Patents

Literature

43results about How to "The reaction rate is stable" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

Method for producing the red pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415665AProlong hydrolysis timeReduce manufacturing costPigmenting treatmentAmmonium sulfateFertilizer

A process for preparing iron oxide red pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining heptahydrated ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN1415666AHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

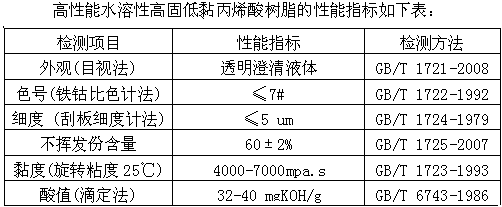

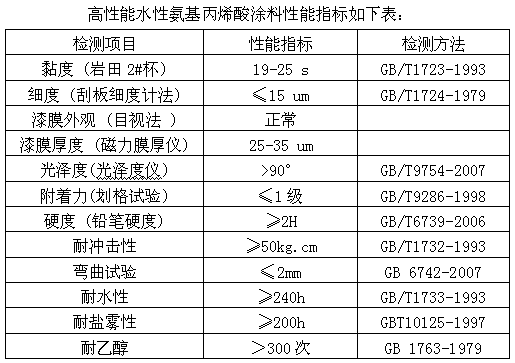

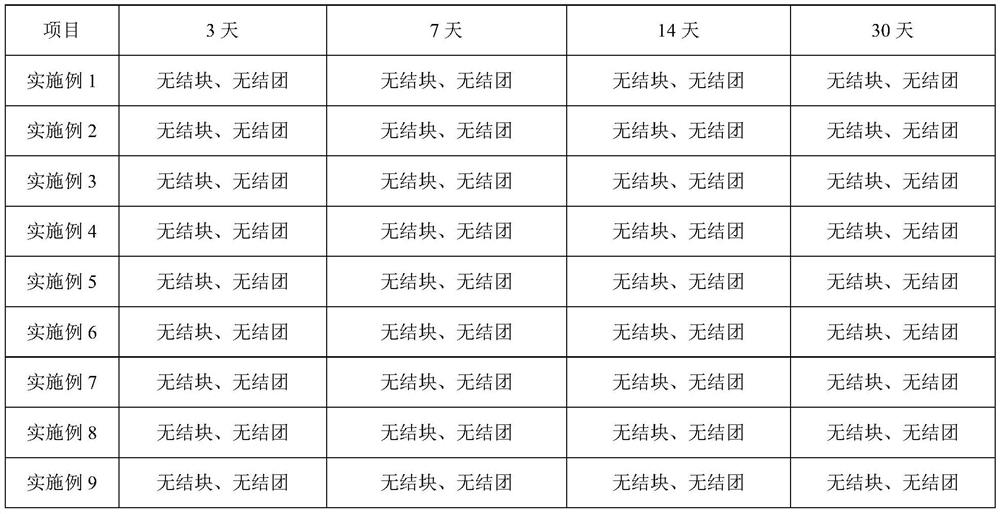

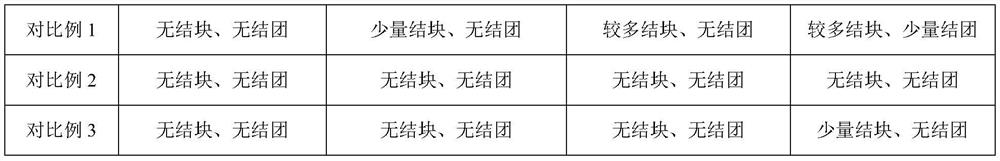

Preparation method of high-performance water-soluble high-solid low-viscosity acrylic resin

ActiveCN108864359AImprove performanceHigh reactivityAntifouling/underwater paintsPaints with biocidesSolubilityWater based

The invention relates to a preparation method of a high-performance water-soluble high-solid low-viscosity acrylic resin. In a compound solvent system, a continuous-process free radical solution polymerization is adopted for preparing the acrylic resin, and the resin is endowed with water solubility. Modification is carried out by utilizing a tertiary carbonate ester, and a large branch structureis introduced, so that the intermolecular force is reduced, the resin viscosity is reduced, and the high-solid resin has lower viscosity. Through a tertiary carbonic acid group, the water resistance and the alcohol resistance of a paint film are remarkably increased, the performances such as the toughness and the impact resistance of the paint film are remarkably improved, and the influence on thehardness of the paint film is less. According to the preparation method of the high-performance water-soluble high-solid low-viscosity acrylic resin provided by the invention, organosilicone is usedfor modifying the acrylic resin, so that the performances such as humidity resistance and corrosion resistance of the paint film are improved; an amino resin is used as a curing agent for directly preparing a water-based amino acrylic acid baking paint, so that the performances such as hardness, fullness, water resistance, alcohol resistance and salt tolerance of the paint film are good, and the paint film is suitable for industrial coating in the industries of automobiles, bicycles, agricultural machinery and the like, an can be used for coating in the industries of fishing rods, wine bottles, dining tables and other industries with a certain humidity resistance and pollution resistance requirements.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI +1

Method for preparing naphthalene series water reducer

The invention provides a method for preparing a naphthalene series water reducer. The method comprises the following steps: sulfonation: carrying out a sulfonation reaction of naphthalene and concentrated sulfuric acid; hydrolysis: adding water into the sulfonation reaction product for hydrolysis, and hydrolyzing a by-product in the sulfonation reaction; condensation: adding poly formaldehyde and water into the hydrolysis reaction product for condensation; and neutralization: adjusting pH of the condensation reaction product to be 6-8, and drying to obtain the naphthalene series water reducer. The preparation method has the advantages of simple and stable production process and easily controlled parameters, and the prepared naphthalene series water reducer product has stable performance and good quality.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

Etching solution for silicon wafer

InactiveCN109321253AReduce uniformityGuaranteed uniformitySurface treatment compositionsReaction ratePhosphoric acid

The invention discloses an etching solution for a silicon wafer. The etching solution is mainly prepared from electronic-grade nitric acid, electronic-grade hydrofluoric acid, electronic-grade sulfuric acid, electronic-grade phosphoric acid, electronic-grade acetic acid, a surfactant and ultrapure water, wherein the nitric acid serves as an oxidizing agent and can oxidize silicon into silicon oxide, the hydrofluoric acid serves as a dissolving agent and can dissolve and remove the silicon oxide so as to realize etching of the silicon wafer, the sulfuric acid can improve the viscosity of the solution, stabilize the reaction rate, not change the etching morphology and improve the etching uniformity, the phosphoric acid can also improve the viscosity of the solution, improve the mass transferresistance, decrease the etching rate and not change the etching morphology, the acetic acid serves as a diluent and can reduce the ionization degree of the nitric acid, inhibit the oxidation capacity of the nitric acid, decrease the reaction rate and influence the surface morphology after etching, and the surfactant can reduce the surface tension of the solution and improve the surface morphology of the etched silicon wafer. The etching solution has the advantages of being stable and controllable in etching rate and uniform and flat in etching surface.

Owner:湖北兴福电子材料股份有限公司

Polishing liquid for grinding and polishing micro crystal glass

InactiveCN1858132AIncrease reaction rateReduce surface roughnessAqueous dispersionsPolishing compositions with abrasivesIonChemistry

Owner:HEBEI UNIV OF TECH

Soda-lime glass frosting liquid and preparation method thereof

ActiveCN112521021AIncrease concentrationIncrease reaction rateSurface treatment compositionsInorganic saltsPhysical chemistry

The invention discloses a soda-lime glass frosting liquid, which comprises the following components by weight: 10-28 parts of a fluorine-containing inorganic salt; 0.1-10 parts of an alkali metal salt; 0.1-15 parts of an ammonium salt; 0.01-50 parts of a hydroxyl-containing organic matter; 0.01-20 parts of an acid substance; and 35-75 parts of water. The soda-lime glass frosting liquid is uniformand stable transparent liquid, does not have the problems of precipitation, precipitation, agglomeration and the like in the storage process, has favorable storage stability, can be directly used, omits the tedious operation of proportionally adding acid or adding water to prepare the liquid in the conventional frosting powder, cancels the heat-preservation curing procedure before use, therefore,the frosting liquid has the characteristics of convenient use and operation, high production efficiency, stable frosting effect and good storage stability, and the production efficiency of frosting treatment of soda-lime glass is remarkably improved. The invention also provides a preparation method of the soda-lime glass frosting liquid.

Owner:广东山之风环保科技有限公司

Cationic rosin size emulsifier and preparation method thereof

ActiveCN108396589AAdjust molecular weightAvoid interferenceWater-repelling agents additionAcetic acidEmulsion

The invention provides a cationic rosin size emulsifier and a preparation method thereof. The cationic rosin size emulsifier is prepared from dimethylaminoethyl methacrylate, styrene, chitosan, glacial acetic acid, water, acrylic acid, acrylamide, potassium sodium tartrate and an initiator. The obtained emulsifier has a good stability, can be used to directly emulsify rosin, and has the advantagesof small use amount, good effect and low cost, a rosin size emulsion obtained after emulsification has nanoscale particles and a stable quality, and can be stably stored (at -5 to 50 DEG C) for a long time; and the rosin size emulsion obtained after emulsification is applied to sizing, has the advantages of small use amount of other sizing additives, small use amount of a sizing agent, good effect and low cost, and makes sized paper have certain antibacterial and bactericidal effects and good durability.

