Patents

Literature

61results about How to "Full-bodied and full-bodied" patented technology

Efficacy Topic

Property

Owner

Technical Advancement

Application Domain

Technology Topic

Technology Field Word

Patent Country/Region

Patent Type

Patent Status

Application Year

Inventor

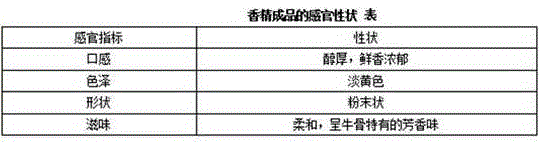

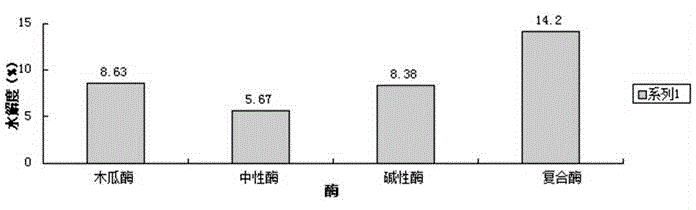

Beef-flavored essence preparation method

InactiveCN104855918AImprove conversion ratePromote digestionFood preparationMaillard reactionFlavoring essences

A beef-flavored essence preparation method, comprising the following steps of: degreasing cleaned ox bones at a high temperature crushing the ox bones by using a crusher after drying treatment for 30 minutes, and sieving by using a 100-mesh sieve to obtain ox bone powder; adding the ox bone powder into a reaction kettle, adding water into the reaction kettle in a material and liquid ratio of 1:14 to prepare an ox bone powder primer solution, adjusting the pH, adding a pepsase for enzymolysis for 3 hours and then adding a compound enzyme in proportion for further enzymolysis, and on the basis, inoculating compound bacteria in a certain proportion to ferment to obtain a bone collagen peptide solution; carrying out Maillard reaction on the bone collagen peptide solution and a reducing sugar to obtain an essence base material; and then mixing the base material with marinade in a certain proportion, blending, concentrating and drying to obtain the beef flavor essence. The beef-flavored essence prepared by the preparation method in the invention has the advantages of being natural in raw material, pure in meat flavor, lasting in fragrance and the like, and is widely applied to foods such as instant noodles, soup bases, fast foods and the like so as to increase or endow the food with a unique meat flavor.

Owner:HENAN UNIV OF SCI & TECH

Concentrated compound condiment with chicken flavor and preparation method of concentrated compound condiment

Owner:SHANGHAI INST OF TECH

Pork essence for meat product

InactiveCN101664155AEasy to useFull-bodied and full-bodiedFood preparation2-heptenal2-methyl-3-furanthiol

The invention provides pork essence for meat product, which is prepared by salad oil, furanone, 2-acetylpyrazine and liquid spices, wherein the liquid spices is selected from one or more of 2-hydrosulphonyl-3-butanol, 4-guaethol, 2-methyl-3-furanthiol, 2-hydrosulphonyl-3-butanone, anisic aldehyde, hydrosulphonyl furan acetate, 2-heptenal, 1,6-ethanthiol, isovalerate and 2-phenyl-5-methyl-2-hexenal, wherein the weight ratio of the salad oil, the furanone, the 2-acetylpyrazine and the liquid spices is 90-99:0.1-1:0.01-0.2:0.1-1.

Owner:TIANJIN CHUNFA BIO TECH GRP

Ganoderma lucidum spore composite fish sausage

The invention discloses a ganoderma lucidum spore composite fish sausage which is prepared by 50-100g of pork, 50-100g of pigskin, 20-25g of sugar, 30-40g of salt, 3-4g of ground pepper, 3-4g of five spice powder, 25-35ml of dark soy sauce, 10-15g of reishi shell-broken spore powder, 10-25g of pumpkin freeze-dried powder and 30-40g of mushroom wine in every1000g of fish paste. The mushroom wine is prepared by 60-100g of dried mushroom, 30-50g of dried lemon and 10-15g of rhizoma polygonati in every 1500g of white spirit. The ganoderma lucidum spore composite fish sausage is reasonable in component distribution ratio, enables the sausage to be mellow in taste, and is delicate in meat while suffusing an exquisite fragrance all around.

Owner:ANHUI HAOSHIYUAN FOOD

Salted egg yolk flavor composite fish sausage

The invention discloses a salted egg yolk flavor composite fish sausage which is prepared by 80-90g of pork, 50-70g of pigskin, 20-25g of sugar, 30-40g of salt, 3-4g of ground pepper, 3-4g of five spice powder, 25-35ml of dark soy sauce, 50-85g of salted egg yolk, 10-25g of pineapple freeze-dried powder and 30-40g of onion wine in every1000g of fish paste. The onion wine is prepared by 400-500g of onion and 30-50g of lotus leaf in every 1500g of red wine. The salted egg yolk flavor composite fish sausage is reasonable in component distribution ratio, enables the sausage to be mellow in taste,and is delicate in meat while suffusing an exquisite fragrance all around.

Owner:ANHUI HAOSHIYUAN FOOD

Frozen fermented glutinous rice or rice noodle products and key preparation method thereof

The invention relates to frozen fermented glutinous rice or rice noodle products and a key preparation method thereof. The products comprise a frozen pure fermented glutinous rice product and a mixedfrozen rice noodle product of fermented glutinous rice and other rice noodles. The key preparation method adopts drying and freezing techniques. Limited by the problems that the fermented glutinous rice is not easy to form due to high water content and not easy to dewater due to high sugar degree, starch is easy to age in products, and the like, the varieties of products using the fermented glutinous rice as a raw material are few, all the products cannot serve as convenient staple food, and the market rate is extremely low. The frozen fermented glutinous rice or rice noodle products are characterized in that glutinous rice and the like are used as raw materials to be fermented into fermented glutinous rice, and then the fermented glutinous rice is subjected to boiling, grinding, drying (partial dewatering) or addition of rice noodles, cooling, forming and freezing to obtain cooked or half-cooked frozen products. When eaten, the frozen fermented glutinous rice or rice noodle products are heated by roasting, frying, deep-frying, steaming, microwaving and the like. The products provided by the invention are purely natural fermented food, are sour, sweet, mellow, fragrant and chewy inmouthfeel, can serve as staple food or non-staple food, can be subjected to large-scale and standardized production, have a long shelf life, a simple and convenient preparation method, simple equipment and low cost, and can be prepared at home.

Owner:HARBIN UNIV OF COMMERCE

Chinese cooked wheaten food cuisine and preparation method thereof

The invention relates to the field of food, and in particular relates to Chinese cooked wheaten food cuisine. The Chinese cooked wheaten food cuisine is characterized by being prepared by extraction on tomato dices, tomato sauce, water, edible oil, edible salt, rock candy, beef dices, chicken dices and the like in base oil, frying and fragrance enhancement of main materials, vacuum back pressure mixing, preheating, filling and sealing and cooling in a three-stage gradient manner. A grading sterilization technology, a vacuum back pressure regulation technology and a three-stage gradient cooling technology are adopted; the tomatoes, the beef and the chicken which particularly meet the taste of Chinese people are used as the main materials, and shallots, gingers, garlic, onion, caraway, pepper, anise, chili, the edible oil and the like which are popular are used as auxiliary materials; the main materials and the auxiliary materials are reasonably matched; part of the main materials are treated by adopting a conventional frying technology, so that a product tastes good, smells good and has the bright color, and a product is a dish which is rich in nutrition and has the unique flavor; the Chinese cooked wheaten food cuisine can be added into cooked wheaten food, is uniformly stirred and eaten after being opened without adding any other auxiliary materials and is convenient to eat; the habits of Chinese people fond of frying food with the edible oil are met, and a requirement of a Chinese dish on the smell and the tastiness is completely met.

