Preparing method of rare earth iron-boron-based anisotropy magnetic powder and prepared magnetic powder

An anisotropic magnetism, rare earth iron boron technology, applied in the field of preparation methods and prepared magnetic powders, can solve the problem of the reduction of magnetic powder remanence and maximum magnetic energy product technical indicators, the reduction of magnetic powder remanence and maximum magnetic energy product, and the increase of the cost of making magnetic powder. and other problems, to achieve the effect of good popularization and application value, uniform coercivity and high coercivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

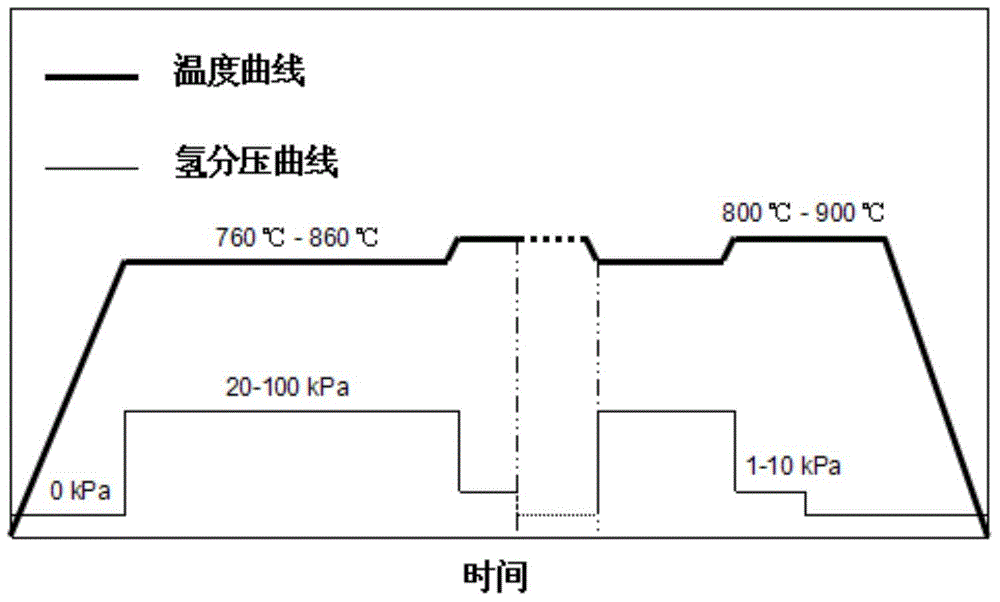

[0034] A method for preparing anisotropic rare earth iron-boron magnetic powder, comprising the following steps:

[0035] Step a: the step of preparing rare earth iron boron alloy particles.

[0036]Specifically: the step of preparing rare earth iron boron alloy particles may include:

[0037] (1) Step a1, according to the general chemical formula R of rare earth iron boron magnetic powder x T 1-x-y-z B y m z Batching is carried out and made into rare earth iron boron alloy ingot or rare earth iron boron alloy quick-setting sheet.

[0038] In the general chemical formula, R is at least one of neodymium (Nd), praseodymium (Pr), lanthanum (La), cerium (Ce), dysprosium (Dy) or terbium (Tb); T is iron (Fe), cobalt At least one of (Co) or nickel (Ni); M is gallium (Ga), niobium (Nb), zirconium (Zr), copper (Cu), aluminum (Al), vanadium (V), titanium (Ti) , at least one of molybdenum (Mo), silicon (Si) or manganese (Mn); B is boron. x, y, and z respectively represent the weig...