Owner:辽宁兴东科技有限公司

Preparation method of narrow-particle-size suspension polytetrafluoroethylene resin

InactiveCN109721670APromote decompositionNot easy to decomposeTetrafluoroethyleneDi-tert-butyl peroxide

The invention discloses a preparation method of narrow-particle-size suspension polytetrafluoroethylene (PTFE) resin. The method comprises the following steps: 1, tetrafluoroethylene is used as a polymerization monomer, materials are prepared, and polymerization is performed to prepare suspension polytetrafluoroethylene resin; 2, when a content of deionized water is 100 parts, a content of a di-tert-butyl peroxide is 1.14 x 10<-2> parts, a content of ferrous naphthenate is 2.28 x 10<-2> parts, and a content of perfluorocycloether is 2.28 x 10<-3> parts; 3, the polymerization starting temperature is 40 DEG C, the temperature is maintained at 40-60 DEG C in the polymerization process, the reaction pressure is a constant value between 1.6-3.0 MPa of gage pressure, a constant-pressure reactionis performed, and the ferrous naphthenate is added into a reaction kettle in a form of a dilute solution with a mass percentage concentration of 1% at a constant speed within 90 min; and 4, the material obtained in the step 3 is repeatedly washed for three times or more by using deionized water until measured conductivity of the filtrate is reduced to 1 [mu]S / m or less; and drying is performed ata temperature not higher than 200 DEG C.

Owner:江苏梅兰化工有限公司

Preparation method for synthesizing high-performance polycarboxylate superplasticizer from novel VPEG polyether

The invention belongs to the technical field of concrete admixtures and specifically relates to a preparation method for synthesizing a high-performance polycarboxylate superplasticizer from novel VPEG polyether. The preparation method comprises the following steps of: 1, preparing a base solution, namely uniformly stirring a VPEG polyether macromonomer, a chain transfer agent, tap water, an unsaturated carboxylic acid micromonomer, a NaOH solution, a metal catalyst and an oxidant to form the base solution; 2, preparing an auxiliary liquid: dissolving an unsaturated carboxylic acid small monomer, a silane coupling agent and a chain transfer agent in tap water to prepare a dropwise-added liquid material A, and dissolving a reducing agent in tap water to prepare a dropwise-added liquid material B; 3, blending and synthesizing, namely dropwise adding the dropwise-added liquid material A and the dropwise-added liquid material B into the base solution at a constant speed by using a dropwiseadding device, stirring, and keeping the temperature for 1 hour after dropwise adding is finished; and 4, adjusting the pH value. The preparation method of the water reducing agent is short in time and easy to control, energy is saved, and the prepared water reducing agent has good water reducing and slump retaining properties.

Owner:GUIZHOU DR SHI TECH

Method for producing the red pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN100396733CHigh recovery rateAchieve the purpose of separationPigmenting treatmentTitanium oxideAmmonium sulfate

A process for preparing iron oxide red pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining heptahydrated ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

Method for precisely controlling degree of Maillard reaction

ActiveCN104667843ARapid responseImprove controllabilityFood shapingChemical/physical/physico-chemical processesMaillard reactionCarrageenan

The invention belongs to the technical field of a food processing method, and particularly relates to a method for precisely controlling the degree of Maillard reaction. The method comprises the steps: enabling a mixed solution of isolated soybean proteins and t-carrageenan under the alkaline condition to be rapidly subjected to the Maillard reaction in the atomizing drying process by adopting an atomizing drying technology to obtain a primary stage product of the Maillard reaction; and obtaining different Maillard reaction products at different reaction degrees under the dry-method reaction condition of 60 DEG C. By adopting the method, a purpose of rapidly controlling the degree of the Maillard reaction can be realized. The method has characteristics that the time for preparing the Maillard reaction product is short, the reaction degree is controllable and the like.

Owner:CHINA AGRI UNIV

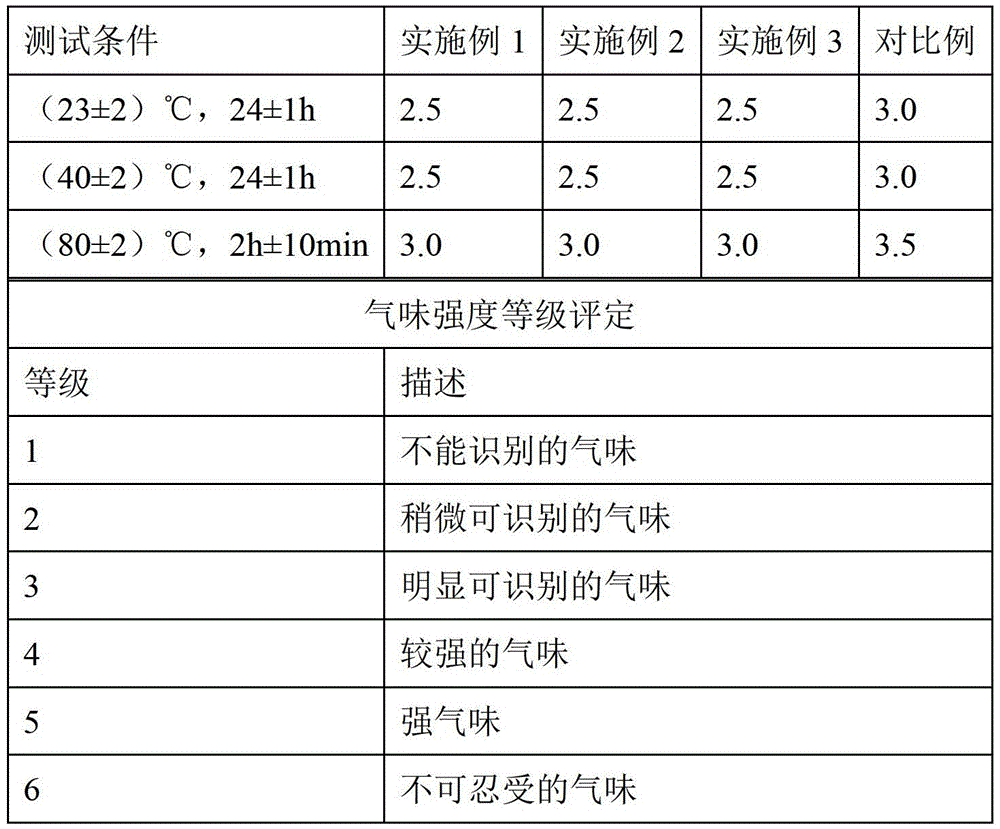

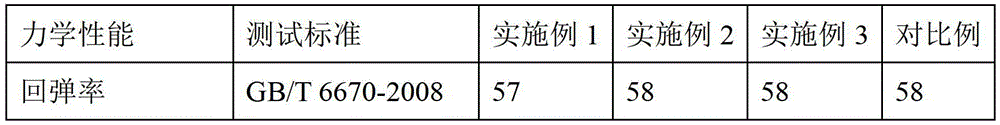

A low-odor high-resilience sponge for passenger car seats and preparation method thereof

The invention discloses a low-smell high-rebound sponge for seats of a passenger car. The sponge is prepared from a composite material and a black material according to a mass ratio of 100: 55-60, wherein the composite material comprises, by weight, 50 to 80 parts of polyether polyol, 20 to 50 parts of grafted polyether, 0.2 to 0.3 part of an amine catalyst, 0.2 to 0.5 part of an early-stage gel catalyst, 0.5 to 0.7 part of a later-stage gel catalyst, 3 to 4 parts of a foaming agent, 1 part of a cross-linking agent and 0.5 to 0.7 part of a stabilizing agent. The invention also discloses a preparation method for the sponge. The low-smell high-rebound sponge for seats of the passenger car employs the black material with low smell and hypotoxicity and the polyether composite material with low smell and hypotoxicity, so the standard smell grade of the sponge is 3.0, TVOC is 13.9 mu g C / g, and the sponge has the characteristics of low smell and high rebound and accords with requirements of people for environmental protection performance and mechanical properties of sponge of automobile seats.

Owner:ZHENGZHOU JINGYIDA AUTO PARTS

Biomass fuel preparation method

InactiveCN109370697AReduce processing costsScientific and reasonable process designBiofuelsSolid fuelsHigh pressureProcessing cost

The invention discloses a biomass fuel preparation method and relates to the technical field of fuel processing. The biomass fuel preparation method comprises the working procedures of raw material pretreatment, steam explosion, sterilization cultureculturing, saccharification sterilization treatment, co-fermentation and mixed adsorption extrusion. Four raw materials are efficiently dried througha counterflow vibration technology, through steam explosion, hemicellulose in straw is decomposed into oligomer dissolved in water, lignin is subjected to bond rupture due to allyl ether to generate low-molecular matter, thus subsequent fermentation treatment is facilitated, and co-fermented biological fuel obtained after sterilization treatment and co-fermentation further contains high-purity liquid ethyl alcohol in addition to flammable cellulose and the lignin; and the co-fermented biological fuel is adsorbed into loose and porous modified coconut shell activated carbon and sepiolite fabricwithout the high-temperature and high-pressure harsh conditions, the raw material treatment cost and processing cost are greatly lowered, the combustion calorific value is stable, and the raw material heat utilization rate is increased.

Owner:彭翔

Solution concentration monitoring method

InactiveCN102023200AConcentration monitoringThe reaction rate is stableMaterial analysisReaction rateMonitoring methods

The invention provides a solution concentration monitoring method. The concentration of a solution is monitored through monitoring the reaction rate of a polysilicon control wafer by utilizing the characteristics that the reaction rates of the polysilicon control wafer and the solution are stable when the solution concentration is in a certain range. Compared with methods in the prior art, the solution concentration monitoring method of the invention greatly decreases the cost.