Owner:BEIJING YUANXIANJI FOOD SCI & TECH

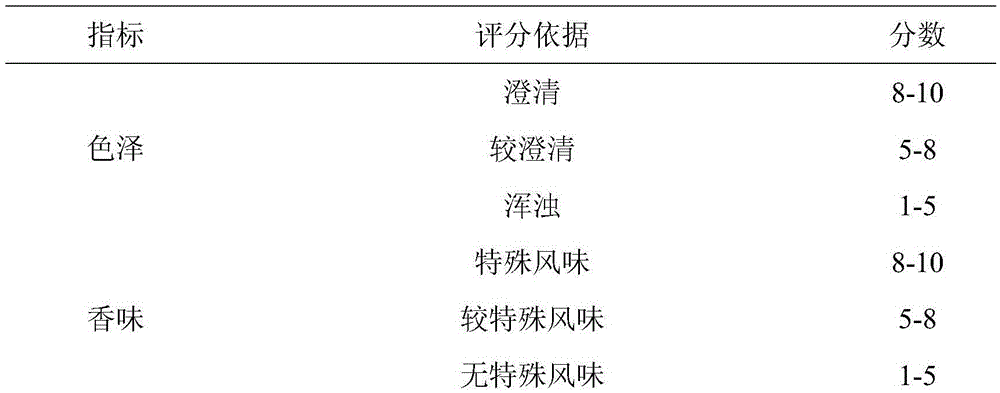

Preparation method of puer tea paste

InactiveCN102919399AReduce leachingFruityPre-extraction tea treatmentTea extractionShallow water areaFood science

The invention discloses a preparation method of puer tea paste and belongs to the technical field of puer tea processing technology. The preparation method is characterized by including the following steps: (1) cutting up puer tea; (2) putting the chopped tea into a bamboo tube and sealing tightly; (3) digging a pit at a shallow water area, burying the sealed bamboo tube into the pit, covering the pit with mud, pressing tightly, and fermenting; (4) burying the bamboo tube for one to six months, taking out the tea to be reserved; (5) containing the fermented tea with a container, smashing, and squeezing out juice to be reserved; (6) filtering the squeezed juice repeatedly through a filtering screen; (7) pouring the filtered juice into a boiling container, boiling the juice with slow fire till the juice become paste; and (8) containing the paste puer tea in a utensil, placing at a ventilation and cool position, and withering naturally to obtain tea paste. The preparation method is reasonable in processing technology, free of any additives, good in taste, convenient to carry and applicable to preparation of puer tea paste.

Owner:刘青

Process method for increasing high-quality baijiu rate of strong aromatic baijiu brewing production

InactiveCN108624461AImprove the cultivation effectExtended fermentation periodAlcoholic beverage preparationYeastDistillation

The invention discloses a process method for increasing a high-quality baijiu rate of strong aromatic baijiu brewing production and relates to the field of baijiu brewing. The process method comprisesthe following steps: preparing fermented grains, and preserving double bottom-fermented mashes of a former round; adding distiller's yeast, replenishing water, piling to culture bacteria, and preparing flavoring fermented grains; carrying out interlayer grain refluxing, forming cross ridges at the bottom of a pool, and sealing the pool to carry out fermentation; prolonging a fermentation period,taking up distillers' grains layer by layer, maintaining a fermentation pit, and retaining the double bottom-fermented mashes of the round in the fermentation pit; carrying out grain circulation distillation, and preparing fermented grains of a next round; placing the double bottom-fermented mashes of the former round at a steamer opening, carrying out distillation, and harvesting baijiu of different types; storing baijiu respectively, aging for a long time, and blending for use. By adopting the process method, process details of pit sealing, cover amounts of surface distillers' grains and pitend mud, and the like, are intensified. The process method disclosed by the invention is adopted to brew strong aromatic baijiu, and compared with a conventional strong aromatic baijiu brewing process, the process method has the advantages that the high-quality baijiu rate is increased, baijiu is mellow and full, thick and graceful in pit fragrance and long lasting and fine in aftertaste, and thepursuit of customers on high-quality strong aromatic baijiu can be met.

Owner:ANHUI GOLDEN SEED WINERY CO LTD

Fruit and vegetable sour soup prepared from tomatoes, and preparation method and application of fruit and vegetable sour soup

PendingCN112704210AExpand selectionImprove degassing effectFood preservationFood ingredient functionsBiotechnologyNutrition

The invention relates to a fruit and vegetable sour soup prepared from tomatoes, and a preparation method and application of the fruit and vegetable sour soup. The fruit and vegetable sour soup comprises the following raw materials in parts by weight: 30-40 parts of tomatoes, 5-10 parts of fresh red pepper, 5-10 parts of fresh oranges, 5-10 parts of lemon, 5-10 parts of carrots, 5-10 parts of crystal pears, 5-10 parts of roxburgh rose, 3-4 parts of edible salt, 0.5-4.5 parts of plant spices and 0.5-1 part of lactic acid bacteria. All raw materials of the fruit and vegetable sour soup prepared by the method disclosed by the invention are environmentally-friendly and natural materials, no chemical preservatives are added in a manufacture process, instead, the plant spices can be taken as raw materials, the fruit and vegetable sour soup has an antiseptic function, the taste of the fruit and vegetable sour soup can be increased, the fermented fruit and vegetable sour soup product has rich nutrients, a peculiar taste, is moderate in sourness, and conforms to pursue of modern people for nature, safety, environment protection, nutrition and health. In addition, the preparation method is simple, is easy in operation, is suitable for industrial large-scale production and can be easily popularized and applied.