Embodiment 1~12

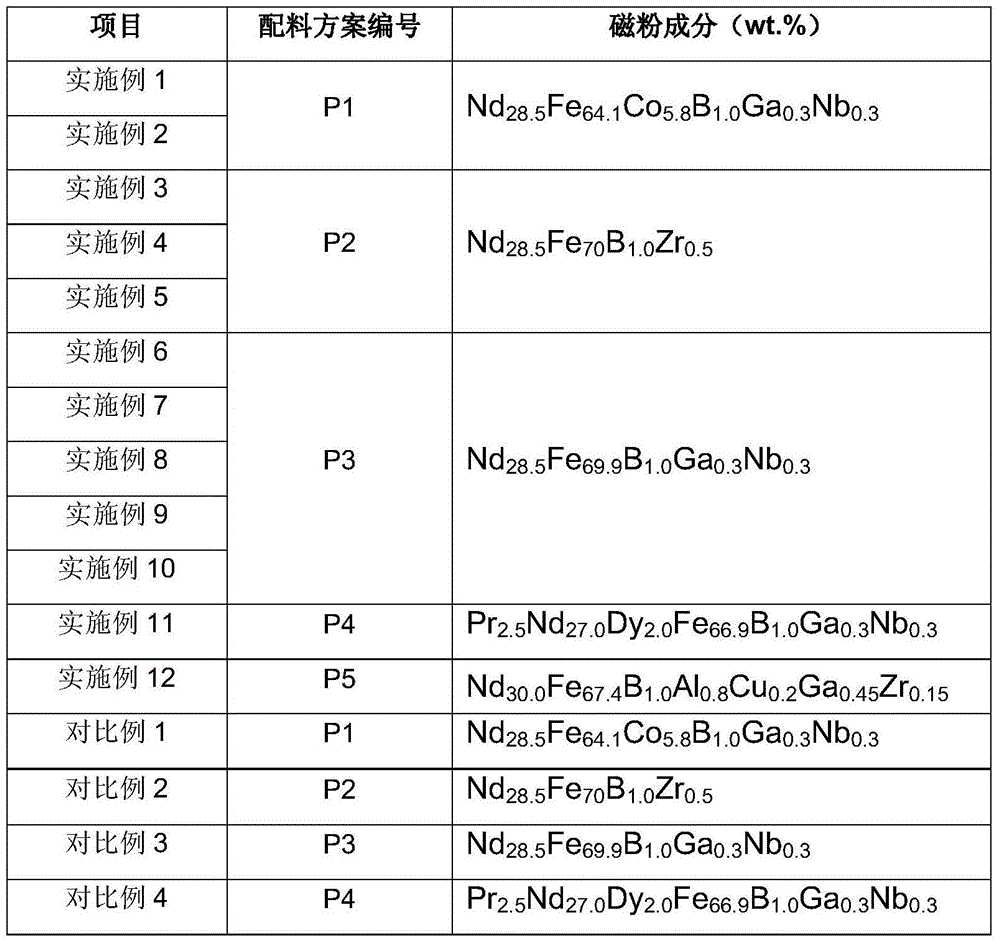

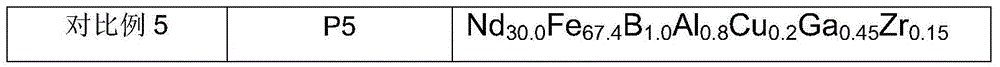

[0069] Dosing according to the magnetic powder composition ratio scheme in Table 1 below, and complete 12 specific examples of the present invention according to the preparation method of the rare earth iron-boron anisotropic magnetic powder described in the above technical solution of the present invention, thereby obtaining 12 kinds of Rare-earth iron-boron anisotropic magnetic powder with high coercivity, and the vibrating sample magnetometer (VSM) in the prior art is used to measure the intrinsic coercive force iHc and remanence of each rare-earth iron-boron anisotropic magnetic powder Br and maximum magnetic energy product (BH) max these performance indicators are measured, and the measurement results can be shown in Table 3 below. Wherein, embodiment 2 of the present invention performs the step of "complete dehydrogenation stage" when performing the first HDDR treatment, while the remaining embodiments of the present invention do not perform the step of "complete dehydrog...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Granularity | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com