Owner:SEMICONDUCTOR MANUFACTURING INTERNATIONAL (BEIJING) CORP +1

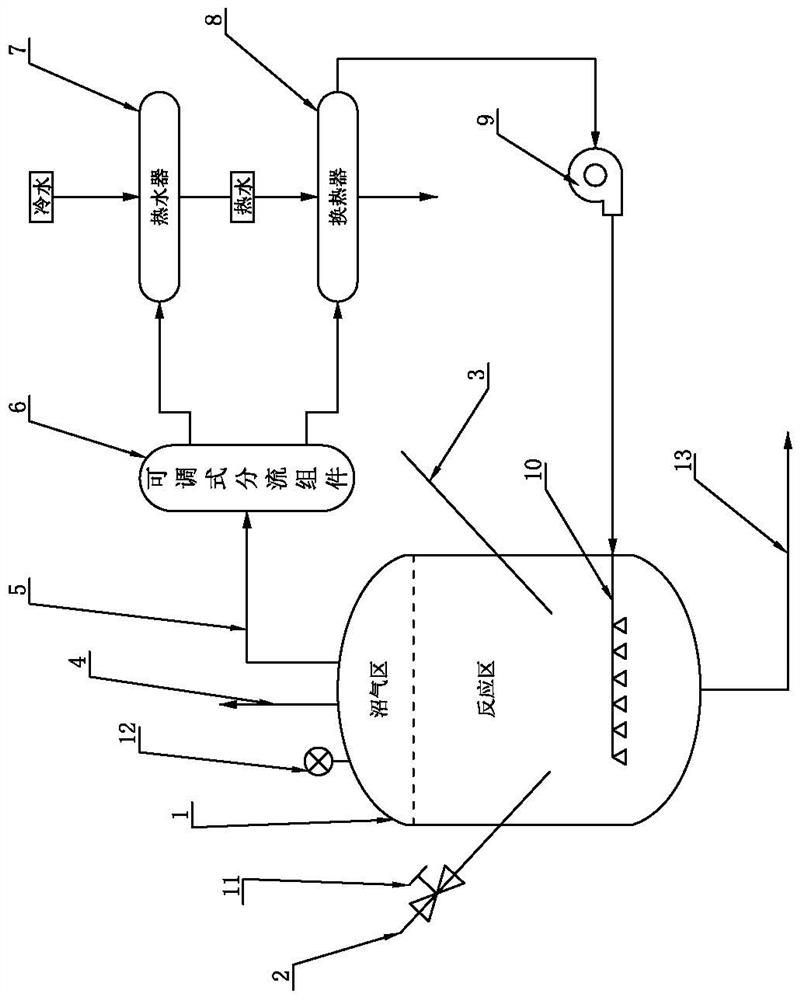

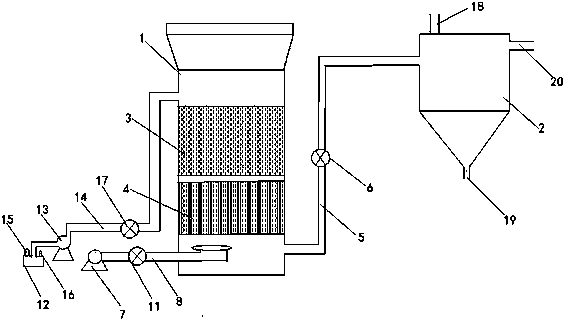

Self-heating temperature-controllable biogas system

ActiveCN111849722ASmooth feedingExhaust efficientlyBioreactor/fermenter combinationsBiological substance pretreatmentsProcess engineeringEnvironmental engineering

The invention discloses a self-heating temperature-controllable biogas system, which comprises a biogas digester, two sides of the biogas digester are respectively connected with a charging pipeline and a discharging pipeline; a biogas area is formed at the top of the biogas digester; the top of the biogas digester is connected with an exhaust pipeline; a control cabinet is arranged outside the biogas digester; the exhaust pipeline is connected with a water heater and a heat exchanger through an adjustable flow dividing assembly; the water outlet end of the water heater is connected with the heat exchanger; an adjustable shunting assembly comprises an air inlet and two air outlets; a gas inlet is connected with the exhaust pipeline, one air outlet is connected with the water heater to provide biogas for water heater combustion, and the other gas outlet is connected with the gas inlet of the heat exchanger, the gas outlet of the heat exchanger is connected with an aeration pipeline through a fan, and the aeration pipeline is used for circulating the heated biogas into the biogas digester, so that the reaction temperature in the biogas digester is maintained in a stable range, and the gas production efficiency is fully guaranteed.

Owner:江苏鑫林环保设备有限公司

Ruminant animal feed additive

InactiveCN108029873AHigh encapsulation rateReduce consumptionFood processingAnimal feeding stuffSpray coatingCalcium

The invention discloses a ruminant animal feed additive. The ruminant animal feed additive comprises the following components in parts by weight: 3 to 5 parts of bentonite, 1 to 1.5 parts of a ureaseinhibitor, 2 to 4 parts of an ion carrier, 6 to 6.8 parts of embedded amino acid and 8 to 10 parts of an organic carrier. The preparation method of the embedded amino acid comprises the following steps: wrapping the amino acid with palm oil fat powder to obtain oil sealed amino acid, performing reaction on a sodium carbonate solution with the concentration of 0.25 mol / L and a calcium chloride solution to form calcium carbonate to wrap the oil sealed amino acid to obtain calcium carbonate microspheres; and spray-coating the calcium carbonate microspheres with 5 to 6 parts of sodium carbonate with the concentration of 0.25 mo / L, performing secondary spray coating with 5 to 6 parts of calcium chloride with the concentration of 0.25 mol / L, performing reaction at 40 to 45 DEG C for 30 to 45 minutes, washing with water and drying to obtain the embedded amino acid. The problem that the traditional ruminant animal feed additive has a bad protective effect on the amino acid components is solved.

Owner:长沙善道新材料科技有限公司

Preparation method of special dispersion PTFE oleo-resin for thread seal tape

InactiveCN109957195AThe reaction rate is stableUniform molecular weight distributionIonAmmonium sulfate

The invention discloses a preparation method of special dispersion PTFE oleo-resin for a thread seal tape, comprising the following step: deionized water is used as a medium, perfluoropolyether ammonium carboxylate is used as an emulsifier, liquid paraffin is used as a stabilizer, ammonium persulfate is used as an initiator, sodium hydrogen sulfite is used as a reducing agent, succinic acid is used as a pH regulator, and tetrafluoroethene is used as a polymerization monomer; the polymerization temperature is 50-60 DEG C, and the pressure is 1.6-3.0 MPa; the reducing agent is added in the dilute solution form of 1% mass concentration at a constant speed within 90 min; and constant-pressure polymerization is conducted to obtain a mixed liquor of the PTFE emulsion and liquid paraffin; and themixed liquor of the PTFE emulsion and liquid paraffin is used as a base material to prepare a modified thread seal tape with special functionality.