Owner:贵州南山婆食品加工有限公司

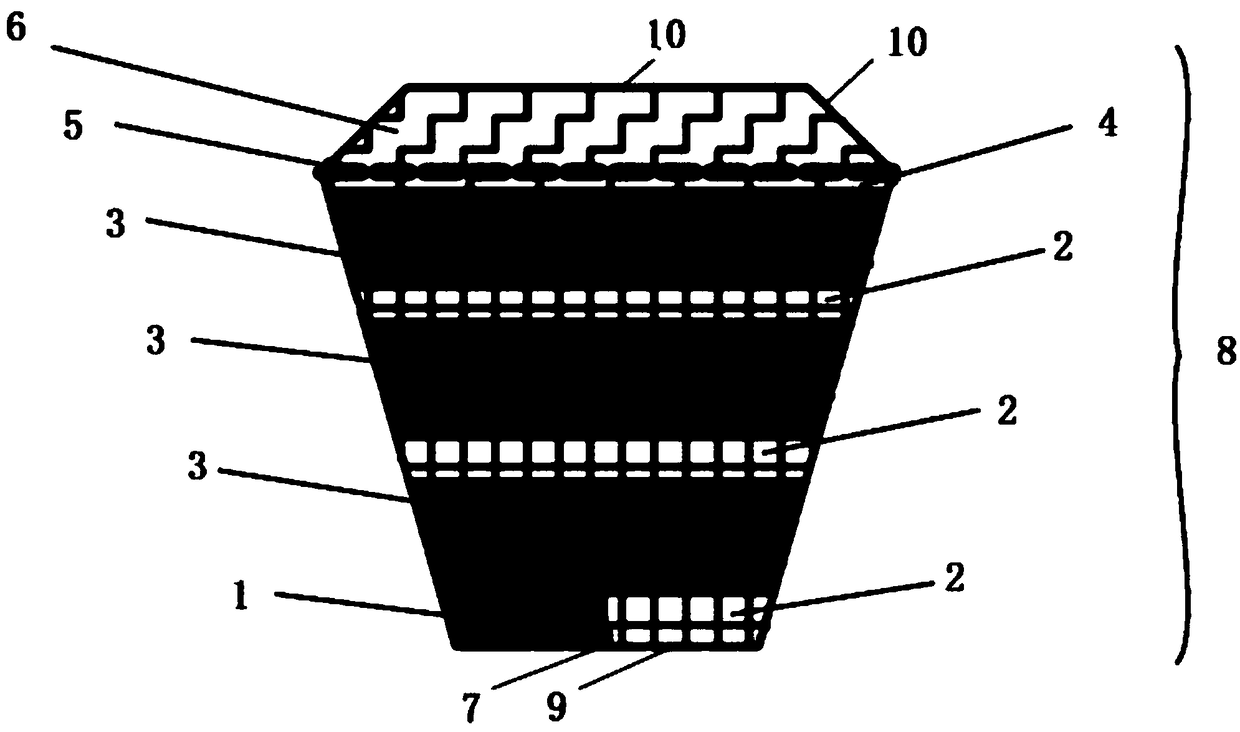

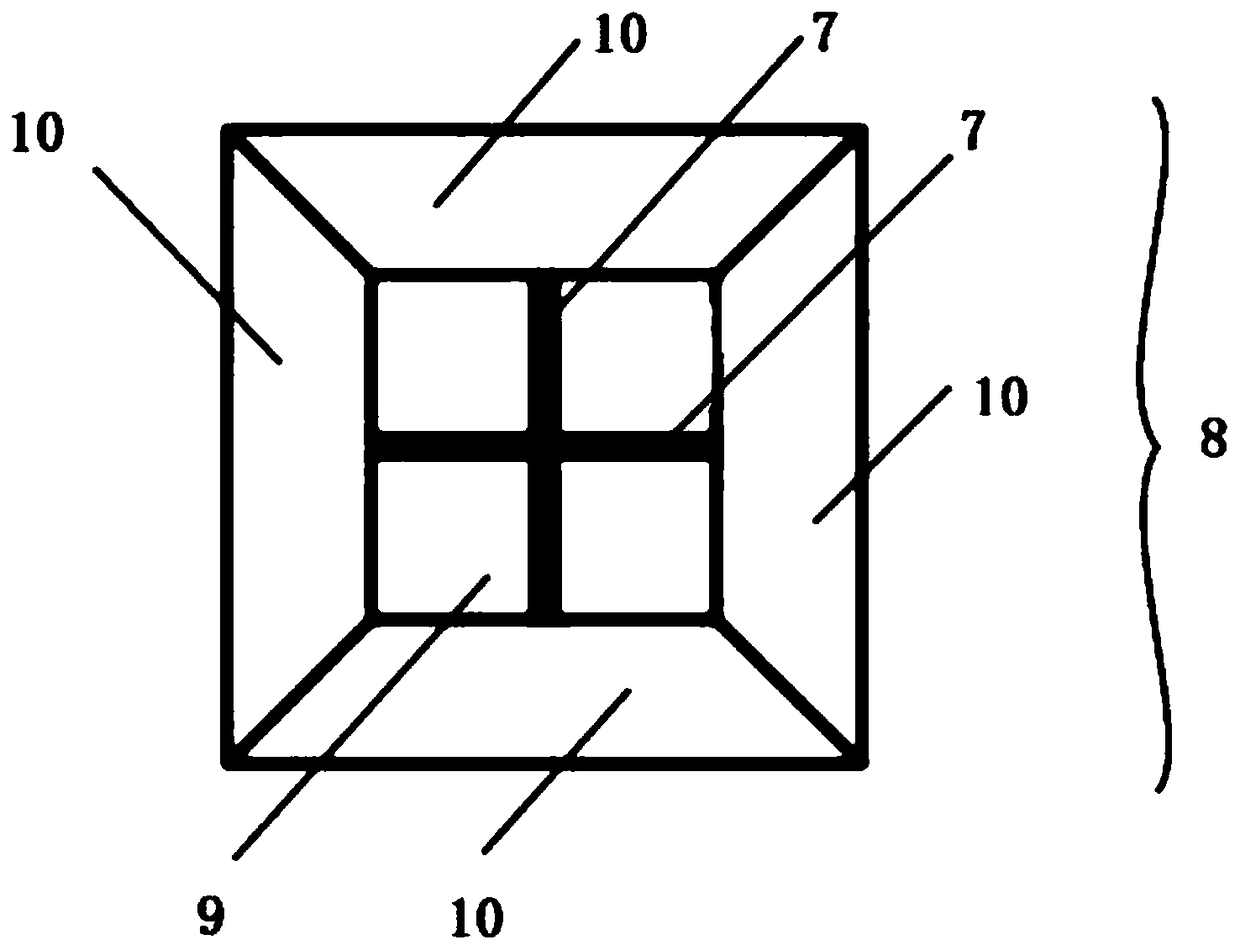

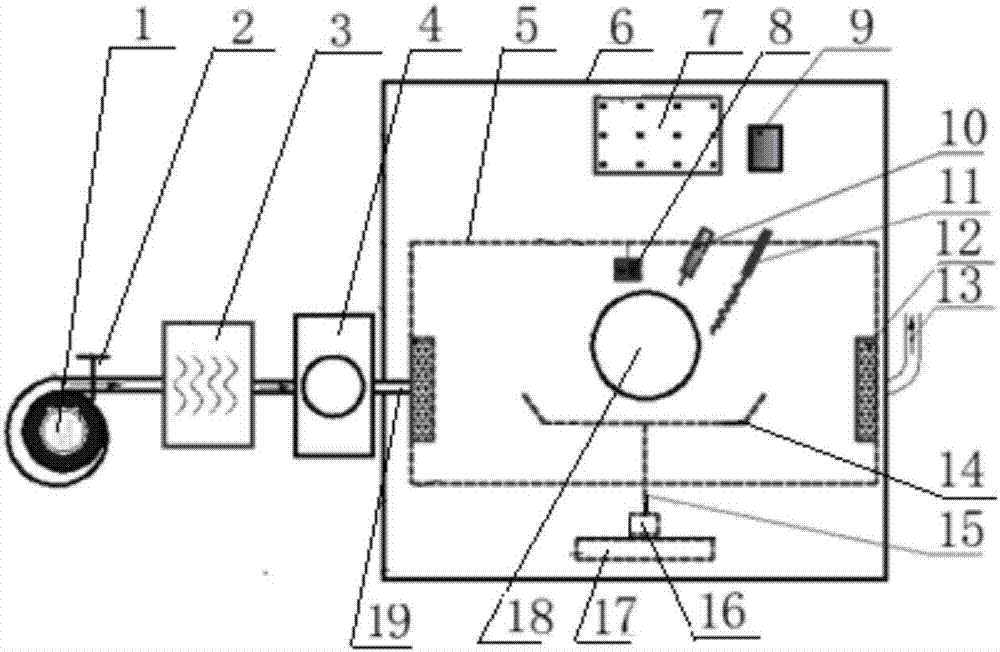

Microwave-convective thermostatic drier and method for making ready-to-eat millet by means of thermostatic drier

InactiveCN107120921ADry evenlyImprove efficiencyDrying solid materials with heatDrying gas arrangementsReady to eatAdditive ingredient

The invention discloses a microwave-convective thermostatic drier and a method for making ready-to-eat millet by means of the thermostatic drier. The drier is formed by connecting an air blower, an air-speed valve, an electric heating box, a thermocouple, a drying chamber, a drying case, a data acquisition and control instrument, a microware emitter, a system switch, an infrared probe, an optical-fiber probe, splitter plates, an air outlet tube, a material disc, a rotating shaft, a motor, an electronic scale, an observing window and an air inlet tube. According to the method for making the ready-to-eat millet by means of the thermostatic drier, millet is soaked, steamed with high pressure steam and then dewatered through the microwave-convective thermostatic drier, and high-quality primary-taste ready-to-eat millet is obtained. When the ready-to-eat millet is eaten, the millet is re-watered in boiling water, and then millet porridge is obtained; millet powder can be obtained by crushing the millet, and millet milk tea with a rich and full taste can be obtained after the millet powder is brewed; and microwave constant-temperature rapid dewatering and recovering of millet products are achieved, nutritional ingredients of the millet products and the inherent flavor of the millet are maintained, and important significance in improvement of quality and efficiency of drying processing and consumption of the millet products is achieved.

