Patents

Literature

72 results about "Isovalerate" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

An isovalerate compound is a salt or ester of isovaleric acid. It is also known as 3-methylbutanoate.

Cured tobacco essence

InactiveCN1590522AConvenient sourcePure smokeTobacco preparationEssential-oils/perfumesNicotiana tabacumRhodinol

An essence for the flue-cured tobacco to improve its fragrance is prepared from vanillin, isopentyl isovalerate, tree orchid extract, rhodinol and furanone. The productive technique is simple.

Owner:SHANGHAI BAIRUN INVESTMENT HLDG GRP CO LTD

Compound fruit fragrance and flower fragrance essence for daily chemicals and preparation method thereof

InactiveCN105316109AImprove stabilityMeet the needs of material and cultural lifeEssential-oils/perfumesBenzoic acidDamascone

Owner:广东铭康香精香料有限公司

Base with ripe fruit sweetness and aroma

InactiveCN105602725AEnhance aromaHighlight the aroma of ripe sweet fruitEssential-oils/perfumesToothpasteISOAMYL BUTYRATE

The invention provides a base which can be combined with multiple fruit essences and enable the fruit essences to generate sweetness and aroma. The base contains 2-10% of isoamyl isovalerate, 10-20% of isoamyl acetate, 15-20% of ethyl acetate, 10-20% of butyl acetate, 1-2% of sweet orange oil, 0.8-1.5% of lemon oil, 10-20% of isoamyl butyrate and 20-30% of ethyl butyrate. The base can be used in food, tobaccos and daily necessities, such as toothpaste, shampoo, toilet soap and the like.

Owner:广东顺大食品调料有限公司 +1

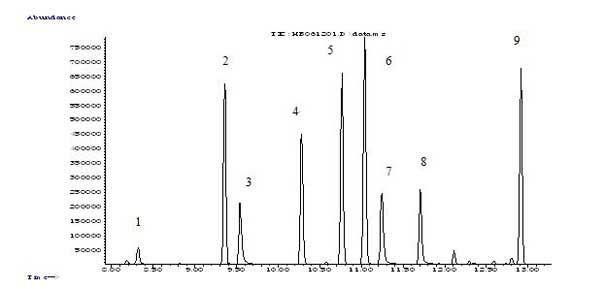

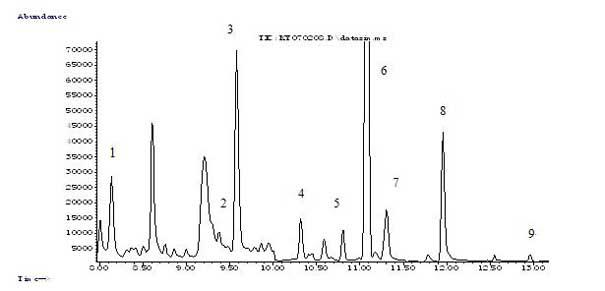

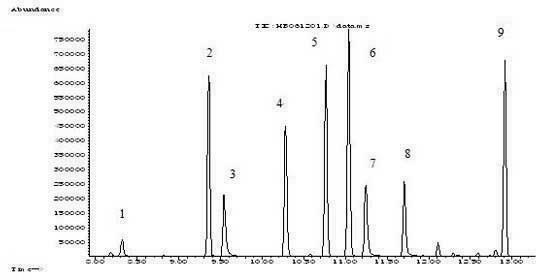

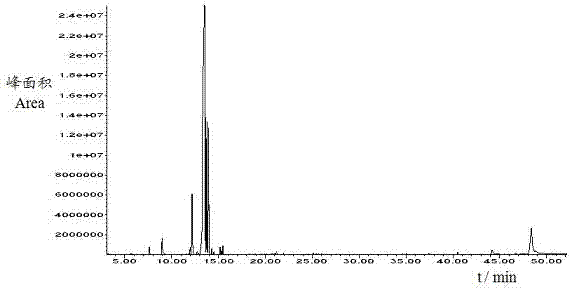

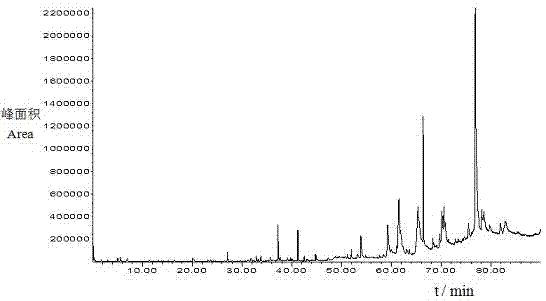

Detection method for simultaneously determining plurality of flavor substances in cigarette cut tobaccos

The invention provides a detection method for simultaneously determining a plurality of flavor substances in cigarette cut tobaccos. The flavor substances comprise furanone, isoamyl isovalerate, maltol, tabanone, menthol, ethyl maltol, 5-hydroxymethyl furfural and anethole. The method utilizes a solvent oscillation extraction method and a gas chromatography and mass spectrometry method to simultaneously determine the contents of a plurality of the flavor substances in the cigarette cut tobaccos; and the contents of a plurality of the flavor substances in a detection sample is calculated by the steps of preparing the detection sample, preparing a standard solution of a plurality of the flavor substances, preparing a sample solution and carrying out gas chromatography and mass spectrometry analysis. The method disclosed by the invention can accurately measure the contents of a plurality of the important flavor substances in a cigarette cut tobacco sample and is used for effectively evaluating the flavoring uniformity of the cigarette cut tobaccos, so as to provide the powerful technical support to a cigarette tobacco primary process. The method disclosed by the invention has the advantages of rapidness and convenience, simplicity in operation, good repeatability and high assay determination flexibility; and the recycling rate of a plurality of the important flavor substances can meet the requirements.