Owner:江苏梅兰化工有限公司

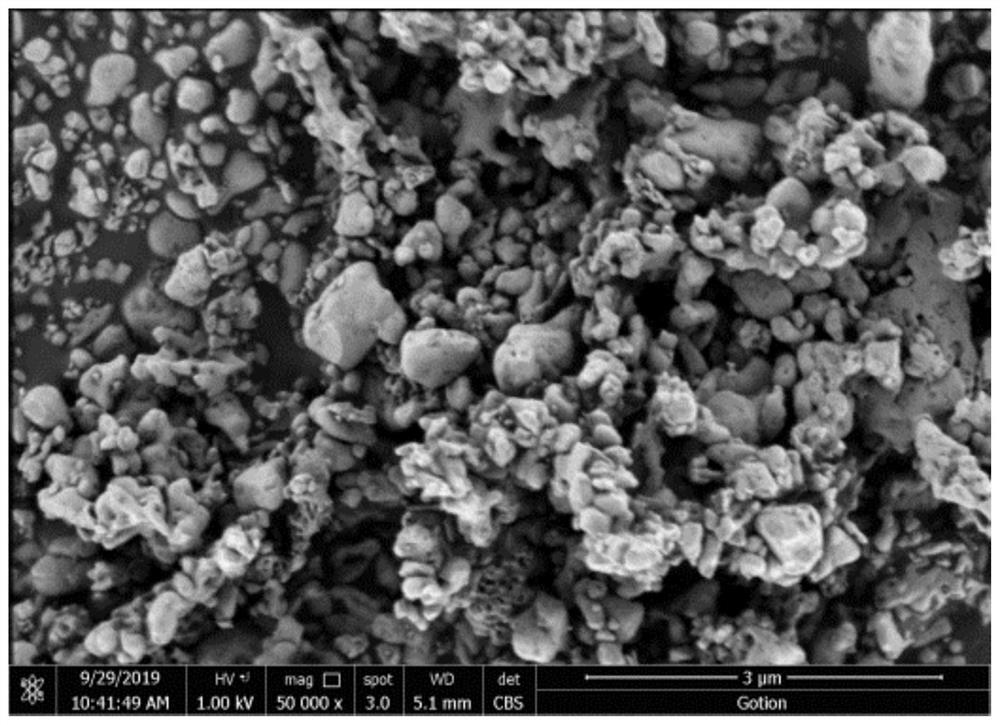

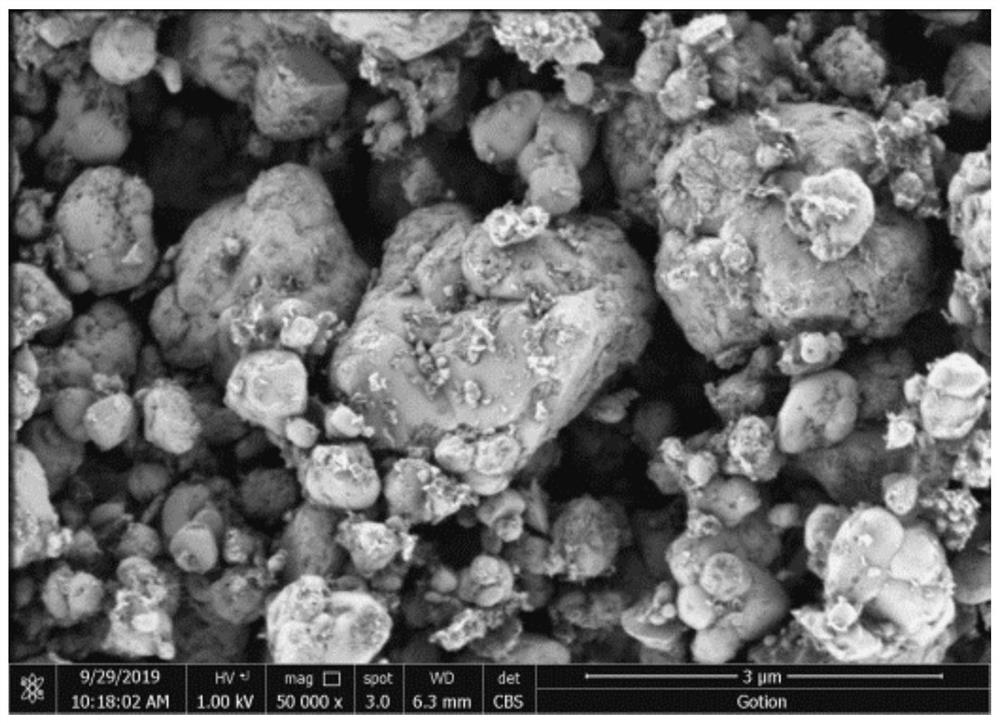

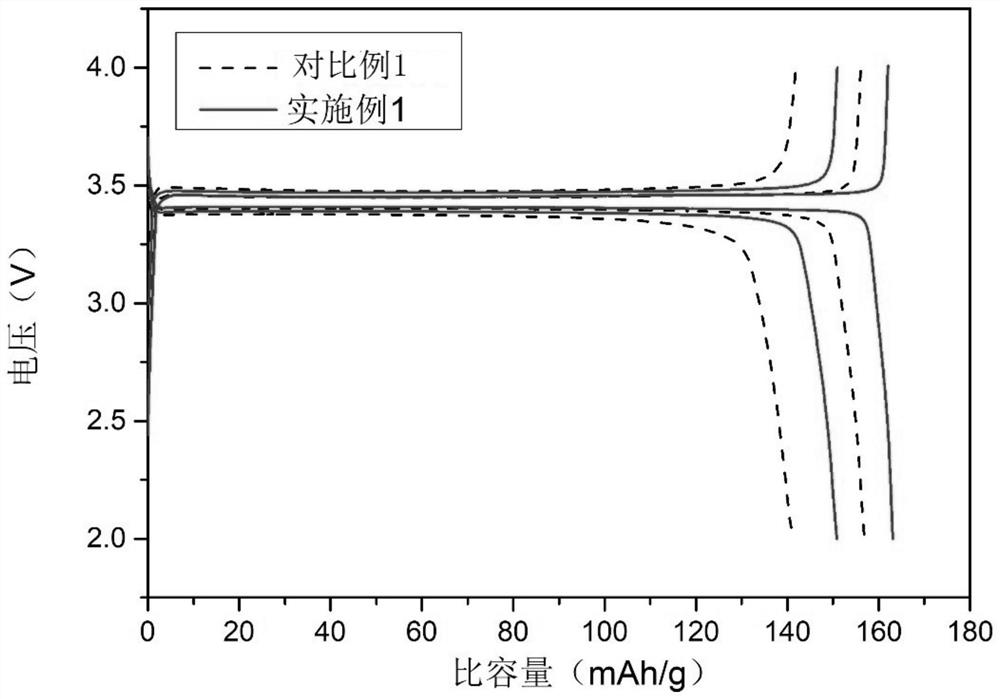

Lithium iron phosphate as well as preparation method and application thereof

ActiveCN113285071AIncrease nucleation numberEasy to wrapMaterial nanotechnologyCell electrodesLithium iron phosphatePhysical chemistry

The invention provides lithium iron phosphate as well as a preparation method and application thereof. The preparation method comprises the following steps of dispersing a lithium source with an emulsifier, and then adding a first initiator to carry out a first polymerization reaction to obtain an intermediate product A, adding a mixed solution of methyl methacrylate, a cross-linking agent and a second initiator into the intermediate product A, and carrying out a second polymerization reaction to obtain an intermediate product B, mixing the intermediate product B, an oxidant, an iron source and a phosphorus source, and carrying out a third reaction to obtain an intermediate product C, and dispersing the intermediate product C with a glucose solution, drying, and calcining to obtain the lithium iron phosphate. The invention also provides the lithium iron phosphate prepared by the preparation method. The invention further provides a positive electrode material which comprises the lithium iron phosphate. According to the preparation method, nanoscale lithium iron phosphate can be directly obtained, and procedures such as crushing and energy consumption in the manufacturing process are reduced. Elements in the lithium iron phosphate are uniformly distributed, and the lithium iron phosphate has good charging and discharging properties when being used as an electrode positive electrode material.

Owner:HEFEI GUOXUAN HIGH TECH POWER ENERGY

A kind of preparation method of high-performance water-soluble high-solid low-viscosity acrylic resin

ActiveCN108864359BStable temperatureThe reaction rate is stableAntifouling/underwater paintsPaints with biocidesPolymer scienceAcrylic resin

The invention discloses a method for preparing a high-performance water-soluble high-solid and low-viscosity acrylic resin. In a compound solvent system, the acrylic resin is prepared by continuous radical solution polymerization, and the resin is endowed with water solubility. Modified with tertiary carbonate, introducing a large branched chain structure, reducing the intermolecular force, lowering the viscosity of the resin, and making the high solid resin have a lower viscosity. The tertiary carbonic acid group significantly increases the water resistance and alcohol resistance of the paint film, significantly improves the toughness and impact resistance of the paint film, and has little effect on the hardness of the paint film. The present invention uses organosilicon to modify the acrylic resin to improve the properties of the paint film such as heat and humidity resistance and corrosion resistance; the amino resin is used as the curing agent to directly prepare water-based aminoacrylic acid baking varnish, and the paint film has hardness, fullness, water resistance and alcohol resistance. , salt spray resistance, etc., suitable for industrial coating of automobiles, bicycles, agricultural machinery and other industries, and can also be used for coating of fishing rods, wine bottles, dining tables and other industries that have certain requirements for resistance to humidity, heat and pollution.