Owner:EASTERN GANSU UNIVERSITY

A kind of preparation method of meat flavor essence

ActiveCN102293395ANatural flavorStrong sense of cookingFood preparationReaction temperatureFood flavor

The invention relates to a method for preparing meat-flavored essence. The method comprises the following steps of: (1) mincing fresh beef, adding papain, and hydrolyzing the beef to obtain beef hydrolyzate; mincing fresh pork, adding the papain, and hydrolyzing the pork to obtain pork hydrolyzate; and mincing fresh chicken, adding the papain, and hydrolyzing the chicken to obtain chicken hydrolyzate; and (2) sequentially adding the beef hydrolyzate, the pork hydrolyzate and the chicken hydrolyzate, reducing sugar, amino acid, vitamin B1 (VB1) and table salt into a reaction kettle, fully stirring, heating and raising the temperature, controlling the reaction temperature to 100 to 200 DEG C and the reaction time to 1 to 3 hours, reducing the temperature after the reaction is finished, sieving with a vibrating screen, and discharging to obtain the meat-flavored essence. The meat-flavored essence prepared by the method has natural flavor, strong cooking feeling, mellow and full meat taste and long-lasting aftertaste.

Owner:TIANJIN CHUNFA BIO TECH GRP

Brewing method for tomato wine

InactiveCN104745370ASolve the problem of concentration and maturity, which is difficult to sellBrewing method is simpleAlcoholic beverage preparationAmyrisPotassium

The invention discloses a brewing method for a tomato wine. The brewing method comprises the following steps: cleaning and juicing tomatoes, adding 0.02% of potassium meta bisulfite into the obtained tomato juice, carrying out uniform mixing under stirring, standing the obtained mixture for 4 to 5 h to kill infectious microbes in the tomato juice and then adding a starch saccharification liquid to adjust a sugar degree to about 20%; adding 0.05% of active dry yeast for fruit wine, carrying out alcoholic fermentation, sealing the obtained fermentation broth in a jar for ageing for 5 months, adding 0.01 to 0.015% of gelatin and 0.08 to 0.012% of tannin in wine liquid, carrying out uniform mixing under stirring, standing the obtained mixture for 2 to 3 d and then carrying out filtering; and carrying out clarification, sterilization and cooling so as to obtain the finished tomato wine. Brewage of the low-alcohol tomato wine with tomatoes is a good approach to overcome the problem that considerable tomatoes are mature in a concentrated period of time and difficult to sell; the brewing method is simple; and the prepared tomato wine has simple, delicate and harmonious bouquet, the flavor of tomatoes, a pure, mild and full wine body, agreeable sour-sweet taste and a style unique to the tomato wine.

Owner:QINGDAO XIUXIAN FOODS

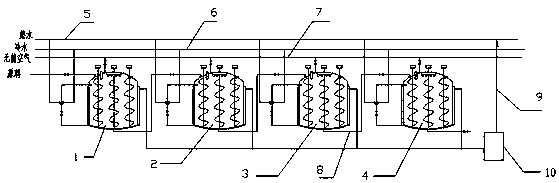

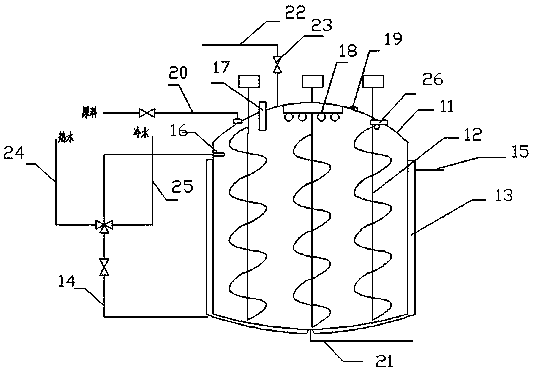

Continuous closed after-ripening fermentation production technology of Pixian thick broad-bean sauce

ActiveCN108391789ARealize closed fermentationReduced Pollution ChancesFood scienceFlavorBiotechnology

The invention discloses a continuous closed after-ripening fermentation production technology of a Pixian thick broad-bean sauce. The production technology is characterized by comprising the followingsteps of step 1, adding fermented mature hot pepper semi-finished products and fermented broad beans in the mass ratio of the fermented mature hot pepper semi-finished products to the fermented broadbeans being 7 to (2-3) to a fermenter I; step 2, raising the temperature of the fermenter I to 24-30 DEG C, performing heat preservation fermentation for 12-24h, and adding table salt to a reactor; step 3, transporting 1 / 2-2 / 3 of the total mass of a thick broad-bean sauce in the fermenter I to a fermenter II, and performing 8-14-period fermentation in the fermenter II; step 4, transporting 1 / 2-2 / 3 of the total mass of a thick broad-bean sauce in the fermenter II to a fermenter III, and performing 8-10-period fermentation in the fermenter III; and step 5, transporting 1 / 2-2 / 3 of the total massof a thick broad-bean sauce in the fermenter III to a fermenter IV, and performing 8-10-period fermentation in the fermenter IV. Through the adoption of the technology provided by the invention, products of which the flavor and the mouth feel meet requirements of the Pixian thick broad-bean sauce can be produced, and besides, the fermentation time is shortened.

Owner:XIHUA UNIV

Auricularia auricula and black garlic wine

ActiveCN105647737AHigh nutritional valueGreat tasteAntinoxious agentsAlcoholic beverage preparationFiltrationMycelial cord

The invention relates to auricularia auricula and black garlic wine prepared with the method as follows: unpeeled garlic is placed in an incubator and fermented at the high temperature, and black garlic is prepared; the black garlic is peeled, water is added after washing, and the black garlic is milled into a black garlic pulp through a colloid mill; the black garlic pulp is inoculated with an activated auricularia auricula liquid after pasteurization, magnesium sulfate is added, and culture is performed in a fermentation tank; after auricularia auricula mycelia grow from the black garlic pulp, the black garlic pulp is added to the fermentation tank after homogenization, sugar is added for sugar degree adjustment, sweet distiller's yeast is added for fermentation, and the surface of the fermentation tank does not bubble; filtration is performed, Fen-flavor yellow water is added for secondary fermentation, filtration is performed, the liquid is stored for 3-4 months after sealing, and the auricularia auricula and black garlic wine is obtained. The auricularia auricula and black garlic wine contains various amino acids and microelements essential to human bodies, contains multiple antioxidant active factors, is high in nutritional value and antioxidant activity, has the fragrant and delicious flavor and tastes strong and mellow.

Owner:HUBEI UNIV OF TECH

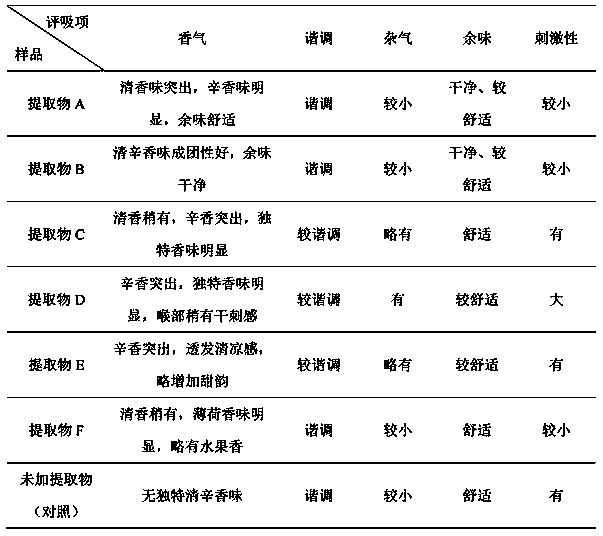

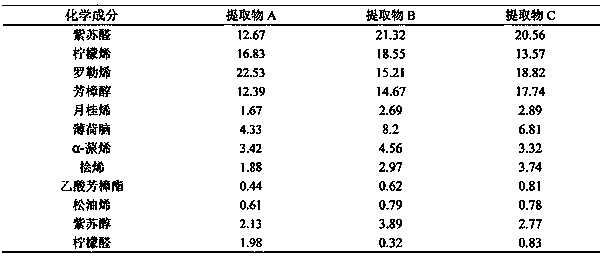

Perfume used for refreshing pungent type flavor cigarettes, preparation method thereof, and applications of perfume in cigarettes

