Quantitative monitoring method for hexavalent chromium in foil washing water

A technology for hexavalent chromium and foil washing water, which is applied in the field of hexavalent chromium determination, can solve the problems of increasing the difficulty of hexavalent chromium wastewater treatment, interfering with water treatment procedures, and large fluctuations in content, so as to reduce the treatment difficulty and reduce the cost. , the effect of simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

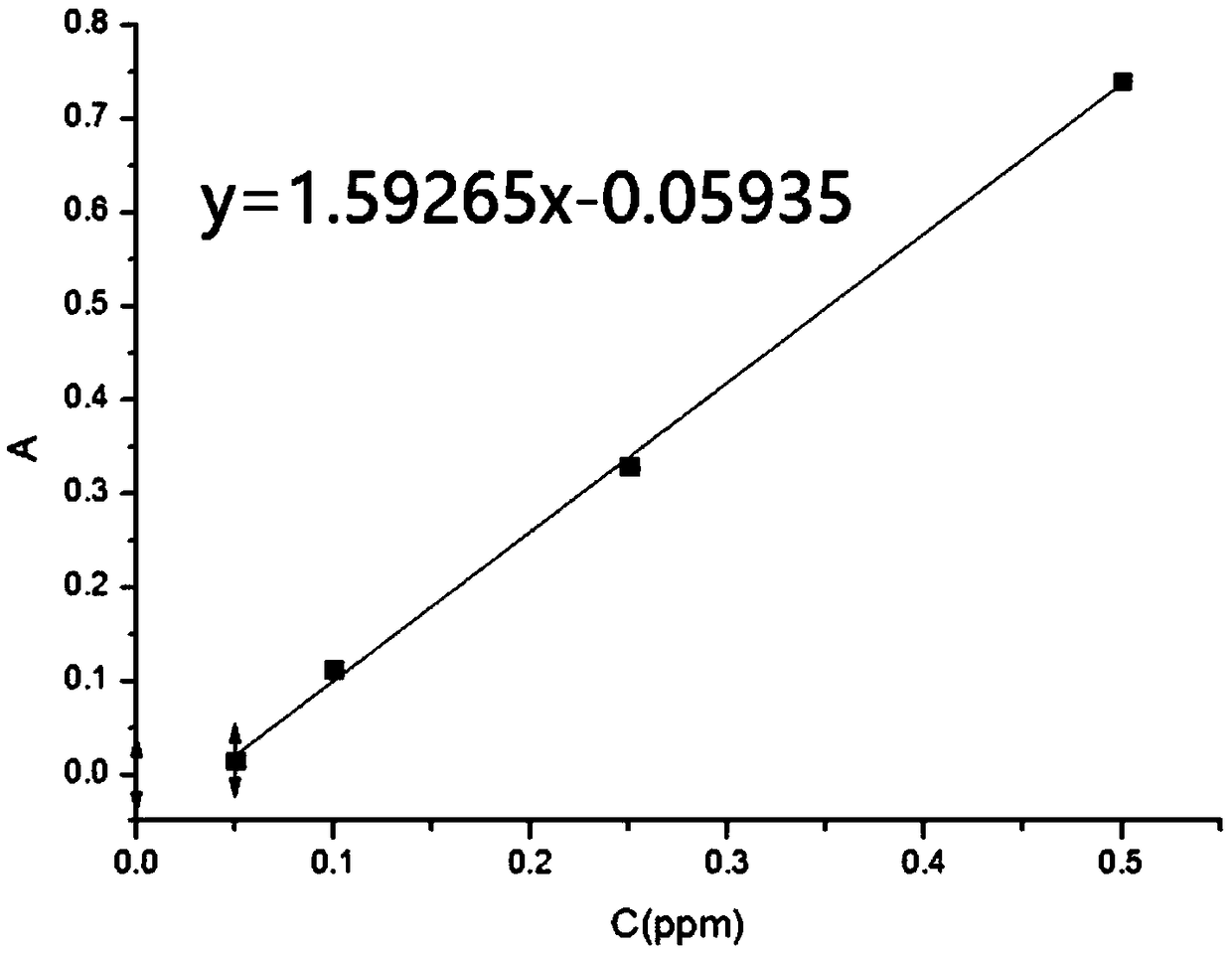

[0042] Take four 25ml volumetric flasks, and add different volumes of 5ppm hexavalent chromium standard solution, respectively, in the amounts of 0.25ml, 0.50ml, 1.25ml, and 2.50ml. Add 1 ml of mixed acid and 1.0 ml of chromogenic agent to the above four volumetric flasks, dilute to the mark with water, shake well, and make standard chromogenic solutions containing different concentrations of hexavalent chromium. After standing for 20 minutes for color development, use The single-wavelength method measures the absorbance of each standard chromogenic solution on a spectrophotometer, and inputs the absorbance-concentration value into the instrument for linear fitting to obtain a standard curve. The coefficient of determination of the curve calibration is 0.9987, and the linear relationship is very good, indicating that the standard curve is qualified. The obtained standard curve is as figure 1 shown;

[0043] Use a pipette to take 5.00 ml of foil washing water, transfer it int...

