Polystyrene ethyl isovalerate, and synthetic method and application thereof

A technology of polystyrene ethyl acrylate and ethyl acrylate, which is applied in construction and other fields, can solve the problem that there is no effective monitoring method for oil production, and achieve the effect of less consumption

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

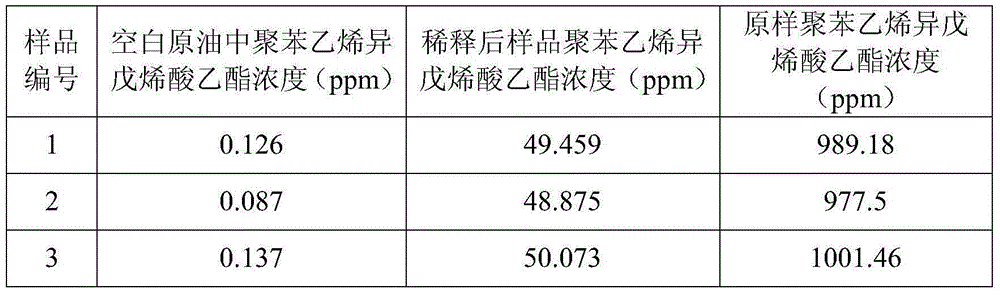

Examples

Embodiment 1

[0031] Dissolve 0.25g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 55g of hot water, raise the temperature to 75°C for 30min, slowly add 40g of ethyl methacrylate, 4g of styrene and 0.9g of styrene peroxide dropwise The mixed solution of formyl was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

Embodiment 2

[0033] Dissolve 0.35g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 60g of hot water, raise the temperature to 75°C for 30min, slowly add 35g of ethyl methacrylate, 3.5g of styrene and 0.7g of peroxide The mixed solution of benzoyl was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

Embodiment 3

[0035] Dissolve 0.45g of polyethylene glycol (PEG4000 average molecular weight 3600-4400) into 65g of hot water, raise the temperature to 75°C for 30min, slowly add 30g of ethyl methacrylate, 3g of styrene and 0.5g of styrene peroxide dropwise The mixed solution of formyl was reacted for 8 hours after the dropwise addition, cooled to room temperature and discharged.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com