ActiveCN110358630AFull-bodied and full-bodiedGood lasting effectTobacco preparationEssential-oils/perfumesFlavorOrganic solvent

The invention belongs to the technical field of tobacco processing and more specifically relates to a perfume used for refreshing pungent type flavor cigarettes, a preparation method thereof, and applications of the perfume in cigarettes. The perfume is composed of, by mass, 20 to 30% of Sichuan pepper bud and leaf, 30 to 60% of perilla leaf, and 20 to 40% of plectranthus tomentosa. In cigarette preparation process, an organic solvent solution containing the dissolved perfume is sprayed onto cut tobacco uniformly, when the weight amount of the perfume accounts for 0.01 to 0.1% of that of the cut tobacco, cigarette smoke can be enriched, effective flavouring effect on cigarette products is achieved. The perfume is capable of proving cigarettes with unique fragrance, cigarette characteristics are improved to be obvious, and cigarette internal quality is increased. The effect of the perfume as a cigarette perfume is obvious, application prospect in preparation of cigarette products with unique characteristics is promising, and the perfume is suitable for cigarette industrialized production.

Owner:CHINA TOBACCO HENAN IND

Composite flavor type mixed liquor and preparation method thereof

InactiveCN109136025AMeet needsFull-bodied and full-bodiedDigestive systemAlcoholic beverage preparationFlavorAdjuvant

The invention relates to the field of mixed liquor, and in particular to composite flavor type mixed liquor and a preparation method thereof. The base liquor of the mixed liquor is prepared by mixingfen-flavor base liquor and base liquor with other flavors, wherein the percent by volume of the fen-flavor base liquor is 80-98%, the percent by volume of the base liquor with other flavors is 2-20%,and the base liquor with other flavors is one or more of strong-flavor liquor, soy sauce flavor type liquor, rice-flavor liquor, fragrant-flavor liquor, Feng-flavor liquor, sesame-flavor liquor, mixed-flavor liquor, medicinal-flavor liquor, soybean-flavor liquor, Te-flavor liquor and Laobaigan-flavor liquor; 0.2-1.6 g / L of tartary buckwheat extracts, 0.01-0.50 g / L of kudzuvine root extracts, 0.01-0.50 g / L of fructus momordicae extracts and 0.45-2.0 g / L of adjuvant material extracts are added into the base liquor, wherein adjuvant materials are selected from one or more of fructus lycii, fructus gardeniae, fructus crataegi, flos chrysanthemi, angelica sinensis, orange peel and pawpaw. Through reviews, it is proved that the liquor body prepared by using the method is full and rich in taste and capable of meeting requirements of more consumers.

