Preparation method for synthesizing high-performance polycarboxylate superplasticizer from novel VPEG polyether

A technology of polycarboxylic acid and water reducing agent, which is applied in chemical instruments and methods, feeding devices, chemical/physical processes, etc., and can solve problems such as unsatisfactory water reducing effect and slump retention performance, long reaction cycle, and high reaction temperature

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

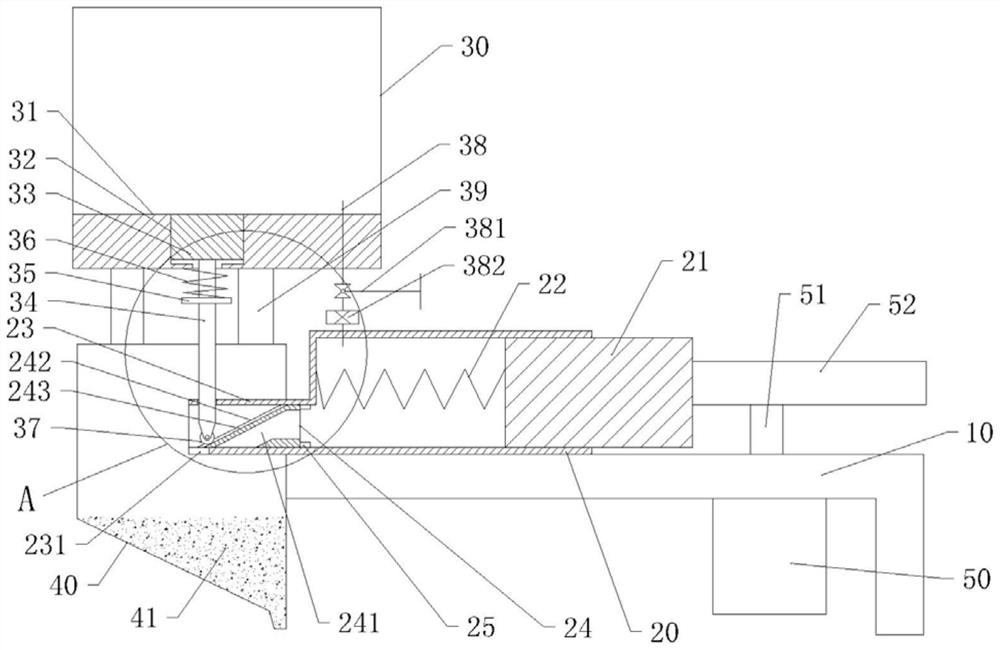

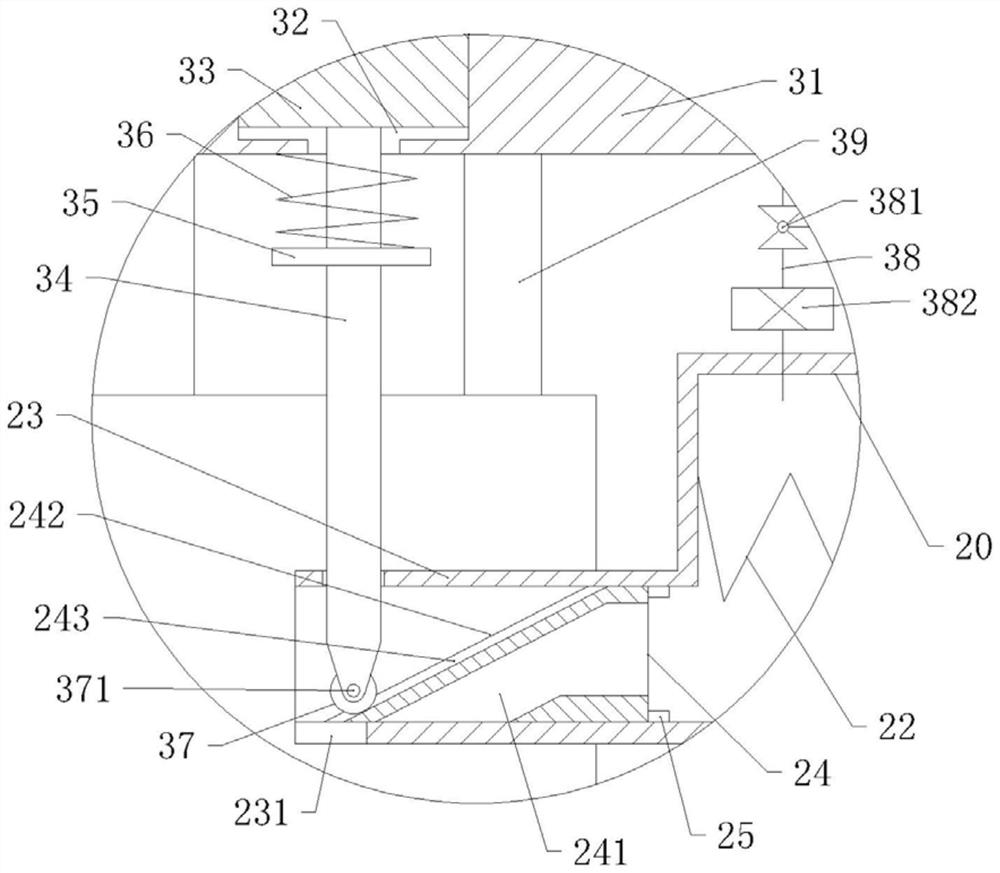

Image

Examples

Embodiment 1

[0047] Step 1, preparation of bottom liquid: dissolve 90 parts of VPEG polyether macromonomer and 0.1 part of mercaptopropionic acid in 100 parts of tap water, stir and dissolve into a uniform and transparent solution, then add 1 part of acrylic acid and 1.8 parts of 30% mass fraction After stirring evenly, add 0.004 part of FeSO4 and 0.5 part of hydrogen peroxide with a mass fraction of 27.5% and stir evenly to form the bottom liquid;

[0048] Step 2, preparation of auxiliary liquid: 9 parts of acrylic acid, 0.4 part of γ-aminoethylaminopropyl trimethoxysilane, 0.4 part of mercaptopropionic acid and 10 parts of tap water are made into dripping liquid A material; 0.3 part of vitamin C and 20 parts of tap water are prepared into dripping liquid B material;

[0049] Step 3, blending and synthesis: after adding hydrogen peroxide in step 1 for 5 minutes, use a dropping device to add dropping liquid A and dropping liquid B into the bottom liquid in step 1 at the same time at room t...

Embodiment 2

[0052] Step 1, preparation of bottom liquid: dissolve 100 parts of VPEG polyether macromonomer and 0.2 part of mercaptoethanol in 100 parts of tap water, stir and dissolve into a uniform and transparent solution, add 3 parts of acrylic acid and 5.5 parts of 30% mass fraction of NaOH solution, after stirring evenly, add 0.006 part of FeSO4 and 0.7 part of ammonium persulfate and stir evenly to form a bottom liquid;

