Water-soluble inorganic zinc-rich paint and preparation method thereof

An inorganic zinc-rich coating, water-based technology, applied in the direction of alkali metal silicate coatings, coatings, etc., can solve the problems of inability to construct, uneven particle size distribution, chipping, etc., to achieve no stress concentration, uniform reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

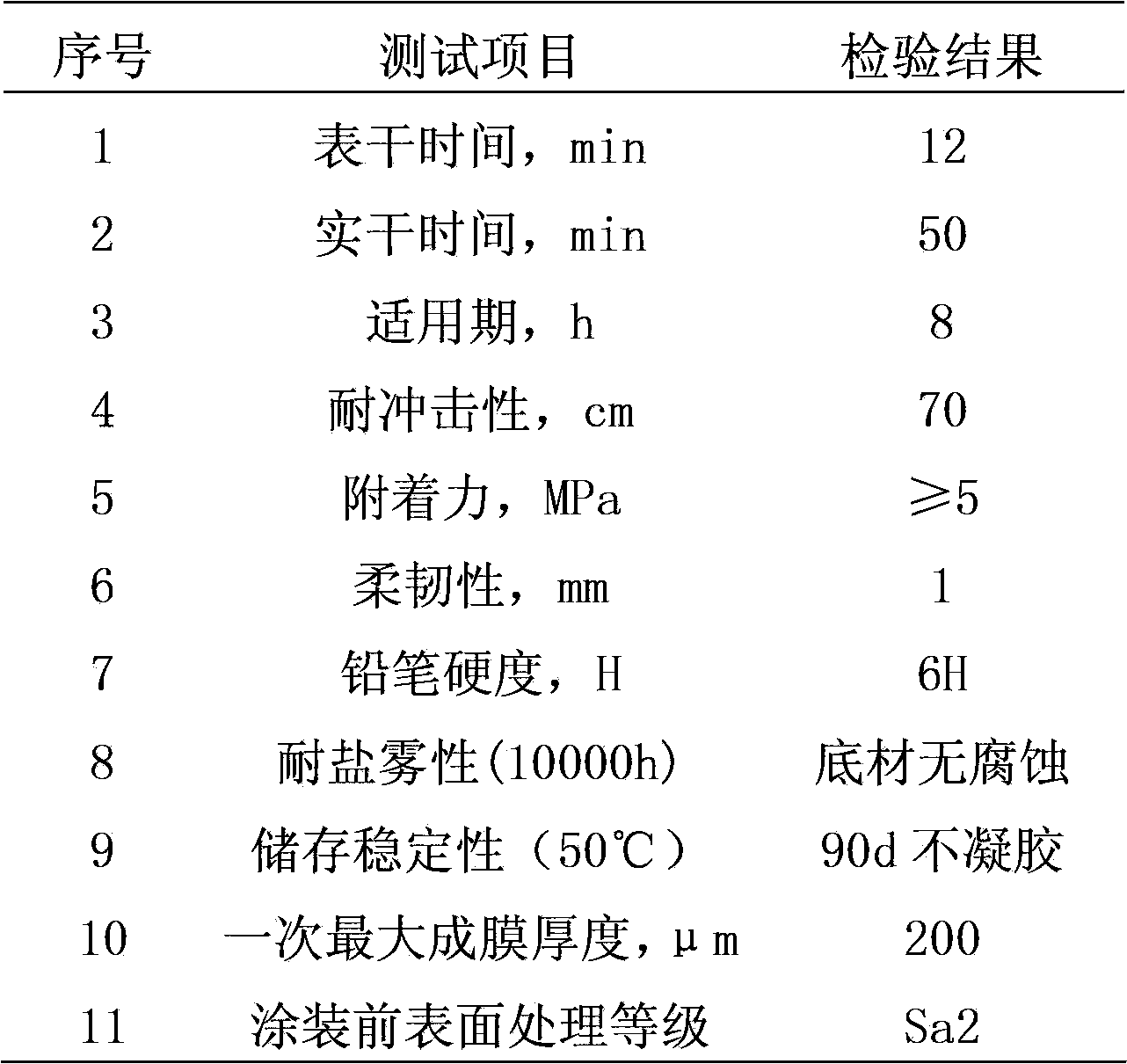

Embodiment 1

[0032] In this embodiment, the high-performance water-based inorganic zinc-rich coating is formed by blending high-modulus potassium silicate solution and zinc powder mixture according to the mass ratio of 1:2.3; in terms of mass percentage, the high-modulus potassium silicate solution Contains the following components:

[0033] Potassium silicate solution 100kg

[0034] Water 59.4kg

[0035] Aluminum modified silica sol 197kg, wherein the molar content of aluminum ions is 0.8%

[0036] Catalyst: Tetramethylammonium Hydroxide 4.6kg

[0037] Siloxane oligomer: bis(1,2-triethoxysilyl)ethane 6.05kg

[0038] Modifier: Octaamino cage silsesquioxane 10.7kg

[0039] Silicone acrylic emulsion 14.25kg

[0040] Anti-sedimentation agent: magnesium aluminum silicate inorganic gel 1.78kg

[0041] Defoamer 0.86kg

[0042] The zinc dust mixture includes the following components:

[0043] Zinc powder 90kg

[0044] Hardener: potassium zirconium carbonate 3.7kg

[0045] Rheology addit...