Owner:HONGYUN HONGHE TOBACCO (GRP) CO LTD +1

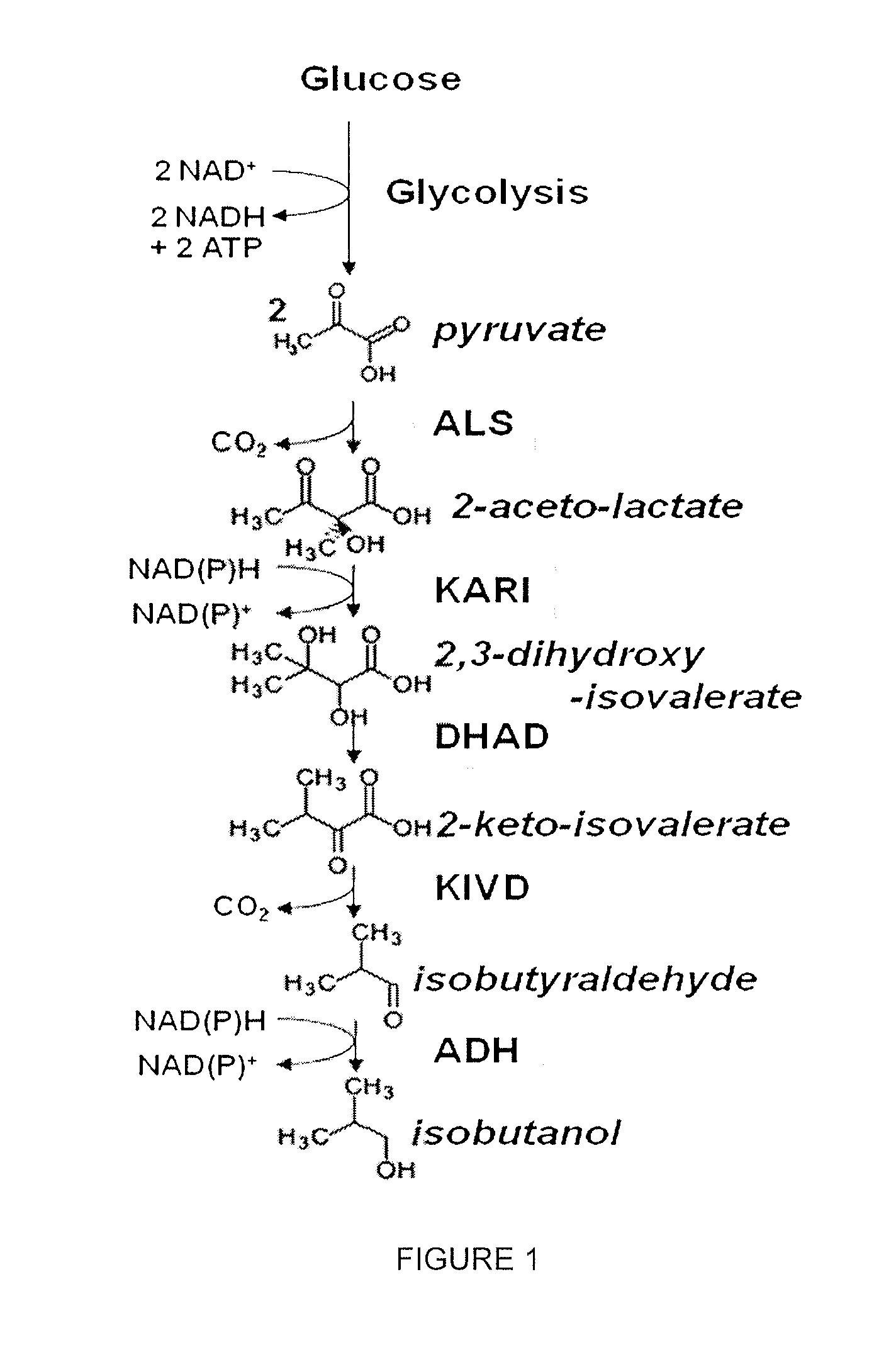

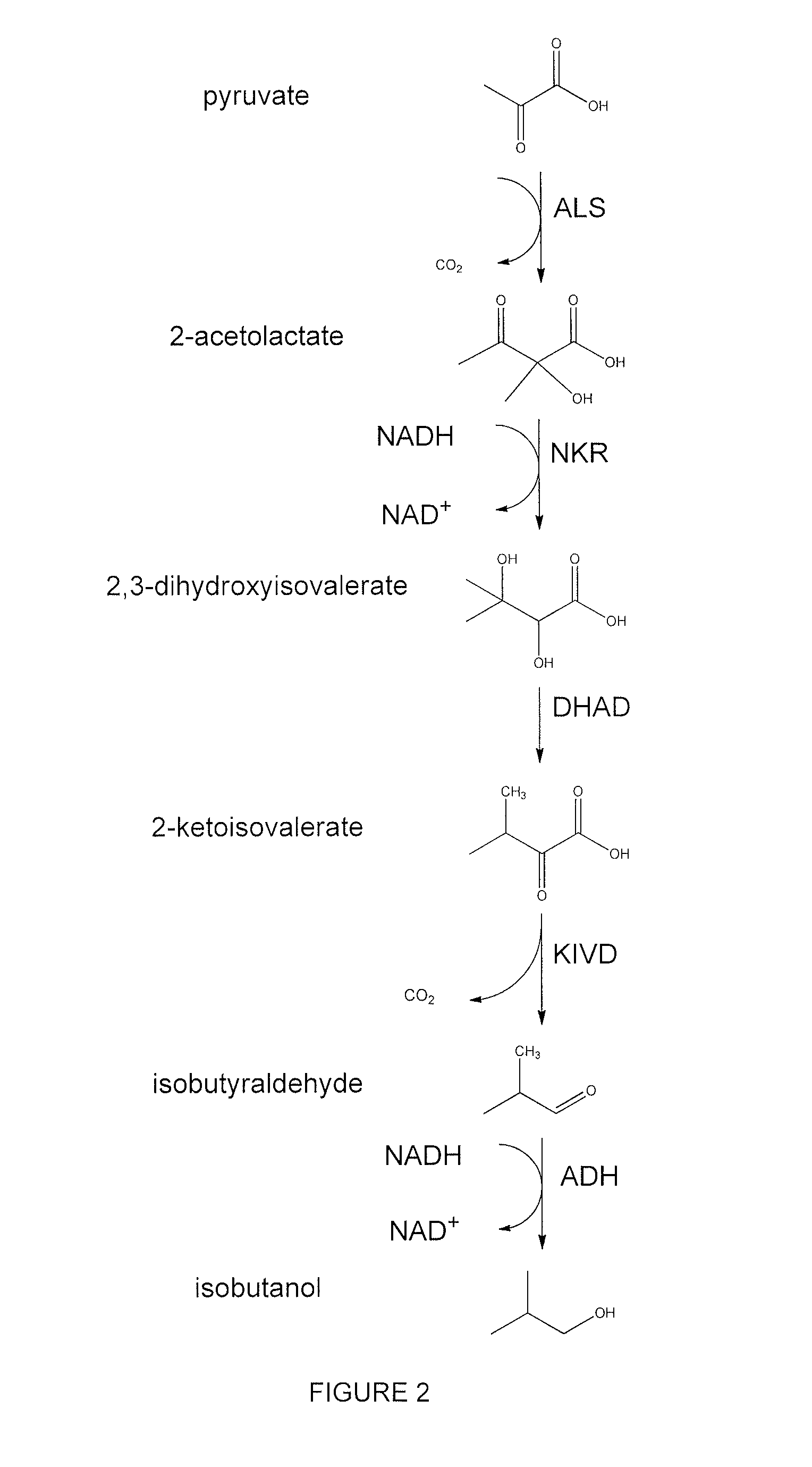

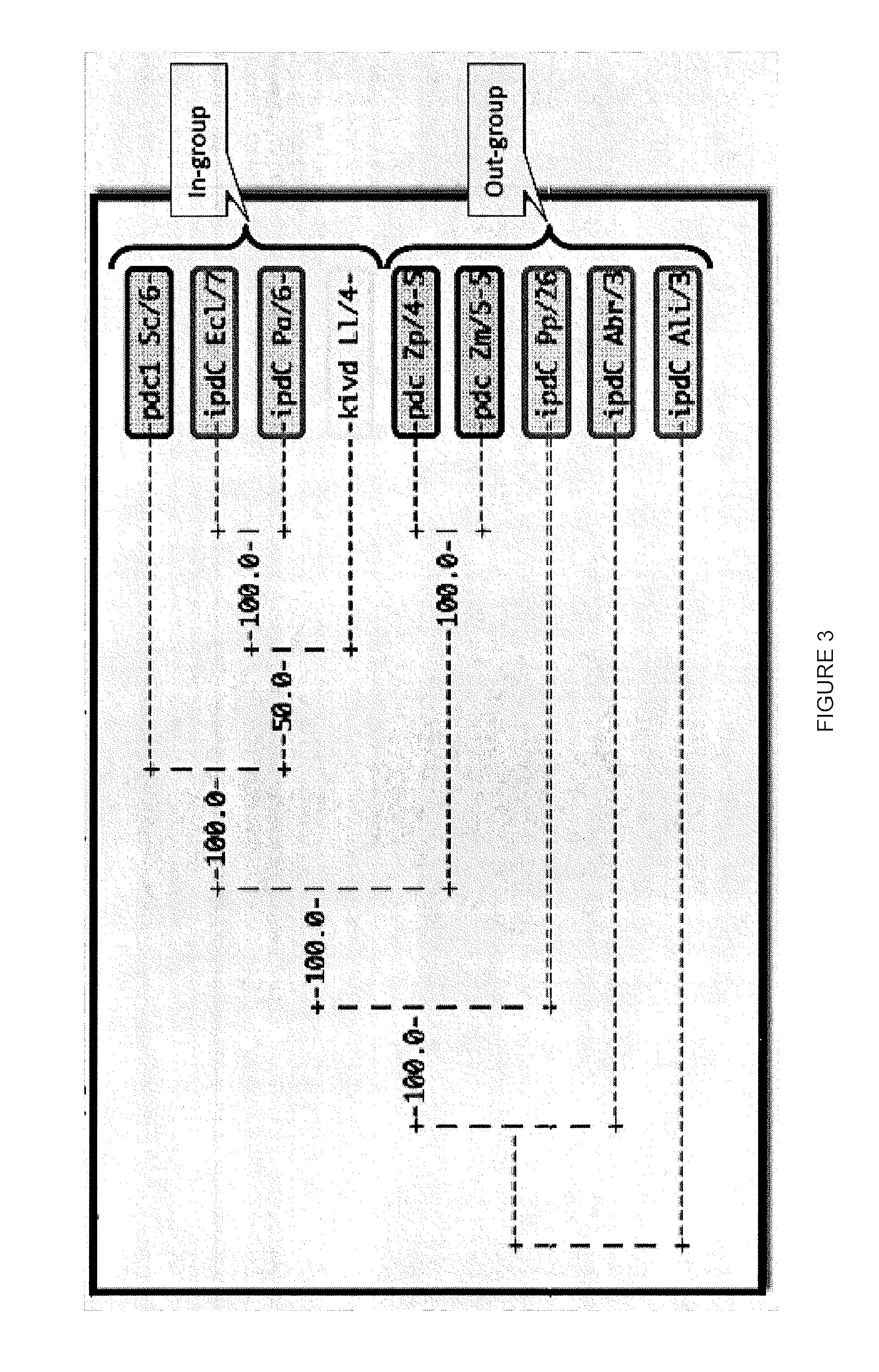

Decarboxylase proteins with high keto-isovalerate decarboxylase activity

InactiveUS20150259710A1High level activityIncrease productionBacteriaSugar derivativesMicroorganismIsobutanol

The present invention relates to recombinant microorganisms comprising an isobutanol producing metabolic pathway and methods of using said recombinant microorganisms to produce isobutanol. In various aspects of the invention, the recombinant microorganisms may comprise at least one nucleic acid molecule encoding a polypeptide with keto-isovalerate decarboxylase (KIVD) activity, wherein said polypeptide is at least about 65%, 70%, 75%, 80%, 85%, 90%, 91%, 92%, 93%, 94%, 95%, 96%, 97%, 98%, or 99% identical to a polypeptide selected from SEQ ID NOs: 1-214. Also provided are modified decarboxylases exhibiting an improved ability to utilize α-ketoisovalerate as a substrate in various beneficial enzymatic conversions.

Owner:GEVO INC

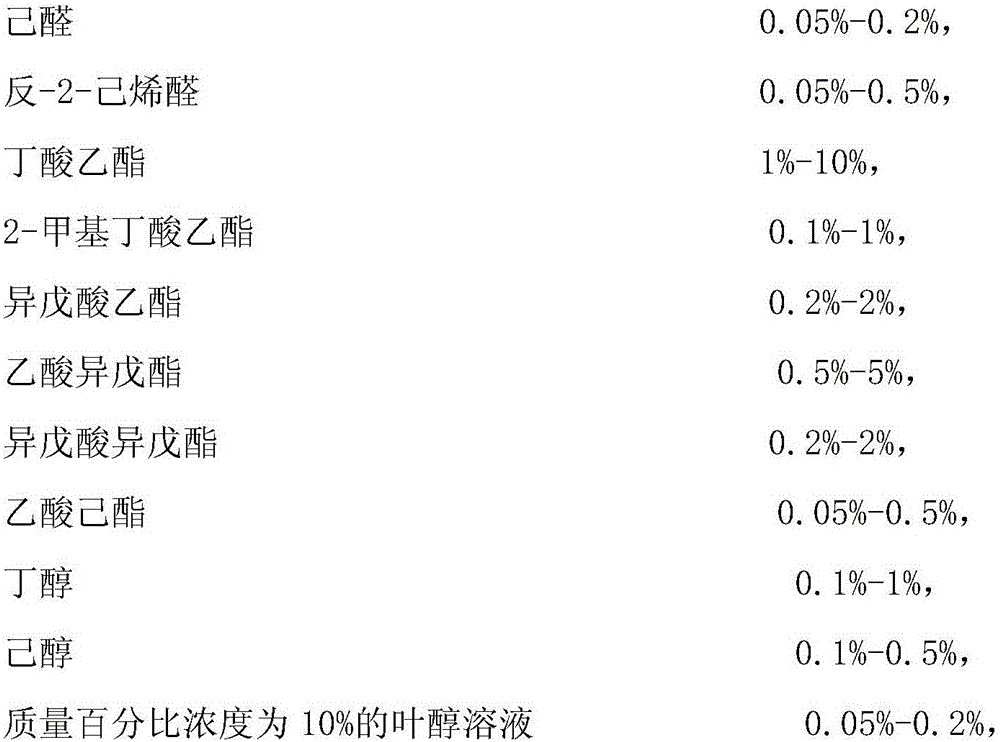

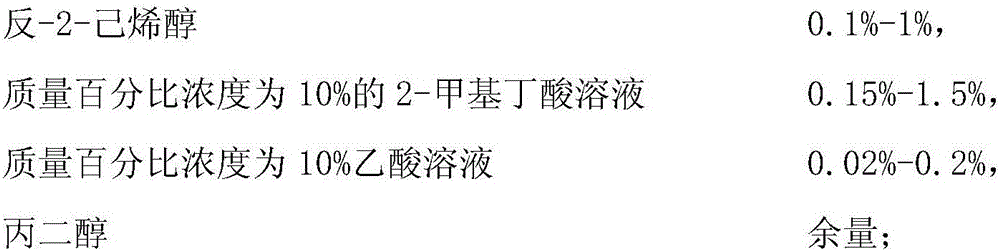

Mixed type apple essence and preparation method thereof

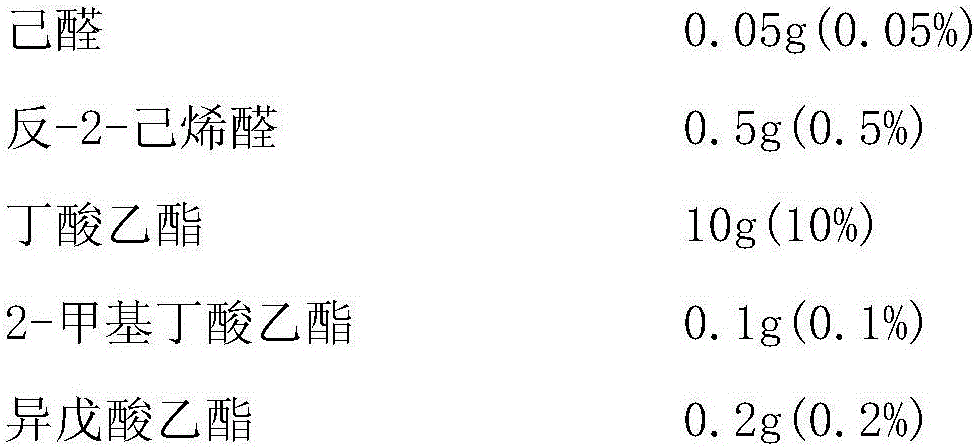

ActiveCN105725161AHigh degree of simulationGood application effectFood ingredient as flavour affecting agentSolventHexyl acetate

The invention discloses mixed type apple essence which is prepared from hexanal, trans-2-hexenal, ethyl butyrate, ethyl-2-methylbutyrate, ethyl isovalerate, isoamyl acetate, isoamyl isovalerate, hexyl acetate, butanol, hexyl alcohol, a leaf alcohol solution with mass percent concentration of 10%, trans-2-hexenol, a 2-methylbutyric acid solution with mass percent concentration of 10%, an acetic acid solution with mass percent concentration of 10% and solvent propylene glycol. The invention further provides a preparation method of the mixed type apple essence. The mixed type apple essence is mixed according to natural apple fragrance, and the obtained apple essence is strong, natural and vivid in fragrance.

Owner:SHANGHAI INST OF TECH

Pork essence for meat product

InactiveCN101664155AEasy to useFull-bodied and full-bodiedFood preparation2-heptenal2-methyl-3-furanthiol

The invention provides pork essence for meat product, which is prepared by salad oil, furanone, 2-acetylpyrazine and liquid spices, wherein the liquid spices is selected from one or more of 2-hydrosulphonyl-3-butanol, 4-guaethol, 2-methyl-3-furanthiol, 2-hydrosulphonyl-3-butanone, anisic aldehyde, hydrosulphonyl furan acetate, 2-heptenal, 1,6-ethanthiol, isovalerate and 2-phenyl-5-methyl-2-hexenal, wherein the weight ratio of the salad oil, the furanone, the 2-acetylpyrazine and the liquid spices is 90-99:0.1-1:0.01-0.2:0.1-1.

Owner:TIANJIN CHUNFA BIO TECH GRP

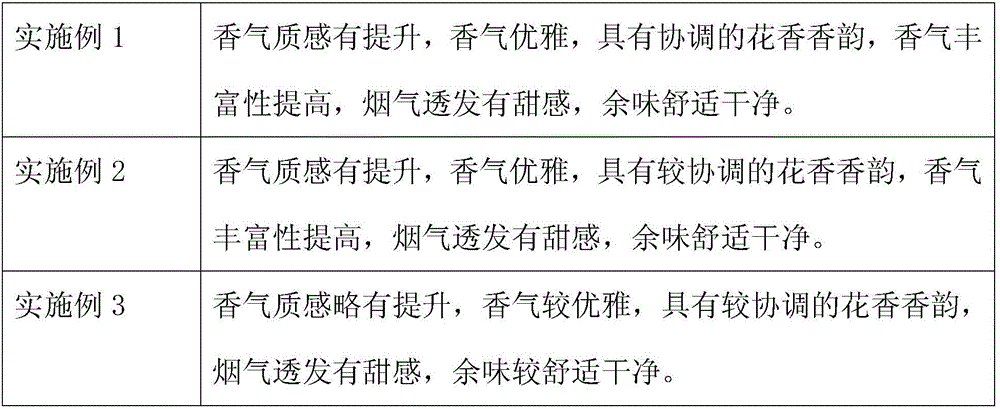

Flowery flavor essence for cigarette dropping pills and application

InactiveCN106118884ASolve coordination problemsRich and comfortable aromaTobacco smoke filtersEssential-oils/perfumesFlavorFlavoring essences

The invention provides flowery flavor essence for cigarette dropping pills and application. The flowery flavor essence is prepared from the following raw materials of valerian oil, neroli essential oil, sweet osmanthus absolute, lavender essential oil, rose essential oil, violet leaf extract, isoamyl isovalerate and olive oil and is obtained by mixing and uniformly stirring the raw materials for 1 to 3 hours, then standing for 24 to 48 hours and filtering out sediment through a sieve which is 60 to 80 meshes. The flowery flavor essence can be prepared into the cigarette dropping pills by using a dropping pill machine, and then the cigarette dropping pills can be located in and applied to a cigarette holder bar. When the flowery flavor essence provided by the invention is used for preparing the dropping pills, the production stability is better, the breakage rate of the cigarette dropping pills is low, and the rate of finished products is 80 to 85 percent. During a smoke panel test of prepared cigarette, a smoker can feel that the flowery flavor in the smoking taste is obviously enhanced, the fragrance is elegant and ethereal, and the remaining taste is comfortable.

