A special aqueous emulsion for plastic film ink and preparation method thereof

A technology of plastic film and water-based emulsion, applied in the field of ink emulsion, can solve the problems of many disputes, poor printability and adhesion, emission of volatile organic compounds, etc., to achieve no pollution to the environment, improve adhesion Strength and surface adhesion, the effect of excellent adhesion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

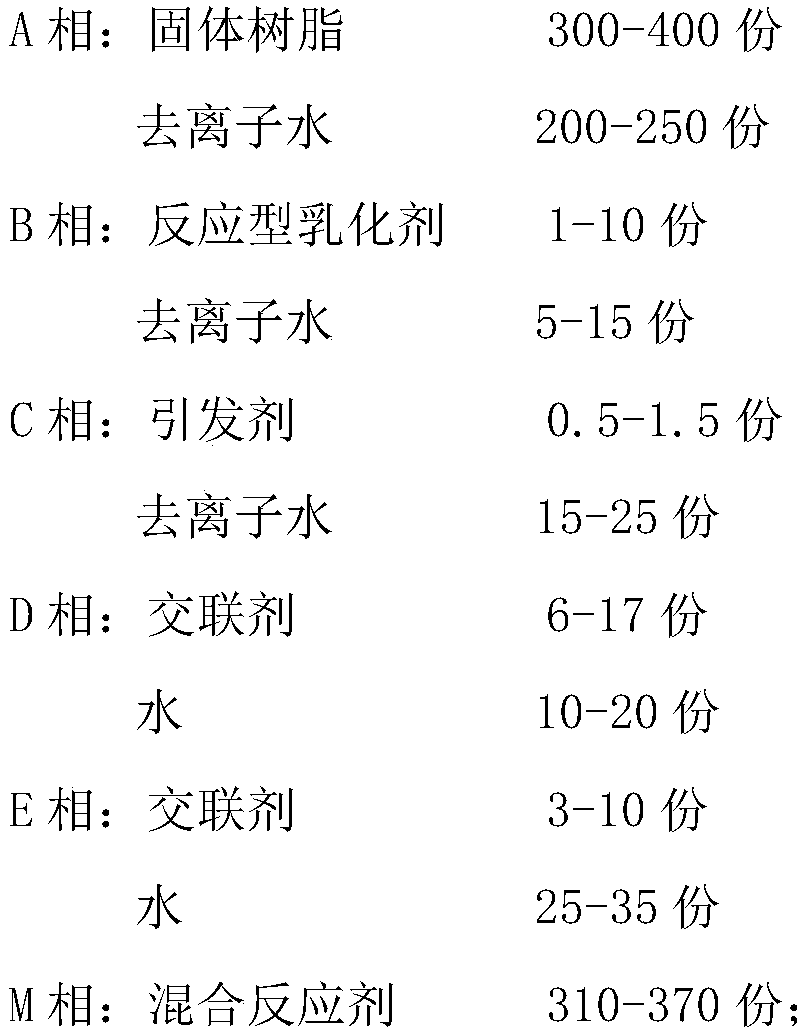

[0060] A special aqueous emulsion for plastic film ink, comprising the following raw materials in parts by weight:

[0061] Phase A: 300 parts of solid resin

[0062] 200 parts of deionized water

[0063] Phase B: 1 part of reactive emulsifier

[0064] 5 parts of deionized water

[0065] Phase C: 0.5 parts of initiator

[0066] 15 parts of deionized water

[0067] Phase D: 6 parts of crosslinking agent

[0068] 10 parts of water

[0069] Phase E: 3 parts of cross-linking agent

[0070] 25 parts of water

[0071] Phase M: 310 parts of mixed reactants.

[0072] In the phase C, the initiator is potassium persulfate.

[0073] In the phases D and E, the crosslinking agent is a mixture of ethylenediamine and acetoacetoxyethyl methacrylate in a weight ratio of 1:1.8.

