Zinc gallate nano material as well as preparation method and application thereof

A nano-material, zinc gallate technology, applied in the field of nano-materials, can solve problems such as changes in physical and chemical properties, and achieve a unique and neat effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0069] A kind of preparation of zinc gallate nanomaterial:

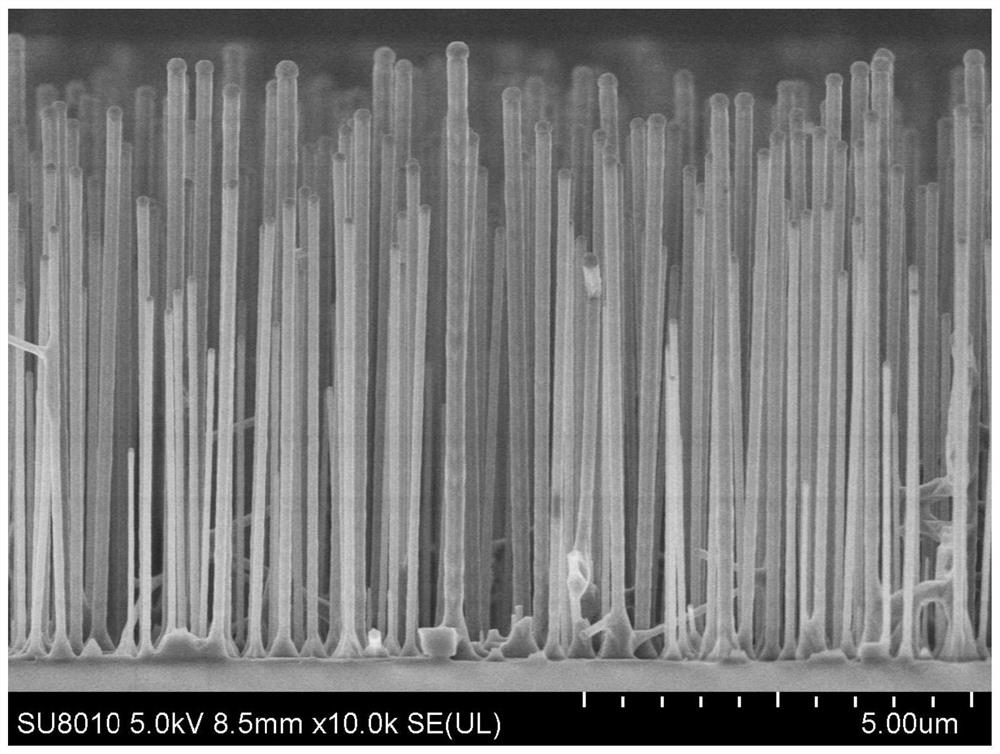

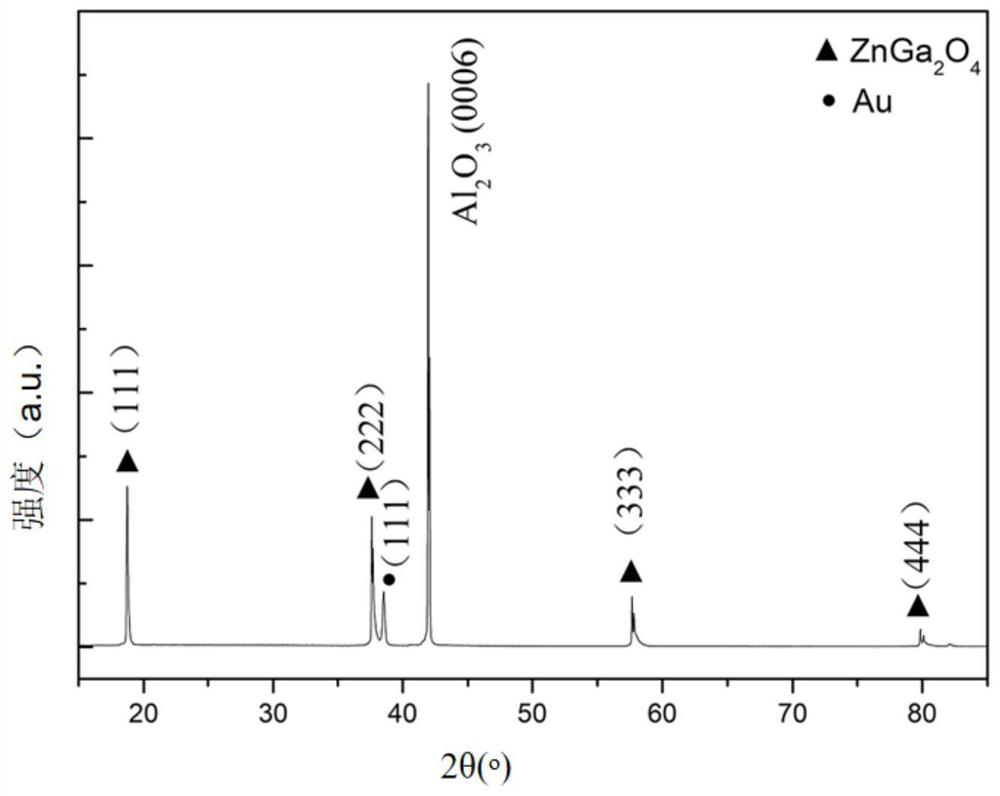

[0070] Weigh 0.2g ZnO powder, 0.5g Ga 2 o 3 powder and 1g graphite powder, and mix evenly. Then they are pressed into blocks and put into a ceramic boat as the source material. The c-plane sapphire with a size of 0.8cm×0.8cm and a 20nm thick gold film on the surface is used as a substrate and placed above the source material in the ceramic boat. . Put the ceramic boat into the quartz tube located in the tube furnace, first use the mechanical pump to pump the furnace to 4mTorr, and then pass the Ar flow into the tube. When the pressure in the tube reaches 100Torr, the furnace starts to heat up at a heating rate of 40°C / min. 980°C, keep constant temperature, and pass O 2 (At this time O 2 The volume ratio to Ar is 0.05:0.95), maintain the pressure in the tube at 50Torr, stop heating after the reaction lasts for 1h, and change the gas flow back to pure Ar flow, when the furnace cools to room temperature, stop venti...