Owner:HUBEI CHINA TOBACCO IND

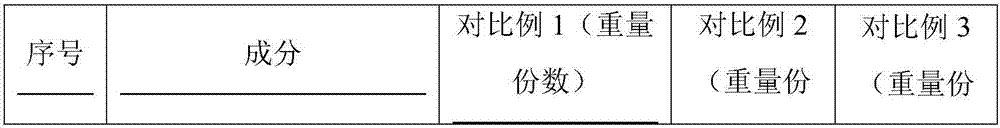

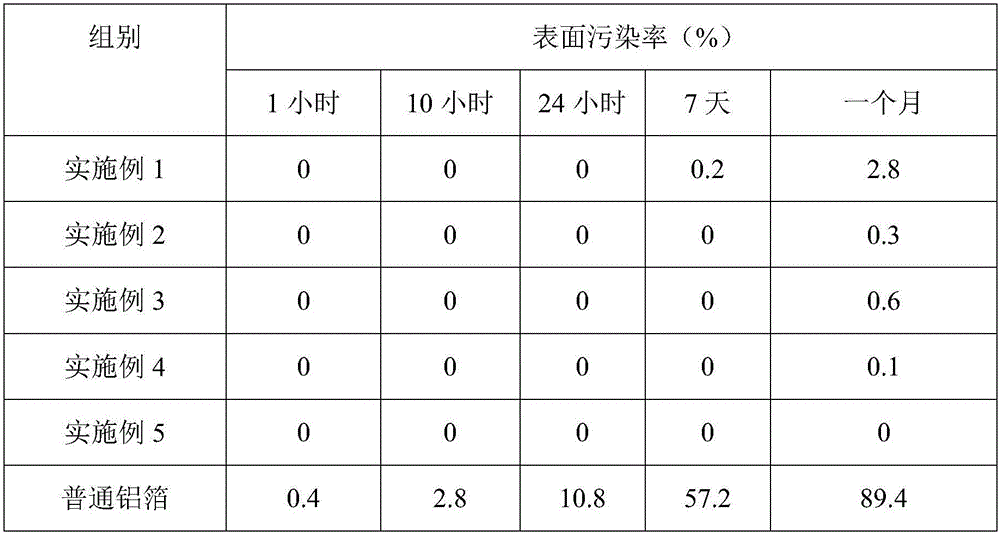

Pickled pod pepper flavor essence and production method of same

ActiveCN106912886AStrong sense of fermentationFull and lasting aromaFood ingredient as flavour affecting agentNatural extract food ingredients1-OcteneButyl caproate

The invention relates to a pickled pod pepper flavor essence, including: propylene glycol, alpha-pinene, butyl caproate, a pod pepper extract, beta-pinene, hexyl butyrate, acetic acid, 1-octene-3-ol, ethyl acetate, pentanal, 3-methylmercapto-propyl alcohol, alpha-terpineol, isopentyl alcohol, ethyl caproate, methyl salicylate, 2-methyl butanol, hexyl acetate, hexyl 2-methylbutyrate, ethyl 2-methylbutyrate, linalool, anisic aldehyde, allyl isothiocyanide, isopentyl isovalerate, mercaptan, 2-methyl butyric acid, 2-methoxy-3-isobutyl pyrazine and 3-methylthio propylaldehyde. The pickled pod pepper flavor essence has strong fermented sense and has a full and durable fragrance, is stable in quality and has pure and natural fragrance, which is approximate to the fragrance of naturally fermented pickled Capsicum frutescens (pod pepper). The pickled pod pepper flavor essence has better effects than other pod pepper flavor essences in meat products and spices, and is well received among customers in practical application and market promotion.

Owner:SHANDONG TIANBO FOOD INGREDIENTS

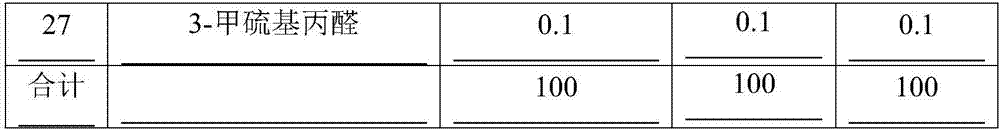

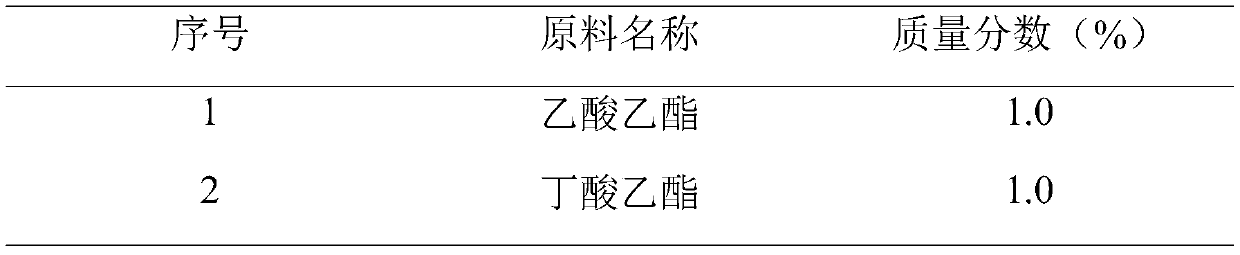

Formula of mint fragrant tobacco additive essence

ActiveCN102204717AGreat tasteAdd natural sweetnessTobacco treatmentEssential-oils/perfumesNicotiana tabacumEugenol

The invention discloses a formula of mint fragrant tobacco additive essence. The formula of the mint fragrant tobacco additive essence consists of the following components in percentage by mass: 1 to 5 percent of L-menthol, 1 to 5 percent of ethyl maltol, 1 to 10 percent of isoamyl isovalerate, 1 to 5 percent of coke fragrant furanone, 5 to 15 percent of ethyl berry ketone, 1 to 5 percent of isophorone, 0.1 to 0.2 percent of phenylethyl isovalerate, 1 to 5 percent of eugenol type basil oil, 1 to 5 percent of ethyl phenoxyisobutyrate, 0.1 to 2 percent of 2-methyl ethyl butyrate, 15 to 25 percent of honey extract, 5 to 15 percent of glycerol, 5 to 15 percent of edible ethanol and 20 to 40 percent of propylene glycol. Because the menthol is added in the formula of the mint fragrant tobacco additive essence, the tobacco can generate cool and refreshing smell of mint, the tobacco fragrance can be improved, the smoking taste is corrected, the smoking taste of the tobacco is finally improved, natural sweet fragrance of the tobacco is increased, the dry, astringent and bitter mouthfeel of customers is improved, and the requirements of the customers are met.

Owner:GUANGZHOU AOJIAN PERFUME

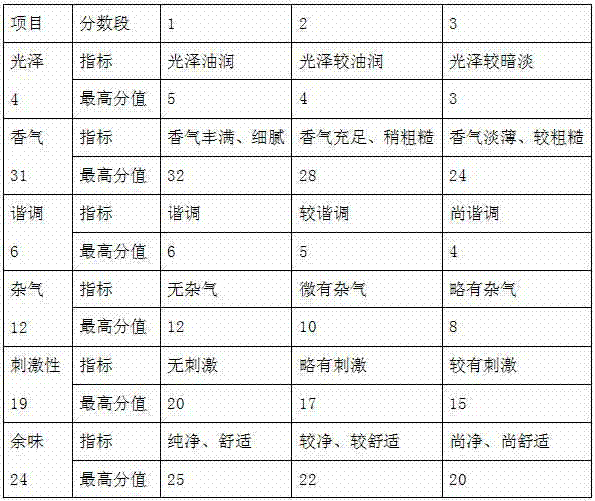

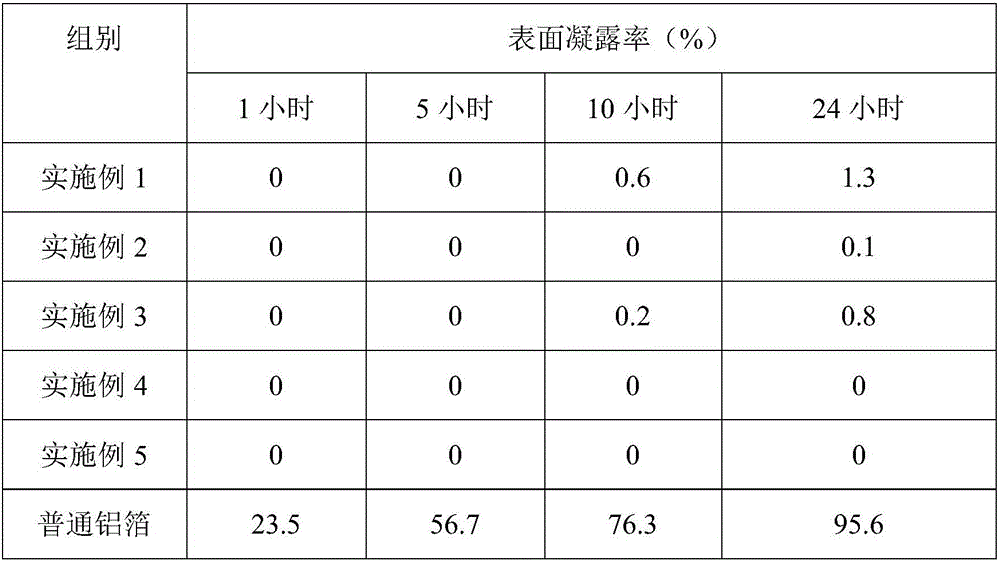

Ultra-hydrophobic aluminum foil and production method thereof

InactiveCN106381033AImprove corrosion resistanceExtended service lifeAnti-corrosive paintsPolyester coatingsFucoidanAqueous sodium hydroxide

The invention discloses an ultra-hydrophobic aluminum foil and a preparation method thereof. The preparation method of the ultra-hydrophobic aluminum foil comprises the following steps: processing an aluminum foil substrate by an aqueous solution of sodium hydroxide, cleaning the processed aluminum foil substrate, immersing the cleaned aluminum foil substrate in a prepared acidic solution to carry out etching treatment, cleaning the etched aluminum foil, immersing the aluminum foil in a prepared liquid hydrophobic material, and carrying out solidifying drying treatment to obtain the ultra-hydrophobic aluminum foil, wherein the liquid hydrophobic material is prepared from, by weight, 26-32 parts of a stearic acid solution, 16-20 parts of modified alkyd resin, 14-20 parts of nanometer titanium dioxide, 6-10 parts of fucoidan, 2-6 parts of neryl isovalerate, 2-8 parts of carboxymethylcellulose sodium and 4-8 parts of fluorinated polyethylene. The ultra-hydrophobic aluminum foil has the advantages of ultra-strong hydrophobicity, effective inhibition of condensation, substantial increase of the corrosion resistance of the aluminum foil and substantial prolongation of the service life of the aluminum foil, and the production method has the advantages of simplicity, small substrate damages, good apparent quality, and suitableness for wide promotion.

Owner:HUANGSHAN TIANMA ALUMINUM

Green apple essence used for water-based ink and preparation method of green apple essence

InactiveCN105132169ANo stratificationSystem stabilityEssential-oils/perfumesPropanoic acidGalaxolide

The invention provides green apple essence used for water-based ink. The green apple essence is prepared from, by weight, 1-30% of green apple flavor, 5-55% of composite modified oligosaccharide and deionized water. The green apple flavor is prepared from ligustral, leaf alcohol, cis-3-hexenyl acetate, cis-3-hexenyl isovalerate, trans-2-hexenal, trans-2-hexenyl acetate, styralyl propionate, linalool, linalyl acetate, fructone, peach aldehyde, isoamyl isovalerate, isoamyl acetate, allyl caproate, sweet orange oil, acetic acid, acetic acid, geranyl acetate, damascene, benzyl acetate, lilial, cedryl acetate, acetoxy-2-tert-butylcyclohexane, ethyl acetoacetate, tonkalide, galaxolide and ethyl alcohol. Composite modified oligosaccharide serves as a wall material for wrapping green apple essence, green apple nanometer capsule slow-release essence is formed, and therefore the fragrance holding property and the water solubility of the essence are improved, and the green apple essence is suitable for perfuming of water-base ink.

