Method for preparing CIGS thin-film solar cell absorption layer employing co-sputtering method

A solar cell and co-sputtering technology, applied in circuits, photovoltaic power generation, electrical components, etc., can solve the problems of CIGS absorption layer stoichiometric ratio deviation, low indium sputtering efficiency and other problems, and is conducive to large-scale industrial production. , the effect of surface uniformity, enhancement of completeness and crystallinity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

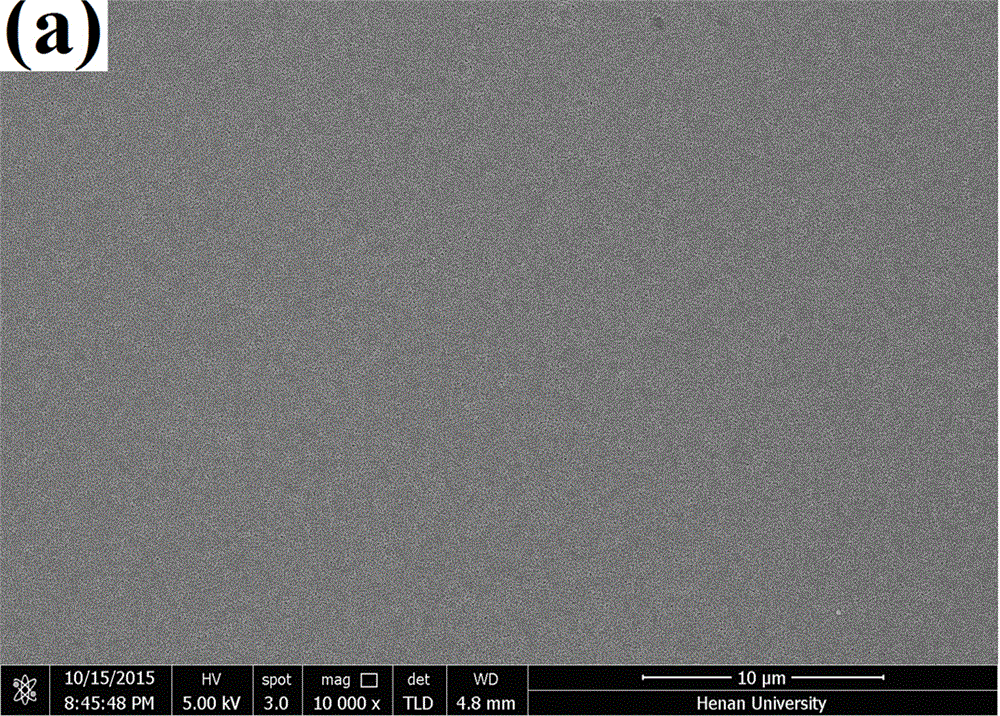

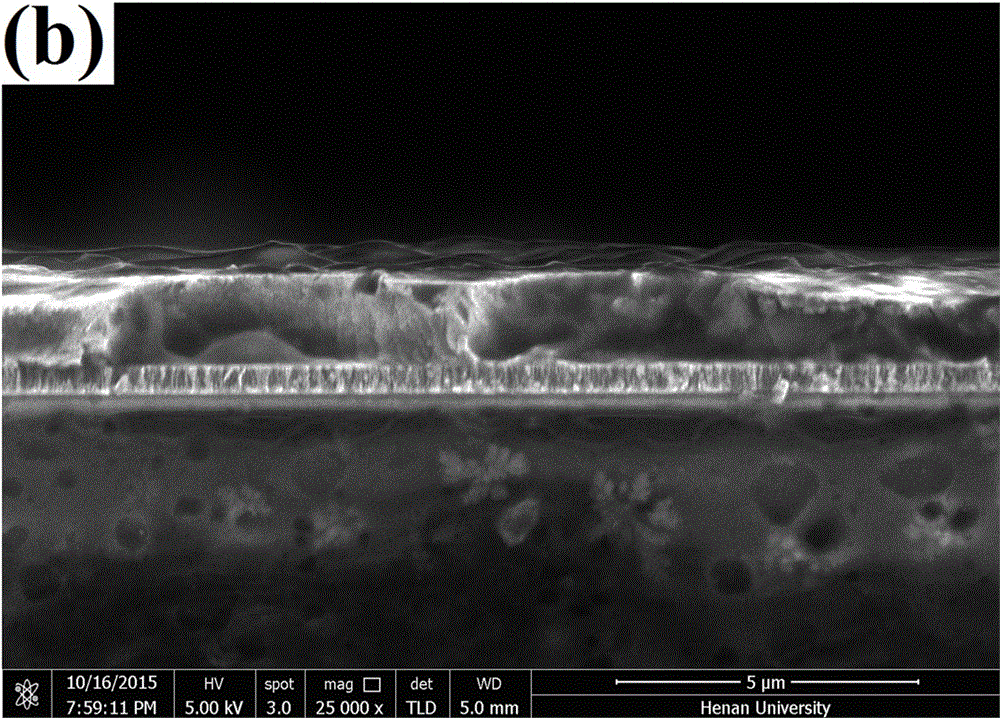

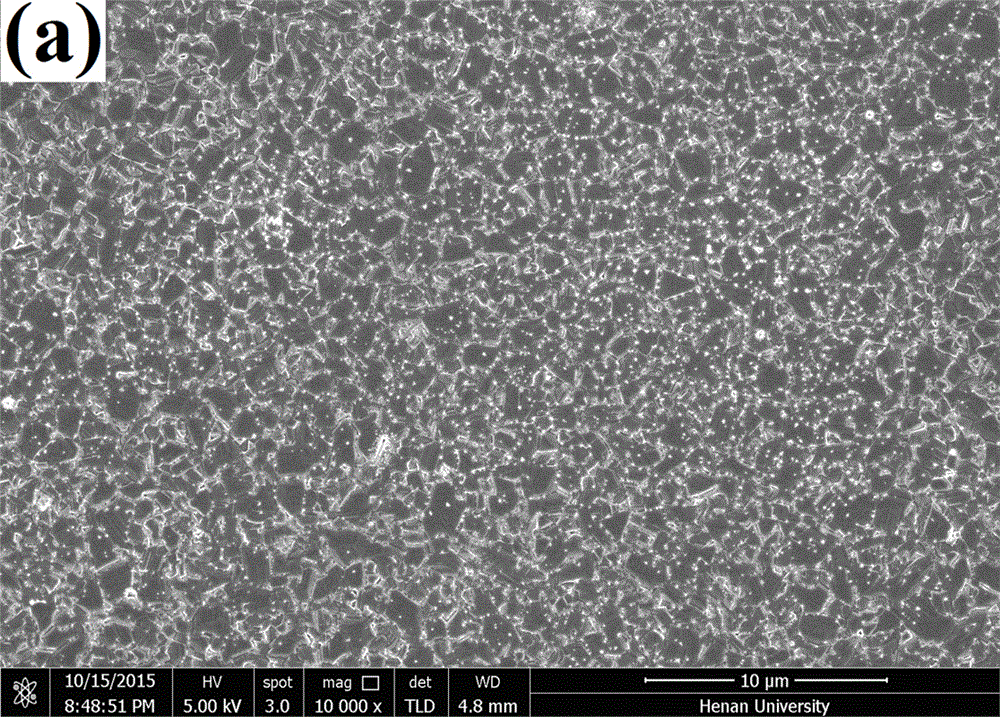

[0016] A kind of co-sputtering method prepares the method for absorbing layer of CIGS thin-film solar cell, comprises the following steps: 1. provides the soda lime glass substrate of molybdenum plating, adopts copper indium gallium selenide target to carry out radio frequency sputtering, adopts indium target to carry out DC sputtering at the same time, The copper indium gallium selenide prefabricated layer was prepared by co-sputtering; the process conditions of co-sputtering are: the vacuum degree of the bulk reaches 8×10 -4 Below Pa, during the sputtering process, the target distance is maintained at 8 cm, the argon gas flow rate is 20 sccm, the substrate rotation speed is 20 r / min, the working pressure is 0.5 Pa, and the co-sputtering time is 120 min. The copper indium gallium selenide target The RF sputtering power of the indium target is 110 W, and the power of the indium target DC sputtering is 70 W; ②Put the prefabricated copper indium gallium selenium layer into a rapi...

Embodiment 2