Embodiment 2

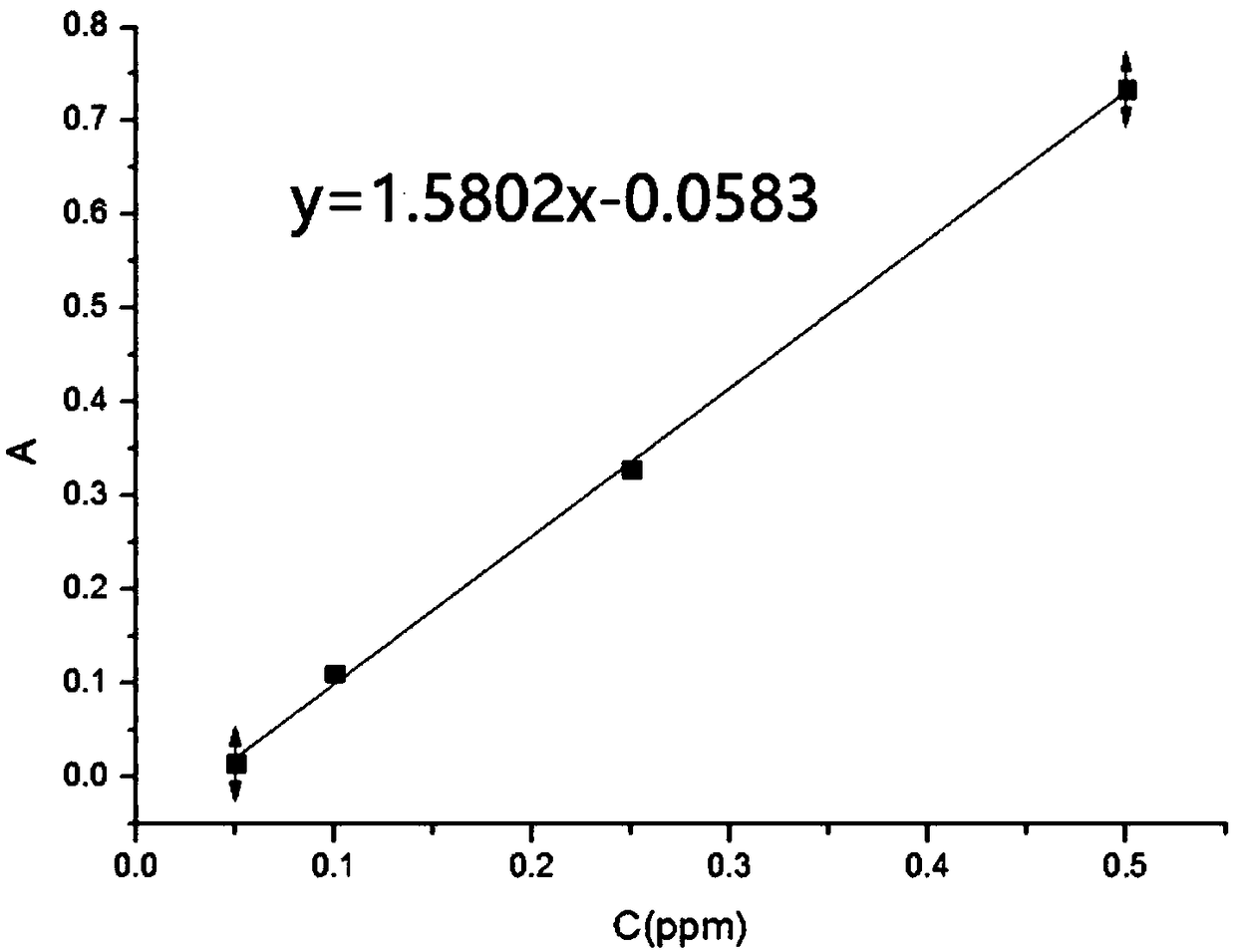

[0052] Take four 25ml volumetric flasks, and add different volumes of 5ppm hexavalent chromium standard solution, respectively, in the amounts of 0.25ml, 0.50ml, 1.25ml, and 2.50ml. Add 1 ml of mixed acid and 2.0 ml of color developer to the above four volumetric flasks, dilute to the mark with water, shake well, and make standard color developer solutions containing different concentrations of hexavalent chromium. In the wavelength method, the absorbance of each standard chromogenic solution is measured on a spectrophotometer, and the absorbance-concentration value is input into the instrument to obtain a standard curve. The coefficient of determination of the curve calibration is 0.9989, and the linear relationship is very good, indicating that the standard curve is qualified. The obtained standard curve is as figure 2 shown;

[0053]Use a pipette to take 2.00 ml of foil washing water, transfer it into a 1000 ml volumetric flask, dilute with water to the mark, and shake w...