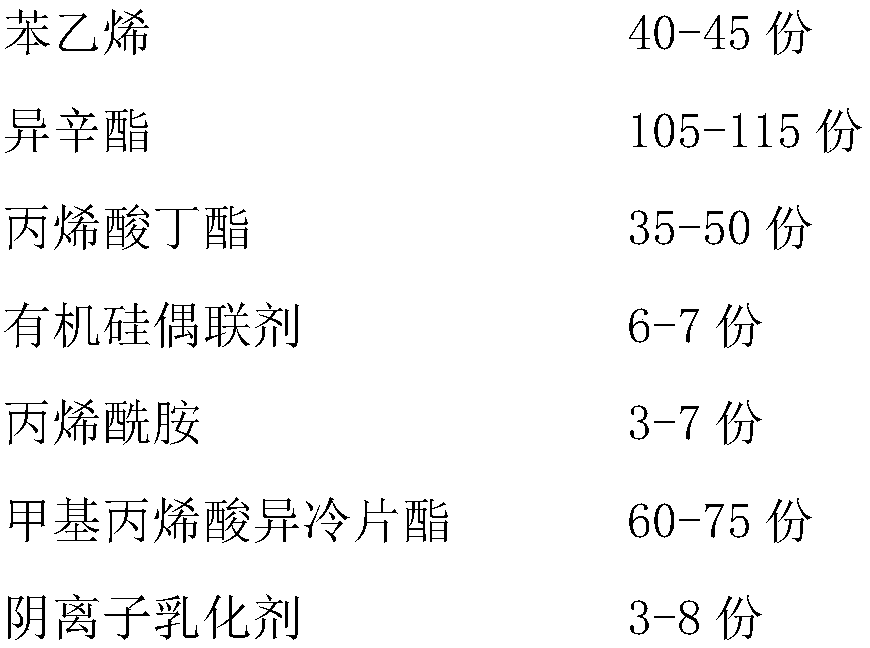

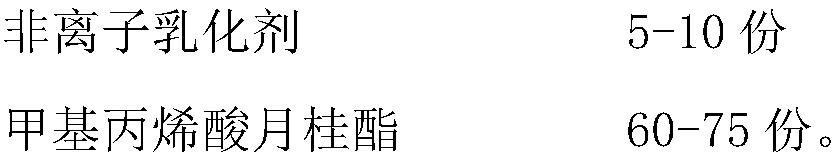

[0074] In the M phase, the mixed reactant includes the following raw materials in parts by weight:

[0075] 50 parts of methyl methacrylate

[0076] 105 parts of isobutyl methacrylate

[0077] Butyl methac...

Embodiment 2

[0092] The difference between this embodiment and above-mentioned embodiment 1 is:

[0093] A special aqueous emulsion for plastic film ink, comprising the following raw materials in parts by weight:

[0094] Phase A: 325 parts of solid resin

[0095] 210 parts of deionized water

[0096] Phase B: 3 parts of reactive emulsifier

[0097] 8 parts deionized water

[0098] Phase C: 0.8 parts of initiator

[0099] 18 parts deionized water

[0100] Phase D: 9 parts of crosslinking agent

[0101] 13 parts of water

[0102] Phase E: 5 parts of cross-linking agent

[0103] 28 parts of water

[0104] Phase M: 350 parts of mixed reactants.

[0105] In the phases D and E, the crosslinking agent is a mixture of acetoacetoxyethyl methacrylate and ethylenediamine in a weight ratio of 1.4:1.

[0106] In the M phase, the mixed reactant includes the following raw materials in parts by weight:

[0107] Styrene 41 parts

[0108] 108 parts of isooctyl ester

[0109] 46 parts of butyl ...

Embodiment 3

[0125] The difference between this embodiment and above-mentioned embodiment 1 is:

[0126] A special aqueous emulsion for plastic film ink, comprising the following raw materials in parts by weight:

[0127] Phase A: 350 parts of solid resin

[0128] 220 parts of deionized water

[0129] Phase B: 5 parts of reactive emulsifier

[0130] 10 parts deionized water

[0131] Phase C: Initiator 1 part

[0132] 20 parts deionized water

[0133] Phase D: 11 parts of crosslinking agent

[0134] 15 parts of water

[0135] Phase E: 7 parts of cross-linking agent

[0136] 30 parts of water

[0137] Phase M: 330 parts of mixed reactants.

[0138] In the C phase, the initiator is ammonium persulfate.

[0139] In the D phase and E phase, the crosslinking agent is composed of adipic acid dihydrazide, diacetone acrylamide, acetoacetoxy ethyl methacrylate and ethylenediamine in a weight ratio of 2.8:1.2:1.8:1 mixture.

[0140] In the M phase, the mixed reactant includes the followin...

PUM

| Property | Measurement | Unit |

|---|---|---|

| glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com