Owner:INST OF APPLIED CHEM JIANGXI ACAD OF SCI +1

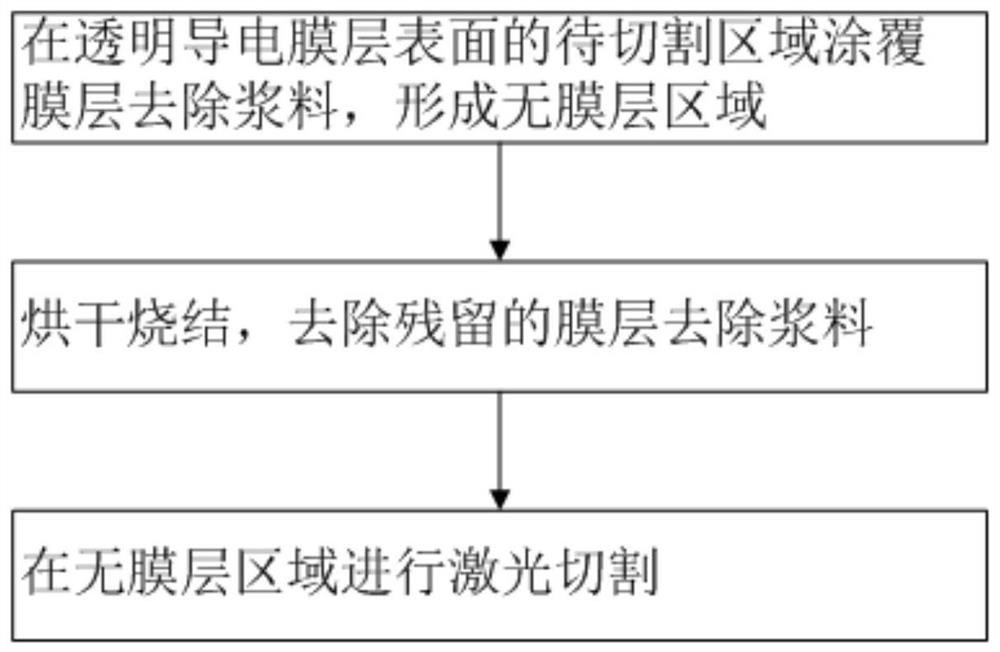

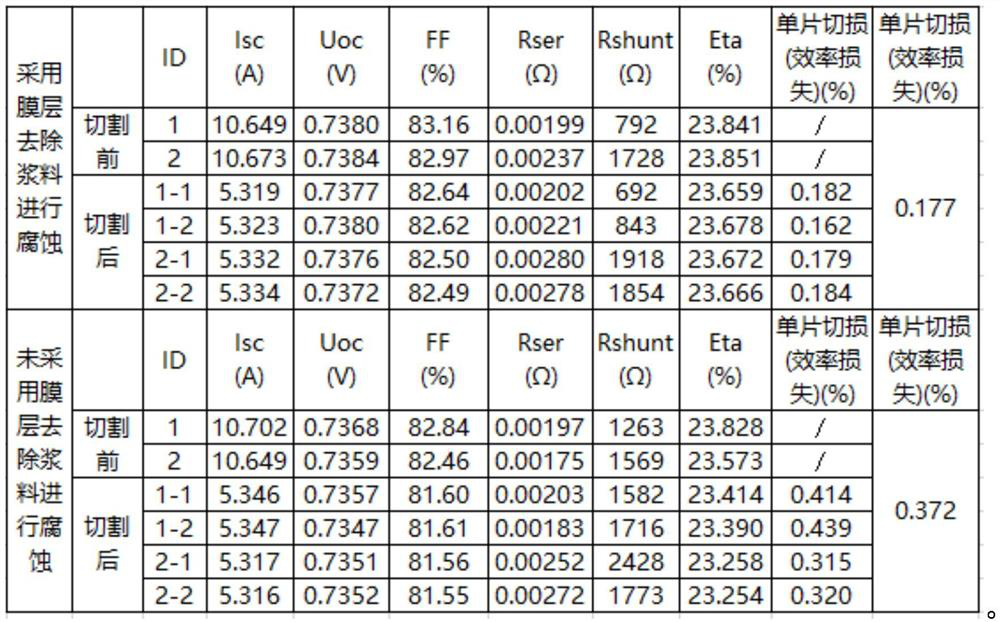

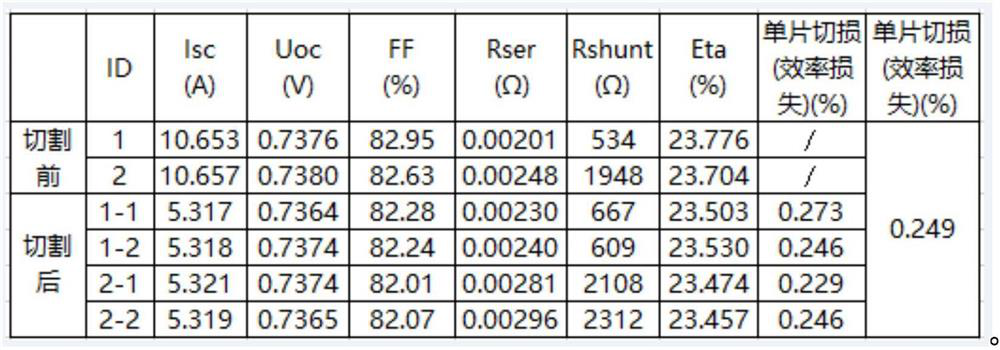

Film layer removal slurry, solar cell cutting method and semiconductor device scribing method

InactiveCN113372916ACleaning steps are stableAccelerated corrosionFinal product manufactureSemiconductor/solid-state device manufacturingDevice materialLaser cutting

The invention belongs to the technical field of semiconductor device preparation, and particularly relates to a film layer slurry removal method, a solar cell cutting method and a semiconductor device scribing method. The film layer removal slurry comprises, by volume, 2-10% of a medium-strong acid; 10-30% of a weak acid; 40-70% of a solvent; 5-20% of an auxiliary agent; and 5-15% of resin, wherein the sum of the volume percentages of the components is 100%. The solar cell cutting method comprises the following steps: coating a to-be-cut area on the surface of a transparent conductive film layer with a film layer to remove slurry so as to form a film-layer-free area; drying and sintering, and removing the residual film layer and slurry; and carrying out laser cutting on the film-free area. The transparent conductive film layer is selectively removed by coating the corrosion slurry, and the blank area is formed on the edge of the transparent conductive film layer; and the residual corrosion slurry can be removed in an inherent drying and sintering step in a battery piece manufacturing process, an additional slurry cleaning step does not need to be introduced, and the method has the advantages of low cost, simple process, high production efficiency and the like.

Owner:ANHUI HUASUN ENERGY CO LTD

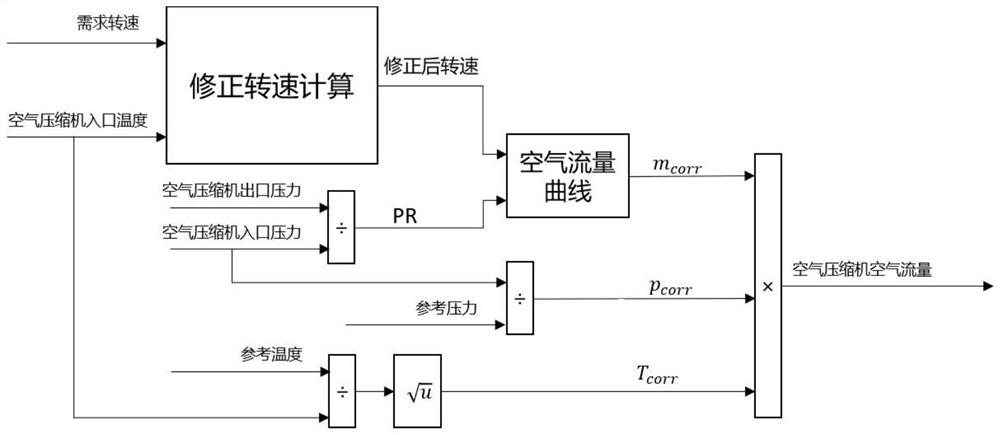

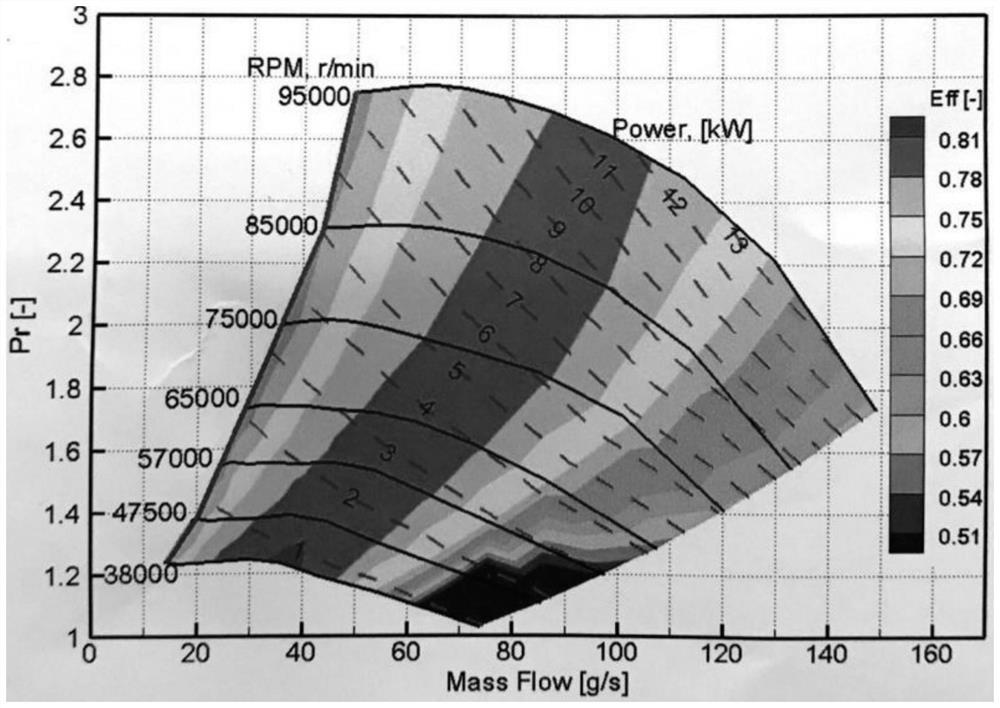

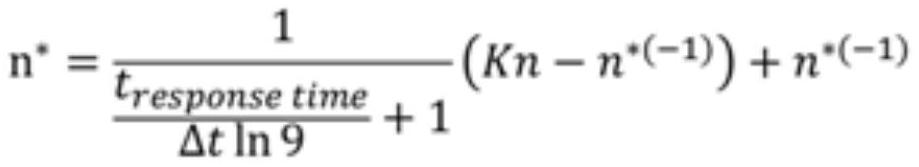

Method for calculating output air flow of air compressor of hydrogen fuel cell automobile

PendingCN114361521ASimple test methodReduce testing costsPump testingPositive-displacement liquid enginesHydrogen fuel cellEngineering

The invention relates to a method for calculating the output air flow of an air compressor of a hydrogen fuel cell automobile, and belongs to the technical field of hydrogen fuel cell automobiles. The method for calculating the output air flow of the air compressor of the hydrogen fuel cell automobile is used for calculating the actual output air flow of an air compressor of a fuel cell system; the method can improve the precision of air flow calculation, improve the efficiency of a fuel cell system, and improve the energy utilization rate.