Embodiment 3

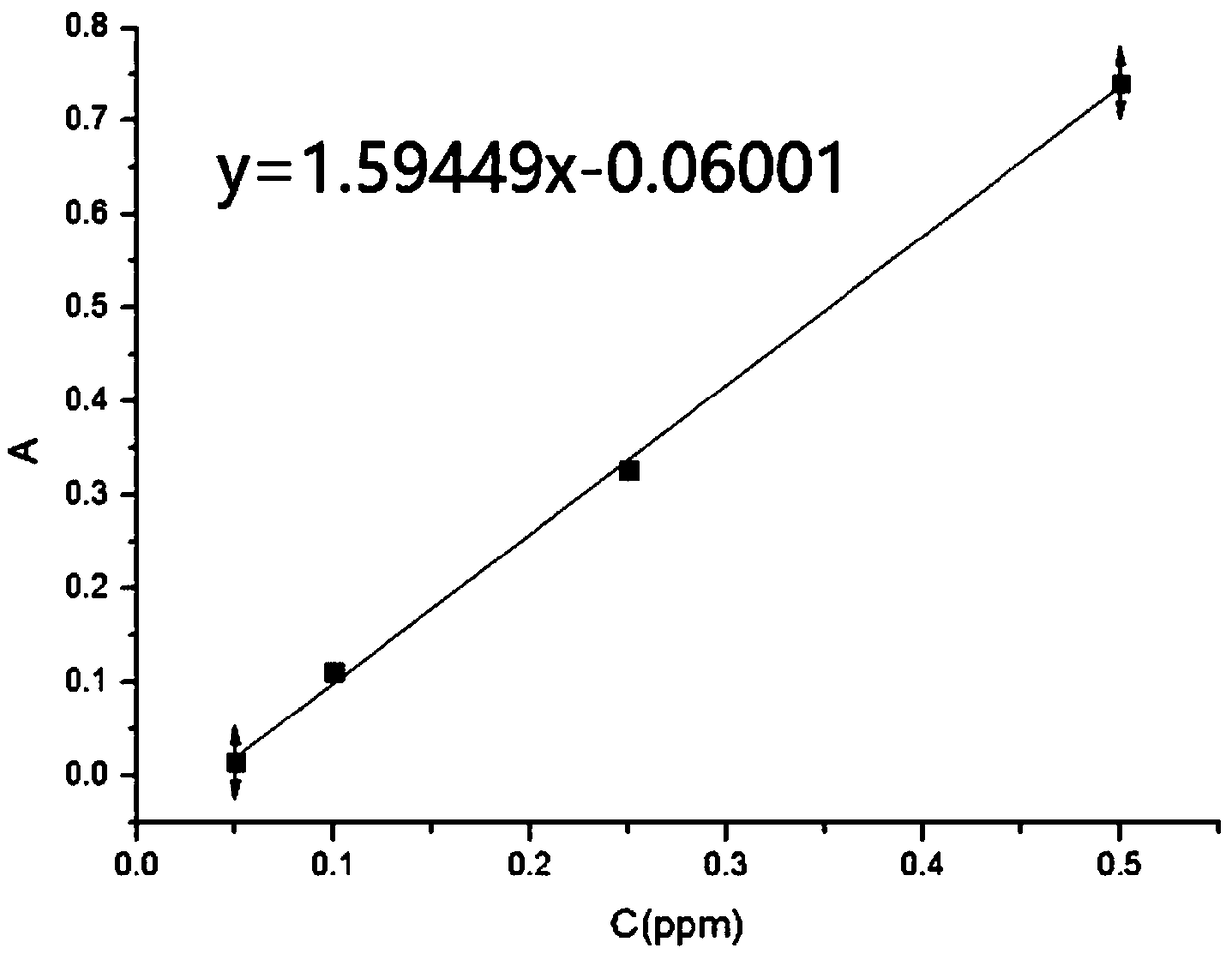

[0062] Take four 25ml volumetric flasks, and add different volumes of 5ppm hexavalent chromium standard solution, respectively, in the amounts of 0.25ml, 0.50ml, 1.25ml, and 2.50ml. Add 1 ml of mixed acid and 3.5 ml of color developer to the above four volumetric flasks, dilute to the mark with water, shake well, and make standard color developer solutions containing different concentrations of hexavalent chromium. In the wavelength method, the absorbance of each standard chromogenic solution is measured on a spectrophotometer, and the absorbance-concentration value is input into the instrument to obtain a standard curve. The coefficient of determination of the curve calibration is 0.9984, and the linear relationship is very good, indicating that the standard curve is qualified. The obtained standard curve is as image 3 shown;

[0063] Use a pipette to take 10.00 ml of foil washing water, transfer it into a 1000 ml volumetric flask, dilute with water to the mark, and shake ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com