Owner:SHANGHAI INSTITUTE OF TECHNOLOGY

Ultra-thin high-temperature-resistant polypropylene capacitor metallized film and preparation method thereof

InactiveCN103762073AReduce contact resistanceOptimize volumeThin/thick film capacitorFixed capacitor electrodesStearic acidPolypropylene

The invention discloses an ultra-thin high-temperature-resistant polypropylene capacitor metallized film. The ultra-thin high-temperature-resistant polypropylene capacitor metallized film is characterized in that the ultra-thin high-temperature-resistant polypropylene capacitor metallized film is prepared by the following raw materials, by weight, 200 parts of isotactic polypropylene, 1-2 parts of antioxygen 330, 1-2 parts of triethanolamine, 2-3 parts of Carbomer, 2-3 parts of double fourteen-carbon alcohol ester, 2-3 parts of n-hexacosanyl isovalerate, 6-8 parts of tributyl citrate, 1-2 parts of stearic acid, 1-2 parts of anti-aging agent RD and 5-6 parts of auxiliaries. The ultra-thin high-temperature-resistant polypropylene capacitor metallized film is simple in processing technic, a thin-film capacitor made of the ultra-thin high-temperature-resistant polypropylene capacitor metallized film is small in contact resistance, products are made to be good in characteristic, even in thickness and not prone to separating, the manufactured capacitor is small in size and has good high-temperature stability, and the ultra-thin high-temperature-resistant polypropylene capacitor metallized film has good current-carrying, inrush current resistant and pulse resistant capacity and is long in service life.

Owner:TONGLING QILI ELECTRONICS MATERIALS

Polypropylene composite material for capacitor films

InactiveCN104725722AImprove adhesionImprove film formationFixed capacitor dielectricNitrocellulosePhthalonitrile

The invention discloses a polypropylene composite material for capacitor films. The polypropylene composite material is prepared from the following components in parts by weight: 90-120 parts of polypropylene, 30-40 parts of glass fiber, 2-7 parts of pentaerythritol, 2-7 parts of para-phthalonitrile, 5-10 parts of sodium silicate, 1-3 parts of n-hexacosanol isovalerate, 0.5-1.5 parts of isoborneol acrylate, 1-3 parts of melamine, 2-6 parts of silicon carbide, 10-12 parts of butadiene resin, 3-6 parts of nitrocellulose and 2-7 parts of assistant. The polypropylene composite material for capacitor films uses the polypropylene as the main raw material, and uses the glass fiber, pentaerythritol, para-phthalonitrile, sodium silicate, n-hexacosanol isovalerate, isoborneol acrylate, melamine, silicon carbide, butadiene resin, nitrocellulose and assistant as the auxiliary materials. The polypropylene composite material for capacitor films has the characteristics of high elastic modulus, high strength, high heat-deformation temperature and favorable dimensional stability.

Owner:SUZHOU HUANYAN ELECTRIC

Coal additive

The invention belongs to an additive used in the combustion process of coal and particularly relates to a coal additive for improving the combustion efficiency and effectively reducing discharging of harmful substances when the coal of a boiler or a kiln is burnt. The coal additive consists of the following raw materials in part by weight: 1 to 20 parts of isoamyl isovalerate, 12 to 30 parts of absolute ethyl alcohol, 20 to 50 parts of water, 5 to 30 parts of oxyhydrogen atom mother solution, 8 to 28 parts of nano lanthana alcohol dispersion liquid with the concentration of 20 percent, 4 to 30 parts of calcium hydroxide, 1 to 5 parts of potassium permanganate, 0.2 to 2 parts of barium acetylacetonate hydrate, 0.02 to 0.2 part of palladium chloride, 0.1 to 1.5 parts of praseodymium nitrate, 1 to 2 parts of cobalt nitrate, 1 to 9 parts of lanthanum acetate, 0.05 to 2 parts of europium nitrate, 1 to 6 parts of myristyl polyoxyethylene ammonium chloride, 0.5 to 3 parts of octyl polyoxyethylene ammonium bromide and 0.5 to 4.5 parts of coconut oil alkyl dimethyl amine oxide. The coal additive has the advantages of improving the combustion efficiency and effectively reducing discharging of harmful substances.

Owner:HENAN XINXIANG SITE ENERGY SAVING ENVIRONMENTAL PROTECTION TECH

Strawberry-flavour essence used for cigarettes and preparing method thereof

InactiveCN104611133AStrong and unique fragranceNourishes the lungs and promotes body fluidTobacco treatmentEssential-oils/perfumesEthyl butyrateMethyl palmoxirate

The invention belongs to the field of daily essence processing, and particularly relates to strawberry-flavour essence used for cigarettes and a preparing method thereof. The essence is prepared from following raw materials by weight: 15-25 parts of strawberry, 1-3 parts of sweet osmanthus petals, 1-3 parts of arabian jasmine petals, 6-12 parts of ethyl acetate, 3-7 parts of ethyl butyrate, 2-5 parts of ethyl 2-methylbutyrate, 1-3 parts of isovalerate, 5-10 parts of propylene glycol and 35-60 parts of ethanol. The essence has unique and rich fragrance, is full in fragrance, unique in style, good in effects on smoke, simple in preparation, low in cost, and wide in raw material sources, and has good functions for improving taste of cigarettes.

Owner:杨秋慧 +1

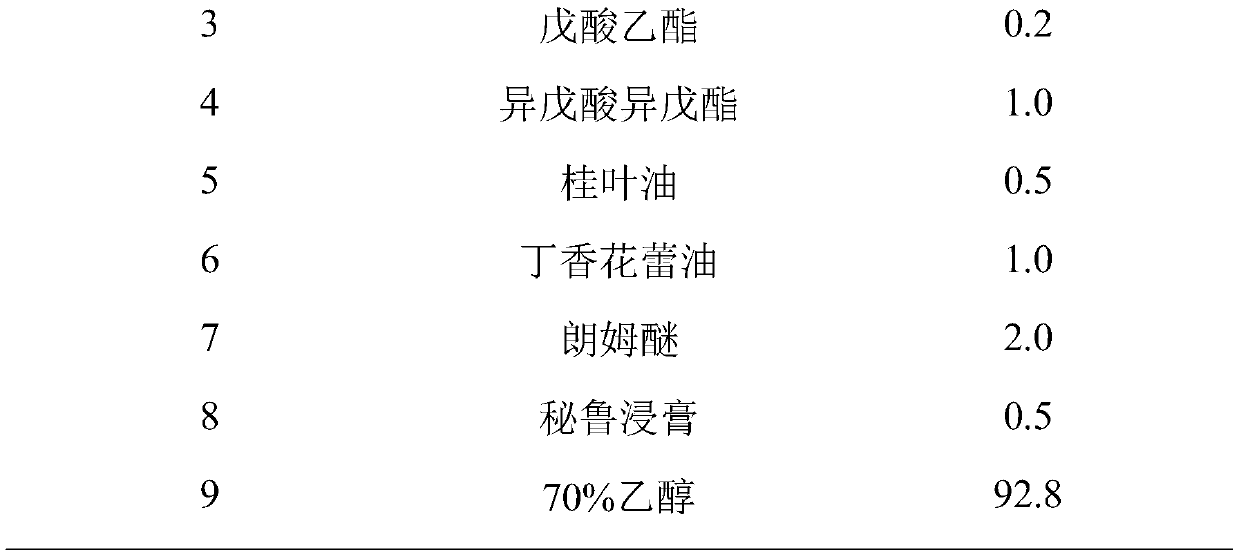

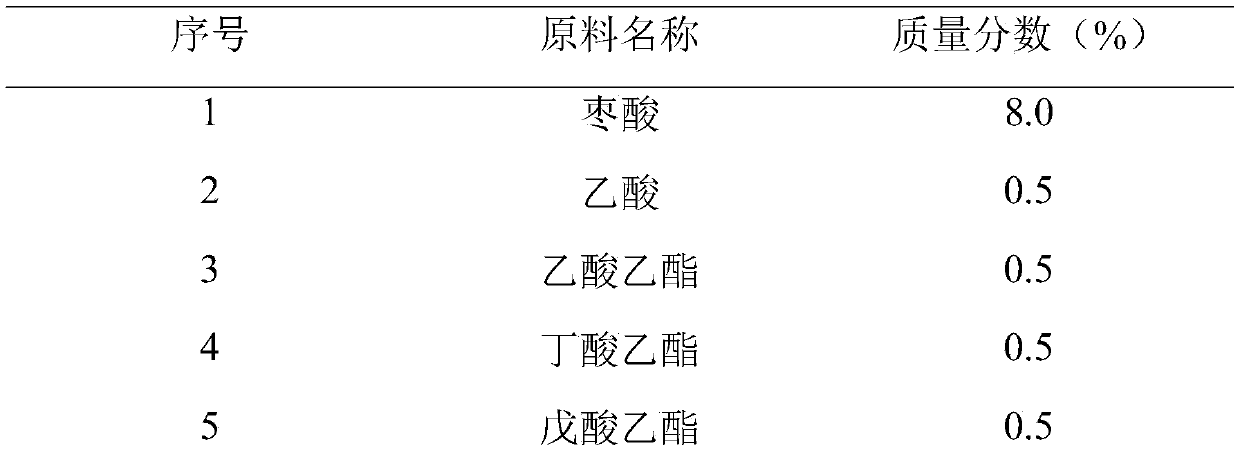

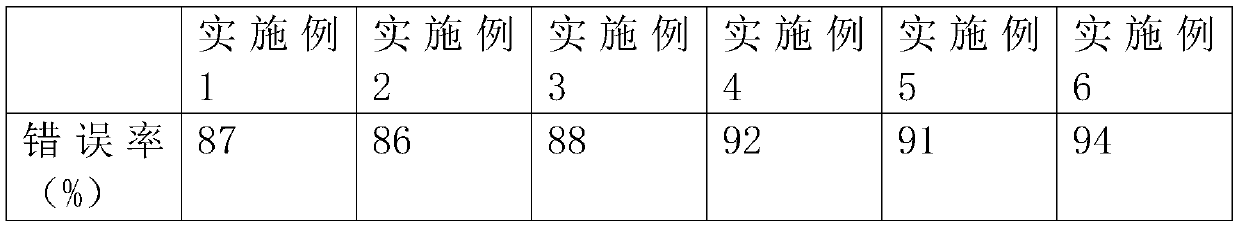

Fruity note base for cigarettes and application thereof

InactiveCN111269749AImprove temperamentIncrease the amount of aromaTobacco treatmentEssential-oils/perfumesBiotechnologyEthyl butyrate

The invention relates to a fruity note base for cigarettes, and belongs to the technical field of tobacco product blending. The fruity note base comprises the following components in percentage by weight: 0-12.0% of jujube acid; 0-12.0% of jujube tincture; 0-1.0% of acetic acid, 0-2.3% of ethyl acetate; 0-2.3% of ethyl butyrate, 0-2% of ethyl valerate, 0-2.0% of isoamyl isovalerate, 0-1.1% of cinnamon leaf oil, 0-1.9% of clove bud oil, 0-3% of sweet orange oil, 0-5.0% of lanamyl ether, 0-1.0% of Peru extract and the balance of a mixture of 95% ethanol and propylene glycol or 70% ethanol, wherein the weight percentage of the ethyl acetate, the ethyl butyrate, the ethyl valerate and the isoamyl isovalerate is not 0. When the fruity note base is added into cigarettes, the fruity aroma of thecigarettes can be increased, the aroma quality and the aroma quantity are improved, the aftertaste is clean, the comfort degree is improved, and the purpose of meeting diversified requirements of consumers on cigarette tastes is achieved.

Owner:CHINA TOBACCO SICHUAN IND CO LTD

Honey essence for daily chemicals

ActiveCN110106024AIncrease aroma intensityPure aromaEssential-oils/perfumesAgainst vector-borne diseasesEthyl phenylacetatePhenethyl acetate

The invention relates to the field of essences, and provides a honey essence for daily chemicals in order to solve the problem that the difference between the aroma of existing honey essence and nature aroma is great. The honey essence for the daily chemicals is prepared from, by mass, 0.1-1 part of phenethyl acetate, 0.1-1 part of isoamyl acetate, 0.01-0.15 part of geranyl acetate, 0.1-1 part ofethyl acetate, 0.1-1 part of ethyl pelargonate, 1-15 parts of phenylethyl isobutyrate, 0.1-1.5 parts of isoamyl isovalerate, 0.5-3 parts of ethyl lactate, 0.1-1 part of ethyl phenylacetate, 0.5-1.5 parts of butyl phenylacetate, 0.1-1 part of methyl phenylacetate, 1-10 parts of phenylethyl phenylacetate, 5-20 parts of phenethyl alcohol, 0.1-1 part of citronellol, 0.01-0.2 part of geraniol, 0.5-3 parts of artificial cognac oil, 1-10 parts of methyl cedryl ether, 0.5-3 parts of ethyl maltol, 0.1-1 part of damascenone, 0.1-1.5 parts of delta damascone, 0.1-1.5 parts of 4-hydroxy-2,5-dimethyl-3(2H)-furanone and 50-70 parts of dipropylene glycol. By controlling the usage ratio of all the components, the aroma intensity of the honey essence for the daily chemicals is easily improved, and the aroma given off by the honey essence for the daily chemicals is closer to the natural aroma.

Owner:广州宝士迪香精香料有限公司

Apple essence formula for dairy product

The invention discloses an apple essence formula for a dairy product. The apple essence is mainly prepared from the following components: cream esterified esters, isoamyl acetate, trans-2-hexenal, hexyl acetate, acetaldehyde, a 40 percent ethanol solution, n-hexanol, hexanal, isoamyl isovalerate, 2-ethyl 2-methyl-butanoate, butanol, ethyl caproate, acetaldehyde diethyl acetal, heptyl acetate, propanediol and glycerol. The apple essence prepared by the formula has the obvious advantages that by utilizing the cream esterified esters which are natural and have strong binding capability with the dairy product as a raw material, on one hand, the natural feeling of the apple essence can be strengthened, and on the other hand, the apple essence can be well bonded with the dairy product, so that the problem that fragrance is wafted to be separated from the theme of a beverage is solved.