Owner:山西三十七度酒业有限公司

Chicken watery essence and preparation method thereof

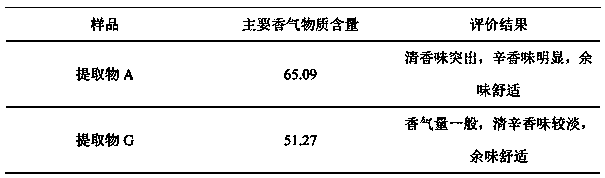

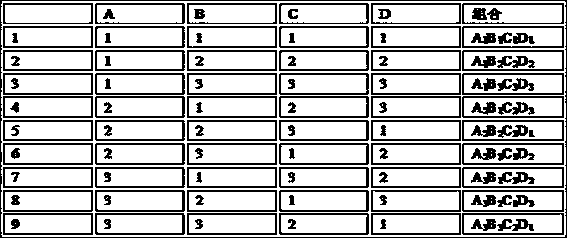

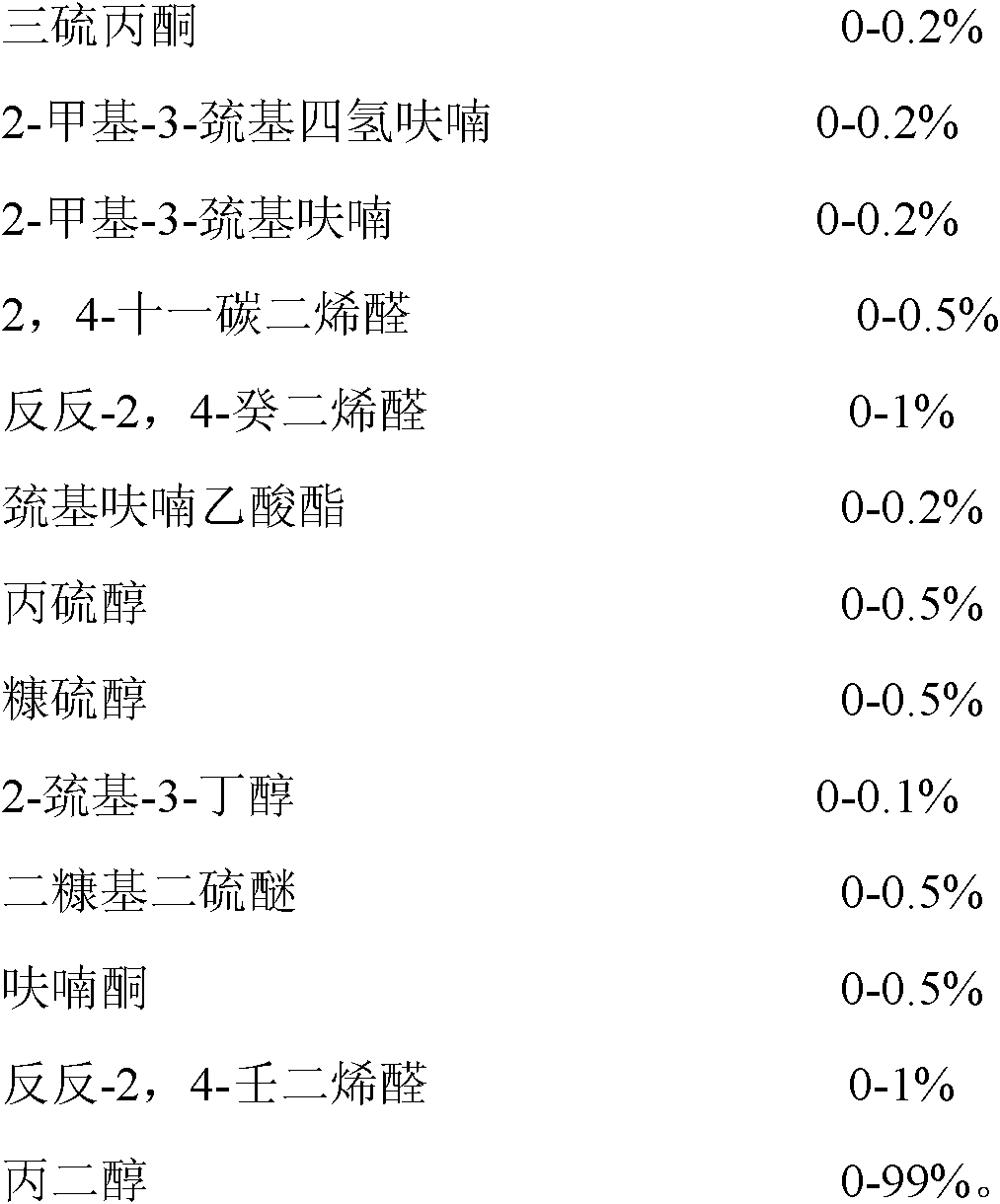

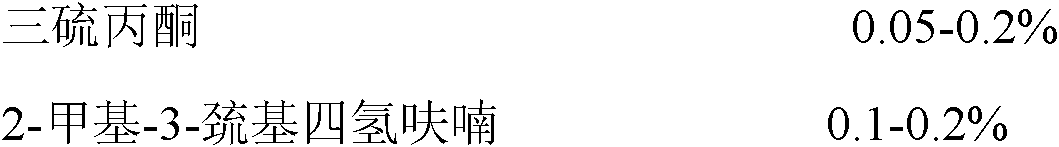

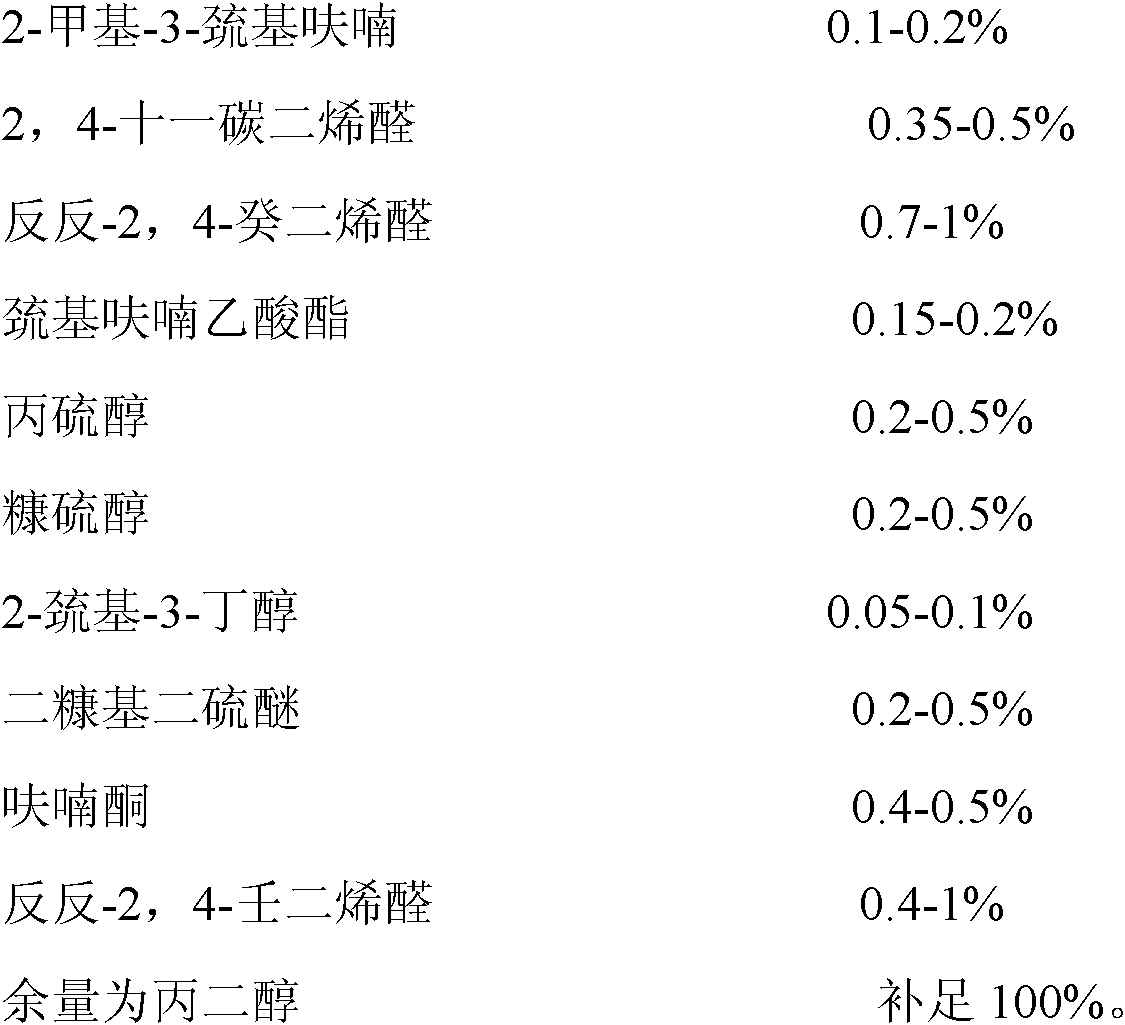

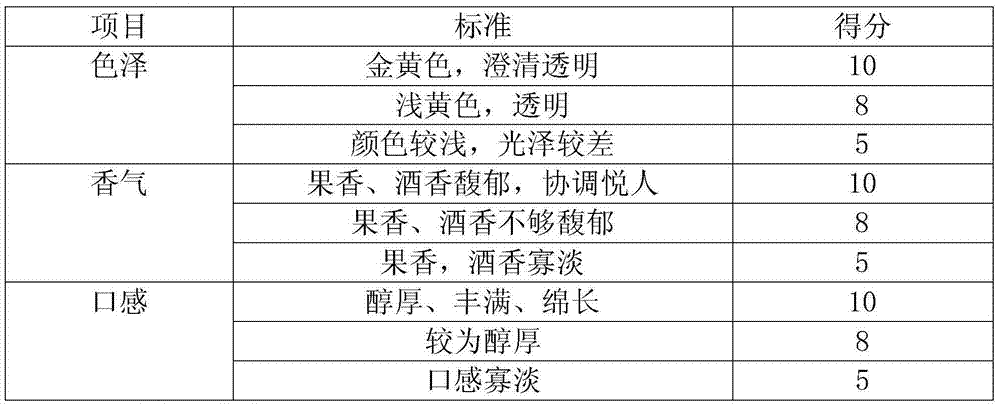

The invention relates to a chicken watery essence and a preparation method thereof. The essence is prepared by using the following raw materials: 2,2,4,4,6,6-hexamethyl-S-trithiane, 2-methyl-3-tetrahydrofuranthiol, 2,4-undecadienal, trans,trans-2,4-decadienal, mercapto furyl acetate, propanethiol, furfuryl mercaptan, 2-mercapto-3-butanol, difurfuryl disulfide, furanone, trans,trans-2,4-nonadienal, and propylene glycol. The prepared essence product has obvious flavor of chicken, is natural and harmonious, and has high degree of truth.

Owner:TIANJIN CHUNFA BIO TECH GRP

Brewing technology of pineapple fruit wine

The invention discloses a brewing technology of pineapple fruit wine. The brewing technology includes the following steps that first, the top of a pineapple is cut so that a notch can be formed, sarcocarp is taken out, and intact pericarp is dried and reserved for use; second, the sarcocarp is sliced and are beaten into pineapple pulp; third, the intact pericarp serves as a container, the pineapple pulp is poured in the container, yeast inoculation is performed, main fermentation is performed for 7-9 days at the temperature of 20-30 DEG C, then the temperature is lowered to 15-20 DEG C, and secondary fermentation is performed for 15-30 days; fourth, fermented broth is taken out of the pericarp, filtered and clarified and then is used as the pineapple fruit wine. Due to the technology, aroma compounds of the pineapple are well reserved, and the finished fruit wine has strong pineapple aromas.

Owner:黄馨莹

Preparation method of dark tea and dark tea brick

ActiveCN103960379BGuaranteed qualityGuaranteed yieldPre-extraction tea treatmentProcess engineeringFermentation

The invention discloses a method for preparing dark tea and dark tea bricks. The preparation method of black tea is as follows: fresh tea leaves are greened, and after kneading, pile up the tea leaves to a height of 0.8-1.5 meters, and carry out pile fermentation for 3-5 times, and the fermentation time of each pile is 2~4 hours. After the heap fermentation is over, remove the tea leaves to dissipate heat, cool down to room temperature, and then carry out the next heap fermentation, then re-knead the tea leaves, dry them, naturally ferment them for 8-15 months, and press them into molds. The tea bricks of the dark tea are neat and compact in shape, and the brewed black tea soup is orange-red in color, rich in fragrance and mellow in taste, and the finished product has a storage time of 10 to 15 years.