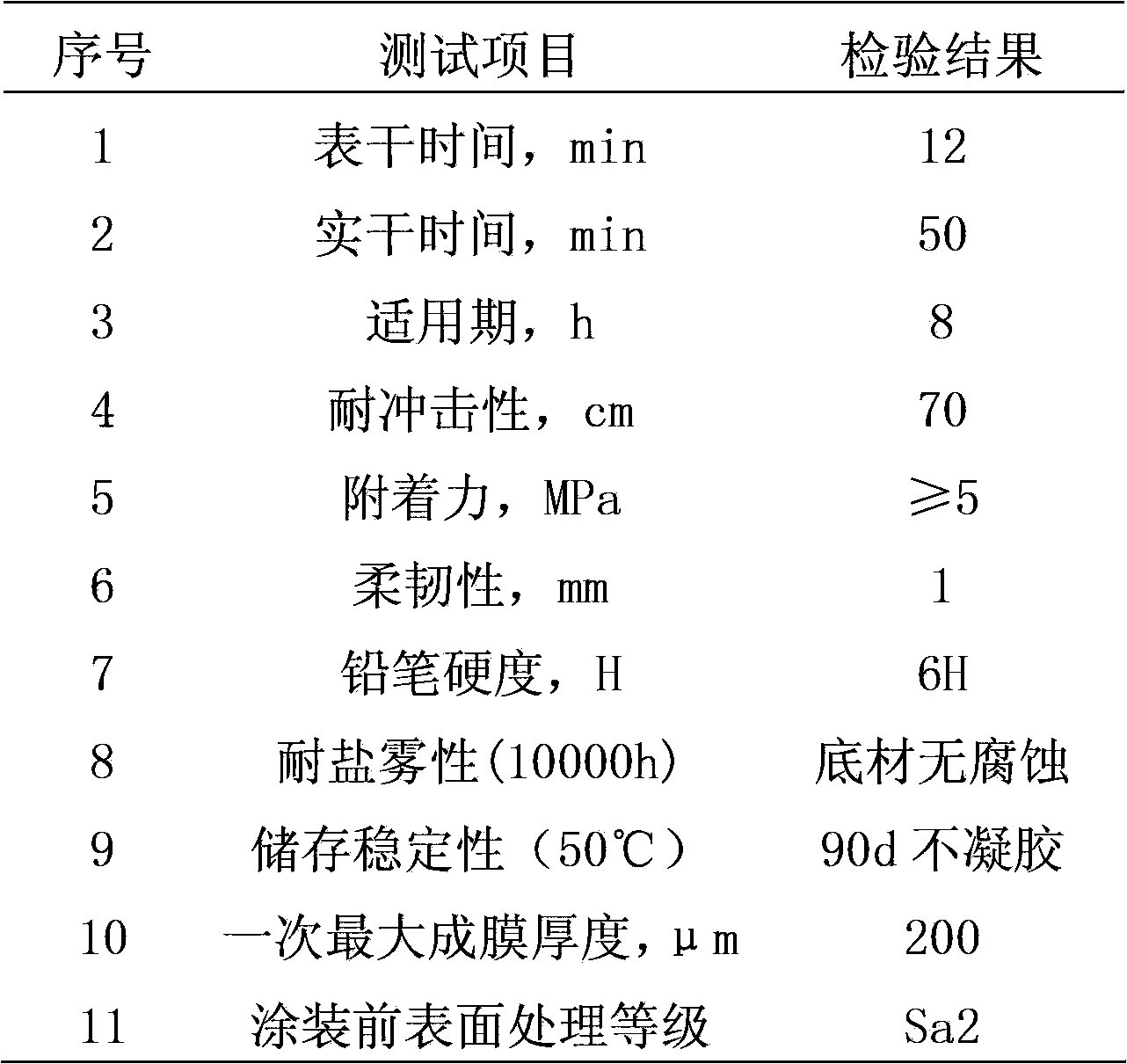

Embodiment 2

[0054] In this example, the high-performance water-based inorganic zinc-rich coating is formed by blending and stirring a mixture of high modulus potassium silicate solution and zinc powder according to the mass ratio of 1:2.6; in terms of mass percentage,

[0055] The high modulus potassium silicate solution comprises the following components:

[0056] Potassium silicate solution 100kg

[0057] 79kg of water

[0058] Aluminum modified silica sol 295kg wherein the molar content of aluminum ion is 1.2%

[0059] Catalyst: tetraethylammonium hydroxide 6.12kg

[0060] Siloxane oligomer: bis(1,2-trimethoxysilyl)ethane 8.05kg

[0061] Modifier: octaepoxy cage silsesquioxane 14.22kg

[0062] Silicone acrylic emulsion 18.98kg

[0063] Anti-sedimentation agent: magnesium aluminum silicate inorganic gel 2.37kg

[0064] Defoamer 1.2kg

[0065] The zinc dust mixture includes the following components:

[0066] Zinc powder 92kg

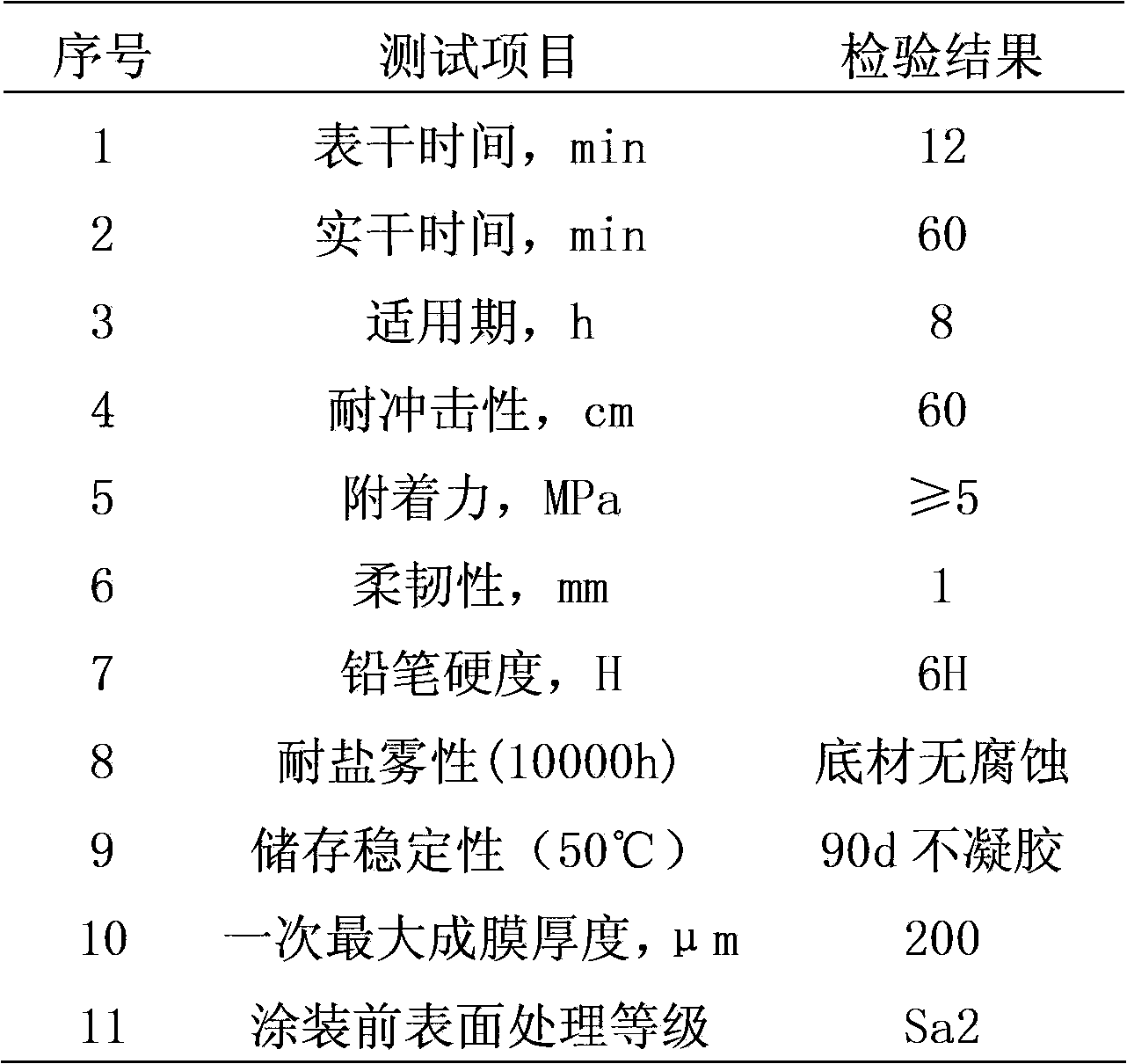

Embodiment 3

[0077] In this embodiment, the high-performance water-based inorganic zinc-rich coating is formed by blending high-modulus potassium silicate solution and zinc powder mixture according to the mass ratio of 1:3.5; according to mass percentage, the high-modulus potassium silicate solution Contains the following components:

[0078] Potassium silicate solution 100kg

[0079] 115kg of water

[0080] Aluminum modified silica sol 380kg wherein the molar content of aluminum ion is 1.2%

[0081] Catalyst: Tetraethylammonium hydroxide 8.18kg

[0082] Siloxane oligomer: bis(1,2-trimethoxysilyl)ethane 10.25kg

[0083] Modifier: octaepoxy cage silsesquioxane 18.28kg

[0084] Silicone acrylic emulsion 21.58kg

[0085] Anti-sedimentation agent: magnesium aluminum silicate inorganic gel 2.15kg

[0086] Defoamer 1.4kg

[0087] The zinc dust mixture includes the following components:

[0088] Zinc powder 88kg

[0089] Hardener: potassium zirconium carbonate 2.7kg

[0090] Rheology ad...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

| modulus | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com