a bi 9 ti 3 fe 5 o 27 Layered multiferroic epitaxial thin film and preparation method thereof

An epitaxial thin film, layered technology, applied in coating, metal material coating process, vacuum evaporation coating and other directions, can solve the problems of complex chemical composition of multiferroic thin films, easy generation of impurity phases in the preparation process, complex chemical composition, etc. Achieve the effect of high repeatability, high phase purity and high crystal quality

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

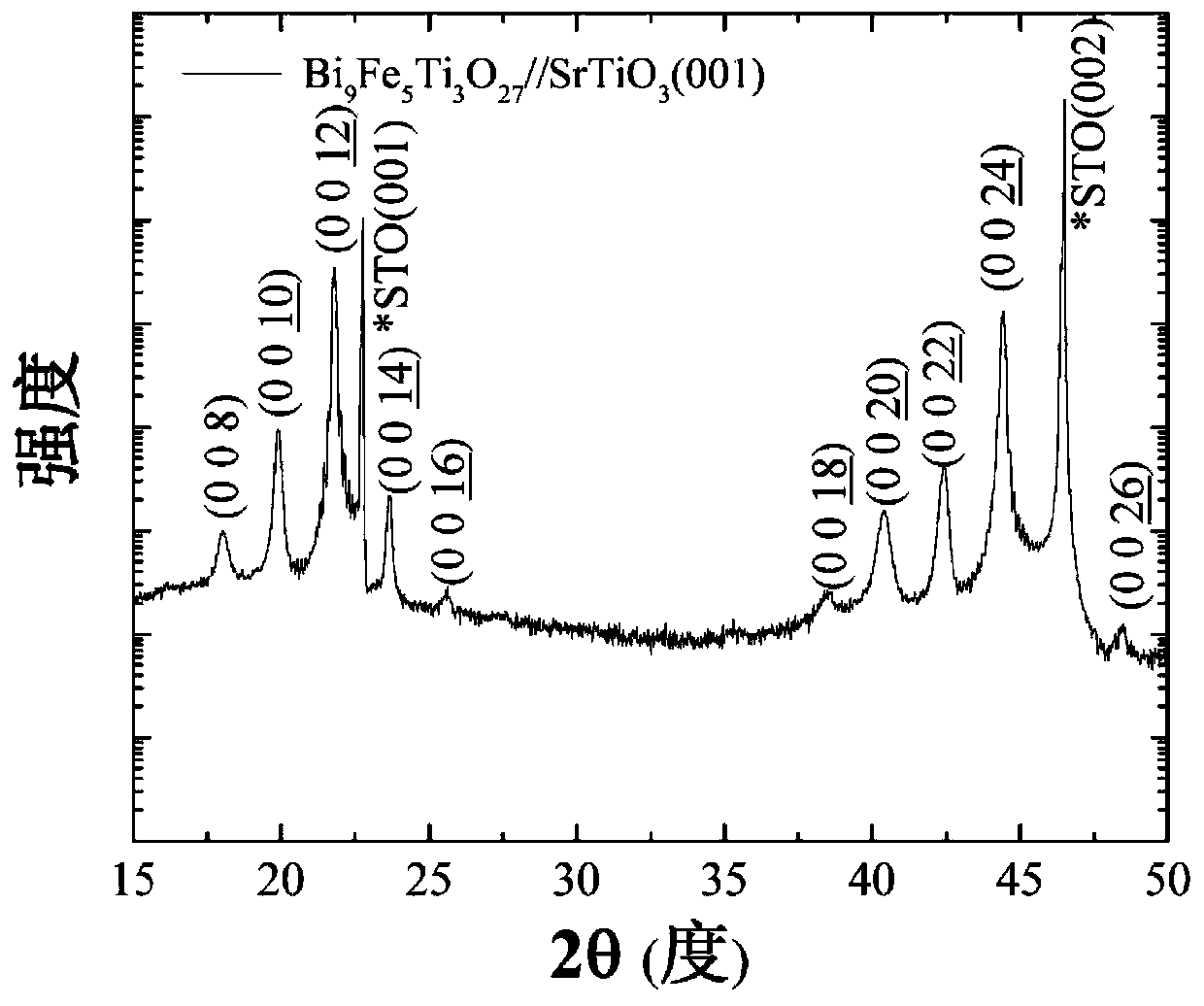

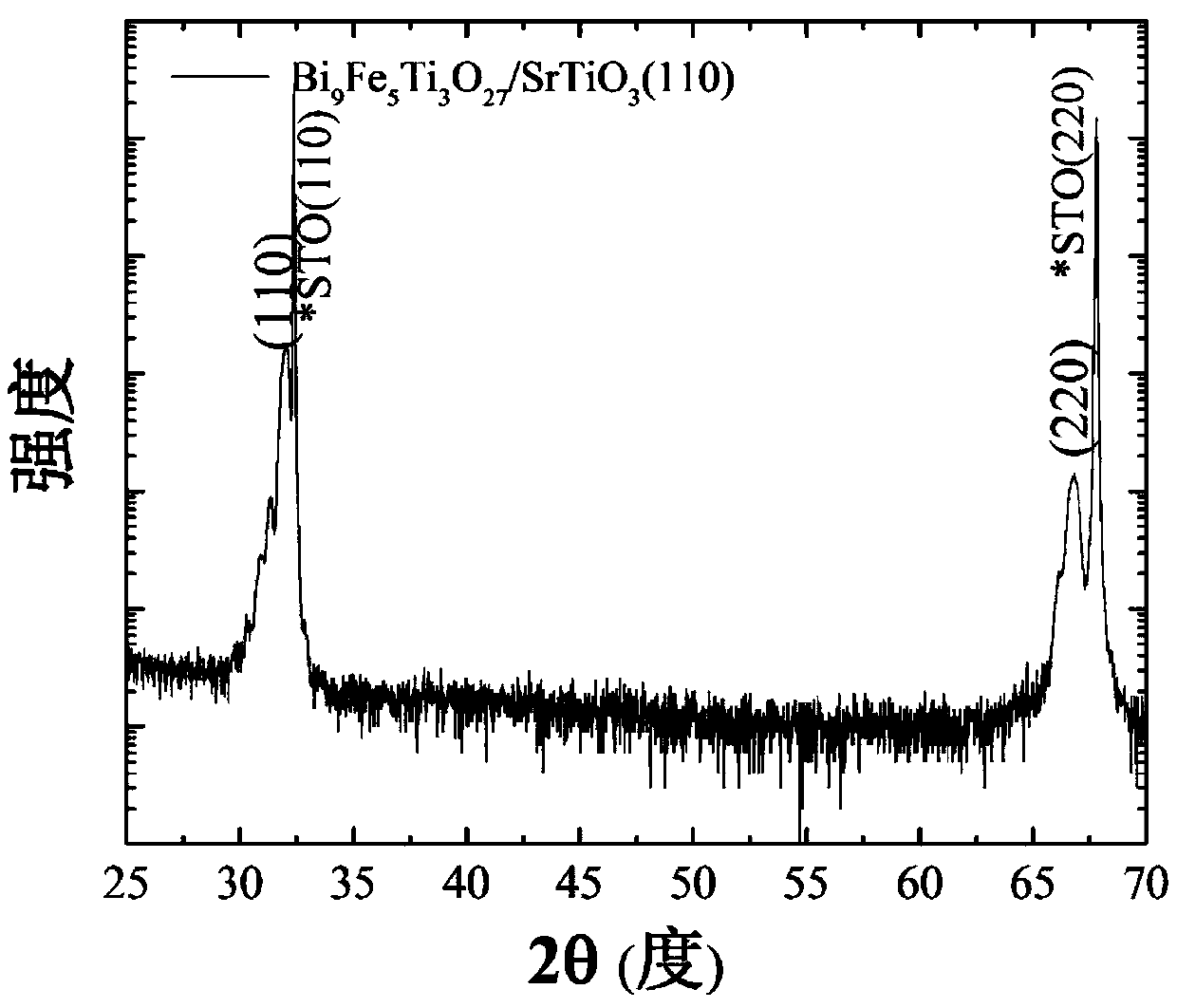

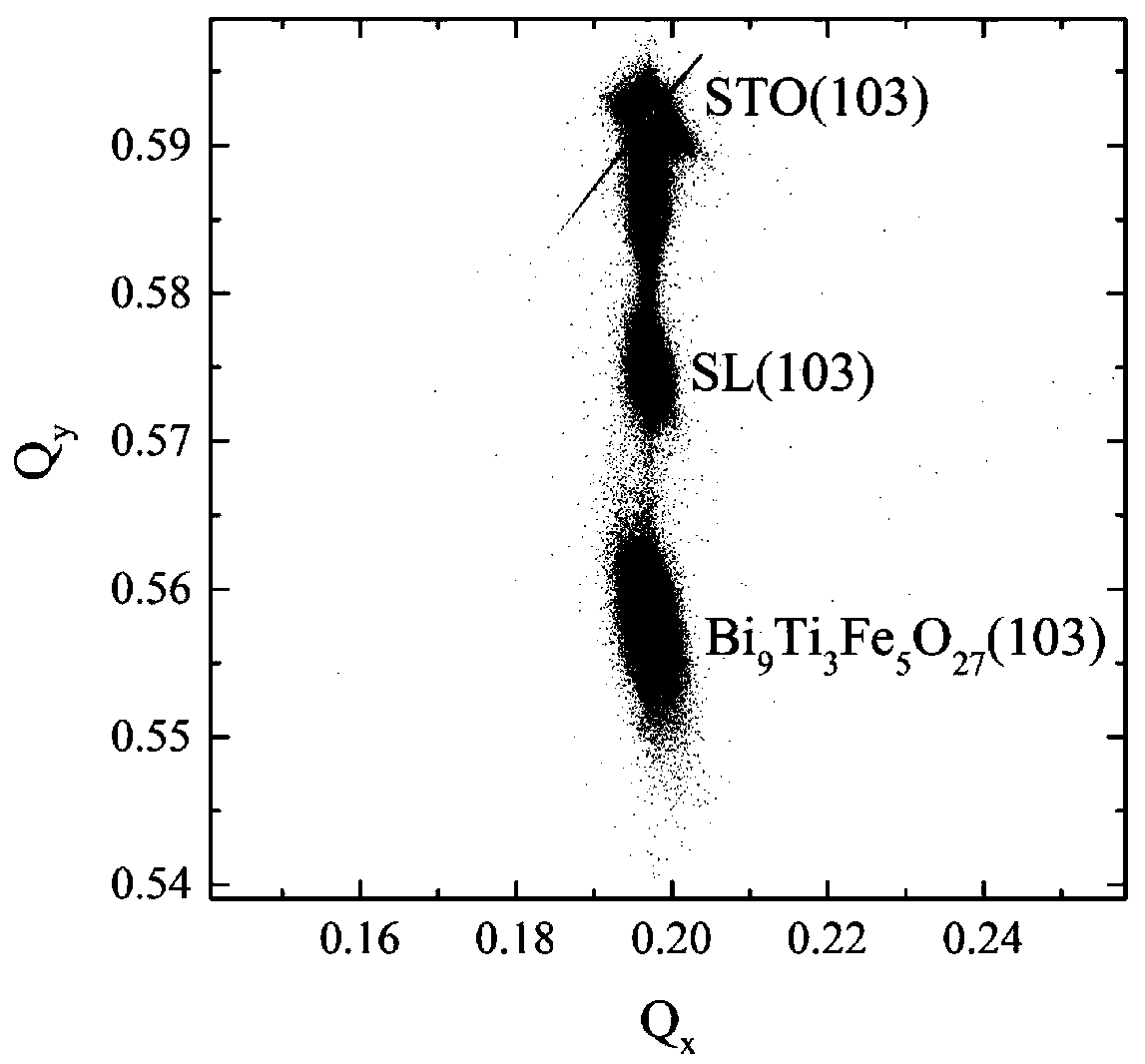

[0035] The present invention relates to a Bi 9 Ti 3 Fe 5 o 27 Multiferroic epitaxial thin film and its preparation method. The method is to combine the five-layer octahedral group BiFeO 3 Insertion into a three-layer layered perovskite ferroelectric Bi 4 Ti 3 o 12 Formation