Owner:贺州市天洲茶业有限公司

Preparation method of spicy pigeon neck

InactiveCN109123454APromote skin cell vitalityIncrease skin elasticityNatural extract food ingredientsFood ingredient as mouthfeel improving agentChemistrySodium bicarbonate

The invention discloses a preparation method of spicy pigeon neck, which comprises the following steps: 1) pickling pigeon necks by using a pickling solution, taking out, and obtaining preserved pigeon neck pieces; 2) boiling pigeon necks by using a jar sealing wine, and pickling with a sodium bicarbonate solution to obtain pretreated pigeon necks; 3) adding pretreated pigeon necks into the prepared seasoning, boiling, taking out, draining, mixing with pre-treated guar gum, and obtaining flavored pigeon necks; the preparation method of the pretreated guar gum comprises the following steps: feeding edible guar gum into water, uniformly stirring, stirring at 70-80 DEG C, adding pretreated montmorillonite particles in a stirring state, continuously carrying out ultrasonic dispersion for 10-15minutes, and spray-drying to obtain pre-treated guar gum; 4) packaging the flavored pigeon necks in a specification, vacuum sealing, and radiating and sterilizing to obtain the spicy pigeon necks. The prepared pigeon neck has the characteristics of elasticity, crispness, delicious taste, comfort taste and the like.

Owner:南宁利腾农业科技有限公司

Tartary buckwheat daqu liquor

ActiveCN103421649AFull-bodied and full-bodiedThe entrance is smooth and comfortableMetabolism disorderAlcoholic beverage preparationBiotechnologyPolygonum fagopyrum

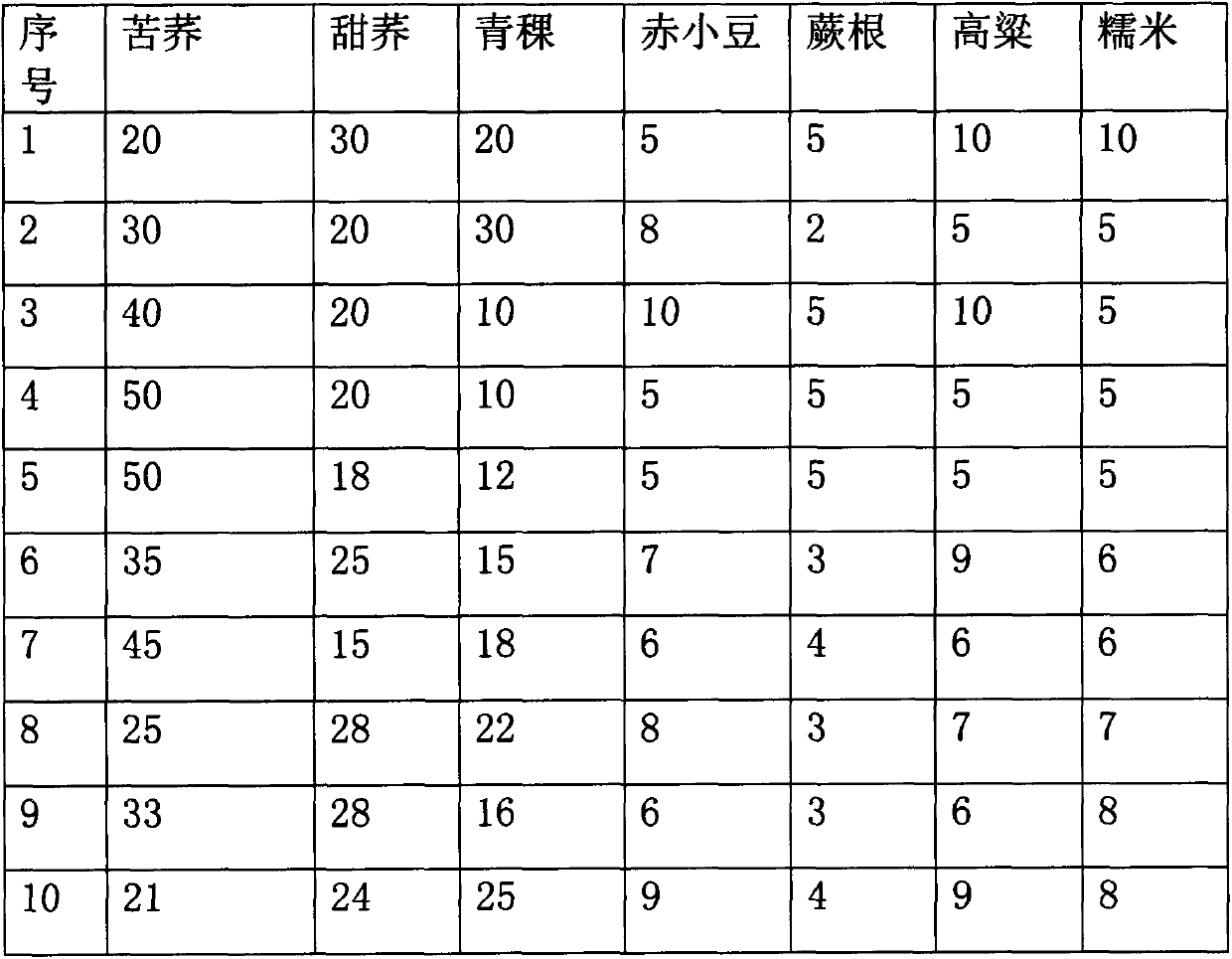

Tartary buckwheat daqu liquor is characterized in that the liquor is prepared through the method which comprises the steps that A. materials are prepared, namely clean and dry tartary buckwheat, common buckwheat, highland barley, phaseolus angularis, broomcorn, sticky rice and pteridium squilinum are sufficiently prepared; a. the tartary buckwheat, the common buckwheat, the highland barley, the phaseolus angularis, the broomcorn and the sticky rice are smashed respectively, the average grain size after smashing is 1 / 4-1 / 8 of the size of raw material particles; b. the pteridium squilinum is crushed into thin segments with the lengths not larger than 3mm; c. 20%-50% of the smashed tartary buckwheat, 20%-30% of the smashed common buckwheat, 10%-30% of the smashed highland barley, 5%-8% of the smashed phaseolus angularis, 5%-10% of the smashed broomcorn, 5%-10% of the smashed sticky rice and 2%-5% of the crushed pteridium squilinum thin segments are weighed according to the raw material overall weight and are evenly mixed to form mixed materials; B. the mixed materials are produced with a mixed steaming continuing grain method, the materials are put into a pit in low temperature, a pit pool is sealed for 75-80 days, then multi-section liquor taking is carried out, and tartary buckwheat daqu base liquor is obtained. The tartary buckwheat daqu base liquor is stored in a segmenting mode for standby application, blending is carried out according to needs, and the tartary buckwheat daqu liquor is obtained. The daqu liquor is nutritional type healthy high-class drinking white spirit which has soft flavor and is fragrant, thick, pure and mild.