Owner:KUNMING YUNNEI POWER +1

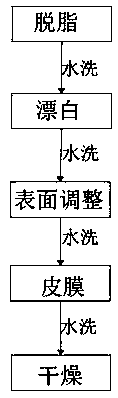

Lossless magnesium and magnesium alloy secondary formation method

InactiveCN109371405AReduce solubilitySlow reaction rateMetallic material coating processesReaction rateSediment

The invention discloses a lossless magnesium and magnesium alloy secondary formation method high in yield and low in cost, and belongs to the technical field of metal surface treatment. The problems that in the current magnesium and magnesium alloy secondary formation process, due to excessive corrosion, the defective rate is high, acid pickling liquid is frequently replaced, and the production cost is increased are solved. The method comprises the procedures of degreasing, bleaching, surface adjusting, membrane treatment and the like. According to the lossless magnesium and magnesium alloy secondary formation method, weak acid bleaching liquid is utilized for replacing the acid pickling liquid to remove disqualified membrane layers on the surfaces of workpieces, the reaction rate is slow,the rate is stable, the reaction can be adjusted in time, the surfaces of the workpieces without the membrane layers are flat, subsequent processing is convenient, and the product yield is high. Thesolubility of bleached products is small, a trace of sediments exist in water and can be separated out through concentration and cooling, removal can be achieved through a filter method, repeated usage can be achieved after a reagent is added in filter liquor in which the sediments are filtered out, and the product production cost is effectively reduced.

Owner:惠州市四维化工有限公司

A kind of preparation method of naphthalene series water reducing agent

The invention provides a method for preparing a naphthalene series water reducer. The method comprises the following steps: sulfonation: carrying out a sulfonation reaction of naphthalene and concentrated sulfuric acid; hydrolysis: adding water into the sulfonation reaction product for hydrolysis, and hydrolyzing a by-product in the sulfonation reaction; condensation: adding poly formaldehyde and water into the hydrolysis reaction product for condensation; and neutralization: adjusting pH of the condensation reaction product to be 6-8, and drying to obtain the naphthalene series water reducer. The preparation method has the advantages of simple and stable production process and easily controlled parameters, and the prepared naphthalene series water reducer product has stable performance and good quality.

Owner:JIANGSU SOBUTE NEW MATERIALS +1

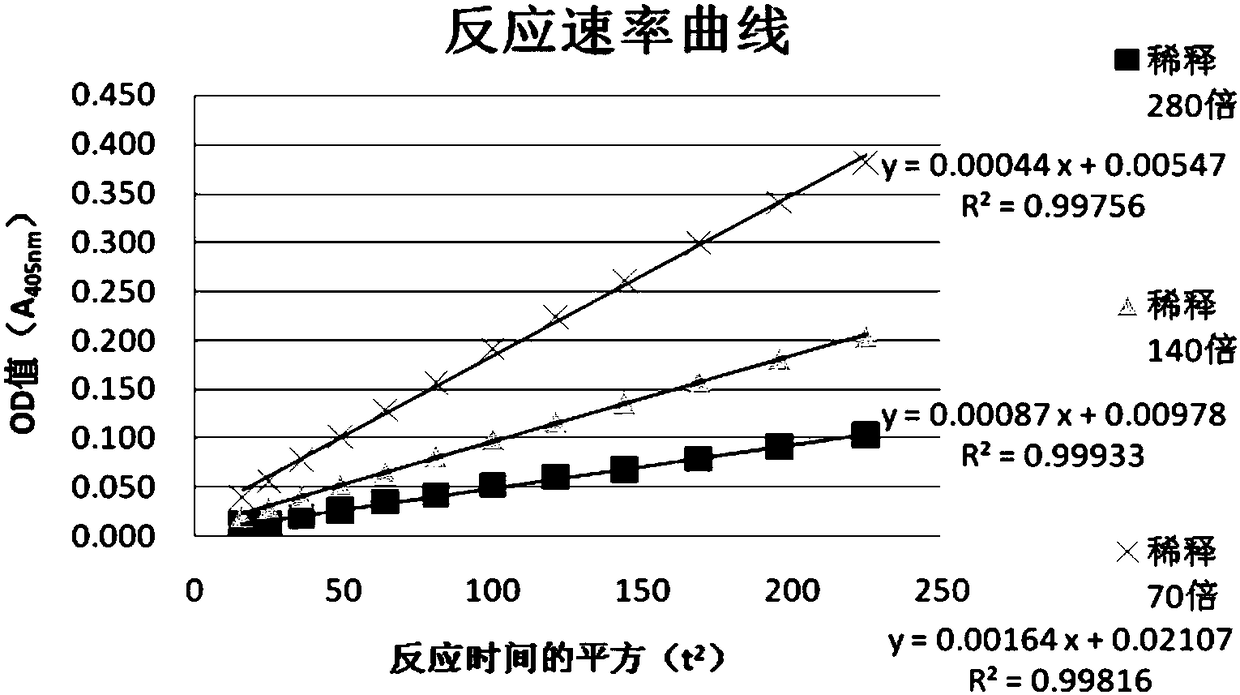

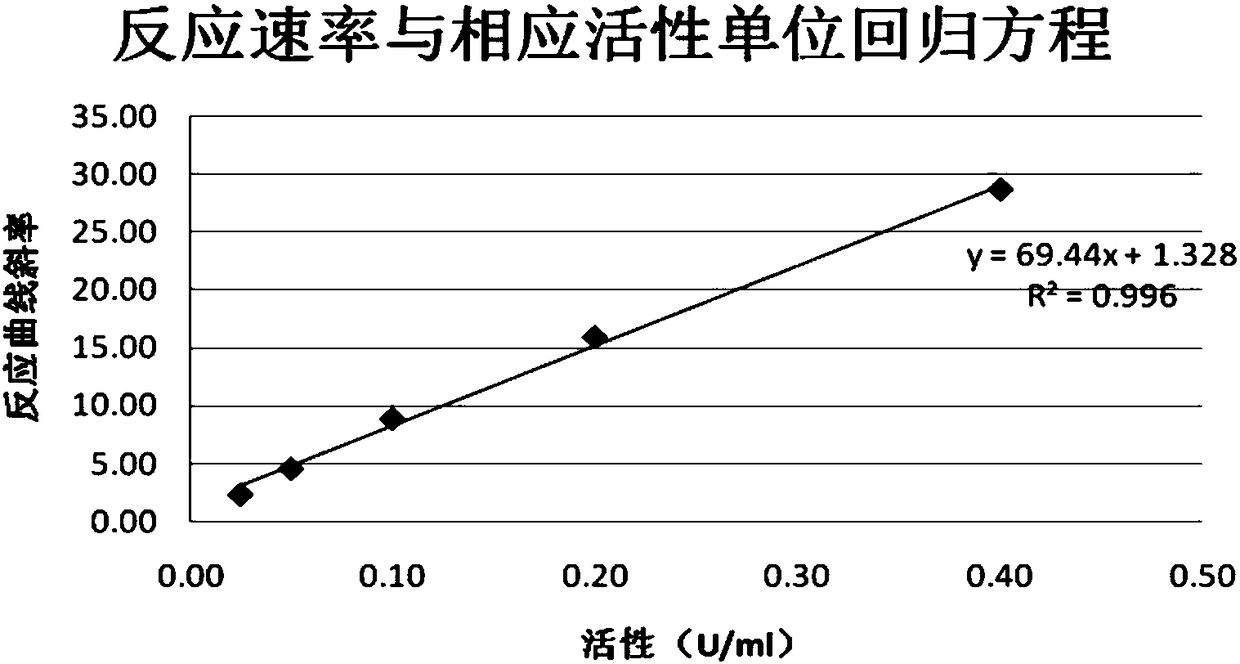

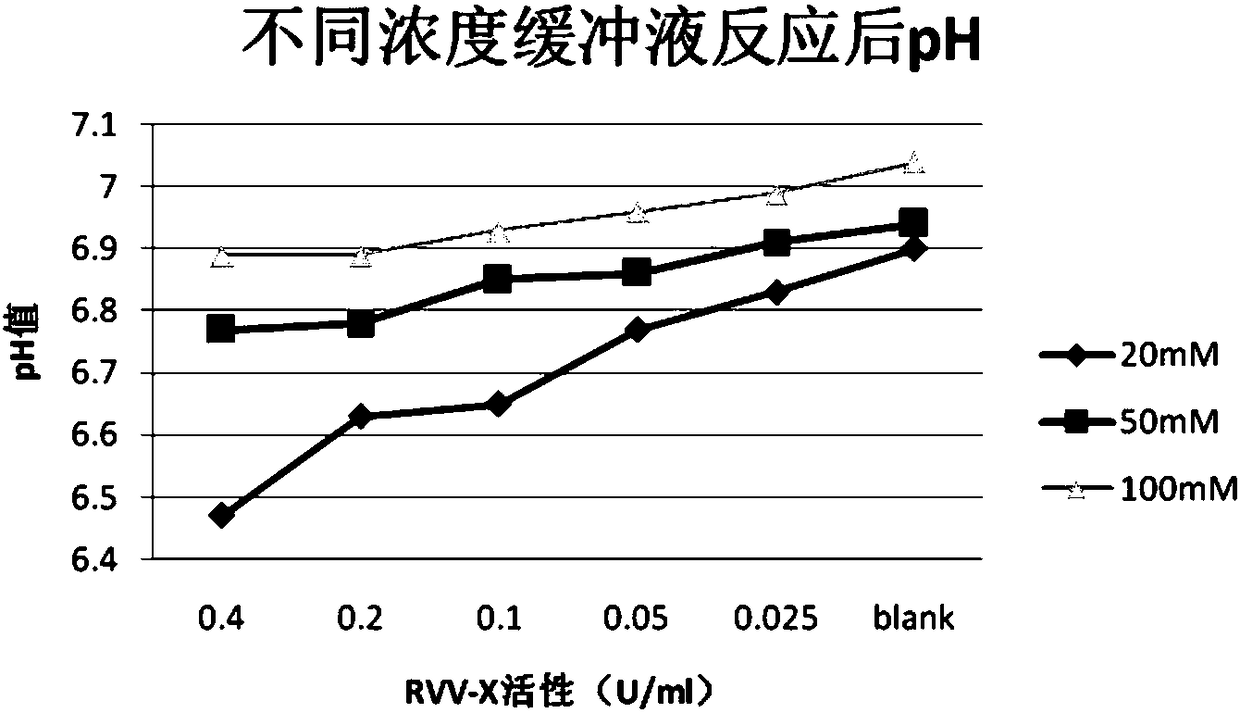

Method for calibrating activity of coagulation factor X activator

ActiveCN108089006AIncrease concentrationImprove buffering effectBiological material analysisBiological testingChromogenic SubstratesReaction rate