Owner:王婧婧

Banana essence formula for dairy product

The invention discloses a banana essence formula for a dairy product. The banana essence is mainly prepared from the following components: cream esterified esters, isoamyl acetate, isoamyl isovalerate, vanillin, isoamyl butyrate, ethyl caproate, ethyl butyrate, ethyl caprylate, citral and heliotropin. The banana essence prepared by the formula has the obvious advantages that by utilizing the cream esterified esters which are natural and have strong binding capability with the dairy product as a raw material, on one hand, the natural feeling of the banana essence can be strengthened, and on the other hand, the banana essence can be well bonded with the dairy product, so that the problem that fragrance is wafted to be separated from the theme of a beverage is solved.

Owner:王婧婧

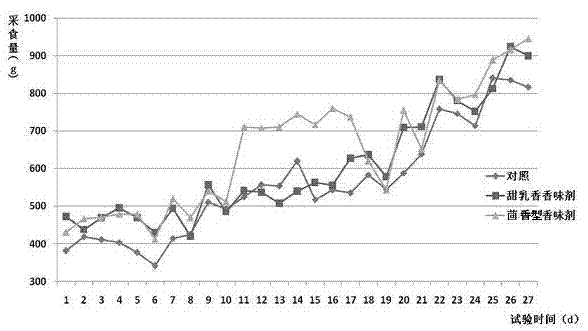

Sow milk bionic feed flavor and use method thereof

ActiveCN103070298AEasy feedingIncrease daily weight gainAnimal feeding stuffAnimal scienceBenzaldehyde

The invention belongs to the field of feed and relates to a sow milk bionic feed flavor and a use method thereof. The sow milk bionic feed flavor is a fennel-type sow milk bionic flavor and is prepared by mixing 49.7 to 67 parts by weight of benzyl alcohol, 30 to 45.2 parts by weight of gamma-nonalactone, 8.3 to 27.8 parts by weight of gamma-octalactone, 8.4 to 16.7 parts by weight of benzyl butyrate, 5 to 10 parts by weight of anethole, 6.7 to 13.4 parts by weight of benzaldehyde, 6.7 to 16.6 parts by weight of vanillin, 1 to 5 parts by weight of ethyl butyrate, 1 to 5 parts by weight of isoamyl isovalerate, 0.5 to 3.3 parts by weight of amyl acetate, 0.4 to 5 parts by weight of ethyl hexanoate, 1.6 to 5 parts by weight of dimethyl methyl butyrate and 833 parts by weight of silica gel as a carrier. The sow milk bionic feed flavor can promote ingestion of piglets and improve daily gain. The fennel-type sow milk bionic flavor has better effects.

Owner:ZHEJIANG FORESTRY UNIVERSITY

Cigarette essence

InactiveCN103695170AHas a strong fragranceEasy to makeTobacco preparationEssential-oils/perfumesCinnamic alcoholPurified water

The invention relates to the field of cigarette flavoring, especially to a cigarette essence, which is characterized by comprising the following raw materials by weight: 30-40 parts of cocoa tincture, 10-15 parts of cinnamyl alcohol, 15-20 parts of phenoxyethyl isobutyrate, 15-18 parts of phenylethyl isovalerate, 12-16 parts of glycerin, and 10-20 parts of purified water. The cigarette essence provided by the invention has the advantages of simple and easily available raw materials, simple preparation and low cost. And the rolled cigarettes are rich in aroma and unique in style during smoking, and have the heavy aroma of cocoa.

Owner:邢娜

Preparation method of pork essence

InactiveCN101664156AEasy to useFull-bodied and full-bodiedFood preparation2-heptenal2-methyl-3-furanthiol

The invention provides a preparation method of pork essence, which comprises the following steps: (1) heating 90-99 parts of salad oil by weight to reach 20-70 DEG C, adding 0.1-1 part of furanone byweight and 0.01-0.2 part of the 2-acetylpyrazine by weight in the salad oil and mixing at constant speed until being completely dissolved to obtain solid dissolved solution; (2) selecting from one ormore of 2-hydrosulphonyl-3-butanol, 4-guaethol, 2-methyl-3-furanthiol, 2-hydrosulphonyl-3-butanone, anisic aldehyde, hydrosulphonyl furan acetate, 2-heptenal, 1,6-ethanthiol, isovalerate and 2-phenyl-5-methyl-2-hexenal to prepare 0.1-1 part of liquid spices by weight after the temperature of the solid dissolved solution obtained in the step (1) is reduced to room temperature, putting the liquid spices in the solid dissolved solution the temperature of which is reduced to room temperature, and mixing evenly to obtain the pork essence.

