Solution concentration monitoring method

A solution concentration, solution technology, applied in measuring devices, instruments, scientific instruments, etc., can solve the problem of high cost of monitoring solution concentration

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] In order to make the content and protection scope of the present invention clearer and easier to understand, the content of the present invention will be described in detail below in conjunction with the accompanying drawings.

[0033] The inventor found a new method to simulate and monitor the concentration of SC1 through multiple experiments and data analysis and summarized the rules. The experimental results confirmed that the etching rate of polysilicon is different for different concentrations of SC1, and within a certain concentration range The etch rate is relatively stable. So we take advantage of this feature to simulate the concentration of SC1 by testing the etching rate of SC1 with a polysilicon control chip. This is completely different from the professional equipment for monitoring SC1 concentration commonly used in the industry at present.

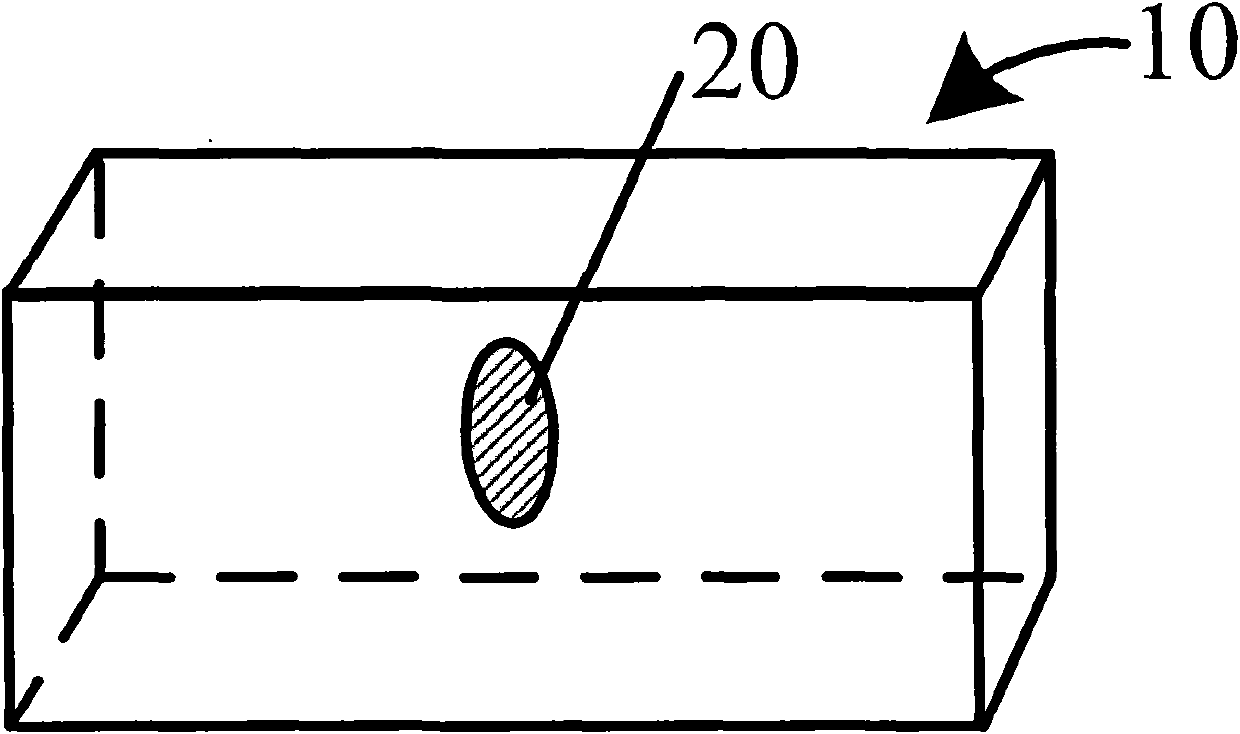

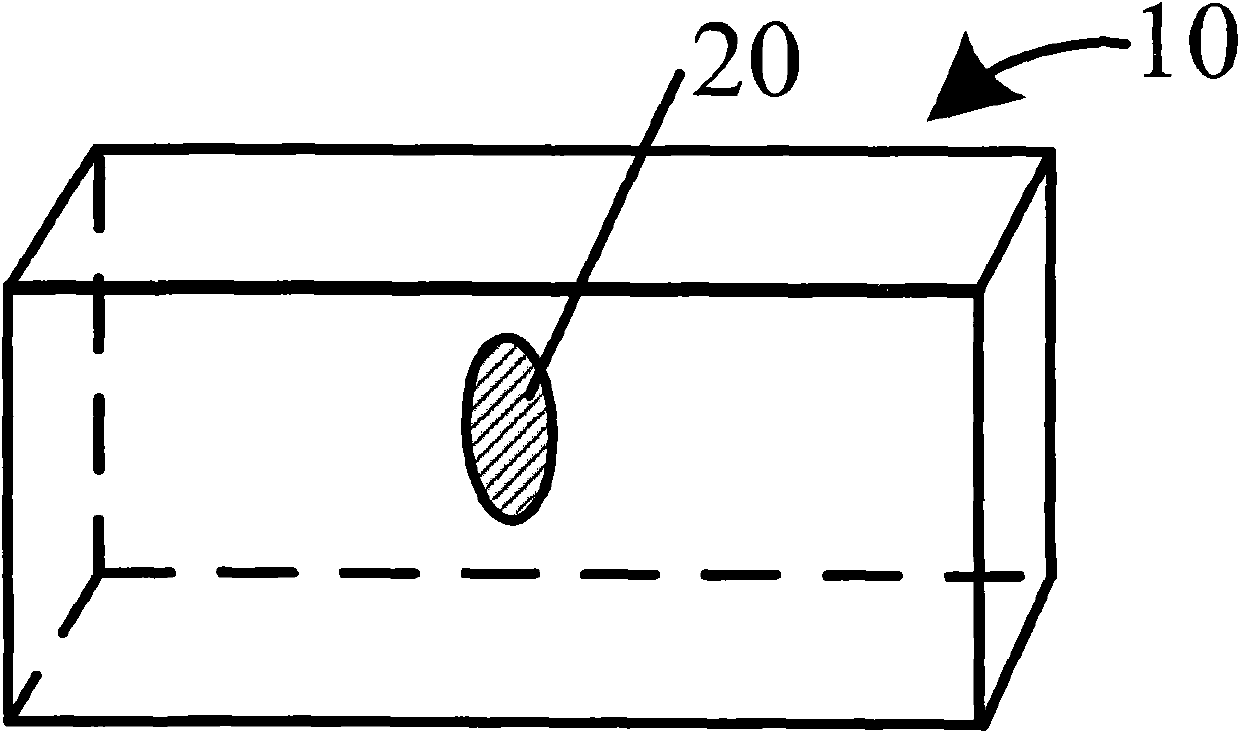

[0034] figure 1 It is a schematic diagram of soaking the polysilicon control chip into the solution. figure 1 In...

PUM

| Property | Measurement | Unit |

|---|---|---|

| thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com