Beef-flavored essence preparation method

A flavor and beef technology, applied in food preparation, application, food science, etc., to achieve the effect of benefiting human health, high content of free amino acids, and long-lasting fragrance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

preparation example Construction

[0028] A preparation method of beef flavor essence, comprising the following steps:

[0029] (1) Preparation of bovine bone powder: select fresh bovine bones, fully wash them, cook and degrease under high temperature and high pressure, then place them in a drying oven at a temperature of 70°C for 30 minutes until the moisture content is less than 6%, and then pulverize them with a pulverizer Cross a 100-mesh sieve to obtain bovine bone meal, and set aside;

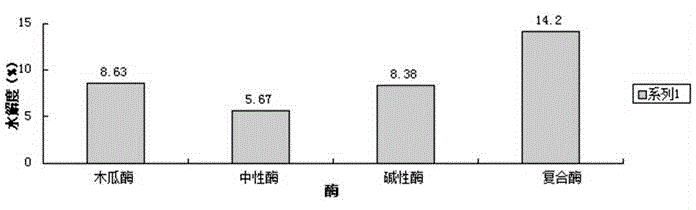

[0030] (2) Preparation of collagen peptides: add water to the bovine bone powder prepared in step (1) at a mass ratio of 1:14 to prepare a bovine bone powder substrate solution, adjust the pH to 1.5-2.0, and adjust the pH according to the enzyme and substrate Add pepsin at a weight ratio of 1:100, enzymatically hydrolyze for 3 hours at 55°C, inactivate the enzyme at high temperature for 5 minutes, and finally prepare A solution, and then add it to A solution according to the weight ratio of enzyme and A solution of 1:80 C...

Embodiment 1

[0042] A kind of preparation method of beef flavor essence, concrete steps are as follows:

[0043] (1) Preparation of bovine bone meal: select fresh bovine bones, fully wash them, cook and degrease them under high pressure at 121°C, then place them in a drying oven at 70°C for 30 minutes until the moisture content is less than 6%. The pulverizer is crushed through a 100-mesh sieve to obtain bovine bone powder, which is set aside;

[0044] (2) Preparation of collagen polypeptide: Add water to the bovine bone powder prepared in step (1) at a ratio of 1:14 to make a bovine bone powder substrate solution, adjust the pH to 1.5, and press the enzyme and substrate solution Add pepsin at a weight ratio of 1:100, enzymatically hydrolyze for 3 hours at 50°C, inactivate the enzyme at 100°C for 5 minutes, then add neutral enzyme and papain to continue the enzyme according to the weight ratio of enzyme to substrate solution at 1:80 Decompose for 2 hours, inactivate the enzyme at 100°C ...

Embodiment 2

[0049] A kind of preparation method of beef flavor essence, concrete steps are as follows:

[0050] (1) Preparation of bovine bone powder: select fresh bovine bones, fully wash them, cook and degrease under high temperature and high pressure, then place them in a drying oven at a temperature of 70°C for 30 minutes until the moisture content is less than 6%, and then pulverize them with a pulverizer Cross a 100-mesh sieve to obtain bovine bone meal, and set aside;

[0051] (2) Preparation of collagen polypeptide: Add water to the bovine bone powder prepared in step (1) at a ratio of 1:14 to make a bovine bone powder substrate solution, adjust the pH to 2.0, and press the enzyme and substrate solution Add pepsin at a weight ratio of 1:100, enzymatically hydrolyze for 3 hours at 55°C, inactivate the enzyme at high temperature for 5 minutes, then add compound enzyme according to the weight ratio of enzyme and substrate solution at 1:80, continue enzymatically hydrolyzing for 2 hou...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com