Owner:TIANJIN CHUNFA BIO TECH GRP

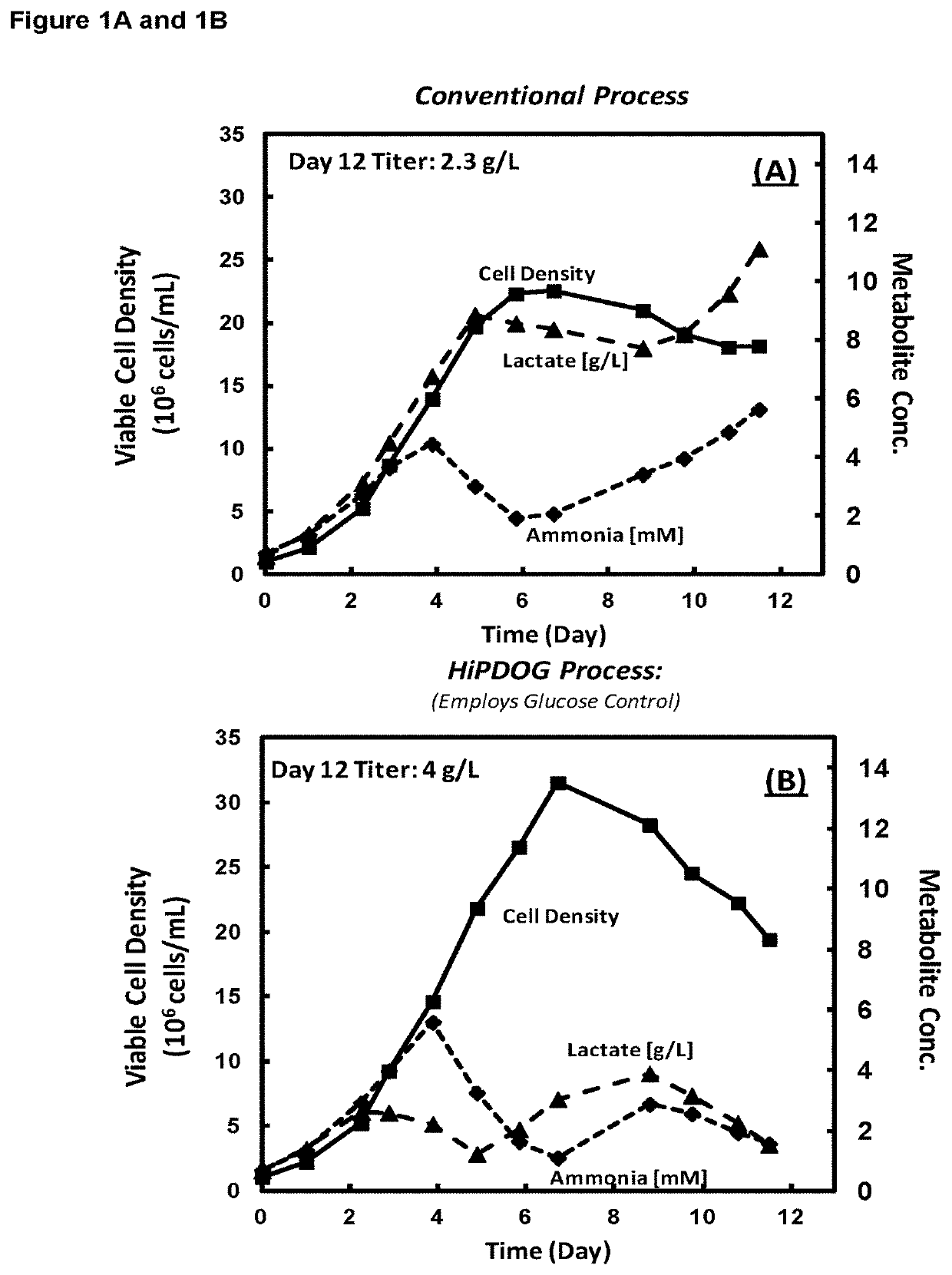

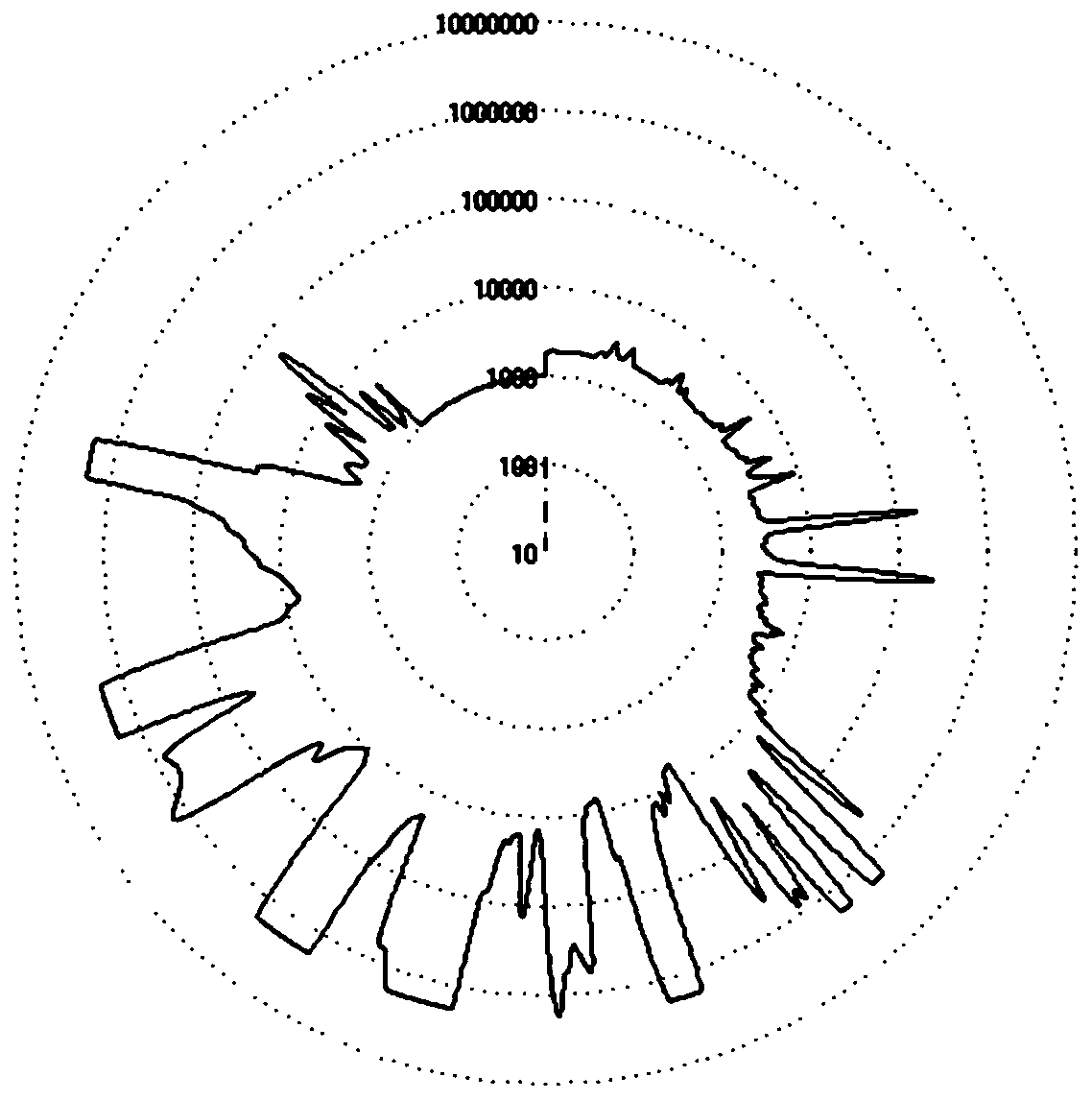

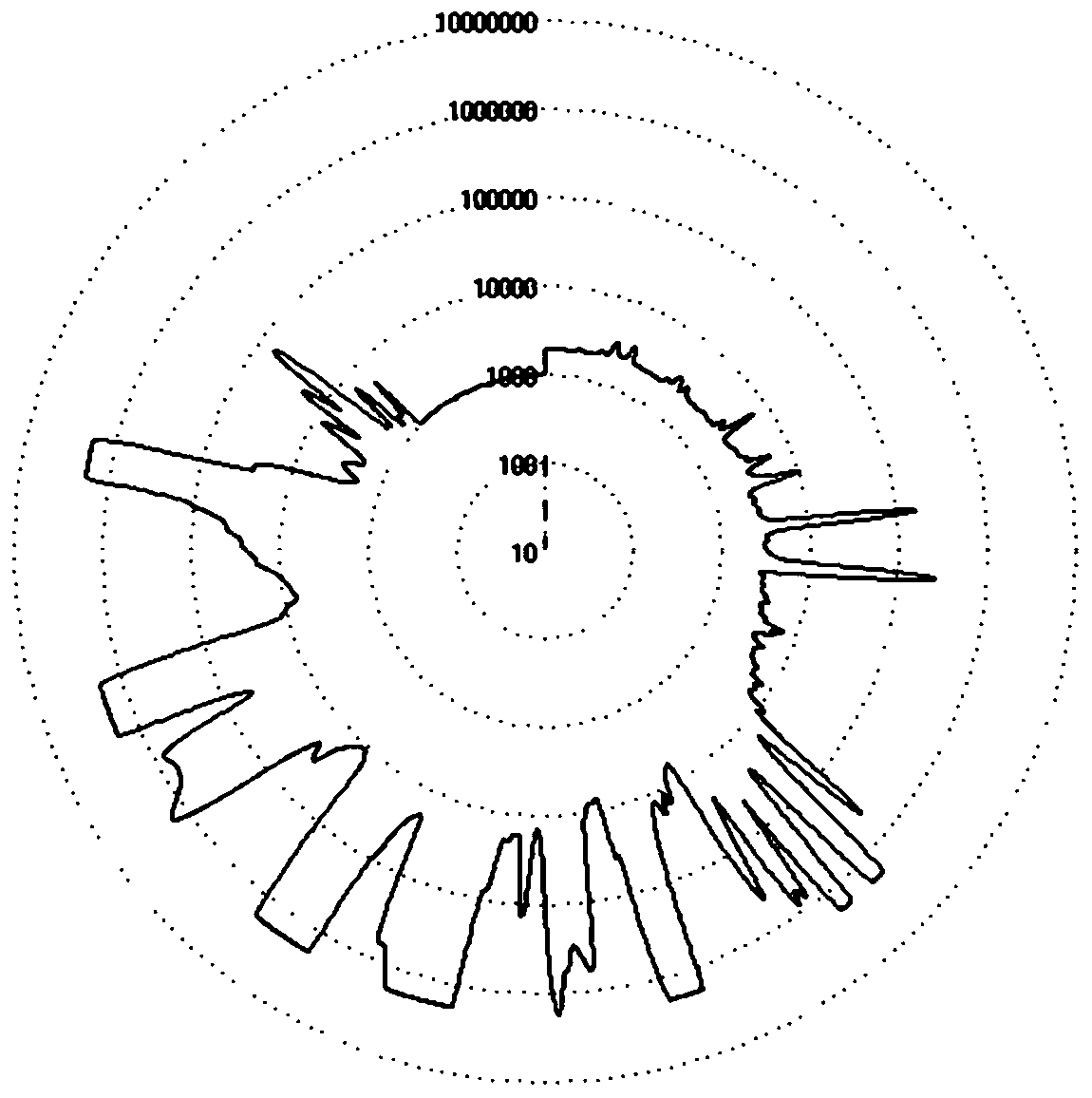

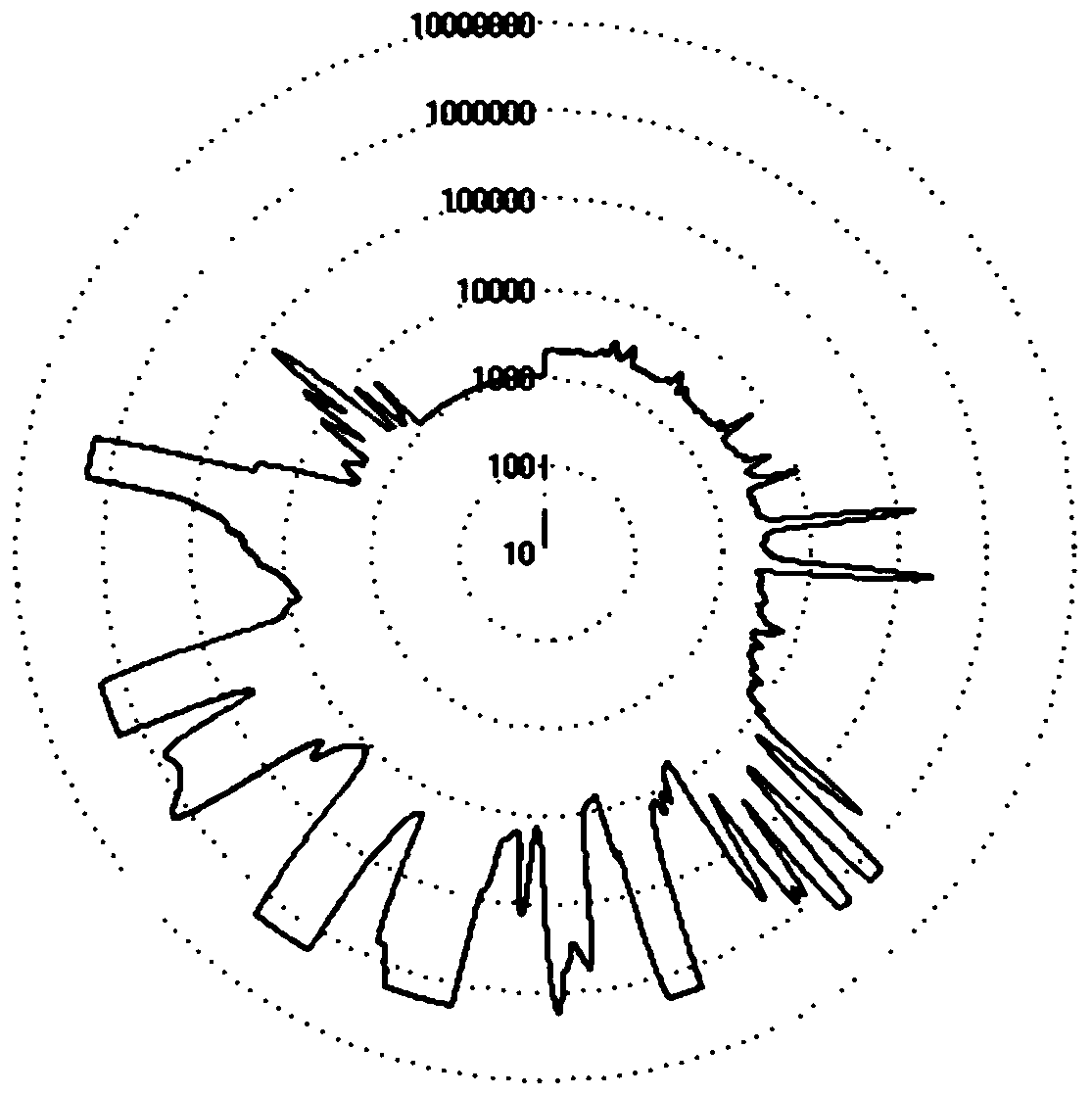

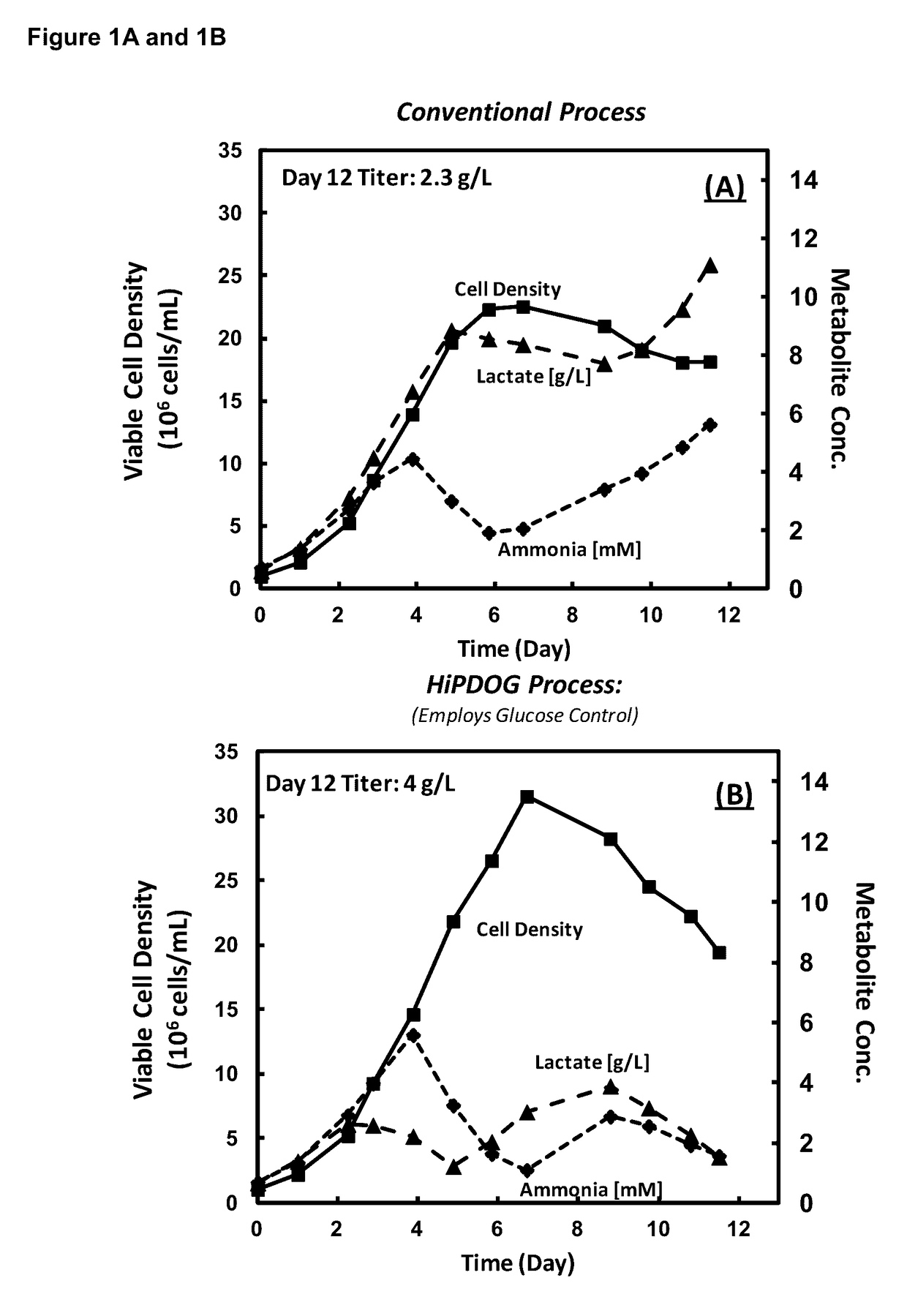

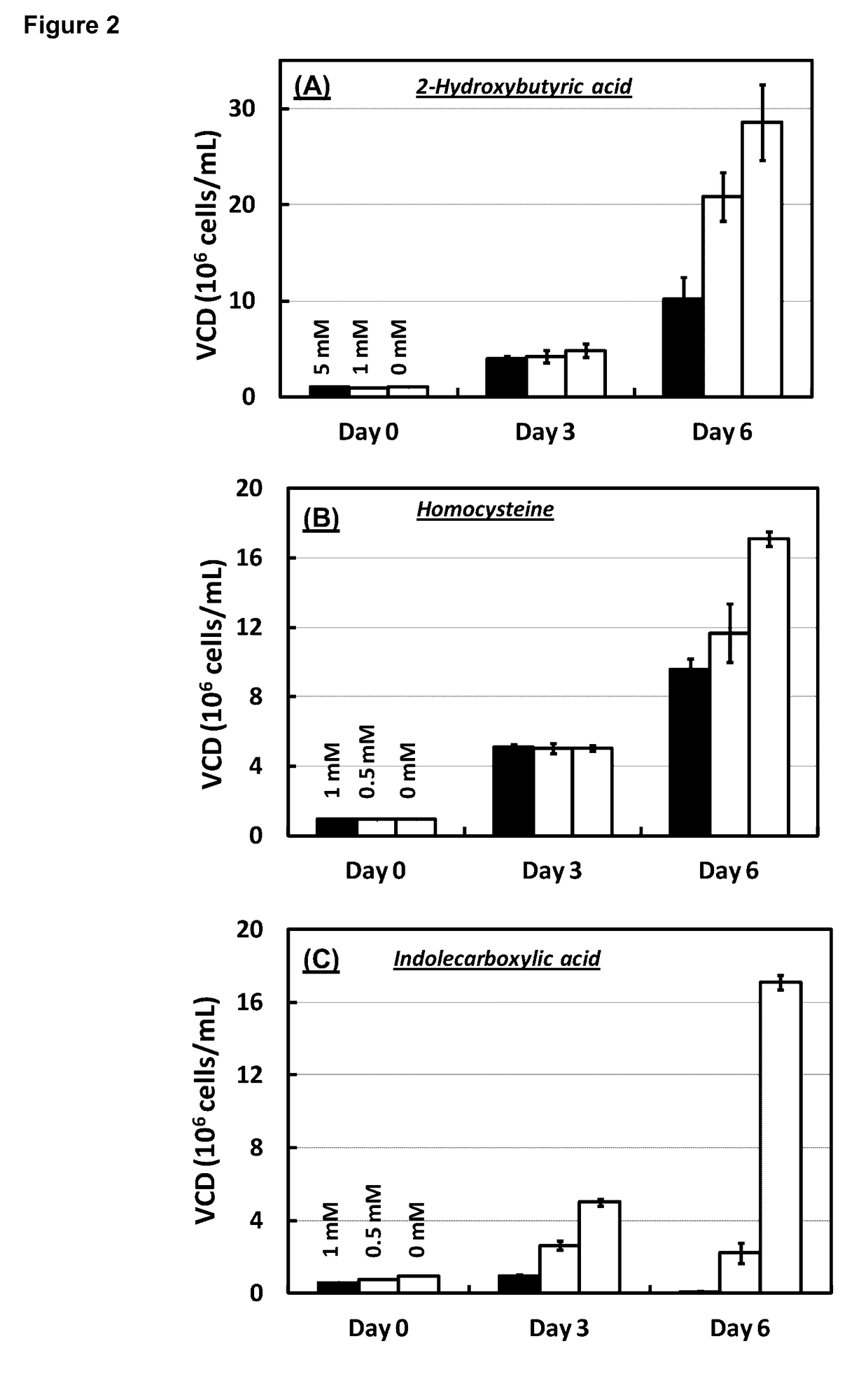

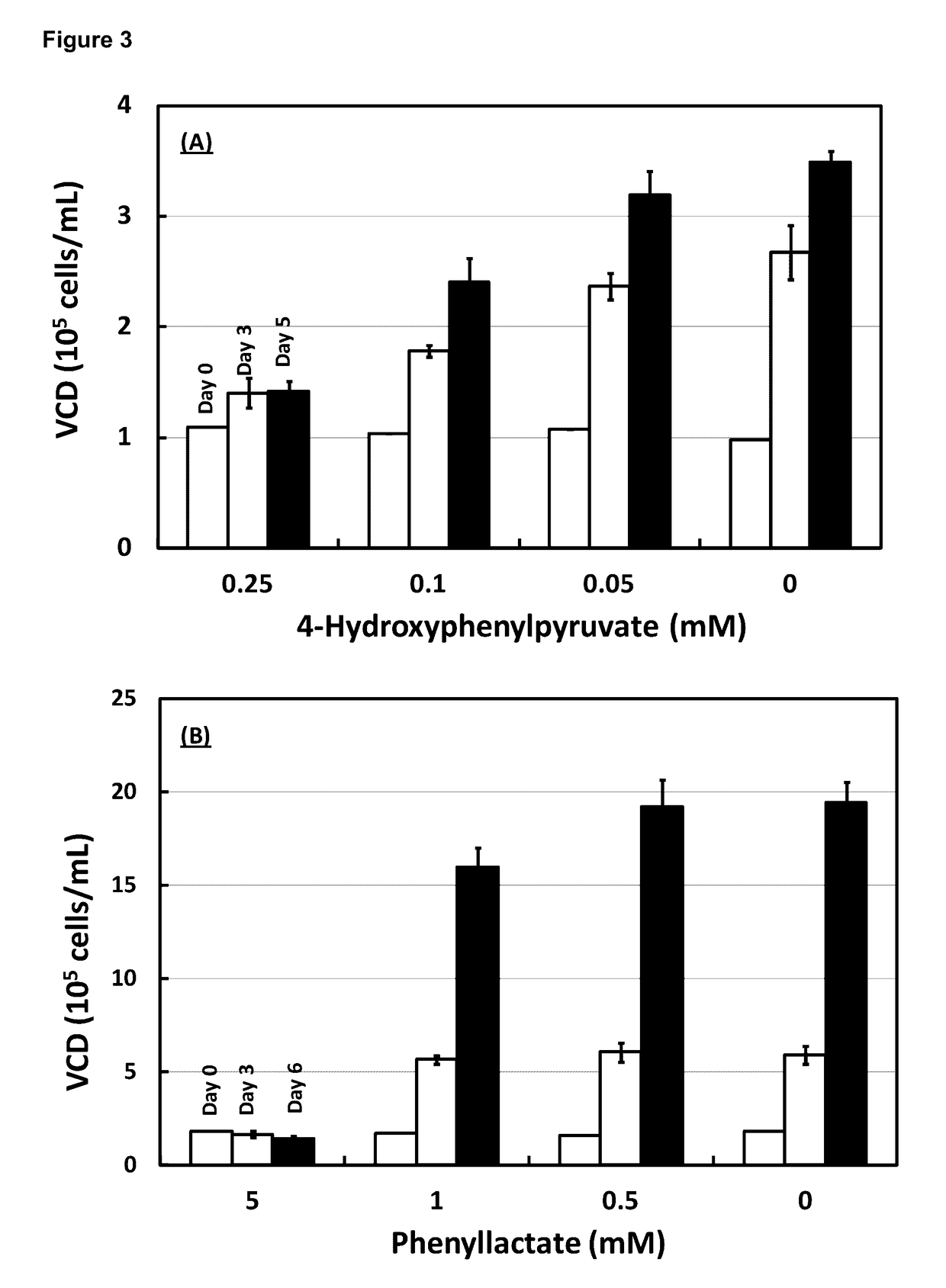

Method of cell culture

Owner:PFIZER INC

Tunnel duct piece joint waterproof ethylene propylene diene monomer rubber sealing gasket and preparation method thereof

The invention discloses a tunnel duct piece joint waterproof ethylene propylene diene monomer rubber sealing gasket and a preparation method thereof. The tunnel duct piece joint waterproof ethylene propylene diene monomer rubber sealing gasket is prepared from, by weight, 33-47 parts of ethylene propylene diene monomer rubber, 24-35 parts of brominated butyl rubber, 16-27 parts of polyurea resin, 3-6 parts of zinc hydrosulfite, 4-7 parts of polycarbodiimide, 8-12 parts of epoxidized soybean oil, 6-9 parts of divinyl benzene, 14-18 parts of strong magnesium powder, 2-3 parts of dilauryl thiodipropionate, 4-6 parts of 4,4-bis(tertiary butyl peroxide)butyl isovalerate, 5-8 parts of polymerized rosin, 3-5 parts of imidazolidinyl urea, 10-15 parts of titanium nitride, 2-3 parts of tetrabenzylthiuramdisulfide, 7-11 parts of diethylene glycol dibenzoate, 4-8 parts of carbonic acid ammonium zirconium salt, 2-4 parts of isobutylene triethoxy silane and 12-16 parts of modifier. The prepared sealing gasket is high in mechanical strength and excellent in water resistance, the water pressure resisting capacity reaches 2.5 MPa or above, and the waterproof capacity index is met.

Owner:HUAINAN CAOAN RUNLONG PLASTIC CO LTD

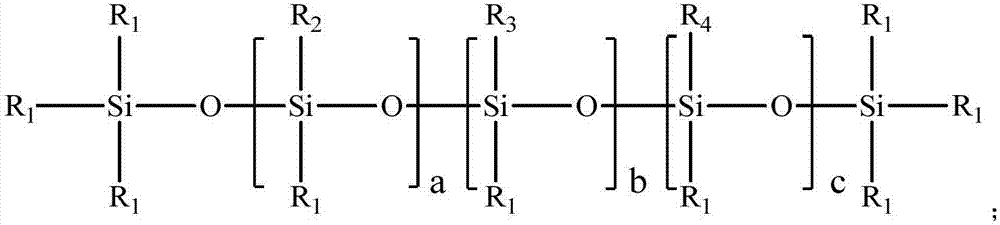

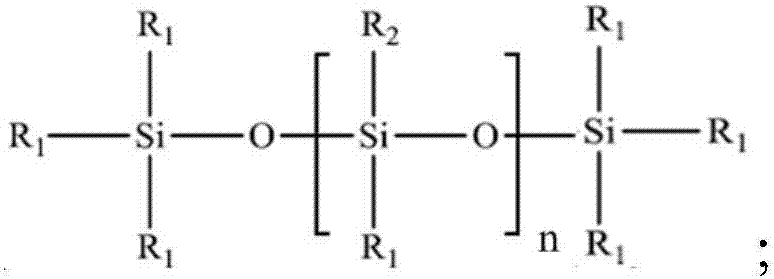

Thickening agent, thickening agent composition and preparation method of thickening agent

ActiveCN107987749AWide applicabilityLow costNon-macromolecular adhesive additivesMacromolecular adhesive additivesPolymer scienceAdhesive