[0021] A kind of co-sputtering method prepares the method for absorbing layer of CIGS thin-film solar cell, comprises the following steps: 1. provides the soda lime glass substrate of molybdenum plating, adopts copper indium gallium selenide target to carry out radio frequency sputtering, adopts indium target to carry out DC sputtering at the same time, The copper indium gallium selenide prefabricated layer was prepared by co-sputtering; the process conditions of co-sputtering are: the vacuum degree of the bulk reaches 7×10 -4 Below Pa, during the sputtering process, the target distance is maintained at 8 cm, the argon gas flow rate is 20 sccm, the substrate rotation speed is 20 r / min, the working pressure is 0.5 Pa, and the co-sputtering time is 120 min. The copper indium gallium selenide target The RF sputtering power of the indium target is 110 W, and the power of the indium target DC sputtering is 70 W; ② Put the prefabricated layer of copper indium gallium selenium into a ...

Embodiment 3

[0024] A kind of co-sputtering method prepares the method for absorbing layer of CIGS thin-film solar cell, comprises the following steps: 1. provides the soda lime glass substrate of molybdenum plating, adopts copper indium gallium selenide target to carry out radio frequency sputtering, adopts indium target to carry out DC sputtering at the same time, The copper indium gallium selenide prefabricated layer was prepared by co-sputtering; the process conditions of co-sputtering are: the vacuum degree of the bulk reaches 8×10 -4 Below Pa, during the sputtering process, the target distance is maintained at 8 cm, the argon gas flow rate is 20 sccm, the substrate rotation speed is 20 r / min, the working pressure is 0.5 Pa, and the co-sputtering time is 120 min. The copper indium gallium selenide target The RF sputtering power of the indium target is 110 W, and the power of the indium target DC sputtering is 70 W; ②Put the prefabricated copper indium gallium selenium layer into a rapi...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com