Acidity reducing method of blueberry wine

A technology of blueberry wine and craftsmanship, applied in the field of wine making, can solve the problems of reducing tartaric acid content, cumbersome operation, harsh conditions, etc., and achieve the effect of soft and pure taste, long aftertaste, and golden wine body

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

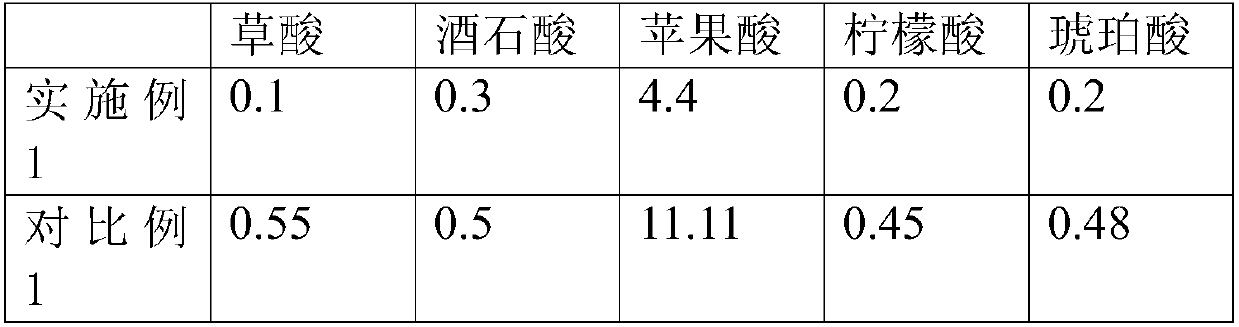

Examples

Embodiment 1

[0020] 1) Crush fresh blueberries, add 0.02% by weight of blueberry pectinase and 0.04% by weight of blueberry cellulase, perform enzymatic hydrolysis at 30°C for 4 hours, and filter to obtain blueberry juice;

[0021] 2) Add 0.01% xylitol by weight to the blueberry juice, drop to 1°C with a cooling rate of 5°C / 30min, stir the blueberry juice during the cooling process, and the stirring speed is 1000r / min; after cooling, Stop stirring, keep the heat preservation for 1h, filter, and get the filtrate for subsequent use; measure the titration acid (calculated as tartaric acid) in the filtrate to be 5.2g / L;

[0022] 3) adding sugar to the filtrate to adjust the sugar content to 16°Bx, inoculating 8% yeast by weight of the filtrate, and fermenting at 20°C for 6 days to obtain raw wine;

[0023] 4) adding diatomaceous earth to the raw wine for clarification, standing for 5 days, taking the clarified solution, aging it at room temperature for 3 months, and sterilizing it, which is bl...

Embodiment 2

[0026] 1) Crush fresh blueberries, add 0.05% by weight of blueberry pectinase and 0.06% by weight of blueberry cellulase, perform enzymatic hydrolysis at 40°C for 6 hours, and filter to obtain blueberry juice;

[0027] 2) Add 0.1% xylitol by weight to the blueberry juice, drop to 2°C with a cooling rate of 10°C / 30min, stir the blueberry juice during the cooling process, and the stirring speed is 2000r / min; Stop stirring, keep warm for 2h, filter, and get the filtrate for subsequent use; measure the titration acid (calculated as tartaric acid) in the filtrate to be 5.1g / L;

[0028] 3) adding sugar to the filtrate to adjust the sugar content to 20°Bx, inoculating 12% yeast by weight of the filtrate, and fermenting at 25°C for 8 days to obtain raw wine;

[0029] 4) adding diatomaceous earth to the raw wine for clarification, standing for 8 days, taking the clarified solution, aging at room temperature for 6 months, and sterilizing, which is blueberry wine.

[0030] The prepared ...

Embodiment 3

[0032] 1) Crush fresh blueberries, add 0.04% by weight of blueberry pectinase and 0.05% by weight of blueberry cellulase, perform enzymatic hydrolysis at 35°C for 5 hours, and filter to obtain blueberry juice;

[0033] 2) Add 0.05% xylitol by weight to the blueberry juice, drop to 1.5°C with a cooling rate of 8°C / 30min, stir the blueberry juice during the cooling process, and the stirring speed is 1800r / min; Stop stirring, keep the heat preservation for 1.5h, filter, and get the filtrate for subsequent use; measure the titration acid (in tartaric acid) in the filtrate to be 5.5g / L;

[0034] 3) adding sugar to the filtrate to adjust the sugar content to 18 ° Bx, inoculating 10% yeast by weight of the filtrate, and fermenting at 22 ° C for 7 days to obtain raw wine;

[0035] 4) Add diatomaceous earth to the original wine to clarify, let it stand for 6 days, take the clarified solution, age it at room temperature for 5 months, and sterilize it, which is blueberry wine.

[0036] ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com