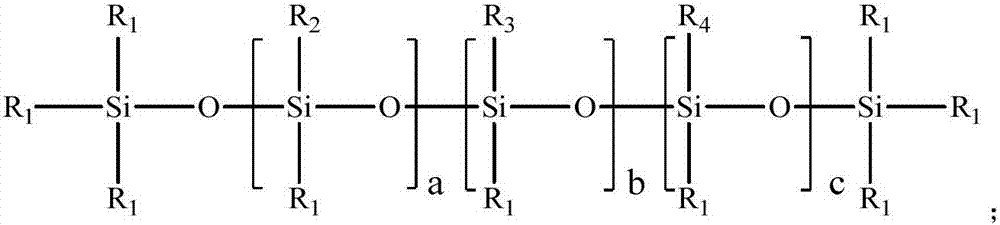

The invention discloses a thickening agent, a thickening agent composition and a preparation method of the thickening agent. The structural formula of the thickening agent is shown in the description,wherein R1 represents methyl, ethyl and phenyl; R2 represents hydrogen; R3 represents allyl glycidyl ether, glycidyl acrylate or 3-allyl-7-oxabicyclo[4.1.0]heptan; and R4 represents one of allyl propionate, allyl butyrate, allyl valerate, allyl isovalerate, allyl heptanoate, allyl octanoate, allyl phthalate; and a is more than or equal to 1, b is more than or equal to 1, c is more than or equal to 1, and the sum of a, b and c is more than or equal to 10 and less than or equal to 60. The composition contains the thickening agent and a metal coupling agent. According to the thickening agent composition, an encapsulation adhesive has relatively wide universality to the adhesion of different bracket materials, and the use cost of the encapsulation adhesive is lowered; and the mechanical performance, operation performance, storage performance and stability of the encapsulation adhesive are not influenced.

Owner:东莞市贝特利新材料有限公司

Novel lubricating grease for weaving machine and preparation method of novel lubricating grease

InactiveCN105255566AImprove the lubrication effectImprove wear resistanceLubricant compositionPolyvinyl alcoholDimethylol urea

The invention discloses novel lubricating grease for a weaving machine and a preparation method of the novel lubricating grease. The novel lubricating grease is prepared from, by weight, 70-85 parts of base oil, 6-8 parts of polyvinyl alcohol, 4-6 parts of epoxy acrylic acid, 3-5 pars of bornyl isovalerate, 3-5 parts of hydroxymethyl cellulose, 1-2 parts of citronellal, 0.5-1 part of dimethylol urea, 0.5-0.8 part of 4-guanidine butyric acid, 0.2-0.4 part of imarcaptoacetate dioctyltin and 0.02-0.8 part of succinic acid. The invention further provides the preparation method of the lubricating grease for the weaving machine.

