Water-based emulsion for beer label and preparation method thereof

A water-based emulsion and label technology, applied in the field of labels, can solve the problems of poor bottle-resistant glue, poor wet adhesion, and poor water resistance, and achieve the effects of outstanding environmental protection advantages, balanced reaction rate, and sufficient reaction.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0031] As an embodiment of the acid and alkali-resistant water-based emulsion for a kind of beer label of the present invention, the emulsion includes the following components by weight:

[0032] Phase A: 80 parts of acrylic resin, 250 parts of deionized water;

[0033] Phase B: 1 part of reactive emulsifier, 3 parts of deionized water;

[0034] Phase C: 0.5 parts of initiator, 1 part of deionized water;

[0035] Phase D: 15 parts of a compound composed of diacetone acrylamide and adipic dihydrazide, 10 parts of deionized water;

[0036] Phase E: 250 parts of mixed reactants;

[0037] Phase E1: 24.8 parts of mixed reactants;

[0038] In the phase C, the initiator is potassium persulfate; in the phase D, the mass ratio of diacetone acrylamide to adipic dihydrazide is 2:1.

[0039] The mixed reactant of phase E includes the following raw materials in parts by weight: 50 parts of styrene, 105 parts of isooctyl ester, 56 parts of butyl acrylate, 6 parts of silane coupling agen...

Embodiment 2

[0050] As an embodiment of the acid and alkali-resistant water-based emulsion for a kind of beer label of the present invention, the emulsion includes the following components by weight:

[0051] Phase A: 100 parts of acrylic resin, 280 parts of deionized water;

[0052] Phase B: 3.5 parts of reactive emulsifier, 4 parts of deionized water;

[0053] Phase C: 0.8 parts of initiator, 5 parts of deionized water;

[0054] Phase D: 10 parts of a compound composed of diacetone acrylamide and adipic dihydrazide, 5 parts of deionized water;

[0055] Phase E: 234.1 parts of mixed reactants;

[0056] Phase E1: 27.52 parts of mixed reactants;

[0057] In the phase C, the initiator is potassium persulfate; in the phase D, the mass ratio of diacetone acrylamide to adipic dihydrazide is 2.5:1.

[0058] The E-phase mixed reaction agent includes the following raw materials in parts by weight: 55 parts of styrene, 76 parts of isooctyl ester, 60 parts of butyl acrylate, 6.1 parts of silane ...

Embodiment 3

[0069] As an embodiment of the acid and alkali-resistant water-based emulsion for a kind of beer label of the present invention, the emulsion includes the following components by weight:

[0070] Phase A: 125 parts of acrylic resin, 300 parts of deionized water;

[0071] Phase B: 5 parts of reactive emulsifier, 5 parts of deionized water;

[0072] Phase C: 1 part of initiator, 12 parts of deionized water;

[0073] Phase D: 15 parts of a compound composed of diacetone acrylamide and adipic dihydrazide, 10 parts of deionized water;

[0074] Phase E: 256 parts of mixed reactants;

[0075] Phase E1: 28.05 parts of mixed reactants;

[0076] In the phase C, the initiator is ammonium persulfate; in the phase D, the mass ratio of diacetone acrylamide to adipic dihydrazide is 2.2:1.

[0077] The E-phase mixed reaction agent includes the following raw materials in parts by weight: 60 parts of styrene, 80 parts of isooctyl ester, 65 parts of butyl acrylate, 6.5 parts of silane coupli...

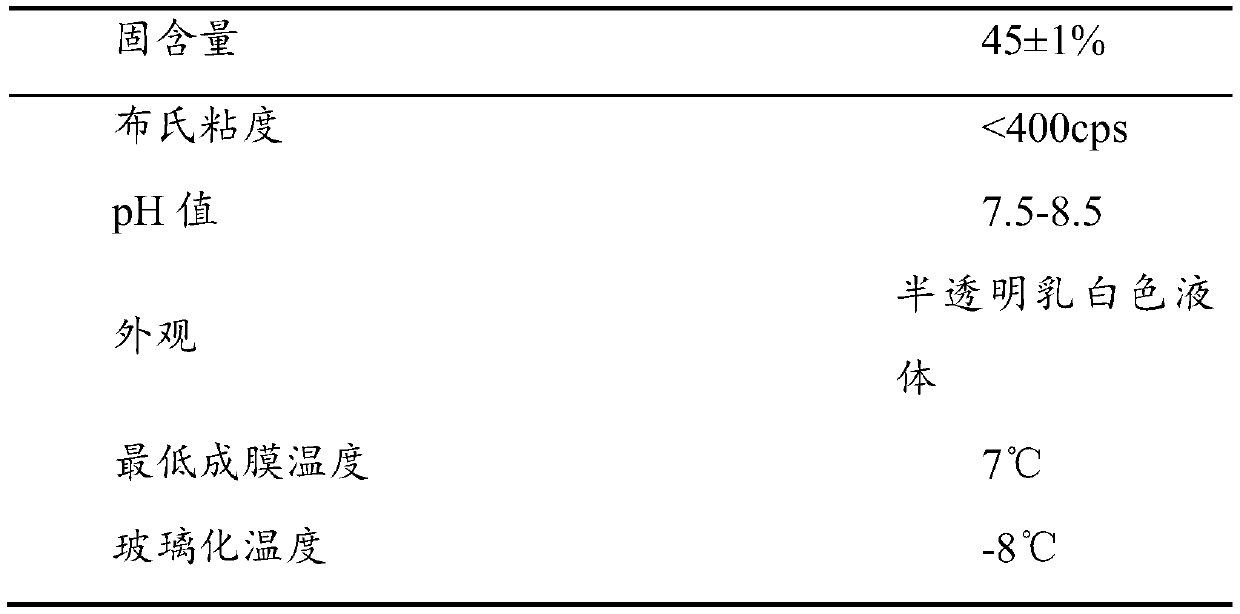

PUM

| Property | Measurement | Unit |

|---|---|---|

| Brookfield viscosity | aaaaa | aaaaa |

| Minimum film forming temperature | aaaaa | aaaaa |

| Glass transition temperature | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com