of a novel eight-layer layered perovskite Bi 9 Ti 3 Fe 5 o 27 Multiferroic films. The present invention adopts Bi for the first time 9 Ti 3 Fe 5 o 27 The ceramic target is coated on a single crystal substrate by pulsed laser deposition. 2 In-situ annealing treatment in the atmosphere, and finally obtained Bi with excellent quality 9 Ti 3 Fe 5 o 27 Layered multiferroic epitaxial thin films. The method requires simple equipment and is compatible with microelectronic technology. Prepared Bi 9 Ti 3 Fe 5 o 27 The layered multiferroic thin film has high phase purity, good ferroelectric properties and considerable ferromagnetism. It is an excellent room temperature multiferroic thin film m...

Embodiment 1

[0061] (a) Bi 9 Ti 3 Fe 5 o 27 Target compression: to analyze pure bismuth oxide (Bi 2 o 3 ), titanium dioxide (TiO 2 ), iron oxide (Fe 2 o 3 ) as the main raw material; according to Bi 9 Ti 3 Fe 5 o 27 Weigh various raw materials that meet the stoichiometric ratio for configuration; in order to compensate for the volatilization of Bi element during the high-temperature preparation process, when weighing Bi 2 o 3 Excessive 8mol%; mix the powder raw materials, put them into an automatic mortar for full mixing and grind for more than 24 hours; put the mixed powder into a mold for pre-compression molding, the shape is cylindrical, the diameter is 2cm, and the thickness is 0.5cm; Cold isostatic pressing into Bi 9 Ti 3 Fe 5 o 27 Target material, load pressure 260MPa, pressure holding time 15min.

[0062] (b) Preparation and cleaning of the substrate: using (001) oriented strontium titanate (SrTiO 3 ) single crystal substrate as the growth substrate, and ultrasonic...

Embodiment 2

[0067] (a) Bi 9 Ti 3 Fe 5 o 27 Target compression: to analyze pure bismuth oxide (Bi 2 o 3 ), titanium dioxide (TiO 2 ), iron oxide (Fe 2 o 3 ) as the main raw material; according to Bi 9 Ti 3 Fe 5 o 27 Weigh various raw materials that meet the stoichiometric ratio for configuration; in order to compensate for the volatilization of Bi element during the high-temperature preparation process, when weighing Bi 2 o 3 Excessive 8mol%; mix the powder raw materials, put them into an automatic mortar for full mixing and grind for more than 24 hours; put the mixed powder into a mold for pre-compression molding, the shape is cylindrical, the diameter is 2cm, and the thickness is 0.5cm; Cold isostatic pressing into Bi 9 Ti 3 Fe 5 o 27 Target material, load pressure 260MPa, pressure holding time 15min.

[0068] (b) Preparation and cleaning of the substrate: using (001) oriented strontium titanate (SrTiO 3 ) single crystal substrate as the growth substrate, and ultrasonic...

PUM

| Property | Measurement | Unit |

|---|---|---|

| remanent polarization | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| ferromagnetism | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com