Embodiment 2

[0076] A preparation of zinc gallate nanomaterial: Compared with Example 1, the difference is only in that compared with Example 1, the difference is only: the reaction duration is 20min

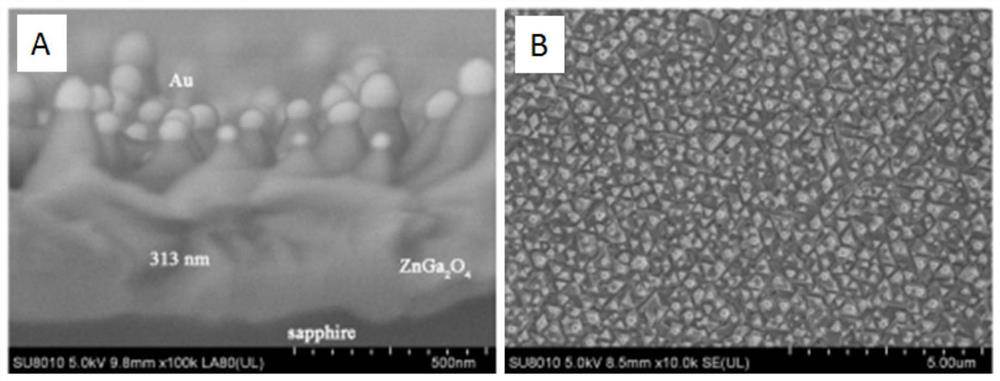

[0077] The obtained sample is marked as sample 2#, and the SEM image of sample 2# is as follows image 3 As shown, A is the cross-sectional topography of the sample. It can be seen that the height of the nanowire is about 300nm, and B is the topography of the sample surface. Combining the two pictures, it shows that the bottom of the nanowire is indeed connected by a thin film.

Embodiment 3~4

[0079] A preparation of zinc gallate nanomaterial: Compared with Example 1, the difference is only in that compared with Example 1, the difference is only as shown in Table 1:

[0080] The difference between the preparation method of table 1 embodiment 3~4 and embodiment 1

[0081]

PUM

| Property | Measurement | Unit |

|---|---|---|

| height | aaaaa | aaaaa |

| thickness | aaaaa | aaaaa |

| height | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com