The invention discloses a method for calibrating activity of a coagulation factor X activator and belongs to the field of biotechnology. The steps are as follows: (1) adding coagulation factor X witha concentration of 22.5 mug / ml to 27.5 mug / ml, a chromogenic substrate solution, and a to-be-calibrated sample with a determined dilution ratio into an enzyme linked immunosorbent assay (ELISA) plate;wherein the chromogenic substrate solution is a solution obtained by evenly mixing a chromogenic substrate solution with the concentration of 4.5 mg / ml to 5.5 mg / ml with a CaCl 2 solution in a volumeratio of 4:3, the volume ratio of the coagulation factor X to the chromogenic substrate solution to the to-be-calibrated sample is 30:23:7, and at least 2 parallel ways are arranged in the same sample; (2) putting the ELISA plate into an ELISA instrument for reading of OD value; (3) taking the OD value of the reaction period of 4 to 15 minutes, and performing linear regression on the average OD value of the parallel ways and the square of the reaction time to obtain a reaction curve; and (4) selecting the slope of the reaction curve, defining the activity unit, and multiplying the dilution ratio of the to-be-calibrated sample to obtain the activity of the to-be-calibrated sample. The method has the advantages of simple operation, stable reaction rate, high calibration precision and high accuracy.

Owner:STAIDSON (BEIJING) BIOPHARMACEUTICALS CO LTD +1

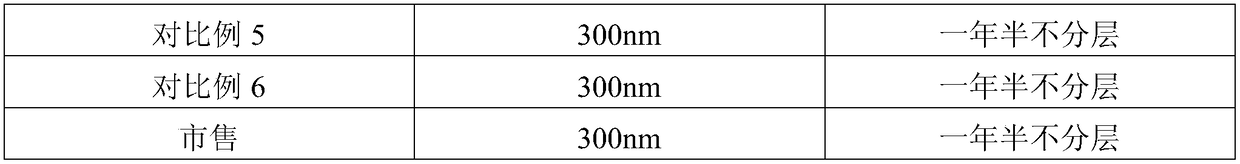

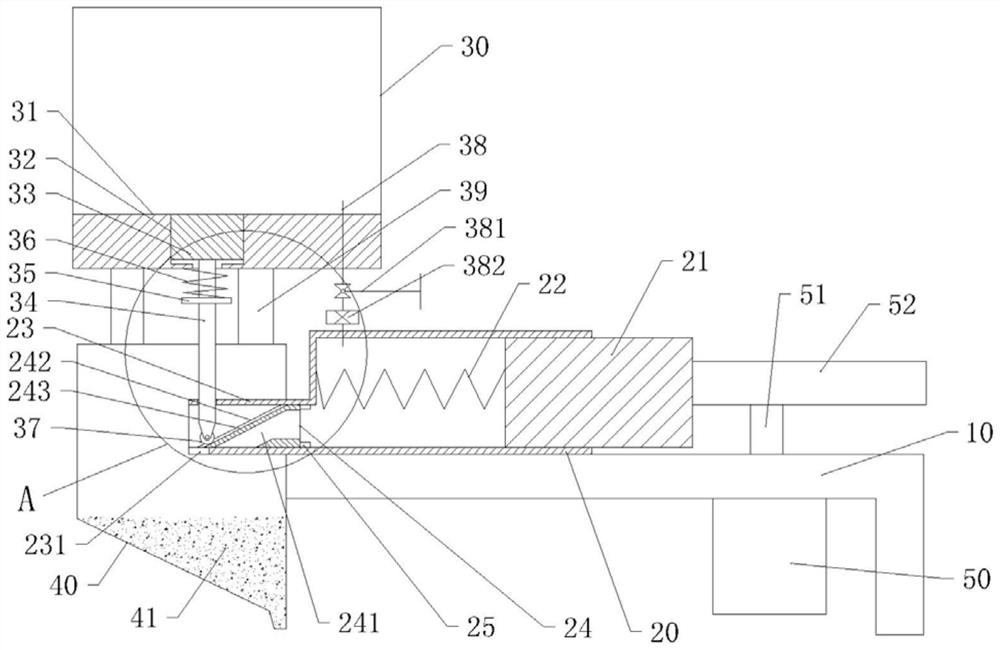

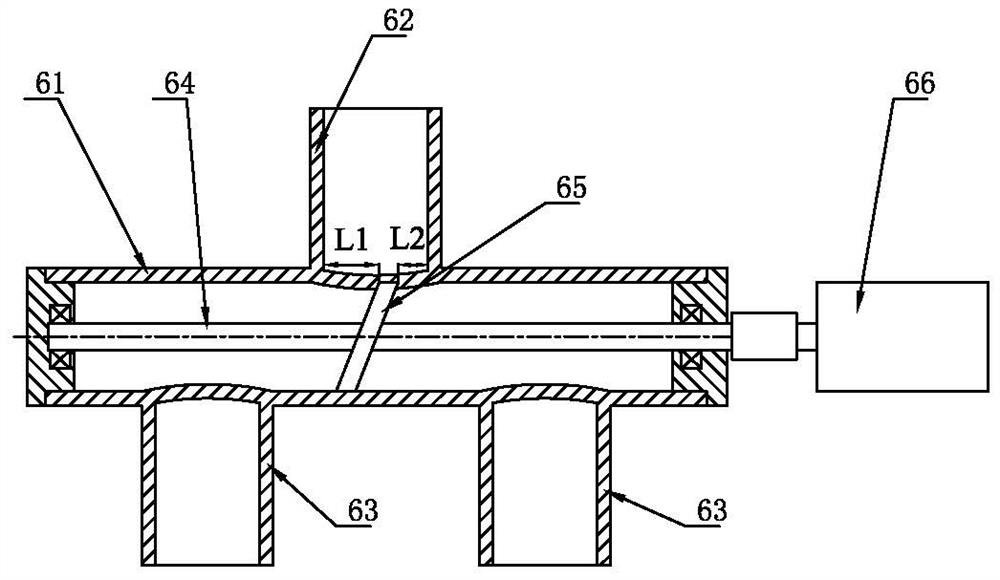

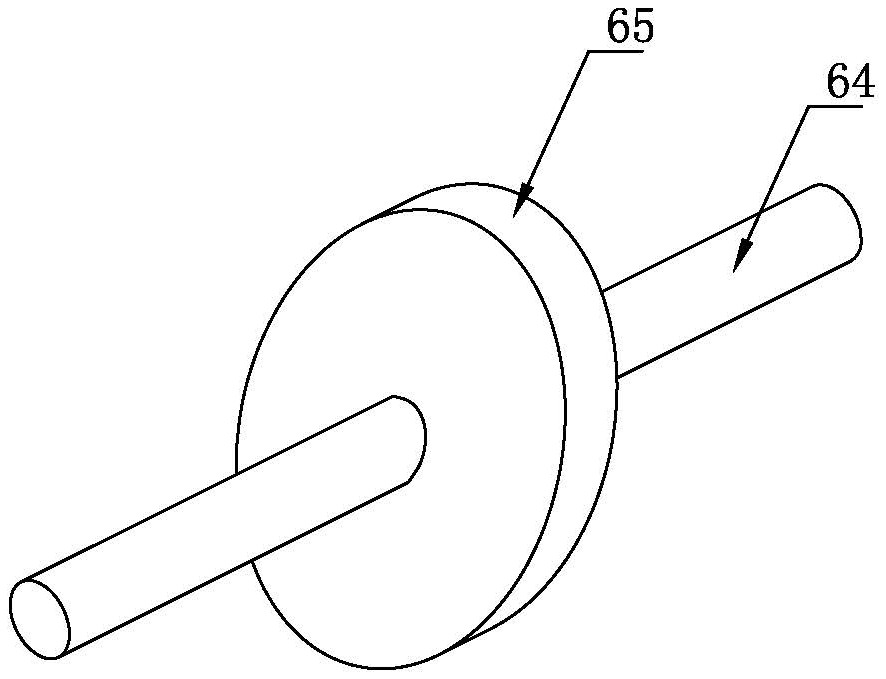

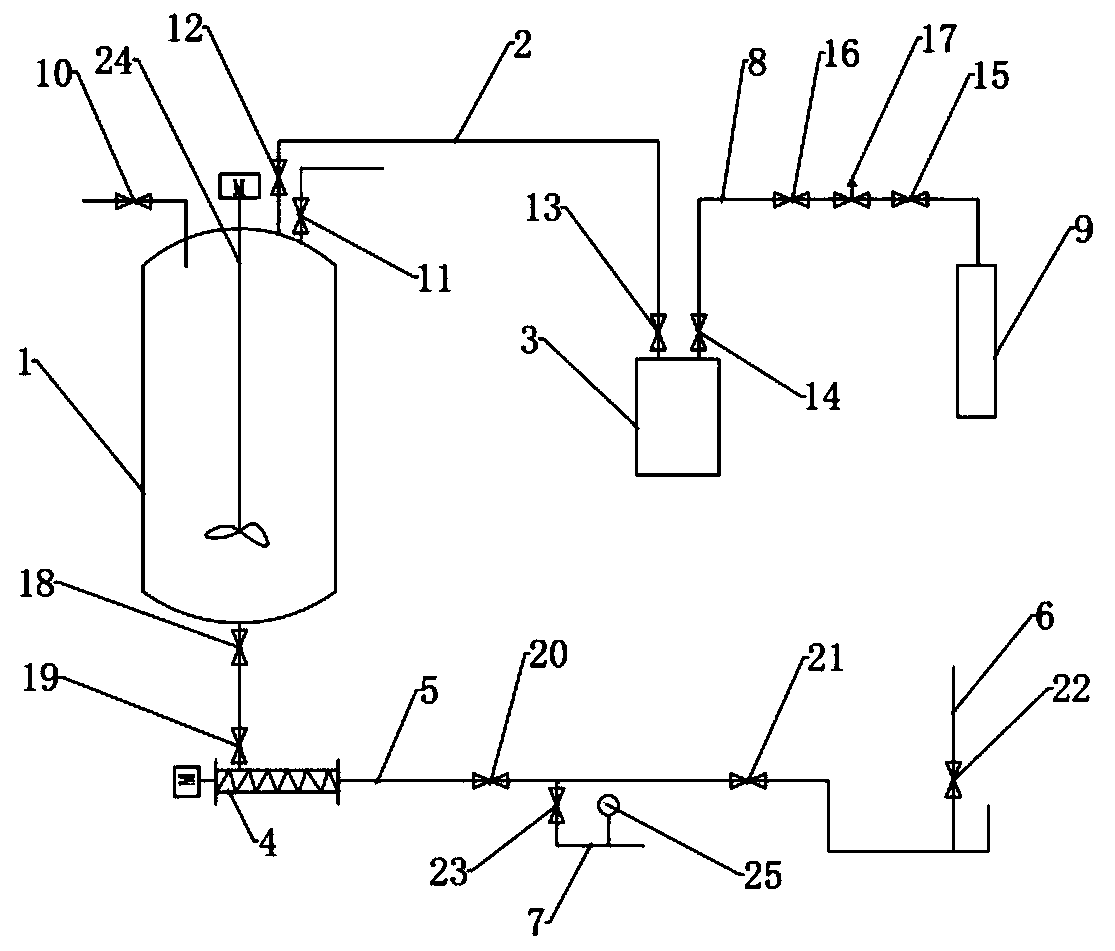

Catalyst adding device and method for continuous production of polypropylene

PendingCN111215006AEvenly dispersedImprove concentration stabilityChemical/physical processesPtru catalystReaction rate

The invention discloses a catalyst adding device and method for continuous production of polypropylene, and belongs to the technical field of polypropylene production. The device includes a stirring tank, the top of the stirring tank is connected to a charging barrel through a charging pipeline, an outlet end of the charging pipeline is connected to the charging barrel, an inlet end of the charging pipeline is connected to the stirring tank, a mixture of a catalyst and white oil is contained in the charging barrel, a discharge port is formed at the bottom of the stirring tank, the discharge port is connected to a screw pump through a pipeline, the screw pump is connected to a propylene pipeline through a discharge pipeline, the discharge pipeline is further connected to a propylene flushing pipeline, and the charging barrel is connected to a nitrogen cylinder through a nitrogen pipeline. The powdery catalyst is uniformly dispersed in the white oil, so that the concentration stability of the catalyst is improved when the catalyst is added into a production system, the mixture of the catalyst and the white oil is quantitatively and uniformly added into the system at a constant speedby using a screw pump, and the purposes of stabilizing the reaction rate and stabilizing the production are achieved.

Owner:SHANDONG ORIENT HONGYE CHEM

Method for producing the yellow pigment of ferric oxide from ferrous sulphate of byproduct abolished by titanium white

InactiveCN100396734CHigh recovery rateAchieve the purpose of separationPigmenting treatmentFerric oxide yellowTitanium oxide

A process for preparing iron oxide yield pigment from ferrous sulfate as the by-product of titanium oxide includes such steps as reducing iron scale at 50-70 deg.c, hydrolyzing for 6-10 hr, flocculating, deposition, refining ferrous sulfate, neutralizing with ammonia to generate crystal seeds, and neutralizing with ammonia while oxidizing with air to obtain target product. Its by-product, solution of ammonium sulfate, can be used for preparing composite fertilizer.