[0053] Step 2, preparation of auxiliary liquid: 9 parts of acrylic acid, 0.5 part of γ-aminoethylaminopropyl trimethoxysilane, 0.5 part of mercaptoethanol and 10 parts of tap water are made into dripping liquid A material; 0.5 part of hanging white block and 20 parts of tap water are made into dripping solution B material;

[0054] Step 3, blending and synthesis: after adding ammonium persulfate in step 1 for 5 minutes, use a dropping device to add dripping liquid A and dropping liquid B into the bottom liquid in step 1 at a constant speed at room temperature and s...

Embodiment 3

[0057] Step 1, preparation of bottom liquid: dissolve 120 parts of VPEG polyether macromonomer and 0.2 part of thioglycolic acid in 120 parts of tap water, stir and dissolve into a uniform and transparent solution, add 3 parts of acrylic acid and 5.5 parts of 30% mass fraction of NaOH solution, after stirring evenly, add 0.007 part of FeCl2 and 1 part of potassium persulfate and stir evenly to form a bottom liquid;

[0058] Step 2, auxiliary liquid preparation: 9 parts of acrylic acid, 0.6 parts of γ-glycidyl etheroxypropyl trimethoxysilane, 0.4 parts of mercaptoacetic acid and 10 parts of tap water are made into dripping liquid A material; 0.4 parts of E51 and 20 parts of Tap water is made into dripping liquid B material;

[0059] Step 3, blending and synthesis: after adding potassium persulfate in step 1 for 5 minutes, use a dripping device to add dripping liquid A and dripping liquid B into the bottom liquid in step 1 at a constant speed at room temperature and stir, drop ...

PUM

| Property | Measurement | Unit |

|---|---|---|

| particle diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com