Preparation method of carboxylic butadiene-acrylonitrile latex

A technology of carboxylated nitrile latex and emulsion, which is applied in the field of seed emulsion polymerization, can solve the problems of high conversion rate, time-consuming, poor stability, and many condensates, and achieve the goals of reduced condensate content, high stability, and balanced reaction rate Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

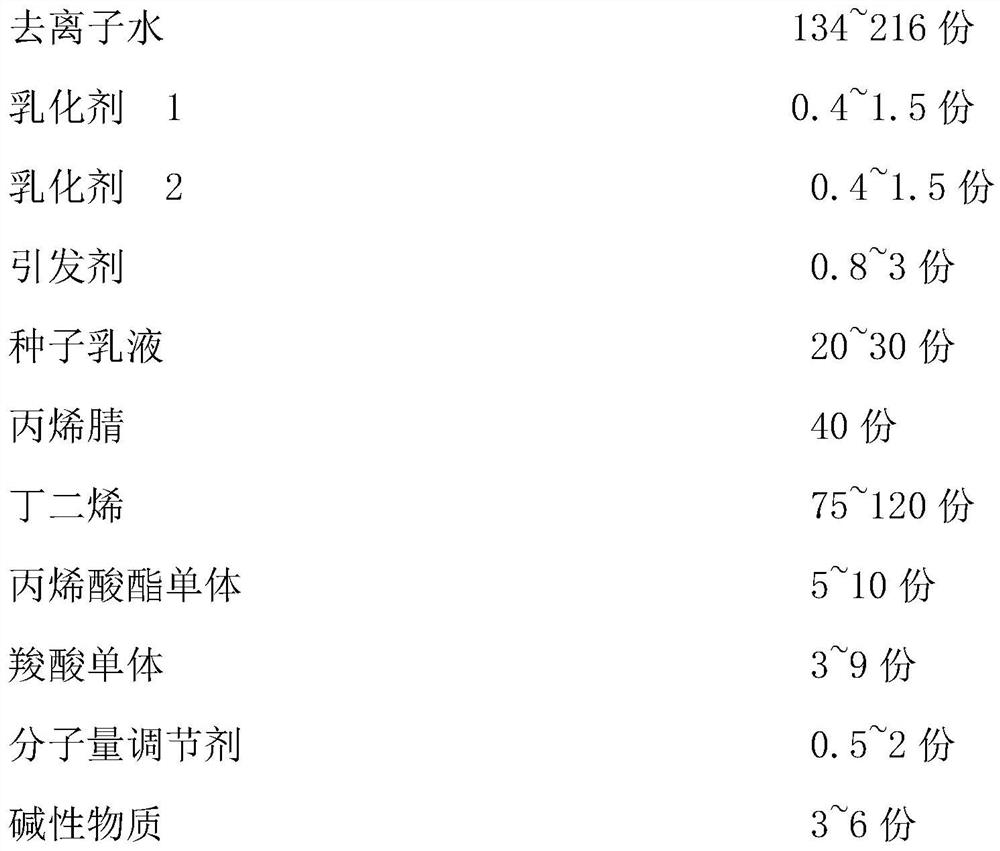

[0026] The preparation of carboxyl nitrile latex comprises following components and parts by weight thereof:

[0027] A, seed emulsion comprise following components and parts by weight thereof:

[0028]

[0029] Preparation method of seed emulsion:

[0030] After the polymerization kettle is evacuated, add deionized water, sodium lauryl sulfate, sodium dodecylsulfonate, sodium p-styrenesulfonate, sodium persulfate, raise the temperature to 70°C, add styrene and acrylonitrile dropwise , acrylic acid, and n-dodecanethiol for free radical emulsion polymerization, the reaction time is 3 hours, the temperature is raised to 90° C. for 0.5 hour, cooled and filtered to obtain a seed emulsion.

[0031] B, carboxylated styrene-butadiene latex include following components and parts by weight thereof:

[0032]

[0033]

[0034] The preparation method of carboxylated nitrile latex:

[0035] After the polymerization tank is vacuumed, add deionized water, sodium alkyl diphenyl et...

Embodiment 2

[0037] The preparation of carboxyl nitrile latex comprises following components and parts by weight thereof:

[0038] A, seed emulsion comprise following components and parts by weight thereof:

[0039]

[0040] Preparation method of seed emulsion:

[0041] After the polymerization kettle is evacuated, add deionized water, sodium dodecylsulfonate, sodium dodecylbenzenesulfonate, sodium p-styrenesulfonate, sodium acrylamidoisopropylsulfonate, ammonium persulfate, and heat up To 90°C, add dropwise a mixture solution of styrene, acrylonitrile, methacrylic acid, and tertiary dodecylmercaptan to carry out radical emulsion polymerization. The reaction time is 6 hours, and the temperature is raised to 90°C and kept for 0.5 hours. After cooling and filtering, Prepare seed emulsion.

[0042] B, carboxylated nitrile latex include following components and parts by weight thereof:

[0043]

[0044] The preparation method of carboxylated nitrile latex:

[0045] After the polymeri...

Embodiment 3

[0047] The preparation of carboxyl nitrile latex comprises following components and parts by weight thereof:

[0048] A, seed emulsion comprise following components and parts by weight thereof:

[0049]

[0050] Preparation method of seed emulsion:

[0051] After the polymerization kettle is evacuated, add deionized water, sodium dodecylbenzenesulfonate, sodium hexadecylacrylate-2-ethanesulfonate, potassium persulfate, raise the temperature to 80°C, add styrene and acrylonitrile dropwise , methacrylic acid, n-butanthiol mixture solution for free radical emulsion polymerization, the reaction time is 4 hours, the temperature is raised to 90 ° C for 0.5 hours, cooled and filtered to obtain the seed emulsion.

[0052] B, carboxylated nitrile latex include following components and parts by weight thereof:

[0053]

[0054]

[0055] The preparation method of carboxylated nitrile latex:

[0056] After the polymerization kettle is vacuumed, add deionized water, sodium dode...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com