Owner:赵何平

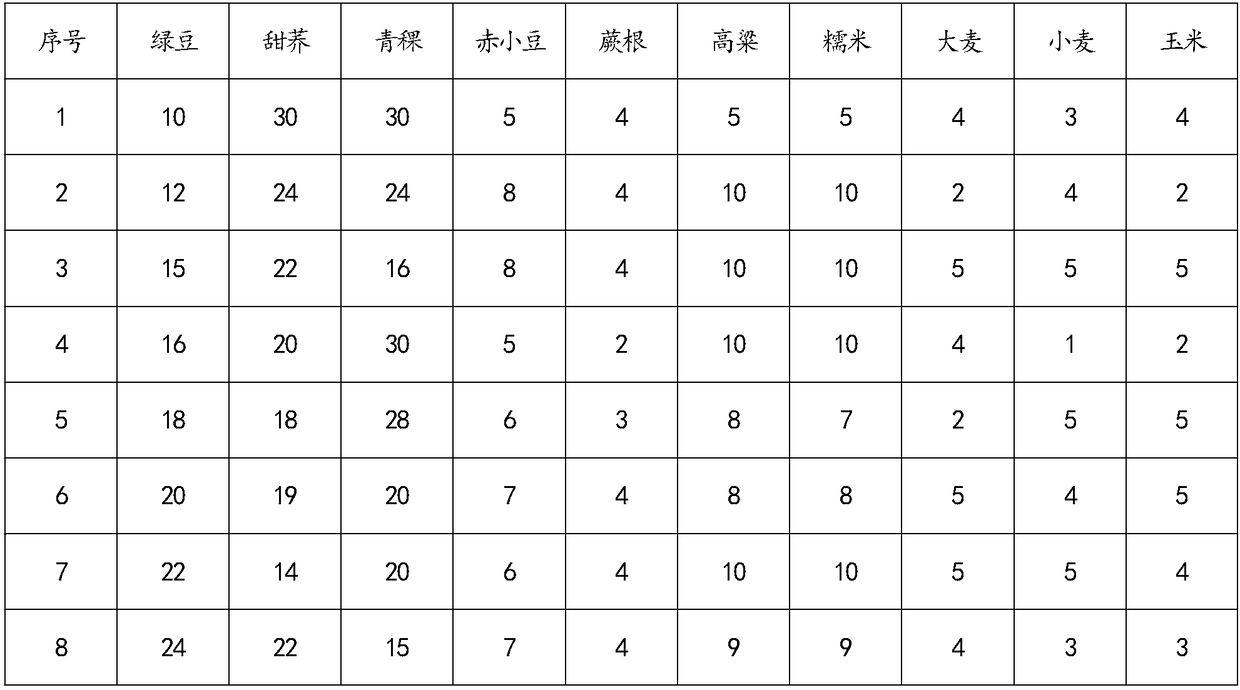

Brewing method of mung bean Daqu liquor

InactiveCN108203645AGet aromaGet the effect of clearing heat and detoxifyingAlcoholic beverage preparationFlavorDecomposition

The invention discloses a brewing method of mung bean Daqu liquor. According to the brewing method, mung bean is taken as one fermentation raw material; in adopted Daqu starter, mung bean powder is taken as a starter raw material; the fragrance and the heat clearing and detoxifying effects of mung bean are achieved; the Daqu starter prepared from mung bean powder is more suitable to be used for decomposition of proteins and starch in mung bean into flavor substances; the brewing method is simple to control, and is more convenient.

Owner:泸州施可富大曲酒厂有限责任公司

Method for reducing organic acid of plum wine

InactiveCN107586659AAdd lessSolve difficult problems that are difficult to physically removeAlcoholic beverage preparationPectinaseOrganic acid

The invention discloses a method for reducing organic acid of plum wine. The method comprises the following steps that: 1) plums are enucleated and broken, pectinase and cellulase are added, enzymolysis is carried out at 15-18 DEG C for 6 to 10h and filtration is conducted to obtain plum Juice; 2) xylitol by weight of 0.01 to 0.1% of the plum juice are added to the plum juice, the plum juice is cooled to 1 to 2 DEG C at a cooling speed of 5 to 10 DEG C / 30min, the plum juice is stirred during a cooling process with a stirring speed of 1000 to 2000r / min, after cooling, stirring is stopped, insulation and standing are conducted for 1 to 2h, filtration is conducted, and filtrate is taken for spare use; 3) sugar content of the filtrate is adjusted to 16 to 20 degree Bx, yeast is inoculated, and fermentation is conducted to obtain original wine; 4) the original wine is clarified, aging is conducted to obtain the plum wine. The method for reducing the organic acid of the plum wine can effectively reduce tartaric acid and malic acid content in the plum wine, and the prepared plum wine has soft wine body, mellow taste and harmonious aroma.

Owner:GUANGXI YUNHENG WINERY

Rabbit sausage with matcha and nutlet

The invention discloses a rabbit sausage with matcha and nutlet. The weight ratio of the raw materials of the sausage is that every 1000 grams of rabbit meet is added with 50 to 100 grams of pork, 20 to 25 grams of sugar, 30 to 40 grams of salt, 3 to 4 grams of pepper powder, 3 to 4 grams of five spices powder, 20 to 30 ml of dark soy sauce, 4 to 5 grams of matcha powder, 5 to 7 grams of fig powder, 5 to 7 grams of badam kernel, 10 to 15 grams of peanut kernel, 5 to 7 grams of pecan kernel, and 30 to 40 grams of qi and blood warming and invigorating wine. The components of the sausage are reasonable in proportion, so that the sausage has mellow taste and tender meat, and is fragrant.

Owner:牛岷

a meat flavor

Owner:TIANJIN CHUNFA BIO TECH GRP

A method for brewing sherry wine by dual-bacteria fermentation

ActiveCN109486601BIncrease acidityIncrease aromaMicroorganism based processesAlcoholic beverage preparationBiotechnologyAlcohol

Owner:SHIJIAZHUANG ZHAOLONG FOOD CO LTD

Method for preparing cereal-flavored highland barley wine

The invention relates to a preparation method of cereal-flavored highland barley wine, which is characterized by comprising the steps of S1, selecting materials; S2, pretreating; S3, moistening grains; S4, cooking; S5, spreading for airing, and adding distiller's yeast; S6, fermenting; S7, baking; S8, extracting; S9, blending; and S10, carrying out final treatment. The highland barley wine prepared via the preparation method of the cereal-flavored highland barley wine has very strong cereal flavor and rice scent, the original plant aroma of the highland barley wine can be weakened, the highland barley wine has composite aroma, the body of the wine is mellow and thick, the taste is mellow and soft, and the wine taste is integrated and excellent.

Owner:西藏达热瓦生物科技股份有限公司

Acidity reducing method of blueberry wine

InactiveCN107557235AAdd lessSolve difficult problems that are difficult to physically removeAlcoholic beverage preparationPectinaseEnzymatic hydrolysis

The invention discloses an acidity reducing method of blueberry wine. The acidity reducing method comprises following steps: 1, blueberries are smashed, pectase and cellulase are added for enzymatic hydrolysis, and an obtained product is filtered so as to obtain blueberry juice; 2, 0.01 to 0.1wt% of xylitol is added into the blueberry juice, an obtained mixture is cooled to 1 to 2 DEG C at a temperature reducing speed of 5 to 10DEG C / 30min with stirring at a stirring speed of 1000 to 2000r / min, after cooling, stirring is stopped, the mixture is allowed to stand at the constant temperature for1 to 2h, and is filtered, and an obtained filtrate is collected for further processing; 3, the sugar degree of the filtrate is adjusted to 16 to 20 DEG Bx, the filtrate is inoculated with saccharomycetes, and is subjected to fermentation so as to obtain a raw wine; and 4, the raw wine is subjected to clarification and aging so as to obtain blueberry wine. The acidity reducing method is capable ofreducing the acidity of blueberry wine effectively, and improving blueberry wine quality greatly.

Owner:GUANGXI YUNHENG WINERY

Acidity reducing method of blackberry wine

InactiveCN107557233AAdd lessSolve difficult problems that are difficult to physically removeAlcoholic beverage preparationEnzymatic hydrolysisSugar

The invention discloses an acidity reducing method of blackberry wine. The acidity reducing method comprises following steps: 1, blackberries are smashed, pectase is added for 24 to 48h of enzymatic hydrolysis at 20 to 25 DEG C, and an obtained product is filtered so as to obtain blackberry juice; 2, 0.01 to 0.1wt% of xylitol is added into the blackberry juice, an obtained mixture is cooled to 1 to 2 DEG C at a temperature reducing speed of 5 to 10DEG C / 30min with stirring at a stirring speed of 1000 to 2000r / min, after cooling, stirring is stopped, the mixture is allowed to stand at the constant temperature for 1 to 2h, and is filtered, and an obtained filtrate is collected for further processing; 3, the sugar degree of the filtrate is adjusted to 16 to 20 DEG Bx, the filtrate is inoculated with saccharomycetes, and is subjected to fermentation so as to obtain a raw wine; and 4, the raw wine is subjected to clarification and aging so as to obtain blackberry wine. The acidity reducingmethod is capable of reducing the acidity of blackberry wine effectively, and improving blackberry wine quality greatly.

Owner:GUANGXI YUNHENG WINERY

Features

- R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

Why Patsnap Eureka

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Social media

Patsnap Eureka Blog

Learn More Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com