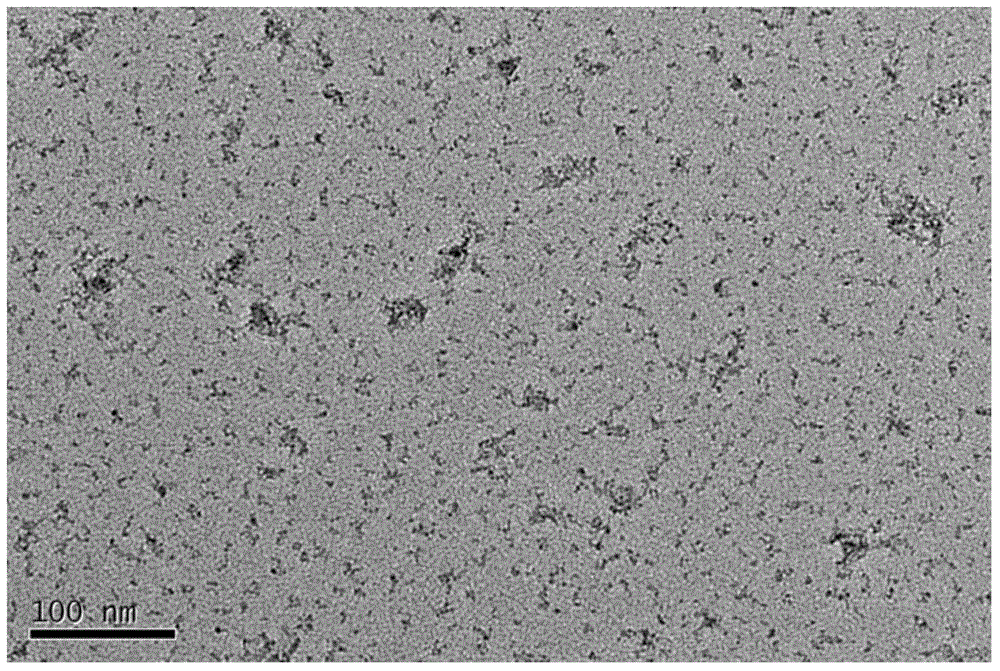

[0043] The XRD spectrum of the barium titana...

Embodiment 2

[0045] Embodiment 2, preparation 5nm barium titanate nanopowder

[0046] Accurately weigh barium hydroxide octahydrate (Ba(OH) 2 ·8H 2 O) 15.1428g (the molar ratio to tetrabutyl titanate is 1.2:1), polyacrylamide (weight average molecular weight 20000) 0.925g (10% of the mass of theoretically synthesized barium titanate), tetrabutyl titanate 13.675g (the molar concentration in triethylene glycol is 1.0mol / L), measure 40ml of triethylene glycol and place it in a three-necked bottle, add a reflux device, react at 190°C for 10 minutes, and then cool naturally to room temperature. Add deionized water 5 times the volume of the sol to the cooled sol, and centrifuge to obtain barium titanate precipitate. Then, the precipitated part was washed with absolute ethanol for 3 times, centrifuged and separated, and dried in an oven at 60°C to obtain completely crystallized nano barium titanate powder.

[0047] The XRD spectrum of the barium titanate nanopowder prepared in this embodiment...

Embodiment 3

[0049] Embodiment 3, preparation 6nm barium titanate nanopowder

[0050] The preparation method is the same as that of Example 2, except that the reaction solvent triethylene glycol is replaced by tetraethylene glycol.

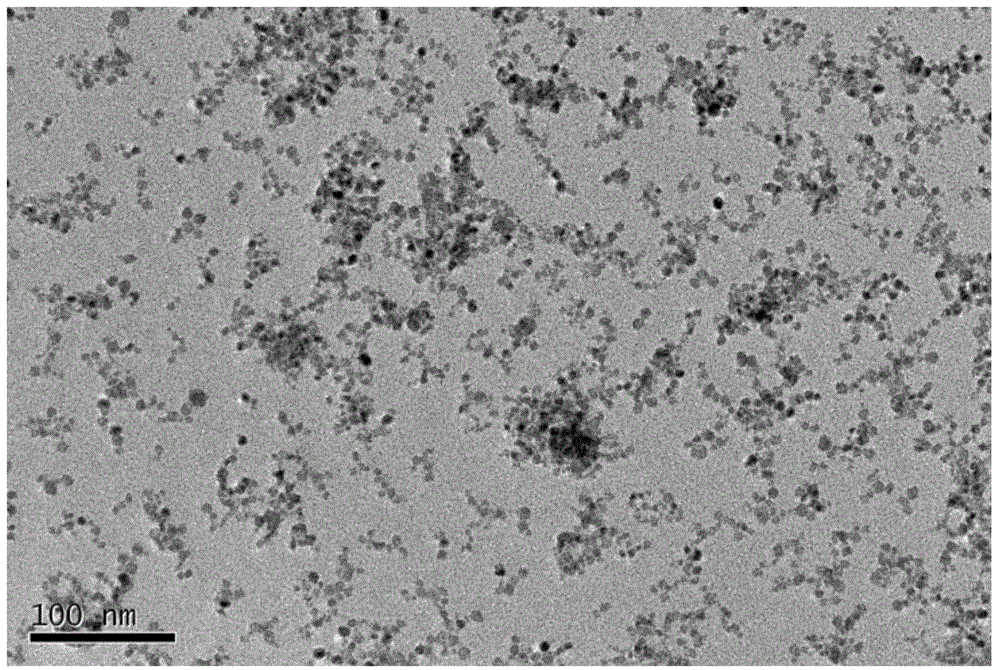

[0051] The XRD spectrum of the barium titanate nanopowder prepared in this embodiment is shown in figure 1 (c), its transmission electron microscope (TEM) picture is as Figure 4 As shown, it can be seen that the average particle diameter of the barium titanate particles prepared in this example is 6 nm, and the size uniformity and dispersion are good.

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

| particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com