Owner:CNOOC CHANGZHOU PAINT & COATINGS IND RES INST

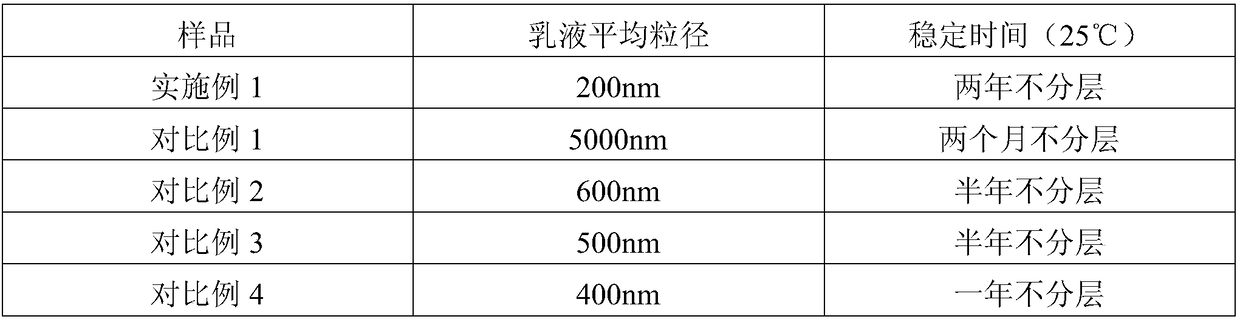

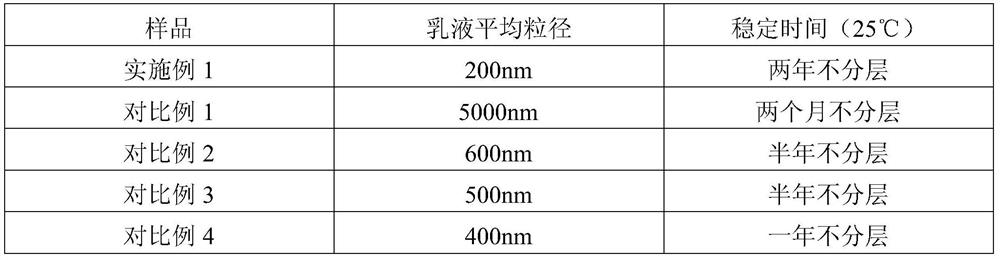

A kind of cationic rosin gum emulsifier and preparation method thereof

ActiveCN108396589BAdjust molecular weightAvoid interferenceWater-repelling agents additionPolymer sciencePotassium sodium tartrate

The invention provides a cationic rosin size emulsifier and a preparation method thereof. The cationic rosin size emulsifier is prepared from dimethylaminoethyl methacrylate, styrene, chitosan, glacial acetic acid, water, acrylic acid, acrylamide, potassium sodium tartrate and an initiator. The obtained emulsifier has a good stability, can be used to directly emulsify rosin, and has the advantagesof small use amount, good effect and low cost, a rosin size emulsion obtained after emulsification has nanoscale particles and a stable quality, and can be stably stored (at -5 to 50 DEG C) for a long time; and the rosin size emulsion obtained after emulsification is applied to sizing, has the advantages of small use amount of other sizing additives, small use amount of a sizing agent, good effect and low cost, and makes sized paper have certain antibacterial and bactericidal effects and good durability.

Owner:辽宁兴东科技有限公司

A kind of graphene catalyst supported by metal particles and preparation method thereof

InactiveCN112536030BReduce generationPromote positive responseCatalyst protectionOrganic compound preparationDoped graphenePtru catalyst

The invention discloses a graphene catalyst supported by metal particles and a preparation method thereof, belonging to the technical field of catalysts. The present invention adds platinum dioxide, graphene, diphenylamine, bromobenzene, and carbon nanotubes, wherein platinum dioxide and carbon nanotubes are doped, and graphene is combined with diphenylamine and triphenylamine after halogenation. Graphene and carbon nanotubes were hot pressed to form a new catalyst. In the present invention, the combination of carbon nanotubes and graphene is selected on the carrier, which increases the contact area between the catalyst and the two reaction substances. On the other hand, it can increase the thermal stability of the catalyst. Platinum dioxide is selected as the catalyst in the design. Added diphenylamine and halogen, on the one hand, can enhance the activity of platinum dioxide, on the other hand, can increase the stability of the catalyst, and improve the life and effect of the catalyst.

Owner:浙江胜烯环境科技有限公司

Chemical waste liquid treatment device

InactiveCN109179871AImprove biodegradabilityHigh removal rateMultistage water/sewage treatmentWater/sewage treatment by neutralisationCompound (substance)Catalytic oxidation

The invention discloses a chemical waste liquid treatment device, which belongs to the technical field of waste liquid treatment. The chemical waste liquid treatment device comprises a first waste liquid treatment tank and a second waste liquid treatment tank, wherein the first waste liquid treatment tank is provided with a micro-electrolytic layer and a catalytic oxidation layer in order from topto bottom, the bottom of the first waste liquid tank is provided with an aeration device, the first waste liquid treatment tank is connected to a waste liquid transport mechanism, and the first wasteliquid treatment tank is connected with the second waste liquid treatment tank through a first conveying pipe, the first conveying pipe is provided with a first valve, and the chemical waste liquid treatment device can effectively treat the chemical wastewater.

Owner:ZHENGZHOU INST OF TECH

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com