Owner:付淑珍

Kyoho grape essence as well as preparation method and application thereof

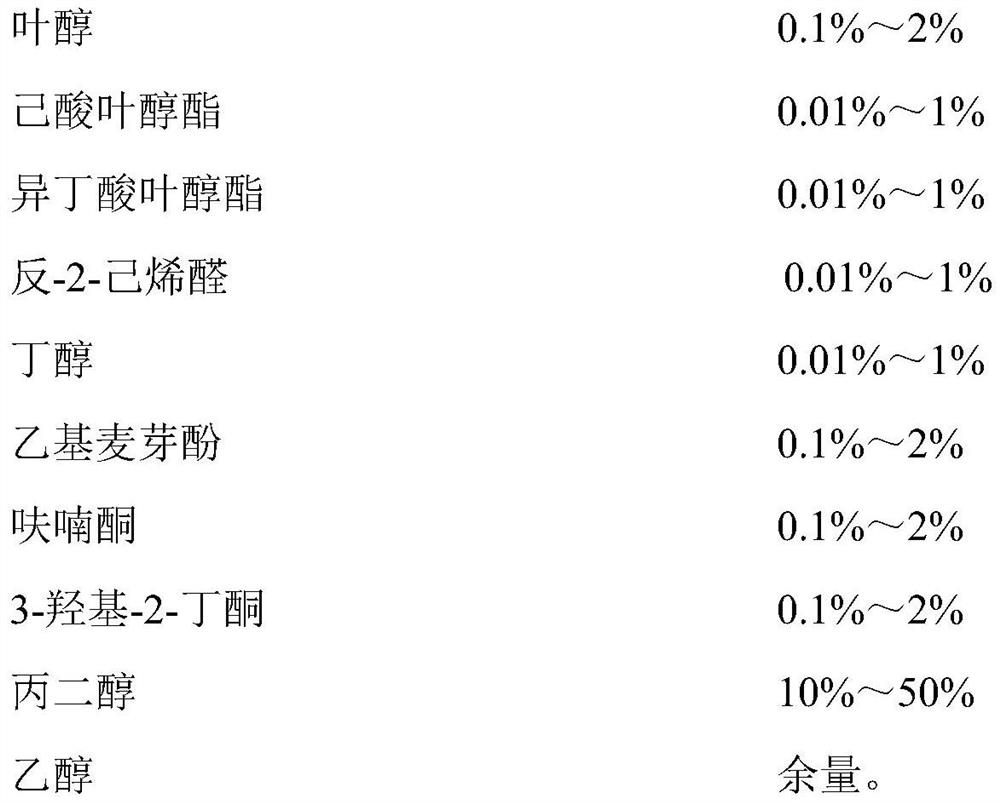

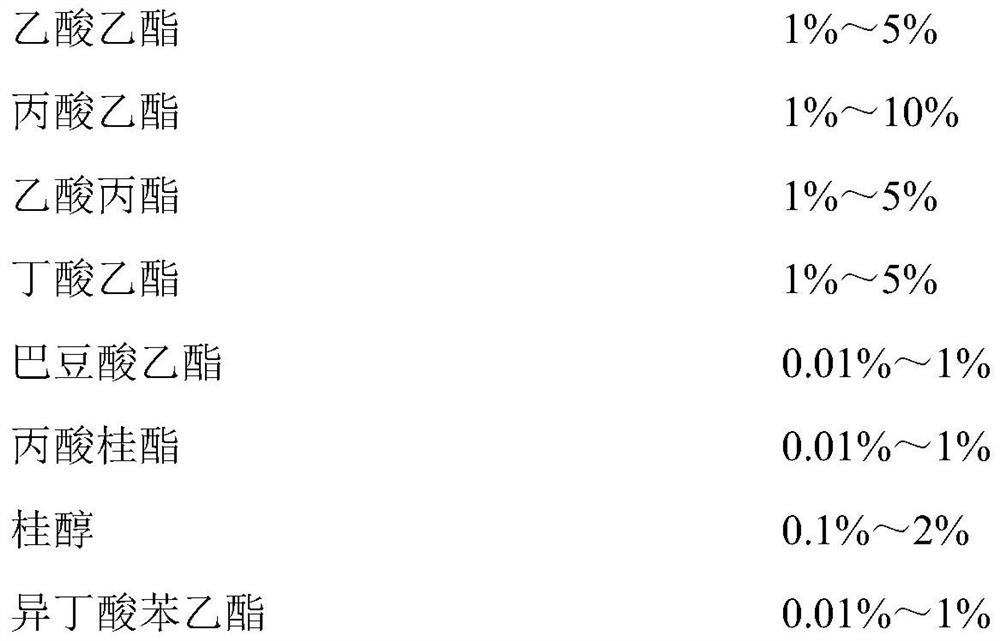

The invention discloses a Kyoho grape essence, which is prepared from ethyl acetate, ethyl propionate, propyl acetate, ethyl butyrate, ethyl crotonate, cinnamyl propionate, cinnamyl alcohol, phenethylisobutyrate, ethyl phenylacetate, beta-damascenone, cis-3-hexenyl isovalerate, storax alcohol, beta-citronellol acetate, beta-citronellol, styrallyl acetate, beta-geranyl acetate, beta-linalyl acetate and methyl anthranilate, N-acetyl anthranilate, ethyl caproate, ethyl caprylate, ethyl caprate, acetic acid, propionic acid, hexanoic acid, butyric acid, linalool, leaf alcohol acetate, leaf alcohol, hexanoic acid leaf alcohol ester, isobutyrate leaf alcohol ester, trans-2-hexenal, butanol, ethyl maltol, furanone, 3-hydroxy-2-butanone, ethanol and propylene glycol. The Kyoho grape essence disclosed by the invention is mellow and full in grape characteristic aroma and strong in natural feeling, and can enable a product to have natural Kyoho grape aroma and taste after being added into foods such as beverages, jam and pastries as a food additive.

Owner:CHINA TOBACCO YUNNAN IND

Blended lucuma nervosa essence and preparation method thereof

The invention discloses blended lucuma nervosa essence and a preparation method thereof. The essence comprises the following raw material components: 1%-3% of methyl cinnamate, 1%-3% of methyl cyclopentenolone, 1%-3% of isoamyl isovalerate, 0.1%-0.6% of isoamyl propionate, 3%-5% of ethyl butyrate, 3%-5% of ethyl acetate, 1%-3% of ethyl levulinate, 1%-5% of ethyl propionate, 0.3%-0.8% of peach aldehyde, 0.5%-2% of isoamyl alcohol, 0.5%-2% of ethyl isovalerate, 0.3%-0.8% of carrot oil, 10%-15% of 5-methylfurfural, 3%-7% of furfural, 3%-7% of ethyl vanillin and the like. The blended lucuma nervosa essence is harmonious and vivid in fragrance, good in fragrance stability, low in cost and suitable for industrial production.

Owner:SHANGHAI INST OF TECH

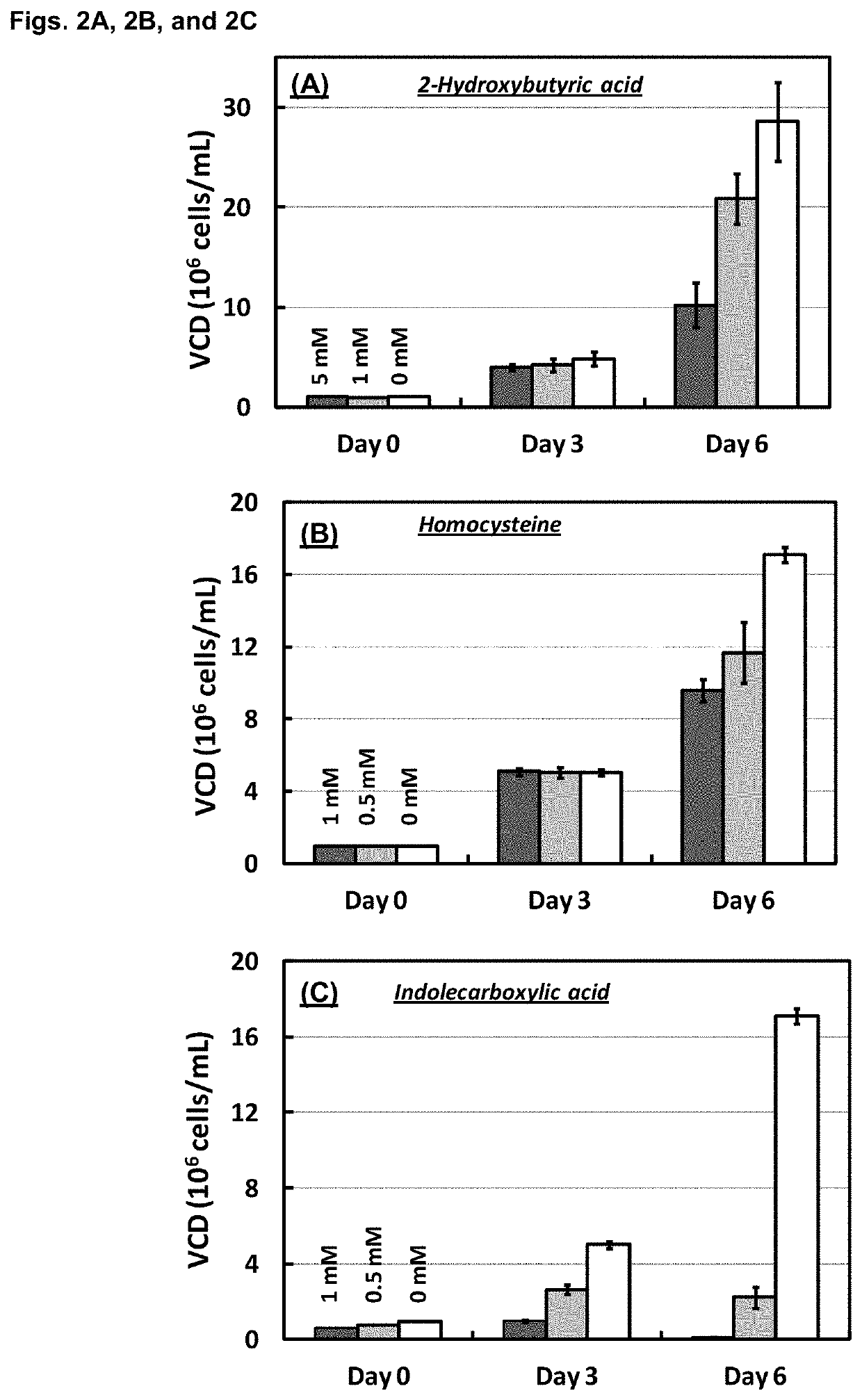

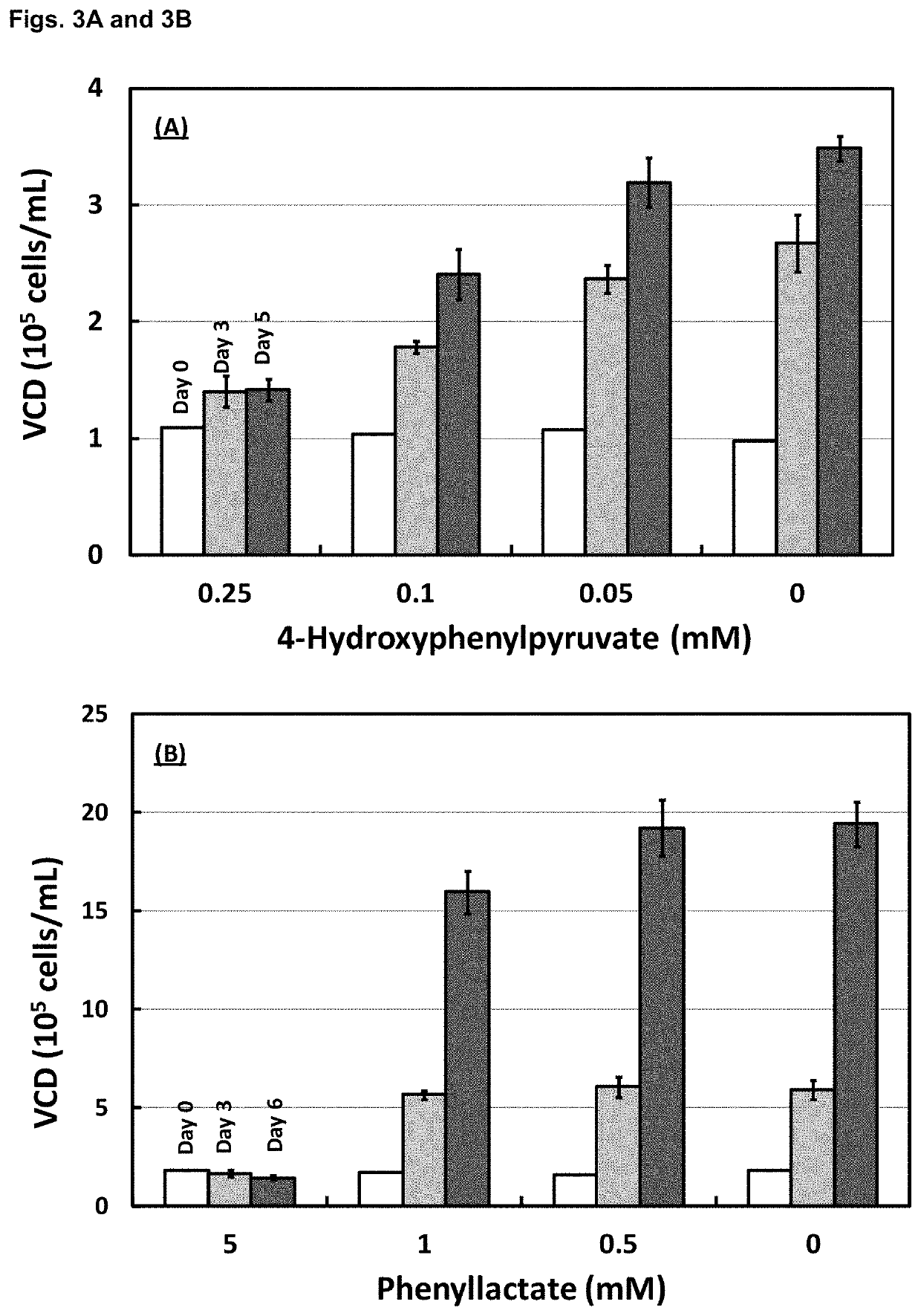

Method of cell culture

ActiveUS20170107552A1Reduce concentrationCulture processCell culture mediaHydroxybutyric acidMetabolite

A method of cell culture comprising providing cells in a cell culture medium to start a cell culture process, and,maintaining at least one metabolite selected from 3-(4-hydroxyphenyl)lactate, 4-hydroxyphenylpyruvate, phenyllactate, indolelactate, indolecarboxylic acid, homocysteine, 2-hydroxybutyric acid, isovalerate and formate below a concentration C1 in the cell culture medium, wherein C1 is 3 mM and / or(ii) maintaining at least one amino acid selected from phenylalanine, tyrosine, tryptophan, methionine, leucine, serine, threonine and glycine below a concentration C2 in the cell culture medium, wherein C2 is 2 mM.

Owner:PFIZER INC

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com